8DO NOT carry the pump by its electrical cable, or outlet pipe. Use the handle only.

8When not in use switch off pump and remove plug from power supply. Rinse pump, drain out any water and store in a frost free, safe

location.

WARNING! DO NOT allow uncontrolled discharge of contaminated water which would pollute the environment.

Children from age 8 years and above, persons with reduced physical, sensory or mental capabilities, those with lack of experience and

knowledge can use the appliance, if they have been given supervision or instruction concerning use of the appliance In a safe way to

understand the hazards involved. Children shall not play with the appliance. Cleaning and user maintenance on the appliance shall not

be maintained by children without supervision.

NOTE: Pollution of liquid could occur due to leakage of lubricants.

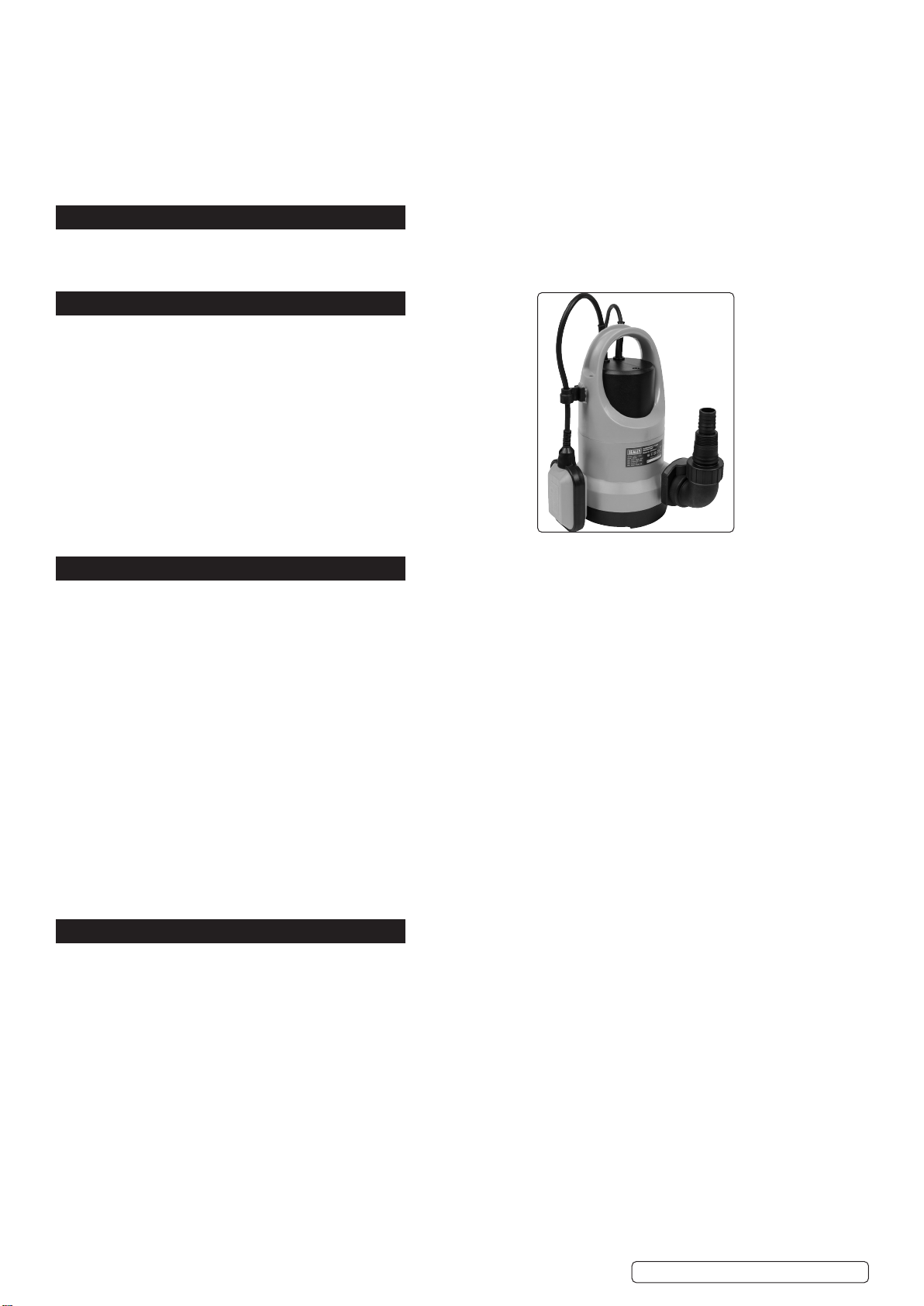

2. INTRODUCTION

Manufactured from corrosion resistant materials with steel motor case and polypropylene base cover. Max. Output: 100L(22gal)/min,

Max. Head: 6m. Automatic cut-out when water goes below minimum depth of 5mm. Designed for clean water although this pump will

accept small particles up to 5mm. Suitable for the effective drainage of cellars, sinks, cisterns, baths and the general transfer of water.

