Air Motor SER 339413

Alemite, LLC 7 Revision (7-06)

Clean and Inspect

1. Clean all metal parts in a cleaning solvent. The solvent

should be environmentally safe.

2. Inspect all parts for wear and/or damage.

• Replace as necessary.

• Use Valve Replacement Kit 393706.

3. Inspect the bores of Cylinder (1) closely for score

marks.

• Replace as necessary.

Assembly

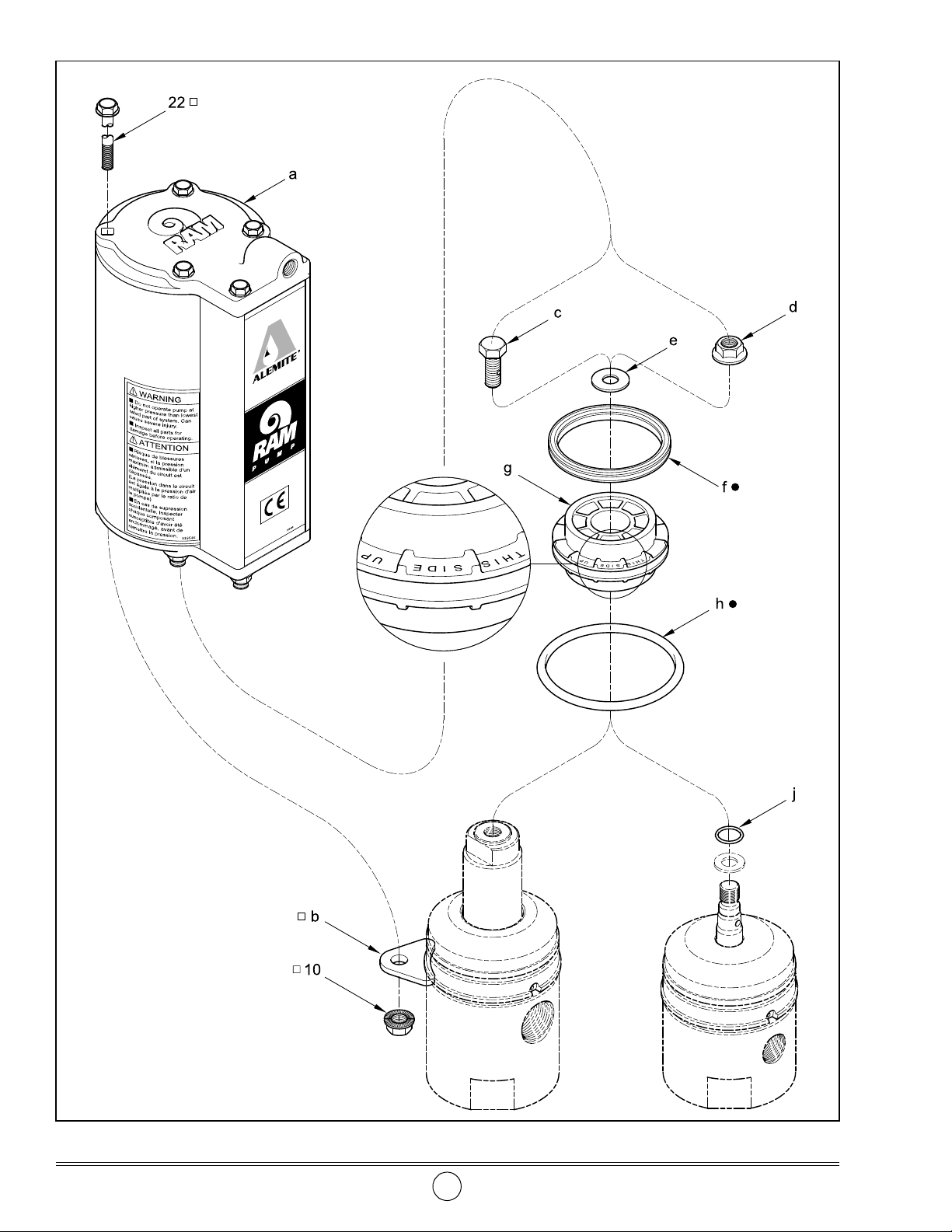

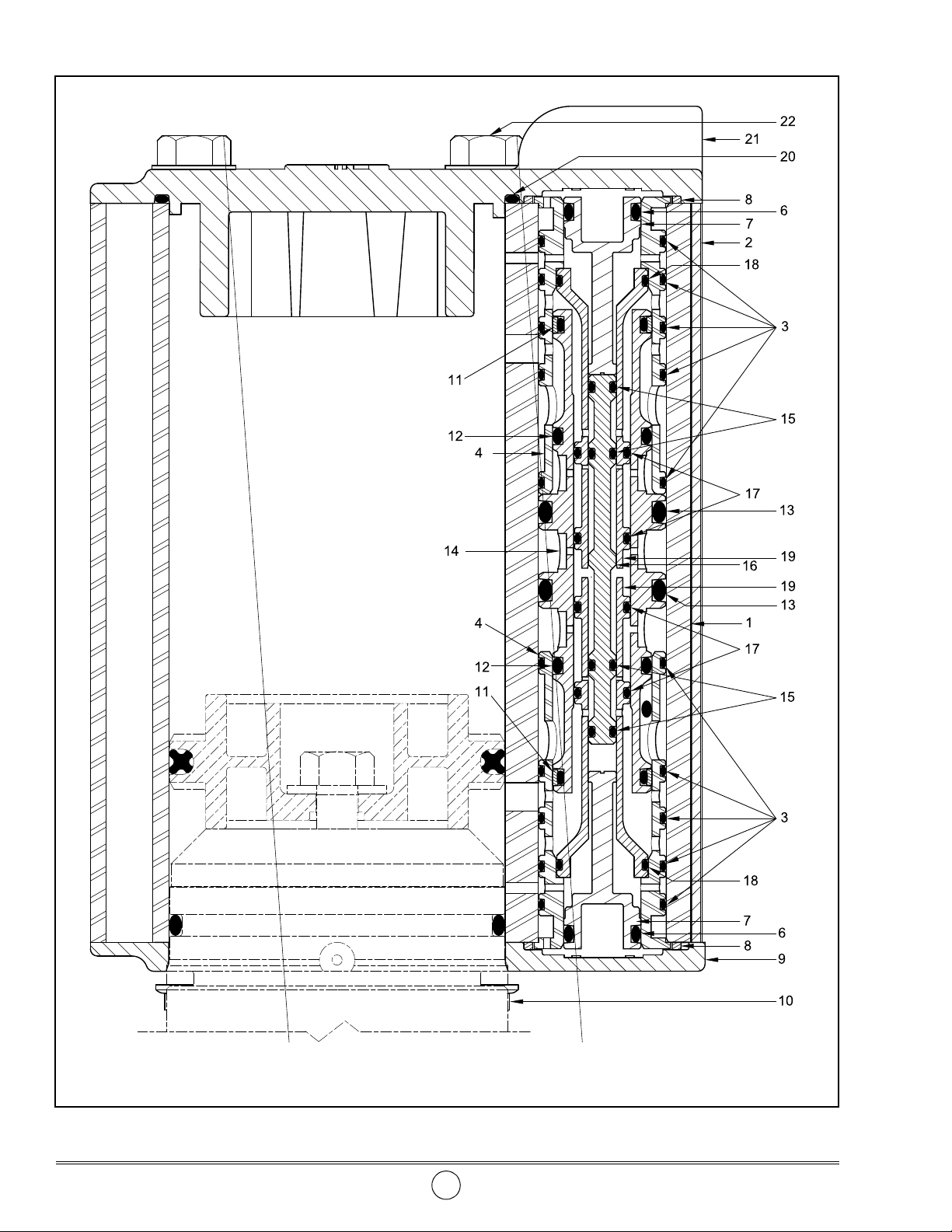

NOTE: Refer to Figures 2 and 5for compo-

nent identification on all assembly proce-

dures.

Air Motor

IMPORTANT: Always use Magnalube-G

Teflon grease in this air motor.

Valve Replacement

NOTE: Procedural steps 1 -4 are applicable

to the Valve Replacement Kit.

1. Remove the Exhaust Adapter and O-Ring assembly

(with Pilot Piston assembly) from one end of the valve

kit.

IMPORTANT: Use care during the assembly

of the logic components. Prevent possible

damage to Seals.

2. Install and seat the remainder of the valve kit assembly

into one end of Cylinder (1).

3. Install and seat the Exhaust Adapter assembly into the

Cylinder and logic components.

4. Install the Pilot Piston assembly into the Cylinder.

Cylinder

HINT: Fill the Gasket groove and the

O-Ring groove in Top Cap (21) with Teflon

grease.

Fill the Gasket groove in Bottom Cap (9)

with Teflon grease.

5. Install Gaskets (8) into Top Cap (21) and Bottom Cap

(9).

• Make sure the Gaskets seat properly.

