3

Alemite, LLC Revision (1-14)

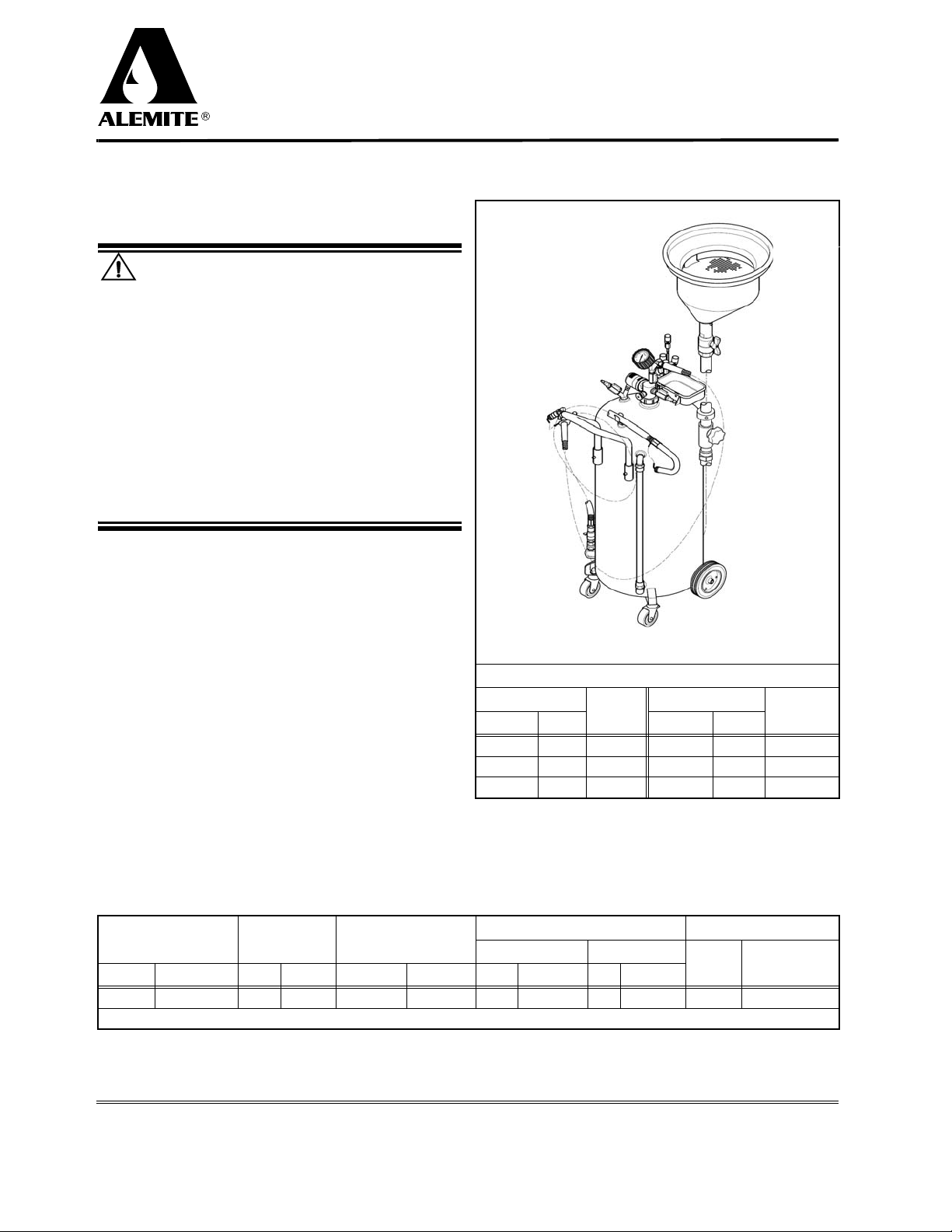

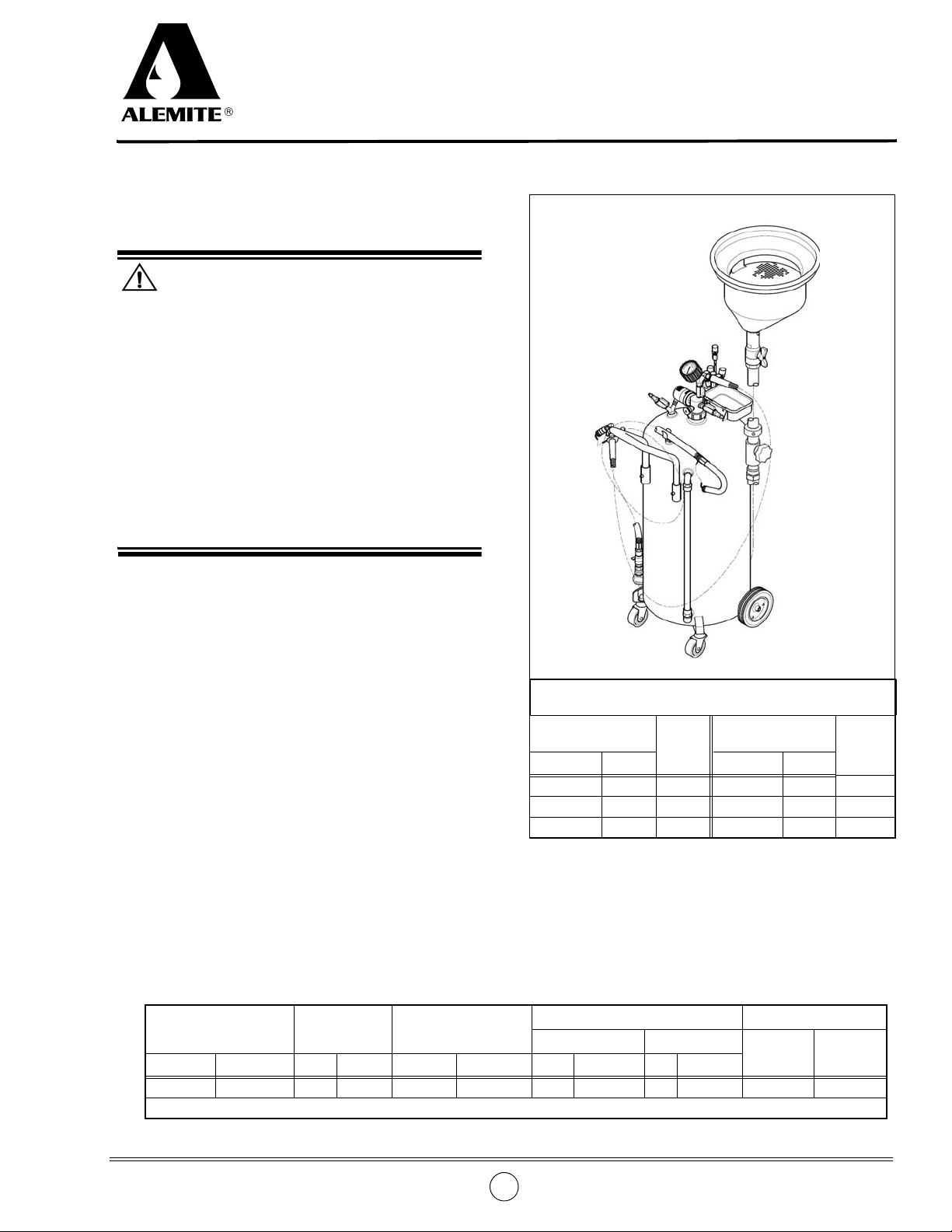

SER 8580

Item #

No. de

artículo#

Pièce n°

Part #

No. de pieza

N° réf. #

Description Descripción Description Qty

Cant.

