Mietzsch VRR Series User manual

Contents: 0. Preface to the operating instructions

1. Basic safety instructions

1.1 Warning symbols

1.2 Conditions of use

1.3 Organisational measures

1.4 Residual risks

2. Transport and storage

3. Installation and commissioning

3.1 Instructions for the electrical system

3.2 Mounting options

3.3 Integration of the fan into the system / Mounting

3.4 Commissioning

4. Operation and maintenance

5. Repair instructions

5.1 Cleaning

5.2 Roof fans with an internal rotor motor (standard motor)

5.3 Roof fans with an external rotor motor (VRR/ALM)

5.4 Roof fans with an EC motor (VRR/ALM-EC)

6. Additional information for explosion-proof fans

7. Waste disposal

Declaration of Conformity

01

OPERATING INSTRUCTIONS

Radial roof fans Series VRR

Original operating instructions

MIETZSCH GmbH Lufttechnik Dresden sGroßenhainer Str. 137 s01129 Dresden sTel (0351) 8433 150 sFax (0351) 8433 160

oi_vrr (11/09)

0. Preface to the operating instructions

These operating instructions are intended to familiarise users with series VRR fans so that they will be able to use them

in accordance with their conditions of use.

These instructions contain important information relating to the safe, appropriate and cost-effective operation of these

fans. Compliance with such instructions helps to avoid danger and to reduce repair costs and downtimes.

These operating instructions should be permanently available wherever the fan is installed. They must be read and

observed by all persons involved with transportation, installation and start-up as well as with maintenance and repairs.

In addition to the present operating instructions and legally binding accident-prevention regulations, the generally

recognised technical rules and regulations pertaining to safe and competent execution of the work must be observed.

For radial fans with an EC motor, there are additional instructions to those given here that apply to commissioning.

1. Basic safety instructions

1.1 Warning symbols

Information regarding cost-effective use of the fan

Details of do's and don'ts to prevent personal injuries and/or material damage

1.2 Conditions of use

The fans have been built according standard practices and recognised safety standards. Nevertheless, their operation

may cause safety hazards or have an adverse effect on other machinery or other material assets. Therefore, it is

extremely important that the conditions of use are observed and that the fan is in perfect working order.

The owner/user must comply with the conditions given below. The conditions stated in the manufacturer's brochure valid

at the time the contract was concluded shall apply, unless specified otherwise by contractual agreements.

a. Requirements with respect to the conveying medium and the surroundings

Compliance with the permissible temperature range, which depends on the type of fan, the operating speed and

the construction materials

The chemical resistance of the construction materials (particularly plastics) to the conveying medium must be

tested

.For explosion-proof fans, the ignition temperature and the explosion hazard zone must be taken into account.

---> Section 6 "Additional information for explosion-proof fans"

The density of the conveying medium must correspond to that of pure air. The medium must not contain foreign

particles and has to be practically dustless. Higher dust loads or impure gases with a tendency to produce deposits

may cause damage.

Condensate accumulating in the housing must be able to drain freely.

The fan must be installed so that it is free of shocks and vibrations (mount on vibration isolators) and must not be

subjected to external mechanical loads.

The compatibility of the fan with its surroundings must be checked. This applies, in particular, to the temperature,

the chemical resistance and the explosion risk.

b. Requirements with respect to the mode of operation

The fan must be operated at the speed (RPM or speed range) specified by the manufacturer.

Parallel connection is permissible.

Roof fans VRR can also be operated outside their characteristic range; however, this should be avoided to

conserve energy.

The technical conditions for electrical connection of the motor must be observed.

Setting and control of the fan speed is only possible for the fan models and control units specified by the

manufacturer.

Non-compliance with the specified requirements constitutes a violation of the conditions of use. The manufacturer is not

liable for damages resulting from such non-compliance.

1.3 Organisational measures

All work with the fan must be carried out by appropriately instructed and reliable personnel.

