Page Number - 2 Form 422734

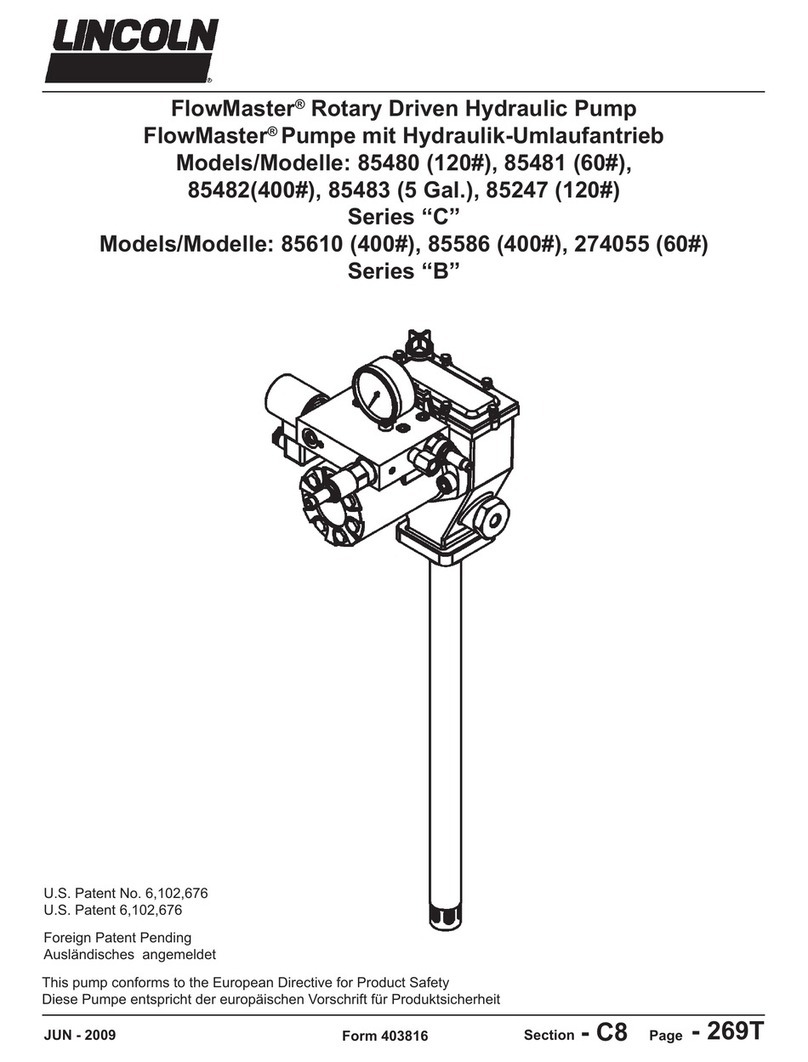

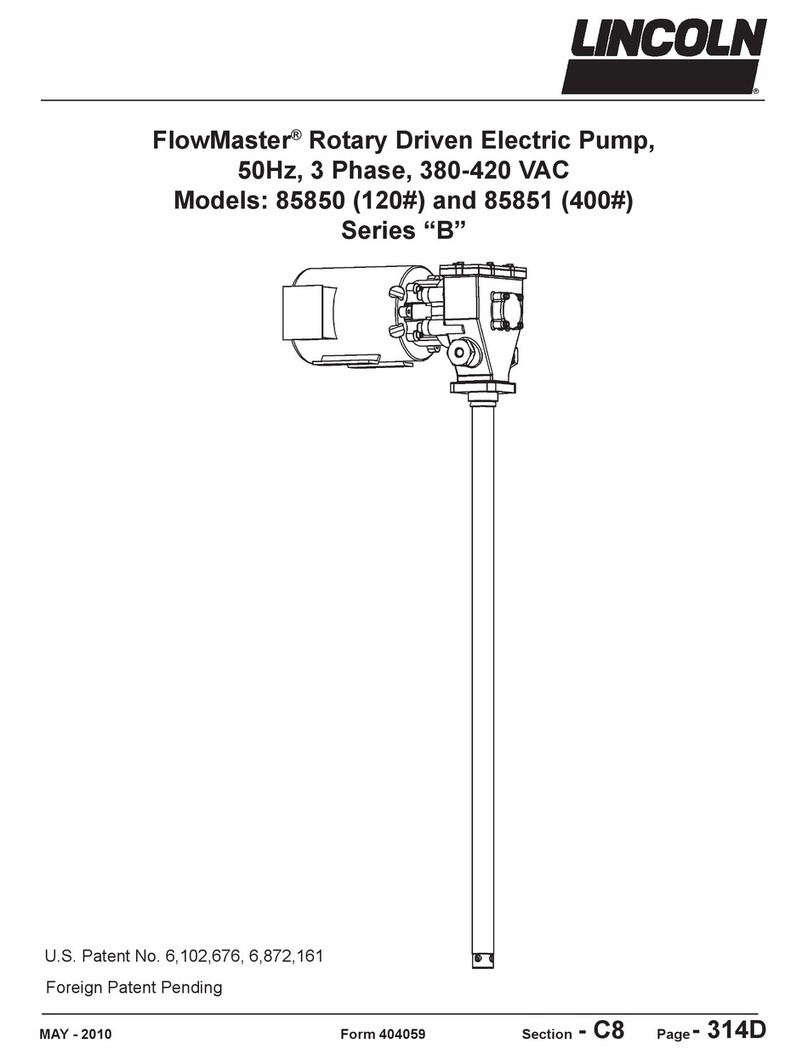

FlowMaster™ Rotary Driven Electric Pump

Description

85567 - Pump for 60 pound drum, 360 RPM maximum,

maximum pressure rating 5,000 psi

85568 - Pump for 90 and 120 lbs. drum, 360 RPM

maximum, maximum pressure rating 5,000psi

85569 - Pump for 5 gallon pail, 100 RPM maximum

maximum pressure rating 2,500 psi.

General Description

The Lincoln Industrial rotary DC electric pump uses a

24VDC motor and either a single a double stage planetary

gear drive. Grease output is proportional to the pump RPM.

The pump is primarily designed for centralized lubrication

systems such as the Single Line parallel, Single Line

Progressive and Two Line systems.

The pump is driven by the rotary motion of the electric motor.

Rotary motion is converted to reciprocating motion through

an eccentric crank mechanism. The reciprocating action

causes the pump cylinder to move up and down. The unit is

a positive displacement double acting pump as grease

output occurs during both the up and down stroke. The

pump motor employs an integral speed control capable of

reducing pump speed to 10% of its maximum value.

During the down stroke, the pump cylinder is extended into

the grease. Through the combination of shovel action and

vacuum generated in the pump cylinder chamber, the grease

is forced into the pump cylinder. Simultaneously, grease is

discharged through the outlet of the pump. The volume of

grease during intake is twice the amount of grease output

during one cycle. During the upstroke, the inlet check

closes, and one half of the grease taken in during the

previous stroke is transferred through the outlet check and

discharged to the outlet port. Typical output of the pump is

shown on page 3.

Appropriate Use

•All pump models are exclusively designed to pump and

dispense lubricants using 24 VDC electric

power, depending on how the motor is wired.

•The maximum specification ratings should not be

exceeded.

•Any other use not in accordance with instructions will

result in loss of claims for warranty and liability.

service center nearest you for repair or adjustments other

than maintenance specified in this manual.

Annual inspection by the factory authorized warranty and

service center nearest you is recommended.

A list of factory authorized warranty and service centers is

available upon request.

