Air Motor SER 323440-4

Alemite, LLC 3 Revision (7-05)

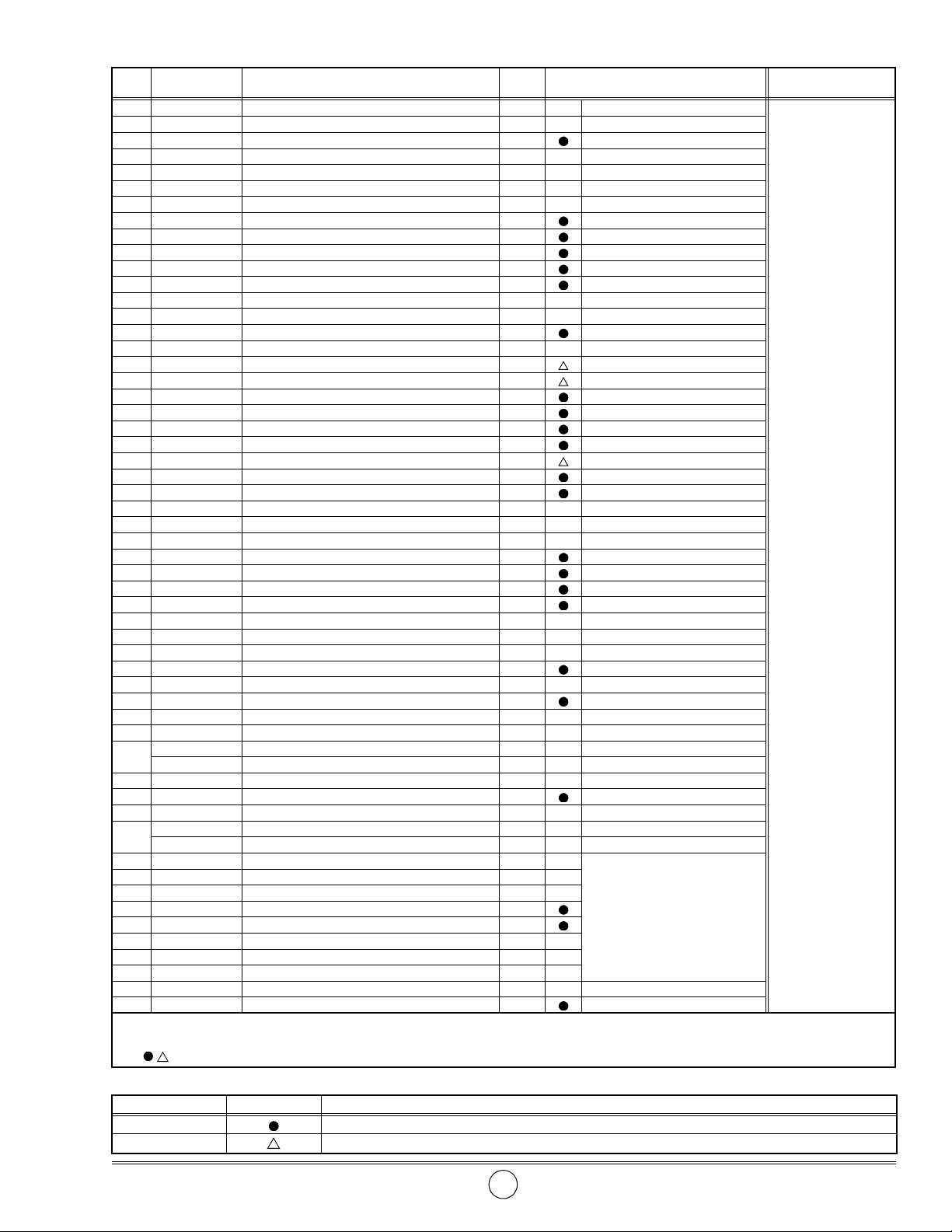

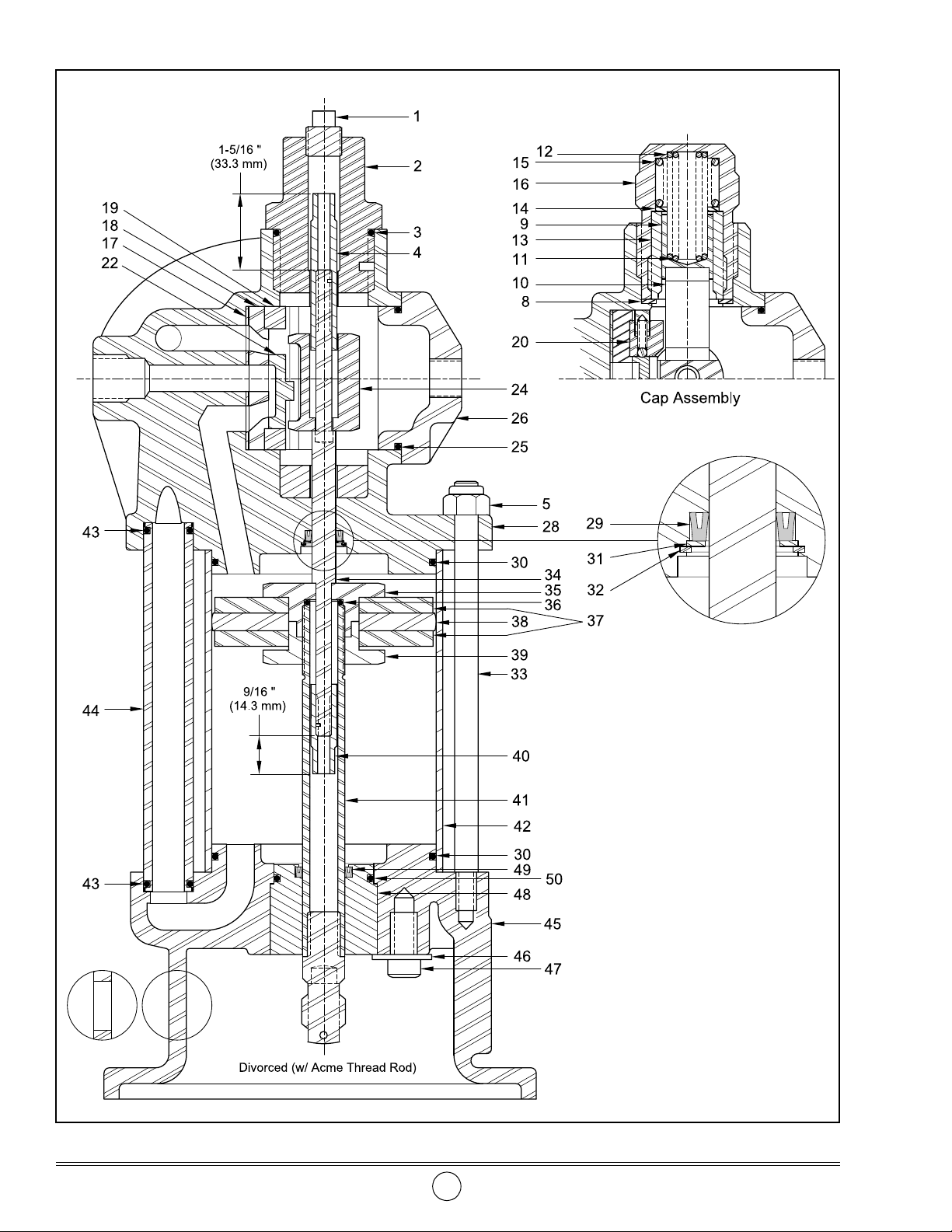

Item

No. Part No. Description Qty Notes Numeric Order

Part # (Item #)

1 48925 Plug, Pipe, 3/8 " NPT 1 11828 (53)

2 324076 Plug,1-3/4 " -12 (m) x 3/8 " NPT (f) 1 14546 (46)

3 171009-29 O-Ring, 1-9/16 " ID x 1-3/4 " OD 1 48925 (1)

4 324432 Nut, Upper Trip Rod, 3-3/8 " Long 1 77807 (51)

5 171130 Nut, Elastic Stop, 1/2 " -20 5 171000-12 (43)

6 323487 Setscrew, 5/16 " -18 x 1/2 " 2 171003-20 (30)

7 Plug, Socket Pipe, 3/8 " NPT 1 171006-15 (32)

8 323482 Gasket, 1.646 " OD (Copper) 2 171009-4 (36)