All work on electrical equipment (motors, control and regulating devices) must be carried out by qualified personnel

(in compliance with DIN VDE 0105 or IEC 364)

Repairs of explosion-proof fans must be carried out by the manufacturer or in consultation with the manufacturer.

Maintenance intervals are to be specified by the owner/user, in consultation with the manufacturer, if necessary. In

the event of any safety-related disturbances (e.g. fan runs unevenly, abnormal noises, visible external damage and

defects), the fan must be taken out of operation and repaired.

All repairs must be carried out with original spare parts. This also concerns the drive motor whose thermal behavior

must be compatible with the plastic materials.

Modifications of the fan that affect the safety are not permitted.

The fan may only be operated if it is in a safe condition. This means that all protective and safety systems (e.g.

electrical motor protection, safety screen) are in place and fully functional and that the fan is integrated into the

system as specified in the project.

02 MIETZSCH GmbH Lufttechnik Dresden swww.mietzsch.de

!

!

!

!

oi_vrr (11/09)

03 MIETZSCH GmbH Lufttechnik Dresden swww.mietzsch.de

1.4 Residual risks

Although the fans are of a reliable design and their manufacture is controlled by a quality assurance system, there is

still a residual risk due to the possible rupture of the impeller, especially in cases in which it cannot be excluded that

the conditions of use (see Section 1.2) are violated. Therefore, the vicinity of the fan must be secured so that

personal injuries and material damage are excluded in the event of a malfunction or an accident.

For high-powered fans, in particular, the sound pressure level may exceed the permissible limit value for sound

immissions. Suitable measures must be implemented to protect persons within this zone from noise-related injuries.

The sound immission data are given in the associated contract documents or the relevant brochures.

2. Transport and storage

Loading work must be carried out by experienced personnel. Hoisting gear and hoist attachments with sufficient

load-bearing capacity are to be used.

The fan must be transported in the mounting position and properly secured against movement, tipping and

collisions.

When selecting a means of transport, attention must be paid to the fact that plastic fans can be damaged by

collisions.

Suspend and transport roof fans using the recesses provided on the lower section to handle and attach 4-cable

hoisting tackle. Never lift the fan by the hood.

Do not use the motor's lifting lugs to suspend the fan.

If roof fans are to be stacked on top of each other, they must be in their original packaging and the stacking height

must not exceed the height stipulated by the manufacturer.

Models VRR400 and VRR 500 are fitted with a drive lock so that they can be transported safely. They are generally

transported on a pallet.

3. Installation and commissioning

3.1 Instructions for the electrical system (for explosion-proof fans, see also Section 6.)

The electrical equipment must be installed by a qualified electrician according to standard practices.

Connect each motor to the mains supply via a motor protection device in accordance with DIN EN 60204-1. Set the

bimetallic trip to the rated current. For pole-changing motors, install either two separate motor protection switches or

one thermal winding protection (PTC thermistor --> special design TS). Fans with external rotor motors (model

ALM) are equipped with thermocontacts in the motor winding. These contacts are either integrated into the supply

cable or are connected to a separate tripping device with a reclosing interlock. Fans with an EC motor have

integrated motor protection and thus do not require additional measures.

If the speed is regulated by a voltage regulator or a frequency converter, a bimetal switch does not provide

adequate protection of the motor. In this case, use thermal motor protection (PTC thermistor --> special design TS;

thermocontacts). Protection by calculating I²t can also be used; this is included in most frequency converters.

Check the electrical connection values (voltage and frequency). Connect the motor according to the enclosed circuit

diagram (see the terminal box or the repair switch).

For three-phase motors, use a star or delta connection, depending on the mains voltage and motor model. If star-

delta switches are used, the mains voltage must agree with the lower voltage given on the motor type plate (e.g.

motor 400/690V and mains 400V).

If a repair switch is installed, the motor is connected in the factory in a star or delta arrangement, depending on the

planned voltage. During commissioning, check that the mains voltage is correct, and reverse the connections in the

motor terminal box, if necessary.