Qté

Kit

Juego

Kit

Notes

Notas

Remarques

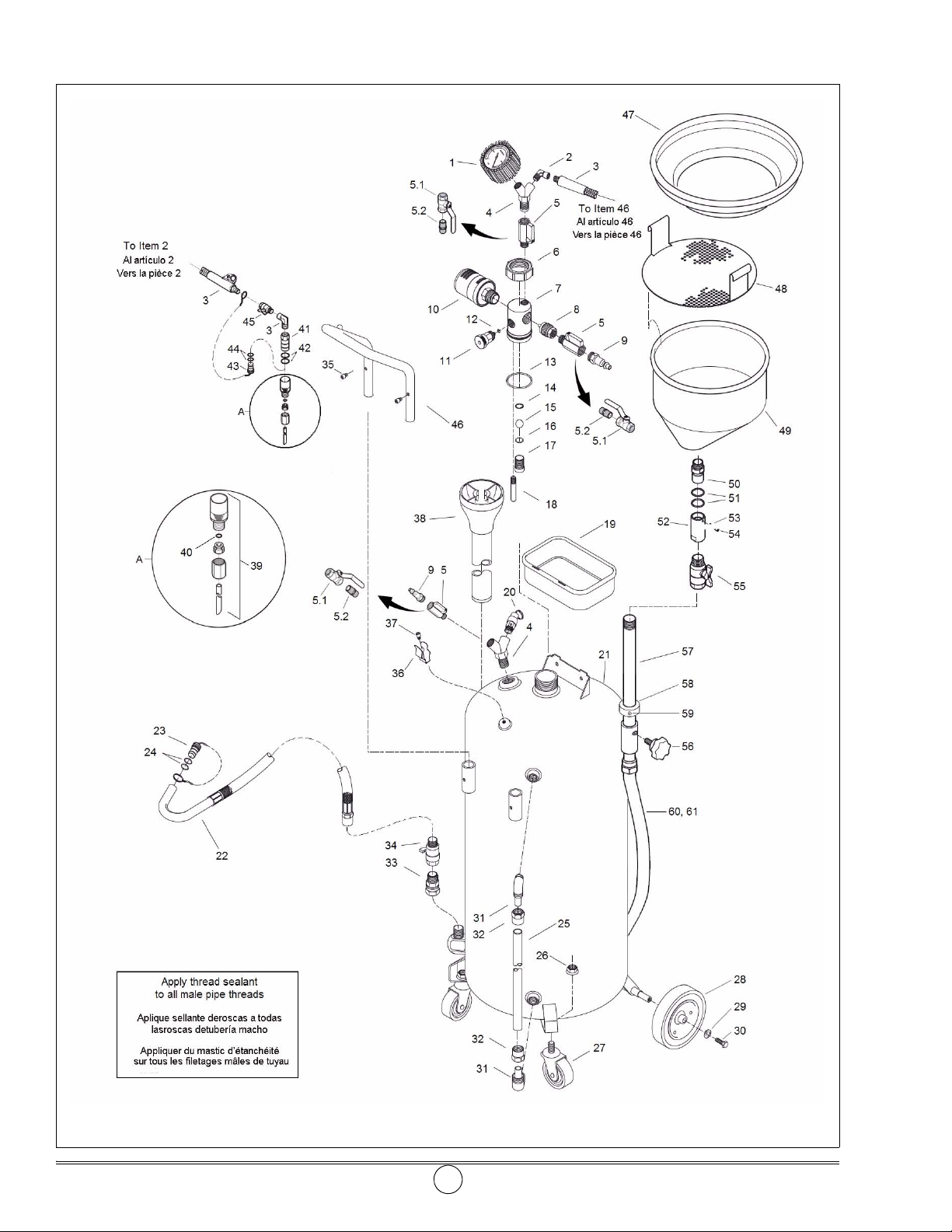

1 393767-19 Gauge, Vacuum Manómetro de vacío Vacuomètre 1

2 Elbow Codo Coude 2

3 393767-20 Hose Manguera Flexible 1

4 393767-5 Adapter, Y Adaptador en Y Raccord en Y 1

5Val ve, Ball Válvula de bola Robinet, boisseau sphérique 3 1/4 " NPTF5.1 SWA288

5.2 327033 Adapter Adaptador Raccord 3

6 Collar Collar Collier 1 □

7 Adapter Adaptador Raccord 1 □

8 Nozzle Boquilla Buse 1 □

9 328034 Connector, Air Conector de aire Raccord, air 2

10 340562 Muffler Silenciador Silencieux 1

11 393767-21 Valve Válvula Robinet 1

12 O-Ring Junta tórica Joint torique 1 ●4.47 mm x 8.03 mm

13 O-Ring Junta tórica Joint torique 1 ●42.5 mm x 47.8 mm

14 Ring, Retaining Anillo de retención Anneau retenue 1 ●

15 Ball Bola Boisseau sphérique 1 ●

16 O-Ring Junta tórica Joint torique 1 ●9.5 mm x 14.8 mm

17 Seat Asiento Siège 1

18 Tube Tubo Tube 1

19 393767-31 Tray, Tool Bandeja de herramientas Plateau, outils 1

20 393767-4 Valve, Relief Válvula de alivio presión Soupape, décharge 1 15 psi (1 bar)