6. Install O-Ring (20) into the Top Cap.

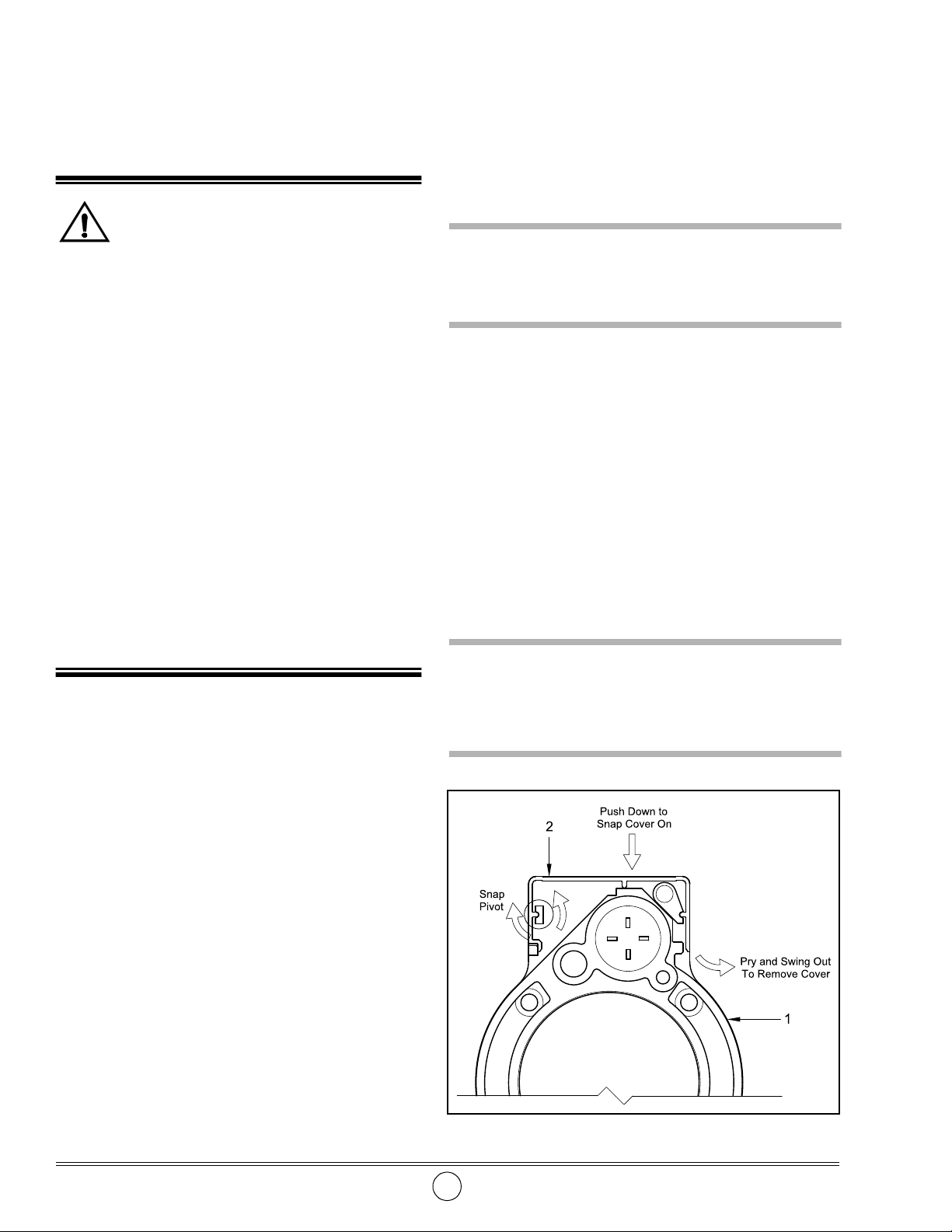

7. Install Muffler (5) into Cover (2).

Attach Air Motor to Pump Tube

Refer to the Pump SER Service Guide for details.

Bench Test and Operation

Refer to the Pump SER Service Guide for details.

Check the motor for air leakage. If the motor leaks,

refer to the Troubleshooting Chart for details.

Installation

General

Additional items that should be incorporated into the

air piping system are listed in Table 1.

Upgrade Kit (Conversion)

NOTE: The Air Motor must be separated

prior to installation onto the pump.

a. Remove Cover (2) from the Air Motor.

b. Remove Flange Nuts (10) and Screws

(22) from the Air Motor.

c. Separate Top Cap (21) from Cylinder (1),

and the Cylinder from Bottom Cap (9).