Before commissioning, measure the insulation resistance of the winding relative to earth. Dry and as-new windings

have a resistance greater than 10 MW. If the measured value lies below 2 MW, dry the winding. More detailed

information is given in the operating instructions for the motor.

Check the direction of rotation of the fan by switching it on briefly. It must agree with the direction indicated by

the red arrow on the motor support ring.

Attention! Even if the direction of rotation is incorrect, the radial fan will still transport the medium at a

certain rate in the normal direction of flow. However, this operating mode may overload the motor.

Measure the current consumption of the motor after commissioning and check it against the value given on the

motor's type plate. If the current consumption is too high, check that the direction of rotation is correct.

!

!

!

!

!

oi_vrr (11/09)

04 MIETZSCH GmbH Lufttechnik Dresden swww.mietzsch.de

3.2 Mounting options

The fan should be installed with its axis in a vertical position.

Permissible tolerances: VRR 160 to VRR 315 10°(VRR160/ALM and VRR200/ALM 90° )

VRR 400 and VRR 500 5°

A comprehensive range of accessories is available for installation:

foundation ring, roof upstand, sound insulation base, foundation plate, hinged roof upstand, etc.

The fan can also be installed directly on vertical pipelines, the stability of which must be checked by the owner/user.

Connect the intake duct using flexible connectors. Connected system components must not exert any mechanical loads

on the fan.

3.3 Integration of the fan into the system / Mounting

•Check the fan for damage sustained during transport. Check that the impeller rotates without contacting the sides and

adjust, if necessary.

For models VRR400 and VRR500, remove the transport locking device. The springs must be correctly seated on the

spring plates and the round steel column must not come into contact with the wall of the borehole in the supporting

frame.

Check the inside of the fan and the connected system for foreign objects and remove any that may have been left

behind.

Pay special attention to forgotten tools and leftover materials.

To ensure that no foreign matter can get into the fan and thus destroy it, check that all components upstream of the fan

are fully functional and securely mounted (especially dampers and gate valves as well as guide vanes of elbow ducts,

etc.).

Install the fan into the system according to the project description. Ensure good accessibility for maintenance and repair

work.

If the fan is operated with a free inlet, prevent accidental contact using a safety device (e.g. a safety screen).

Extreme weather conditions may lead to the ingress of small amounts of rainwater into the intake duct, particularly

when the fan is not operating. Therefore, do not locate any sensitive equipment or systems in the intake side.

Installation sequence

Prepare the foundation, upstand, base etc.; affix foam sealing strips, if necessary

Connect the electricity cable. The electricity cable can be routed outside or inside the foundation structure or shaft. If a

sound insulation base is used, route the cable to the motor through the cable glands in the base, then through the lower

section of the fan and through the borehole in the supporting column.

For models VRR400 and VRR500, route the cable from below through the flexible protective hose to the motor.

Ensure that the cable is not abraded by fan components. Check that the cable does not have any sharp bends.

If a hinged base is used, fit a flexible cable.

The insulation of cables laid inside the ducting must be resistant to the conveying medium.

Remove the fan hood and safety screen (upwards), fit the fan and screw it lightly to the support. Subsequently, seal the

screw holes in the lower section with sealing compound.

Connect the electrical cables, then replace the safety screen and the hood.

Note: Some of the special models are fitted with a lock that has to be opened before the safety screen can be removed.

During reassembly, make sure the screen is firmly mounted and fully functional.

3.4 Commissioning

Before commissioning, check that the fan complies with the conditions of use (see Section 1.2). Cordon off the vicinity of the

fan so that there is no risk of personal injuries or damaging material assets if the fan has been damaged during

transportation or it sucks in foreign bodies.

Proceed in the same way when switching on the fan after a repair or a long downtime.