21 Tank Depósito Réservoir 1

22 393767-6 Hose and Nozzle Manguera y boquilla Flexible et buse 1

23 393767-7 Plug and Chain Tapón y cadena Obturateur et chaîne 1

24 O-Ring Junta tórica Joint torique 2 11.2 mm x 16 mm

25 393767-8 Gauge, Level Indicador de nivel Jauge, niveau 1 ●

26 Nut, Flange Tuerca embridada Écrou, embase 2 Δ

27 Caster Rueda orientable Roulette 2 Δ

28 Wheel Rueda Roue 2 ▲

29 Washer Arandela Rondelle 2 ▲

30 Screw Tornillo Vis 2 ▲

31 393767-26 Elbow (set of 2) Codo de codos (2) Coude (jeu de 2) 1

32 393767-27 Ring (set of 2) Conjunto de anillos (2) Bague (jeu de ) 1

33 Adapter Adaptador Raccord 1 1/2 " BSP (f) x 1/2 "

34 Valve, Ball Válvula de bola Robinet, boisseau sphérique 1 1/2 " NPTF

35 Screw Tornillo Vis 2

36 Clip Presilla Attache 1

37 Screw Tornillo Vis 1

38 Container Recipiente Auge 1

39 393767-22 Wand Set (6) Conjunto de varillas (6) Jeu de lances (6) 1

40 O-Ring Junta tórica Joint torique

2

•

5 mm x 8.6 mm

2 6 mm x 9.6 mm

1 6.9 mm x 10.5 mm

1 8 mm x 11.6 mm

41 Connector Conector Connecteur 1 ○