3. SPECIFICATION

Model No:.................................................WPC100A.V3

Cut-Out: ..........................................................Automatic

Fuse Rating:................................................................5A

IP Rating:................................................................ IPX8

Maximum Head:.........................................................6m

Maximum liquid temperature:.................................35 °C

Maximum Output:............................................. 100L/Min

Maximum Particle Size:...........................................5mm

Maximum Water Depth:..............................................7m

Minimum Water Depth:............................................5mm

Motor Power:..........................................................250W

Outlet OD:.................................................. 25mm/38mm

Power Supply Cable Length:....................................10m

Supply:....................................................................230V

4. BEFORE USE

4.1. Read all safety warnings and all instructions. Failure to follow all warnings and instructions may result in electric shock, re and/or

serious injury. Save all warnings and instructions for future reference.

4.2. The pump can be connected to any shock-proof plug which has been installed according to regulations in force.

WARNING! When the pump is to be used near swimming pools or garden ponds and in their area of protection, it must be equipped

with a PRCD (residual current circuit breaker) with a nominal trip current of max.30mA . The pump must not be operated while people

are in the swimming pool or in the garden pond. Please contact your electrician.

WARNING! (Important for your own security) Before starting to run your new submersible pump, please have the following items

checked by an electrician:

• Ground connection

• Zero conductor

• Fault current breaker switch must correspond the safety regulations in force in that region.

They must work faultlessly.

4.3. The electrical connections must be protected from moisture.

4.4. If there is danger of ooding, the electrical connections must be taken to higher ground.

4.5. Circulation of aggressive uids, as well as the circulation of abrasive materials must be avoided at all costs.

4.6. The submersible motor-driven pump must be protected from frost.

4.7. The pump must be protected from running dry.

4.8. Access on the part of children should also be prevented with appropriate measures.

4.9. These submersible pumps is designed for the circulation of water with a maximum temperature of 35° C. This pump may not be used

for other uids, especially motor fuels, cleaning uids, and other chemical products.

5. INSTALLATION

5.1. The submersible pump is installed as follows:

• In a stationary position with xed pipeline or

• in a stationary position with a exible hose pipe.

NOTE: Never install the pump by suspending it unsupported from its delivery pipe or power cable. The submersible pump must be

suspended from the specially provided handle or be placed on the bottom of the shaft.

5.2. To guarantee that the pump works properly, the bottom of the shaft must be kept free of sludge and dirt of all kinds. If the level of water

sinks too far, any sludge in the shaft will dry out quickly and stop the pump from starting up. Therefore it is necessary to check the

submersible motor pump regularly (by carrying out start-up tests).

5.3. The oat switch must be adjusted in a way that the pump can start immediately.

NOTE: The pump shaft should have minimum dimensions of 40 x 40 x 50 cm, so that the oating switch can move freely.

