Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

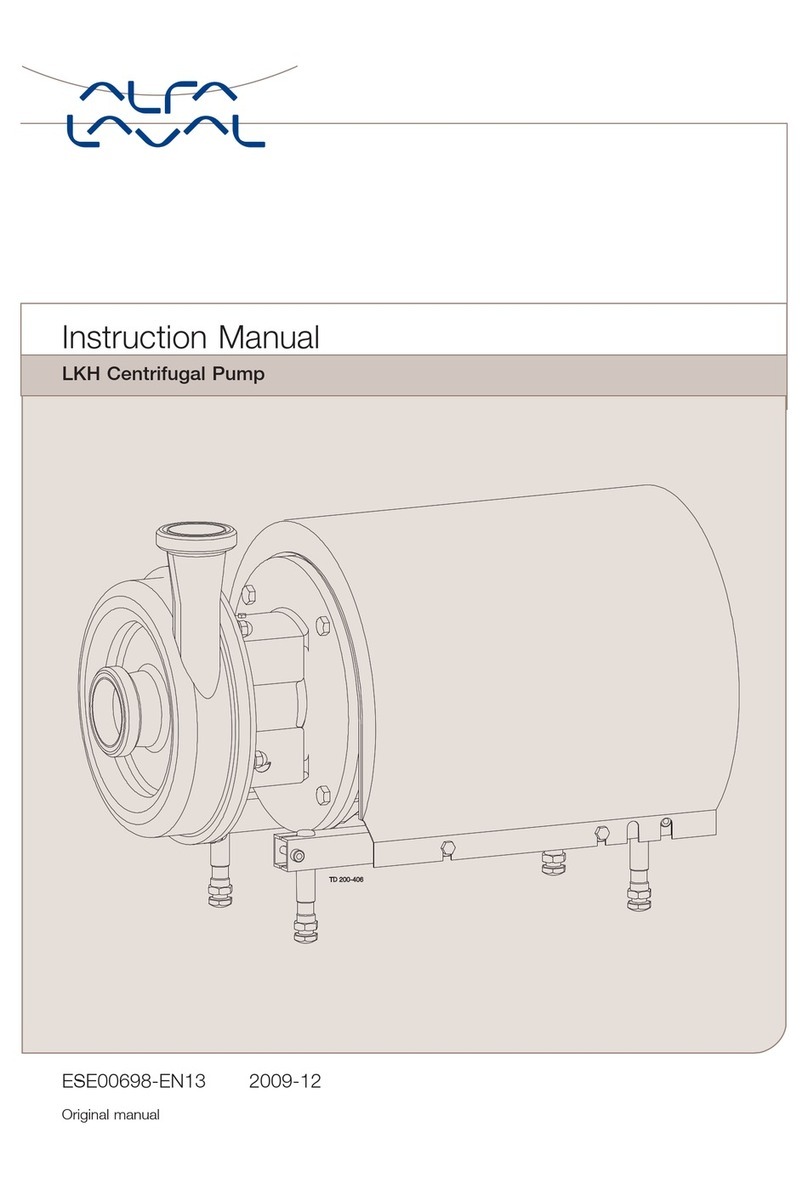

1. EC Declaration of conformity ....................................................................... 5

2. Safety .................................................................................................... 6

2.1. Generel information ............................................................................... 6

2.2. Target groups ..................................................................................... 6

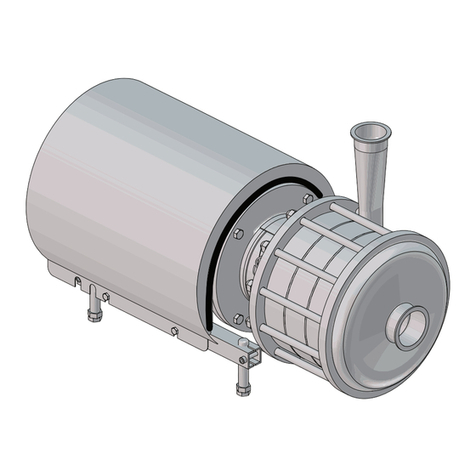

2.3. Symbols ........................................................................................... 6

2.4. Danger levels ...................................................................................... 6

2.5. Proper use ......................................................................................... 7

2.6. Safety information ................................................................................ 7

3. Installation .............................................................................................. 8

3.1. Unpacking and checking the state of delivery ................................................. 8

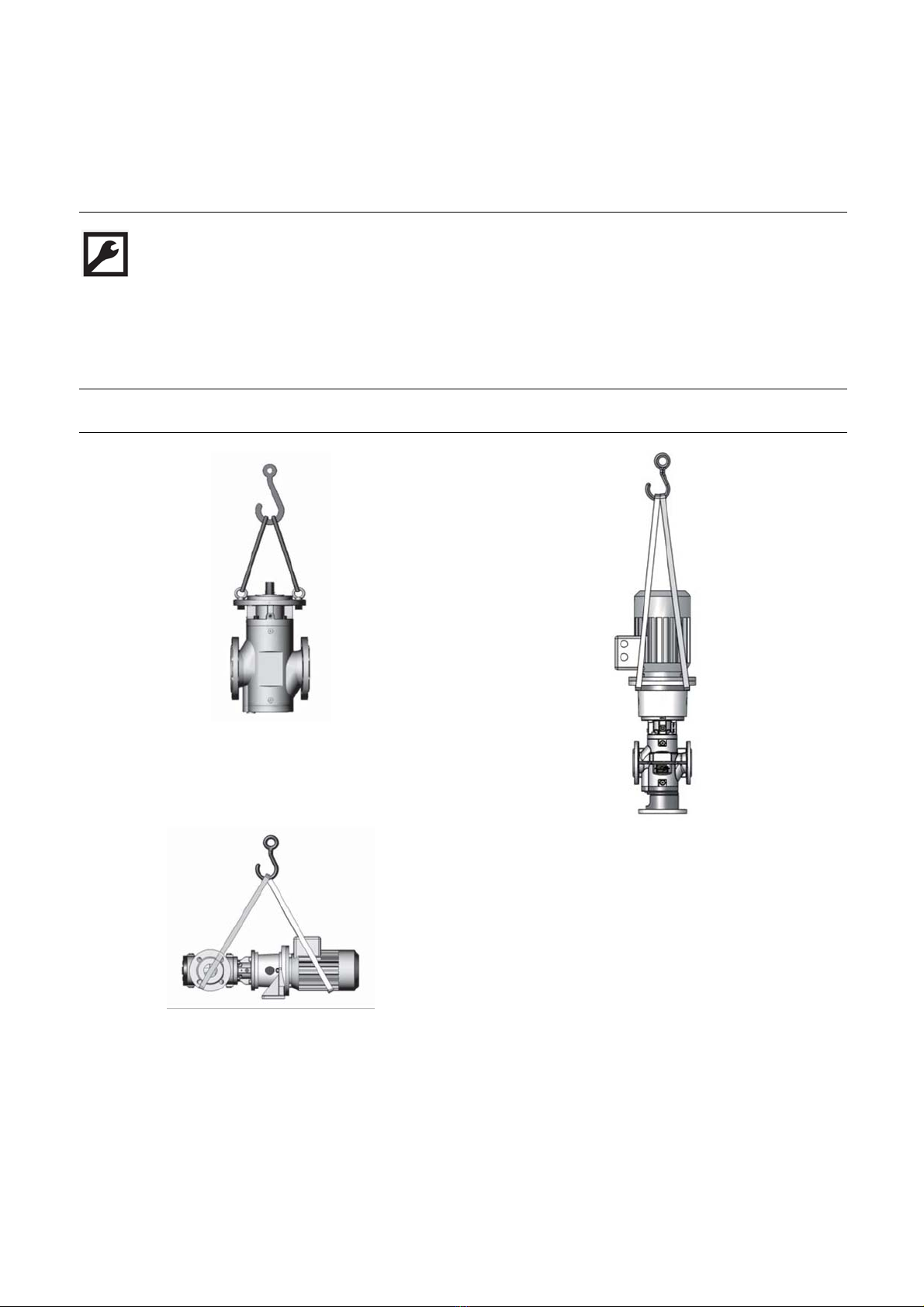

3.2. Lifting the pump/pump unit ...................................................................... 8

3.3. Storage ............................................................................................ 9

3.4. Preservation ....................................................................................... 9

3.5. Disposing of the pump ........................................................................... 11

3.6. Installation ......................................................................................... 12

3.7. Connecting the motor ............................................................................ 13

3.8. Removing the pump .............................................................................. 13

3.9. Heating system ................................................................................... 14

3.10.Electric heating system ........................................................................... 14

3.11.Fluid heating system .............................................................................. 16

3.12.Heating system special design .................................................................. 17

4. Operation ............................................................................................... 18

4.1. Commissioning .................................................................................... 18

4.2. During operation .................................................................................. 21

4.3. Taking the pump out of operation ............................................................... 22

4.4. Recommissioning the pump ..................................................................... 23

5. Maintenance ........................................................................................... 24

5.1. Safety instructions ................................................................................ 24

5.2. Required maintenance ........................................................................... 24

5.3. Replacing the magnetic coupling ............................................................... 25

5.4. Installing the magnetic coupling ................................................................. 27

5.5. Replacing the ball bearing and screw set ...................................................... 29

5.6. Possible faults ..................................................................................... 31

5.7. Troubleshooting ................................................................................... 31

6. Technical data ......................................................................................... 33

6.1. Type code ......................................................................................... 33

6.2. Name plate ........................................................................................ 34

6.3. Operating limits ................................................................................... 34

6.4. Sound pressure level ............................................................................. 34

6.5. Required NPSH values ........................................................................... 35

6.6. Weights ............................................................................................ 36

6.7. Structure ........................................................................................... 39

6.8. Housing variants .................................................................................. 40

6.9. Magnetic coupling ................................................................................ 41

6.10.Overflow valve ..................................................................................... 41

6.11.Tightening torques ................................................................................ 42

3