42 O-Ring Juna tórica Joint torique 2 ○● 13.2 mm x 16.8 mm

43 Plug and Chain Tapón y cadena Obturateur et chaîne 1 ○

44 O-Ring Junta tórica Joint torique 2 ○● 6.9 mm x 10.5 mm

45 Valve, Ball Válvula de bola Robinet, boisseau sphérique 1 1/4 " NPTF

46 Handle Asa Poignée 1

47 393767-1 Guard, Splash Protector contra salpicaduras Pare-éclaboussures 1

48 393767-32 Strainer Colador Crépine 1

49 393767-2 Bowl Cubeta Entonnoir 1

50 Stem,Swivel Vástago giratorio Tige, à pivotante 1 ■

51 O-ring Junta tόrica Joint torique 2 ■28 mm x 33.3mm

52 Body, Swival Cuerpo giratorio Corps, pivotant 1 ■

53 Washer, Lock Arandela de traba Rondelle, frein 1 ■

54 Screw Tornillo Vis 1 ■

55 Valve, ball Válvula de bola Robinet, boisseau sphérique 1 3/4 " NPTF

56 Wheel, Hand Rueda manual Molette 1 ♦

57 Extention Tube Tubo de extensión Tube de rallonge 1 ♦

58 Collar Collar Collier 1 ♦

59 Screw, Set Tornillo de presión Vis, de pression 1 ♦M8-1 x 8mm

60 Hose Assy Conjunto de la manguera Flexible 1 ◊

61 Elbow Codo Coude 1 ◊3/4" NPT

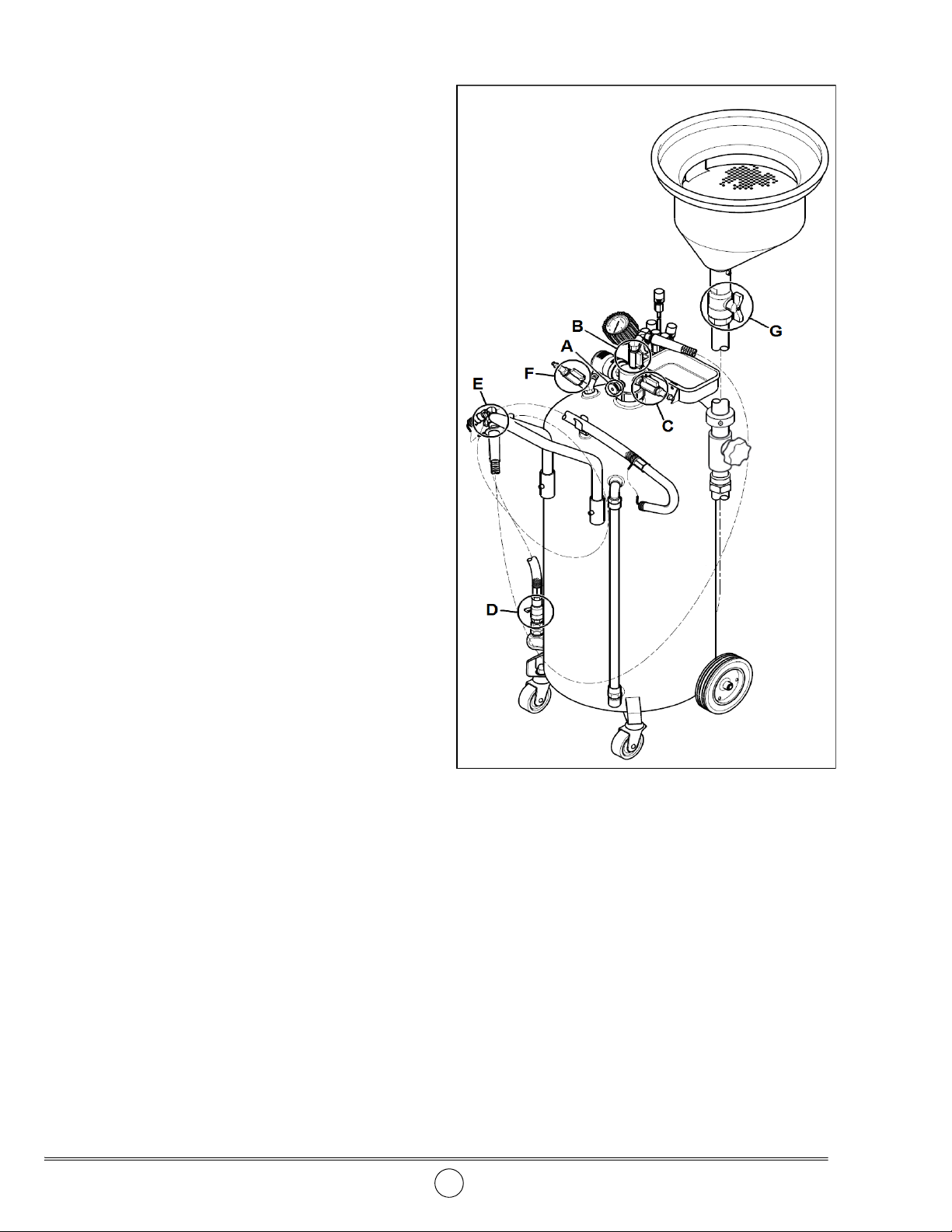

Portable Oil Drain/Extractor