1

1 - 5

General information and Maintenance

Engine oil level

In four-stroke engines oil is used to lubricate the valve

gear components, the crankshaft bearings and the

thermal unit. A lack of engine oil can cause serious

damage to the engine.

In all four-stroke engines, oil deterioration and con-

sumption are, to some extent, normal, especially during

running-in. Consumption partly depends on the riding

style (for example, constantly riding at full throttle in-

creases oil consumption).

Checking the oil level

Perform this operation when the engine cold, as de-

scribed below:

1) Put the vehicle on its central stand on a flat surface.

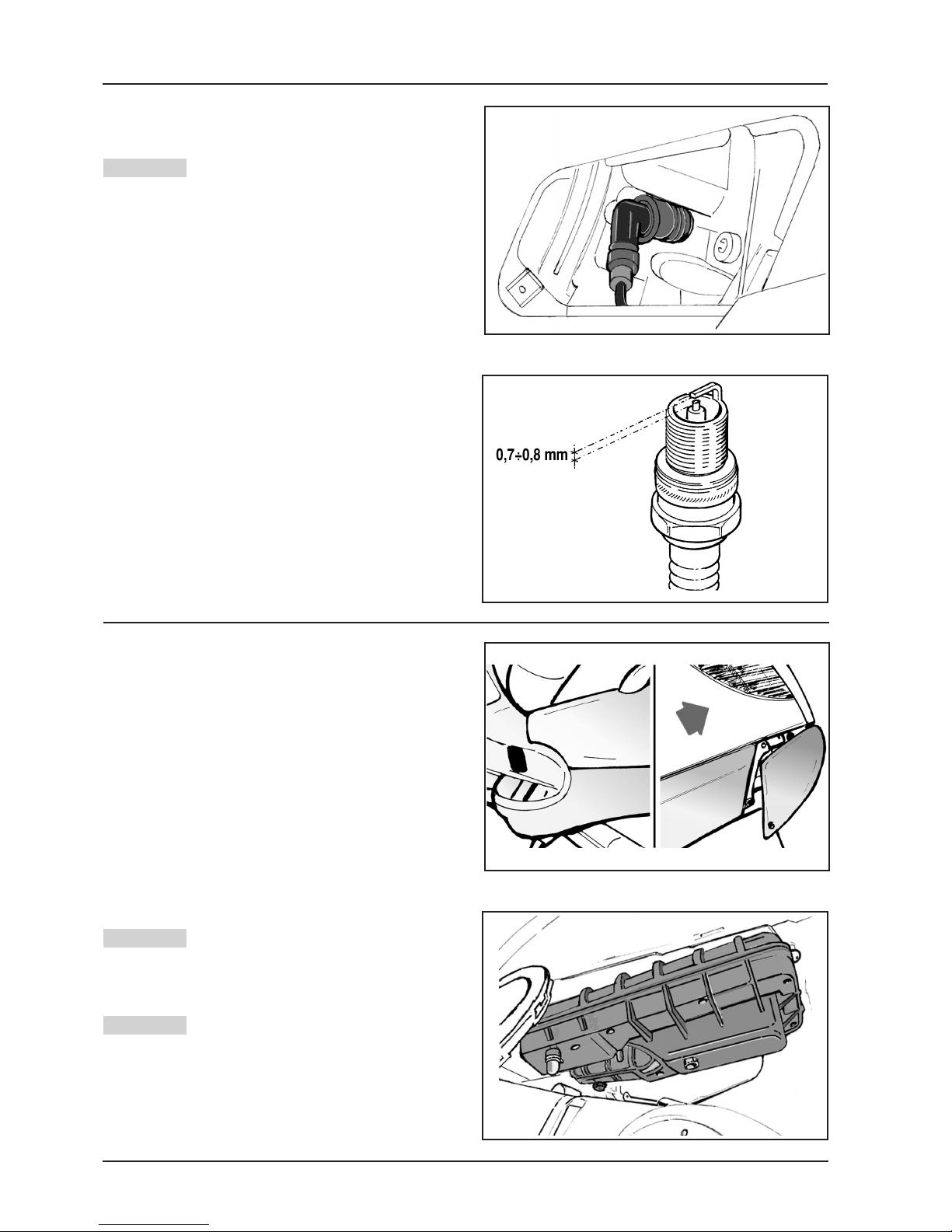

2) Unscrew dipstick «A», dry it with a clean cloth and

refit by screwing it completely.

3) Remove the dipstick again and check that the oil

level is between the MAX and MIN marks on the

dipstick; top up if necessary.

Il riferimento del livello di MAX indica una quantità di

circa 1700 cc di olio nel motore.

The level will be lower if checked after using the vehicle

(i.e. when the engine is hot). To obtain a correct indi-

cation of the oil level, wait for at least 10 minutes after

switching off the engine.

Topping up

If the oil level is too low, top up by adding fresh oil

without exceeding the MAX level.

Approximately 400 cc of oil are needed to restore the

level between the MIN and MAX marks.