It is prohibited to operate the fan until it has been integrated into the system in accordance

with the project. The fan must not be operated without contact guards protecting the intake

and/or outlet if they are unconnected and thus free.

Abnormal noises, uneven running and excessive motor current often indicate fan defects that must be remedied without

delay. Contact the manufacturer if this occurs during the warranty period.

Unauthorised measures and modifications void the warranty.

4. Operation and maintenance

Operate the fan in accordance with the safety regulations as well as the conditions of use stipulated in Section 1. The fan

must be inspected at regular intervals. The inspection intervals must be specified by the owner/user depending on the

respective operating conditions (soiling, operating time, temperature, etc.). Account must be taken of possible hazards and

damage occurring during downtime or in the event of a malfunction or an accident.

Recommended inspection interval: every 5,000 operating hours or once a year.

The inspection must include the following:

All electrical connections and the motor protection system

All fan components for obvious damage

Smooth running as well as bearing noises or rubbing noises

All screwed connections on the motor, support ring and hood

Soiling of the fan and the motor

!

!

!

oi_vrr (11/09)

05 MIETZSCH GmbH Lufttechnik Dresden swww.mietzsch.de

Uneven running of the fan is often a clear indication of deposits on the impeller. Check and clean immediately.

The motors are usually equipped with permanently lubricated bearings with a service life of up to 50,000 hours,

depending on the operating conditions. Relubrication is thus unnecessary.

Replace defect antifriction bearings or renew the complete motor (see Repair instructions).

The fan must be inspected thoroughly after about 10 years. A specialist must then decide on its further use.

5. Repair instructions

Always switch off the fan before starting any work on it. Take measures to ensure that it cannot be switched on during

repair work.

After repairs, proceed as for commissioning (see Section 3.4).

5.1 Cleaning

To clean the fan, detach the hood and the entire drive assembly (impeller, motor and motor support ring) from the lower

section (see Section 5.2).

For pressure-controlled fans, carefully disconnect the pressure measuring hose from the pressure sensor before

dismantling. The bore for the pressure sensor must be clean and free of deposits.

Cleaning fluids must not damage the construction materials, particularly the plastics.

Do not use hard objects for mechanical cleaning.

5.2 Roof fans VRR/702(701) with an internal rotor motor (standard motor)

To replace the drive assembly or the motor, dismantle the fan into its main assemblies:

Dismantling

Detach the hood and the safety screen (upwards). If necessary, remove the deflector ring first.

Disconnect the electrical connections

Unfasten the connection between the motor support ring and the support column and lift off the drive assembly

(motor with motor support ring and impeller). The drive assembly is available as a spare part and can be replaced

at the site without any special tools.

Attention! For pressure-controlled fans (DR), carefully disconnect the pressure measuring hose from the

pressure sensor before dismantling.

Remove the hub cap (caps glued or welded on must be destroyed)

Unfasten the hub fastener and pull the impeller off the motor shaft (use a puller, if necessary)

Replace the motor or repair according to the operating instructions for the motor.

Mounting

Reassemble the fan in the reverse order. Replace the destroyed hub cap as well as the lock washer of the shaft

lock.

Note: Some of the special models are fitted with a lock that has to be opened before the safety screen can be removed.

During reassembly, make sure the screen is firmly mounted and fully functional.