Damaged Pumps

Any pump that appears to be damaged in any way, is badly

worn or operates abnormally, shall be removed from use

until repairs are made. Contact the factory authorized

warranty and service center nearest to you for repairs.

Tableof Contents Page

Safety….……………………................................................................2

Description....................................................................................2

Appropriate Use................................................................2

Pump Performance and Specifications..............................3

Installing the Pump.....................................................................4

Operation.....................................................................................5

Maintenance and Repair...........................................................5

Pump Dimensions.............................................................7

RepairPartsList................................................................................9

TroubleShooting.........................................................................10

Safety

Read and carefully observe these operating instructions

before unpacking and operating the pump! The pump must

be operated, maintained and repaired exclusively by per-

sons familiar with the operating instructions. Local safety

regulations regarding installation, operation and

maintenance must be followed.

Operate this pump only after safety instructions and this

service manual are fully understood.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Safety Instructions

This equipment generates very high grease pressure.

Extreme caution should be used when operating this

equipment as material leaks from loose or ruptured

components can inject fluid through the skin and into the

body causing serious bodily injury. Adequate protection

is recommended to prevent splashing of material onto

the skin or into the eyes.

If any fluid appears to penetrate the skin, get emergency

medical care immediately. Do not treat as a simple cut.

Tell attending physical exactly what fluid was injected.

Inspection

If overpressurizing of the equipment is believed to have

occurred, contact the factory authorized warranty and service

center nearest you for inspection of the pump.

Specialized equipment and knowledge is required for repair

of this pump. Contact the factory authorized warranty and