This Limited Warranty does not apply to normal wear and tear, nor to claimed

defects, malfunctions, or failures that result from improper installation, abuse,

neglect, improper maintenance, alteration, misuse, and damages resulting from

collision, weather events, or acts of God. AMS does not warrant the work of

others who have installed the fans.

In order to exercise your rights under this Limited Warranty, the original owner

must contact AirMotion Sciences, Inc. to initiate a warranty claim, obtain a

Return Authorization if necessary, or obtain approval to commence reimbursable

on-site warranty work. Should this fan or any part of it be determined to be

covered by this Limited Warranty, it will be repaired or replaced at AMS’ sole

option, which will be conclusive and binding. The original owner will pay for all

shipping costs, travel costs, and repair labor costs not covered as noted above.

This is an integrated and final statement of AMS’ Limited Warranty. AMS does

not authorize or allow anyone, including its authorized dealers, to extend any

other warranties, express or implied, for AMS. No other representation, and no

statement of anyone but AMS, including a demonstration of any kind by anyone,

shall create any warranty regarding this Fan. All of the remedies available to the

original owner are stated herein.

It is agreed that AMS’ liability under this limited warranty shall be no greater than

the amount of the original purchase price and in no event shall AMS be liable for

incidental or consequential damages.

DISCLAIMER

All other remedies, obligations, liabilities, rights, warranties, express or implied,

arising from law or otherwise, including but not limited to, any claimed implied

warranty of merchantability, any claimed implied warranty arising from course of

performance, course of dealing or usage of trade, and any claimed warranty of

fitness, are disclaimed by AMS and waived by the original owner. Some states,

jurisdictions, countries, provinces, do not allow some or all of the limitations set

forth herein, or the exclusion or limitation of incidental or consequential

damages. If any provision is found unenforceable, only that provision shall be

stricken and all others shall apply. This limited warranty does provide the original

owner with certain legal rights and recourse and the original owner may possess

other rights or recourse, depending on the state, jurisdiction, country, or

province.

AirMotion Sciences, Inc. (AMS), a Massachusetts corporation located at 9 Green

Street. Holliston, MA 01746, makes the following Limited Warranty concerning its

AltAir™ HVLS Fans.