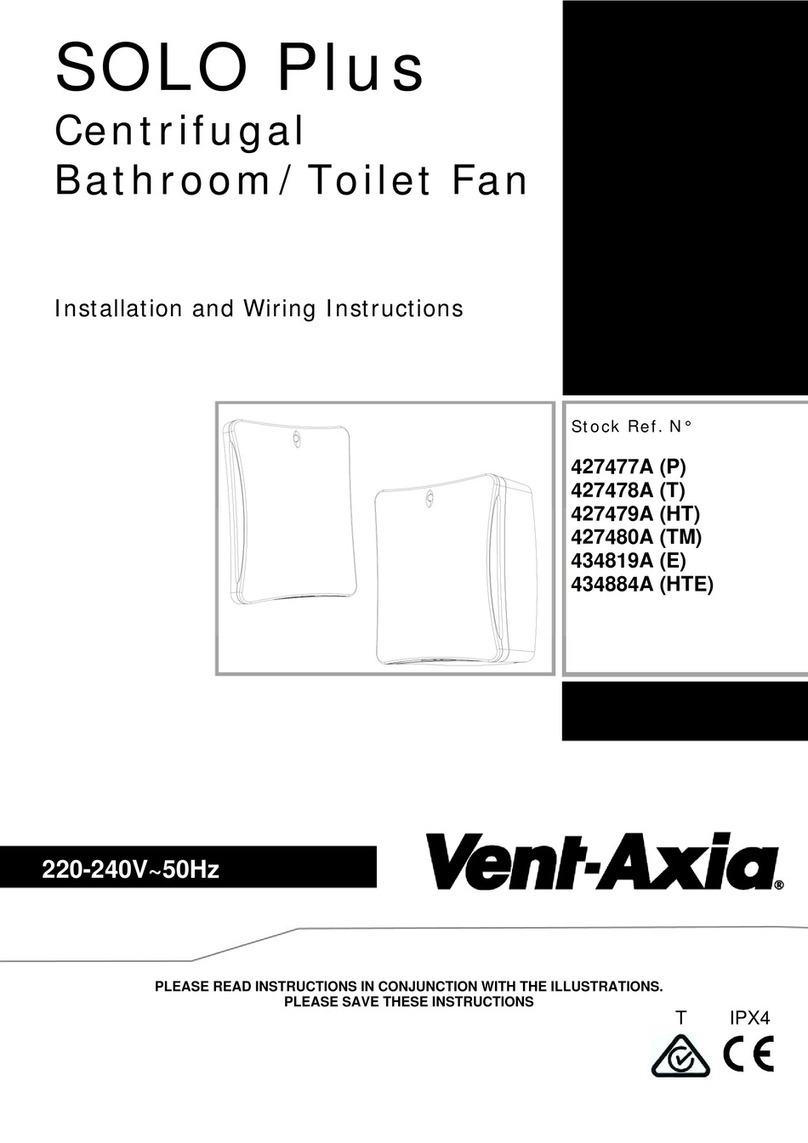

5.3 Roof fans with an external rotor motor (VRR/ALM)

safety screen

hood (PUR)

A

B

motor support ring

impeller

motor

inlet nozzle lower section (PUR)

AIsolation of structure-borne noise

(models 160, 200 and 315)

rubber

BVibration isolation

(models 400 and 500)

steel spring

Dismantle these fans analogously to VRR/702 (See Section 5.2). In

models with an external rotor motor, the entire drive assembly (impeller,

motor and support ring) has to be replaced. The fan may not be correctly

balanced if only the motor is replaced.

Attention! For the special design DR (pressure-controlled), carefully

disconnect the pressure measuring hose from the pressure sensor before

dismantling.

5.4 Roof fans with an EC motor (VRR/ALM-EC)

Remove the drive assembly (impeller, motor and support ring as well as

the control unit mounted on the support ring) as described in Section 5.3.

The control unit should only be removeed or repaired after consultation

with the manufacturer.

hood (PPs)

external rotor

motor

repair switch

oi_vrr (11/09)

06 MIETZSCH GmbH Lufttechnik Dresden swww.mietzsch.de

6. Additional information for explosion-proof fans

Compliance with the conditions of use is the basic requirement for explosion-proof state of a fan.

Ensure that the fan has an approval for the respective explosion zone conditions (zone, equipment group, equipment

class, explosion group, ignition temperature --> see the markings on the fan and the supplied documentation).

