Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC Declaration of Conformity ....................................................................... 5

2. Safety .................................................................................................... 6

2.1. Important information ............................................................................. 6

2.2. Warning signs ..................................................................................... 6

2.3. Safety precautions ................................................................................ 7

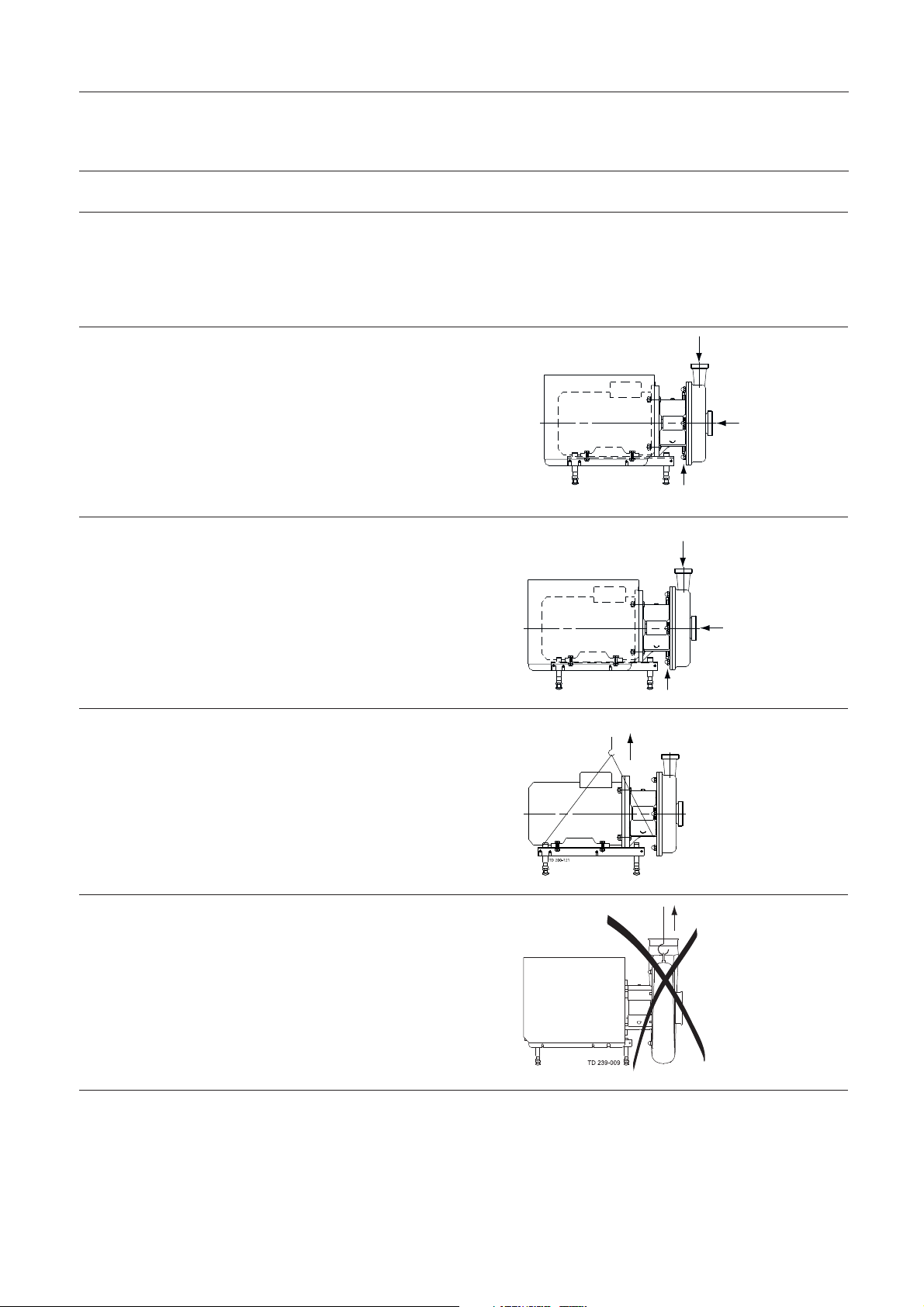

3. Installation .............................................................................................. 8

3.1. Unpacking/Delivery ............................................................................... 8

3.2. Installation ......................................................................................... 9

3.3. Pre-use check - Pump without/with impeller screw ........................................... 10

4. Operation ............................................................................................... 11

4.1. Operation/Control ................................................................................. 11

4.2. Fault finding ....................................................................................... 13

4.3. Recommended cleaning ......................................................................... 14

5. Maintenance ........................................................................................... 15

5.1. General maintenance ............................................................................. 15

5.2. Dismantling of pump/shaft seals ................................................................ 17

5.3. Assembly of pump/single shaft seal ............................................................ 19

5.4. Assembly of pump/flushed shaft seal ........................................................... 21

5.5. Assembly of pump/double mechanical shaft seal ............................................. 23

5.6. Adjustment of shaft (LKH-5) ..................................................................... 25

5.7. Adjustment of shaft (LKH-10 to -90) ............................................................ 27

5.8. Cleaning Procedure ............................................................................... 29

6. Technical data ......................................................................................... 30

6.1. Technical data ..................................................................................... 30

6.2. Relubrication Intervals ............................................................................ 31

6.3. Addendum ......................................................................................... 32

7. Parts list and Service Kits ........................................................................... 33

7.1. LKH-5 Sanitary Version .......................................................................... 33

7.2. LKH-10, -15, -20, -25, -35, -40, -50, -60 Sanitary Version .................................. 34

7.3. LKH-70 - 90 Sanitary Version ................................................................... 35

7.4. LKH-5 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal .............. 36

7.5. LKH-10 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 38

7.6. LKH-15 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 40

7.7. LKH-20 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 42

7.8. LKH-25 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 44

7.9. LKH-35 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 46

7.10.LKH-40 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 48

7.11.LKH-45 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 50

7.12.LKH-50 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 52

7.13.LKH-60 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 54

7.14.LKH 5-60 Centrifugal Pumps, Shaft Seals ..................................................... 56

7.15.LKH-70 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 58

7.16.LKH-75 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 60

7.17.LKH-80 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 62

7.18.LKH-85 Centrifugal Pump Single, Flushed and Double Mechanical Shaft Seal ............ 64

3