Limited THREE YEAR WARRANTY On Complete Fan

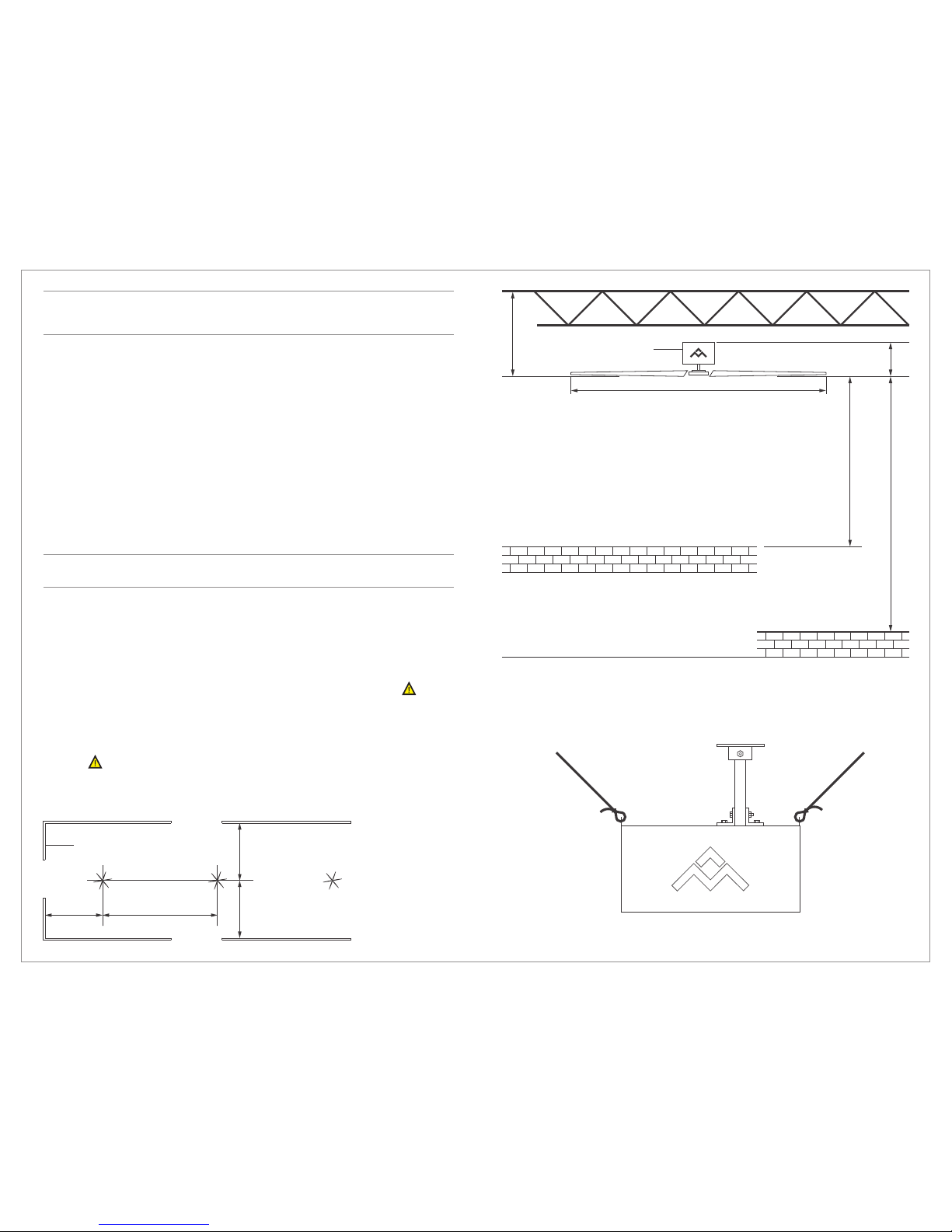

Subject to the following limitations, terms, and conditions, AMS warrants to the

original purchaser of each new AMS AltAir Fan that this new Fan is free of

defective materials and workmanship. This warranty shall expire three (3) years

from the date of the original purchase of the Fan through AMS or its authorized

dealers and is conditioned upon the fan being operated and maintained under

normal conditions and use, and installed in accordance with AMS installation

instructions. This warranty is void if other conditions exist.

Limited LIFETIME WARRANTY on AMS Blades and Hub

Subject to the following limitations, terms, and conditions, AMS warrants for the

lifetime of the original purchaser of each new AMS AltAir Fan that the fan blades

and hub are free of defective materials and workmanship. This Limited Lifetime

Warranty is conditioned upon the fan being operated and maintained under

normal conditions and use, and installed in accordance with AMS installation

instructions. This warranty is void if other conditions exist.

Limited ONE YEAR WARRANTY on Repair Labor Costs Up to $250.00

Subject to the following limitations, terms and conditions, and subject to prior

approval by AMS, AMS warrants to the original purchaser of each new AMS AltAir

Fan, that AMS will reimburse the original owner for warranty claim labor and

repair costs performed on site up to $250.00. This warranty shall expire one (1)

year from the date of the original purchase of the fan from AMS or its authorized

dealers and is conditioned upon the fan being operated and maintained under

normal conditions and use, and installed in accordance with AMS installation

instructions. This warranty is void if other conditions exist.

Additional Conditions

This Limited Warranty is made only to the original owner of this new AMS AltAir

HVLS fan purchased from AMS or its authorized dealer, and it shall remain in

force only as long as the original owner retains ownership of the fan. This

Limited Warranty is not transferable.

AMS LIMITED WARRANTY INFORMATION

AIRMOTION

SCIENCES,

INC.

9 GREEN STREET HOLLISTON MA 01746 USA T 508.429.4411 F 508.429.4401 [email protected]