The following apply to fans fitted with motors with increased safety (EEx e):

permissible cooling air temperature -20 to +40 °C

permissible voltage tolerance +/- 5%,

permissible frequency tolerance +/- 2%

Integration of the fan into the system

In general, the fan should be installed so that it is protected against external mechanical loads. This particularly

applies at temperatures below -5 °C because the impact strength of plastics is reduced.

Measures must be implemented to prevent foreign matter falling in or being sucked into the fan and the motor cooling

fan. If necessary, safety devices, e.g. screens, must be installed in the system.

The air inlet connection must be gastight.

Modifications and attachments to the fan are only permissible after consultation with the manufacturer.

Before commissioning or start-up after a long downtime, carry out a thorough inspection of the fan. Any damage,

such as housing cracks, contact between the impeller and the housing, strong vibrations or noises, must be remedied

without delay Do not operate fans and motors if they are damaged.

Instructions for the electrical system / motor protection (see also the operating instructions for the motor)

Requirements for the electrical connections:

Clearance distances between non-insulated parts > 10 mm.

Cable glands and sealing plugs must have an approval for explosion hazard zones

Reliable explosion protection of motors requires the installation of the correct motor protection system. Tripping

devices must have an ATEX approval.

Motors with increased safety (EEx e):

A motor protection device with a current-dependent delay and an ATEX approval must be installed so that, in the

event of an overload, it will disconnect the motor from the mains supply within the permissible heating period

(tEtime). The motor can be additionally protected by a PTC thermistor. However, protection of the motor using only

a PTC thermistor is not permissible.

Motors with a flameproof enclosure (EEx de):

Motor protection devices with a current-dependent delay and/or PTC thermistors (TS) can be used.

Motors with increased safety (EEx e) do not have an approval for operation with a frequency converter.

Motors with a flameproof enclosure (EEx de) can be operated in conjunction with special temperature monitoring of

the converter with a PTC thermistor.

Inspection, maintenance and repairs

The fan must be inspected at regular intervals to maintain explosion protection and to recognise and remedy faults at

an early stage.

The inspection intervals are to be specified by the owner/user depending on the respective operating conditions

(soiling, operating time, temperature, etc.); however, after every 4,000 operating hours or every 6 months at the latest.

It is advisable to document these activities in writing.

Main points of inspection and maintenance work:

Cleaning of the housing, impeller and motor

Check of smooth running (imbalance) and motor bearing (noise, vibrations); relubricate, if necessary

Check that the impeller is rotating freely. Check the gap between the impeller and the housing

Check that all screwed connections are firmly secured and that connected components and flange connections

are gastight

Check the state of the shaft seal (particularly if the internal and external explosion zones are different)

Check the motor current and insulation resistance as well as the motor protection device

Check the state of the electrical connections

Check all other monitoring equipment

Work in potentially explosive atmospheres must be carried out with suitable and appropriately approved tools. It is

prohibited to open the terminal box when the fan is operating. All work on the fan should thus be carried out in a non-

energised state and only if the possibility of a potentially explosive atmosphere can be excluded.

Plastic parts must be cleaned with damp agents to avoid electrostatic charges.

Repairs of explosion-proof fans must be carried out by the manufacturer or in consultation with the manufacturer.

7. Waste disposal

MIETZSCH fans are built to last. Thus disposal issues only crop up after many years of operation. The individual

components are not regarded as hazardous waste according to current legislation.

Dispose of metal components (base, motor, screws, etc.) in the usual manner

Clean plastic components and then dispose of them as normal waste

The owner/user must dispose of residual materials and deposits in the fan in an environmentally acceptable manner.

oi_vrr (11/09)

MIETZSCH GmbH Lufttechnik

Großenhainer Str. 137 - D 01129 Dresden

EG-Konformitätserklärung

im Sinne der EG-Maschinenrichtlinie

Hiermit erklären wir, dass die nachfolgend bezeichnete

Maschine aufgrund ihrer Konzipierung und Bauart sowie

in der von uns in Verkehr gebrachten Ausführung den

einschlägigen grundlegenden Sicherheits- und

Gesundheitsanforderungen der EG-Maschinenrichtlinie

entspricht. Bei einer nicht mit uns abgestimmten

Änderung der Maschine verliert diese Erklärung ihre

Gültigkeit.