Oil pressure warning light

A warning light on the instrument panel comes on when

the ignition key is turned to the “ON” position. The light

must go out after the engine has started.

Should the warning light come on while braking,

idling or cornering, check the oil level and the

lubrication system as soon as possible.

Renewing the oil and the filter

The oil and the filter must be renewed every 6,000 km.

Drain all the oil from the engine by removing gauze

strainer drain plug «B» on the transmission side. To

facilitate the outflow, also remove cap/dipstick «A».

Once the oil has drained completely through the drain

hole, unscrew oil filter cartridge «C» and remove it as

described below.

01_005

01_007

01_006

MAX MIN

A

B

C

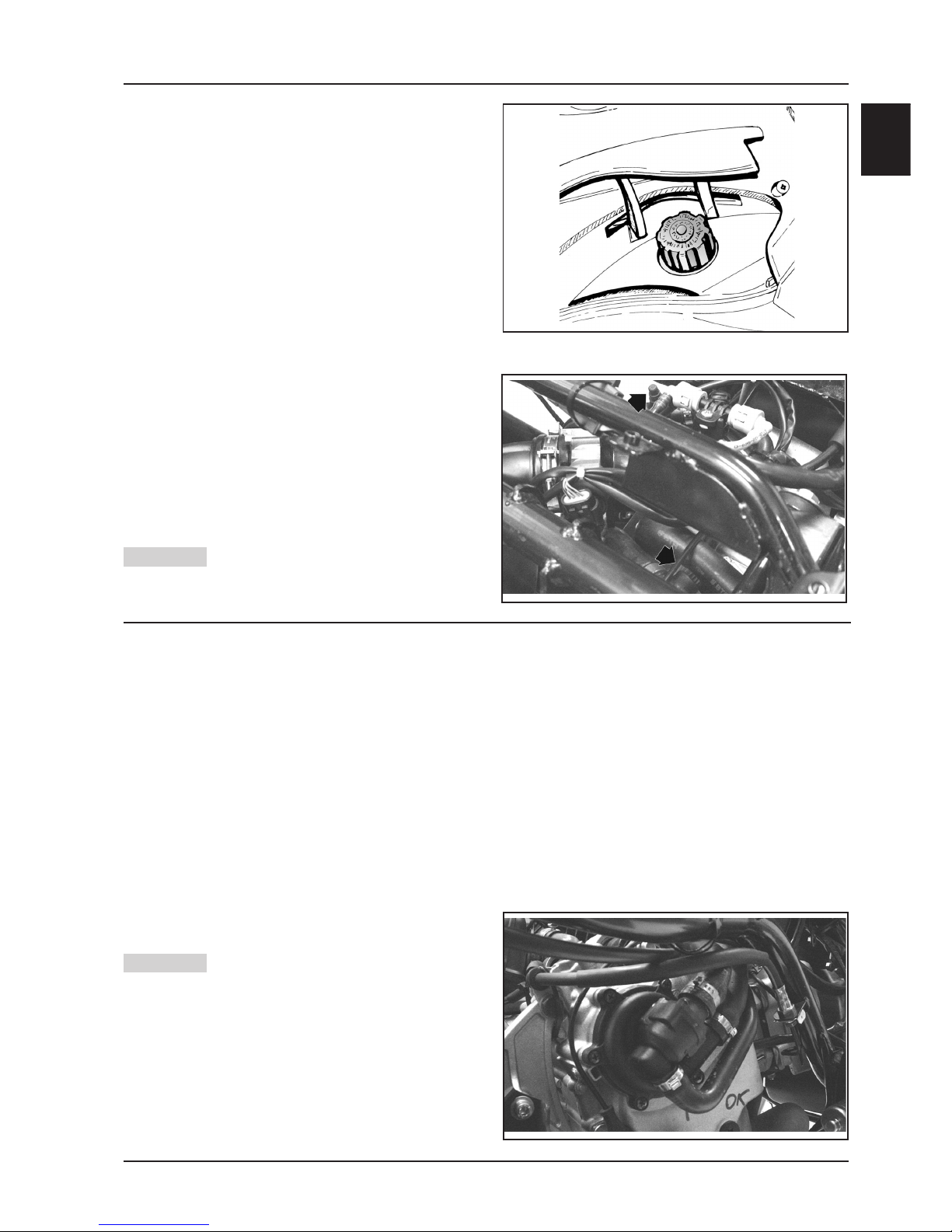

Since a certain amount of oil remains in the circuit, the

replenishment must be made by adding approximately

1,500 cc of fresh oil through cap «A». Subsequently

start the engine, let it idle for a few minutes and then

switch it off. After about 5 minutes, check the level and

if necessary top up without ex-ceeding the MAX level.

The filter cartridge must be replaced every time the oil

is changed. For top-ups and

renewals use fresh oil of the Selenia HI Scooter 4 Tech

type.

N.B.: Renew the oil when the engine is hot.

When the oil level is at MAX the engine contains

1700 cc of oil.