9 323450 Plunger 2 171009-29 (3)

10 323464 Toggle 2 171009-33 (50)

11 326738 Spring, 2.44 " Long 2 Model 323440-4, -A1 171009-35 (a)

12 323486 Spring, 3.00 " Long 2 171009-47 25)

13 323481 Cylinder, 1-5/16 " -20 2 171130 (5)

14 323484 Washer, 0.7 " ID 2 172013 (22)

15 323485 Spring, 1-5/16 " Long 2 172207-4 (52)

16 323483 Cap 2 311738 (7)

17 323468 Gasket, 2-13/16 " OD (Rubber) 1 314632 (49)

18 Seat, Valve 1 323443 (27)

19 323469 Stop 2 323444-2 (44)

20 323830 Guide, Valve 2 323466-4 (26)

21 Lockwasher, 5/16 " 4 323450 (9)

22 Screw, Cap, 5/16 " -18 x 1 " 4 323451-3 (41)

23 Slide, Valve 1 323459-2 (33)

24 323473 Shuttle 1 323460 (39)

25 171009-47 O-Ring, 2-11/16 " ID x 2-7/8 " OD 1 323461 (37)

26 323466-4 Body, Inlet, 3/4 " NPTF (f) 1 323462 (38)

27 323443 Screw, Cap, 3/8 " -16 x 7/8 " 4 323464 (10)

28 333203-D1 Head Assembly, Casting 1 323467 (18)

29 324290 V-Packing 1 323468 (17)

30 171003-20 O-Ring, 4 " ID x 4-1/4 " OD 2 323469 (19)

31 323474 Washer, 0.52 " ID 1 323470 (23)

32 171006-15 Ring, Retaining, 7/8 " Diameter 1 323473 (24)

33 323459-2 Rod, Tie, 1/2 " -13 x 1/2 " -20 5 323474 (31)

34 326471-1 Rod, Trip 1 323477-2 (42)

35 323478 Retainer, Piston 1 323478 (35)

36 171009-4 O-Ring, 5/8 " ID x 3/4 " OD 1 323479 (40)

37 323461 Washer 2 323481 (13)

38 323462 Packing 1 323482 (8)

39 323460 Nut, Piston, 13/16 " -20 1 323483 (16)

40 323479 Nut, Lower Trip Rod, 1-5/8 " Long 1 323484 (14)

41 323451-3 Rod, Piston 1 Model 323440-4, -A1, -C1, E1 323485 (15)

338833 Rod, Piston 1 Model 323440-D1 323486 (12)

42 323477-2 Cylinder 1 323487 (6)

43 171000-12 O-Ring, 5/8 " ID x 13/16 " OD 2 323488-5 (45)

44 323444-2 Tube 1 323493-B4 (45)

45 323493-B4 Base, Air Motor (w/ weep hole plug) 1 Model 323440-4, -A1, E1 323550 (48)

323488-5 Base, Air Motor (w/o weep hole plug) 1 Model 323440-C1, -D1 323551 (47)

46 Washer, 1/2 " 3

Model 323440-A1

323830 (20)

47 Screw, 1/2 " -13 x 7/8 " 3 324076 (2)

48 323550 Retainer, Packing (Brass) 1 324290 (29)

49 314632 V-Packing 1 324432 (4)

50 171009-33 O-Ring, 1-13/16 " ID x 2 " OD 1 326471-1 (34)

51 Nut, 1/2 " -20 4 326738 (11)

52 Lockwasher, 1/2 " 4 333203-D1 (28)

53 Screw, Cap, 1/2 " -20 x 2 " 4 338833 (41)

54 340122 Adapter, 3/4 " BSPP (f) x 3/4 " NPTF (m) 1 Model 323440-E1 340122 (54)

a 171009-35 O-Ring, 1-15/16 " ID x 2-18 " OD 1 Model 323440-4, -C1 384232 (21)

Legend:

Part numbers left blank (or in italics) are not available separately

designates a repair kit item

Repair Kits

Part No. Kit Symbol Description

398978-4 Kit, Major Repair (Includes Tube of 394009 Loctite 242 and 398030 Viscous H Lubricant)

398989 Kit, Slide Valve, Seat, and Gasket