1. Remove the PML motor from the pump.

2. Remove the air motor piston from the rod.

• Discard the piston and o-ring assembly.

3. Remove the o-ring from the body of the pump and

discard.

4. Install and secure Piston (g) onto the rod.

5. Install lubricated Quad-Ring (f) onto the Piston.

6. Lubricate the bore of Cylinder (1) with Magnalube-G

Teflon grease.

7. Install Bottom Cap (9) onto the pump’s body.

8. Install lubricated O-Ring (h) onto the upper groove of

the pump body.

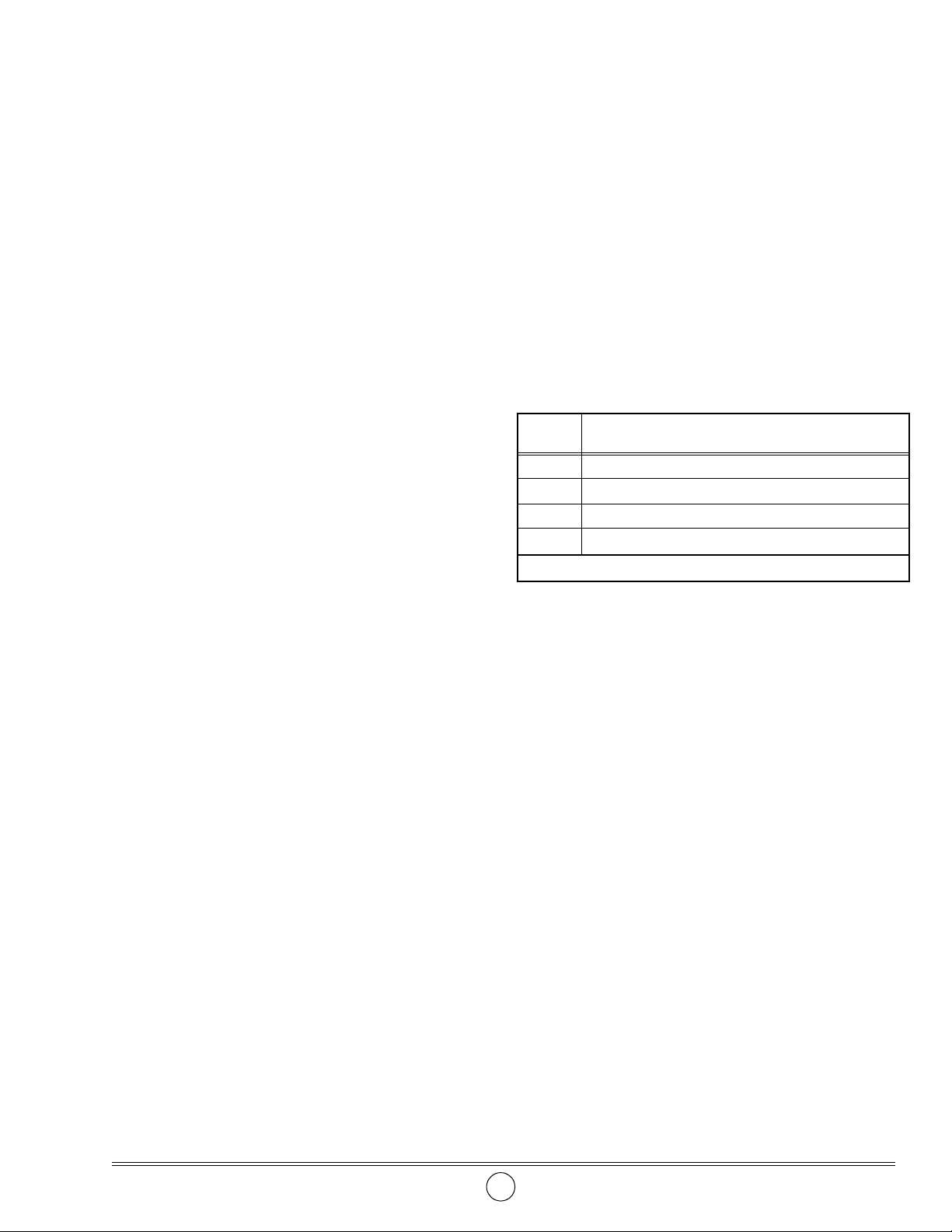

Part

Number Description

338860 Regulator, Gauge, Separator Combination (w/ Auto Dump)

7604-B Regulator and Gauge (Included with 338860)

5604-2 Moisture Separator (Included with 338860)

5904-2 Lubricator *

* Not recommended, use only as required.

Table 1 Air Line Components