Safety Section 1-5

SAFETY

© 2005Alamo Group Inc.

SAFETY

8650A 07/05

DANGER! DO NOT operate this Implement on a Tractor that is not properly

maintained. ShouldamechanicalorTractorcontrolfailureoccurwhile

operating, immediately shut down the Tractor and perform repairs

before resuming operation. Serious injury and possible death could

occurfromnotmaintainingthisImplementandTractoringoodoperating

condition. (SG-36)

DANGER! Do Not approach the front of the snow blower while the fan is

rotating. Contact with the rotating fan can result in serious in-

jury or even death. Stay away until all motion has stopped and

the snow blower is securely blocked up before removing mate-

rial, performing service, and making repairs. (SSB-05a)

DANGER! Donot put hands or feet near the rotating fan. Fan contact can result

inseriousinjuryorevendeath. Stayawayuntilallmotionhasstopped

andthesnowblowerissecurelyblockedupbeforeremovingmaterial,

performingservice,andmakingrepairs. (SSB-6)

DANGER! Do not operate the implement while wearing loose fitting clothing. En-

tanglementoftheclothingwiththerotatingelementscanresultinserious

injuryoreven death. Stayclear ofallrotatingelementsatalltimes. (SSP-

3)

Connecting or Disconnecting Implement Safety Instructions and Practices

WARNING! DONOTuseaPTOadaptertoattachanon-matchingImplementdriveline

toaTractorPTO. Useofanadaptercandoubletheoperatingspeedofthe

Mower resulting in excessive vibration, thrown objects, and blade and

mower failure. Adapter use will also change the working length of the

drivelineexposingunshieldeddrivelineareas. Seriousbodilyinjuryand/or

equipment failure can result from using a PTO adapter. Consult an

authorizeddealerforassistanceiftheImplementdrivelinedoesnotmatch

the Tractor PTO. (S3PT-14)

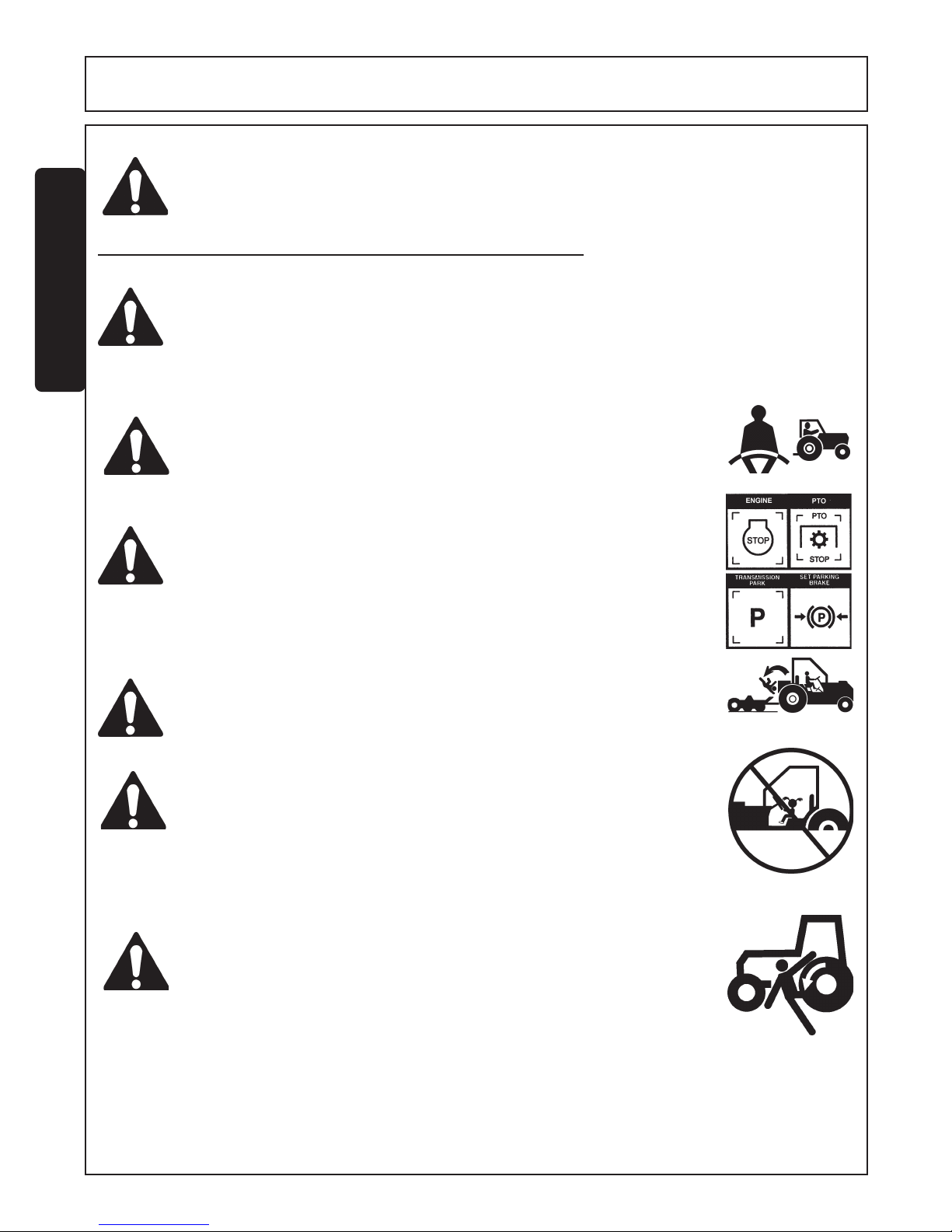

DANGER! AlwaysshuttheTractorcompletelydown,placethetransmissioninpark,

andsettheparkingbrakebeforeyouoranyoneelseattemptstoconnect

or disconnect the Implement and Tractor hitches. (S3PT-15)

WARNING! When attaching the Implement input driveline to the Tractor PTO, it is

important that the connecting yoke spring activated locking collar slides

freelyandthelockingballsareseatedsecurelyinthegrooveontheTractor

PTOshaft. AdrivelinenotattachedcorrectlytotheTractorPTOshaftcould

come loose and result in personal injury and damage to the Implement.

(S3PT-17)

WARNING! Before operating the Mower, check to make sure the Implement input

drivelinewillnotbottomoutorbecomedisengaged. Bottomingoutoccurs

when the inner shaft penetrates the outer housing until the assembly

becomessolid-itcanshortenno more. Bottomingoutcancauseserious

damagetotheTractorPTObypushingthePTOintotheTractorandthrough

thesupportbearingsordownwardontothePTOshaft,breakingitoff. A

broken drive line can cause personal injury. (S3PT-18)