5.4. MAINS SUPPLY

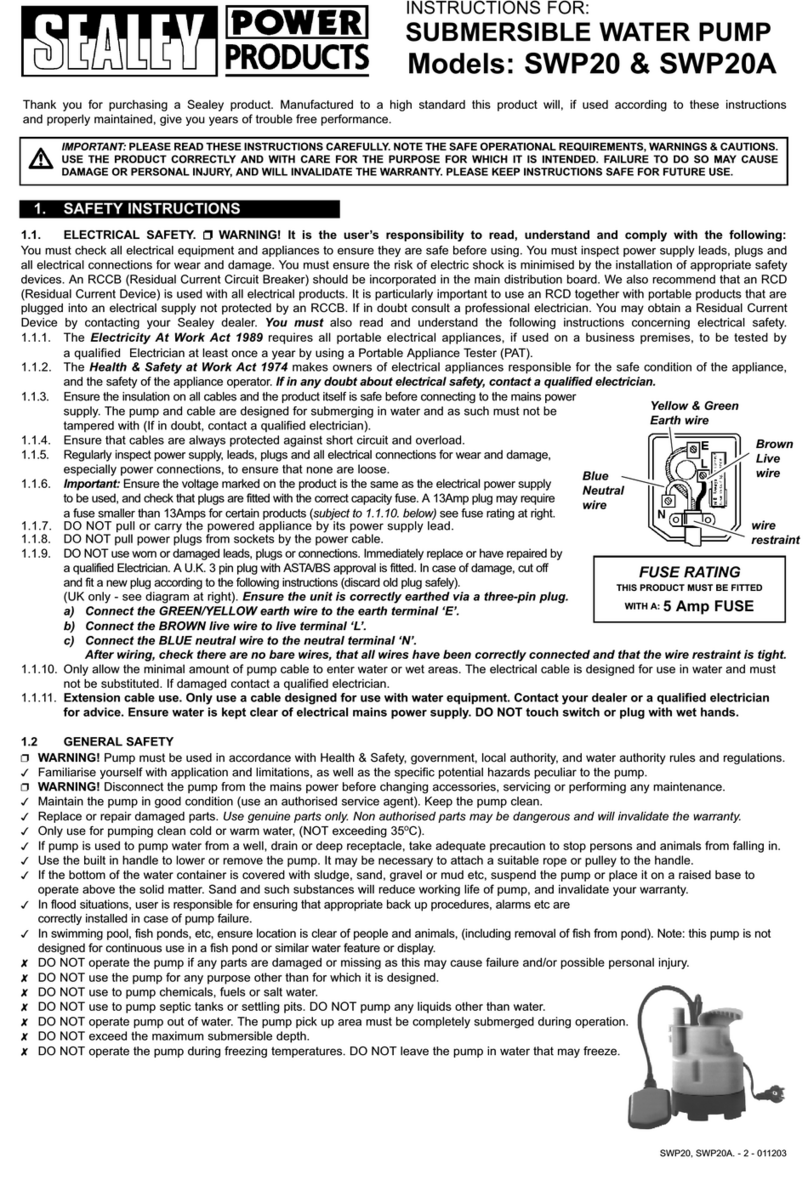

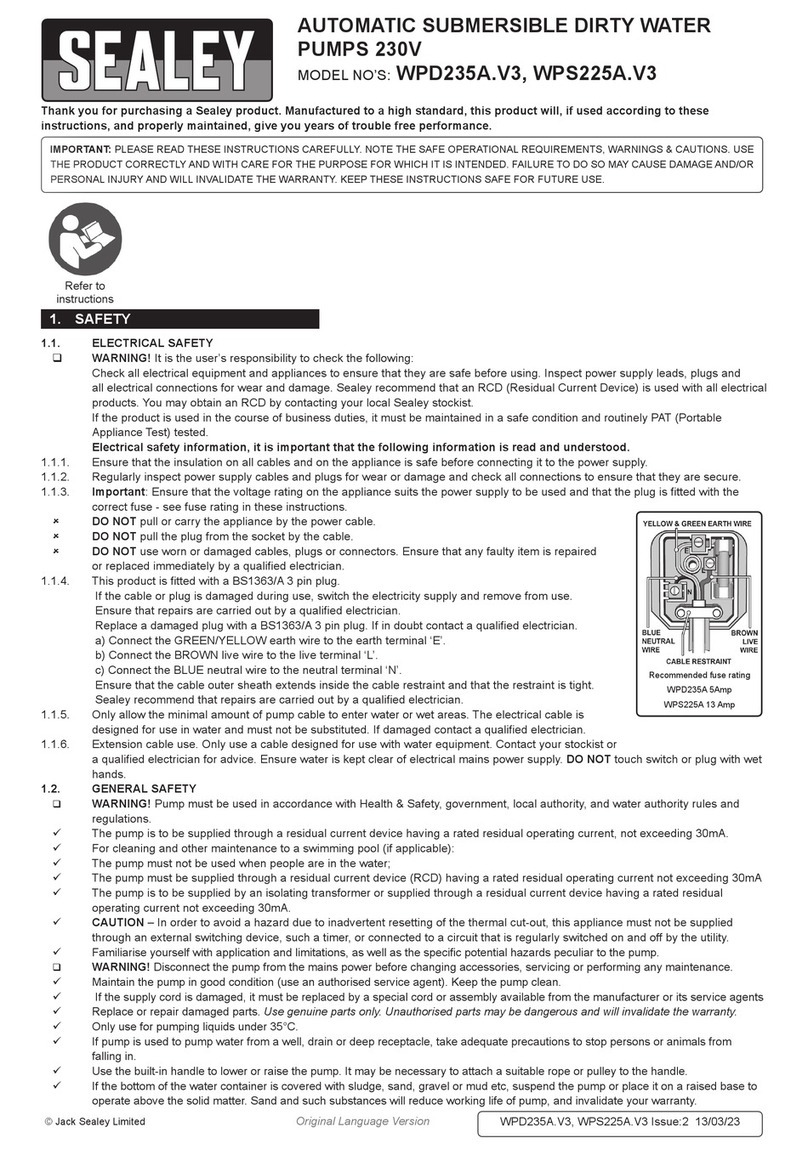

5.4.1. Submersible pump is equipped with a shock-proof plug according to regulations. The pump is designed to be connected to a 230V -

50Hz earthed socket. Make sure that the socket is sufciently secured {min. 6 Amp.) and is in excellent condition.

5.4.2. IMPORTANT: If the mains cable or plug suffers any damage from external action, repairs to the cable should be serviced by a qualied

pecialist using genuine spare parts.

5.5. Fit appropriate discharge pipe to pump outlet and secure with clip. Ensure the diameter of the discharge pipe is the same as, or greater

than, the outlet diameter. A smaller pipe will adversely effect the pump flow rate.

Original Language Version

© Jack Sealey Limited WPC100A.V3 V2 Issue:2 (1,3) 26/10/23