Bezeichnung: Radialdachventilator

Maschinentyp: Baureihe VRR / 702

Baureihe VRR / ALM

Maschinen-Nr. / Baujahr: Siehe Typenschild

Einschlägige EG-Richtlinien:

EG-Maschinenrichtlinie (2006/42/EG)

EG-Niederspannungsrichtlinie (2006/95/EG)

EMV-Richtlinie (2004/108/EG)

Angewandte harmonisierte Normen, insbesondere:

EN ISO 12100-1, EN ISO 12100-2 und EN ISO 13857

- Sicherheit von Maschinen

EN 60204-1 Elektrische Ausrüstung von Maschinen

Ventilatoren in EX-Ausführung entsprechen zusätzlich:

Europäische Richtlinie 94/9/EG (ATEX)

EN 14986 Konstruktion von Ventilatoren für den

Einsatz in explosionsgefährdeten Bereichen

EN 13463-1 und -5 Nichtelektrische Geräte für den

Einsatz in explosionsgefährdeten Bereichen

EN 50014, EN 50018, EN 50019

Elektrische Betriebsmittel für

explosionsgefährdete Bereiche

Angewandte nationale Normen und technische

Spezifikationen, insbesondere:

VDMA 24167 Ventilatoren;Sicherheitsanforderungen

VBG 5, VBG 5 DA Kraftbetriebene Arbeitsmittel

Rausch

Geschäftsführer Dresden, den 25.02.2013

D

MIETZSCH GmbH Lufttechnik

Großenhainer Str. 137 - D 01129 Dresden

EC-Declaration of Conformity

as defined by the EC Council Direktive on Machinery

Herewith we declare that the machinery designated

below, on the basis of its design and construction in the

form brought onto the market by us is in accordance with

the relevant safety and health requirements of the EC

Council Directive on Machinery.

If alterations are made to the machinery without prior

consultations with us, this declaration becomes invalid

Designation: Radial roof fan

Machinery type: Series VRR / 702

Series VRR / ALM

Machinery -No. / Year of production : see rating plate

Relevant EC Council Directives:

EC-Machinery Directive (2006/42/EG)

EC-Low Voltage Directive (2006/95/EG)

EMC-Guideline (2004/108/EG)

Applied harmonized standards, in particular:

EN ISO 12100-1, EN ISO 12100-2 and EN ISO 13857

-Safety of Machinery

EN 60204-1 Electrical Equipment of Machines

Explosion-proof Fans additionally apply to:

European Directive 94/9/EG (ATEX)

EN 14986 Design of fans working in potentially

explosive atmospheres

EN 13463-1 und -5 Non-electric equipment fo

potentially explosive atmosphere

EN 50014, EN 50018, EN 50019

Electrical apparatus for potentially

explosive atmospheres

Applied national standards and technical specifications,

in particular:

VDMA 24167 Fans; Safety requirements

VBG 5, VBG 5 DA Accident Prevention Regulations

´Power Driven Tools´

Rausch

Manager Dresden, 25.02.2013

GB

EG-Konformitätserklärung

EC-Declaration of Conformity

MIETZSCH GmbH Lufttechnik Dresden swww.mietzsch.de

konf_vrr

Table of contents

Other Mietzsch Fan manuals

Popular Fan manuals by other brands

American Aldes

American Aldes AIRLET 200 Installation operation & maintenance

LUCCI

LUCCI FUTURA ECO Installation, operation & maintenance instructions

Princess

Princess 352600 Instructions for use

Vortice

Vortice VORT NOTUS Instruction booklet

MALTEC

MALTEC WL85-BR Operation and maintenance manual

Pullman Holt

Pullman Holt F500 Specifications