Align Combo T-REX 550E User manual

Other Align Toy manuals

Align

Align Super Combo TREX 500PRO DFC RH50E01XT Troubleshooting guide

Align

Align T-rex 450SE User manual

Align

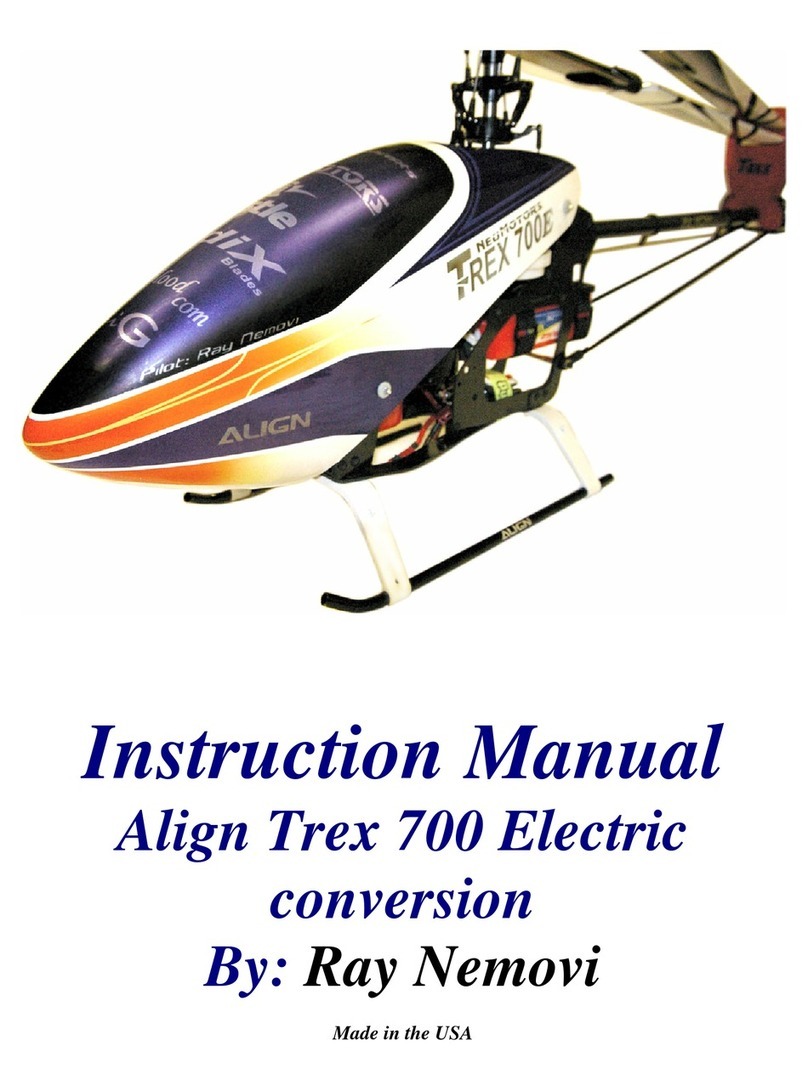

Align Trex 700 Electric conversion User manual

Align

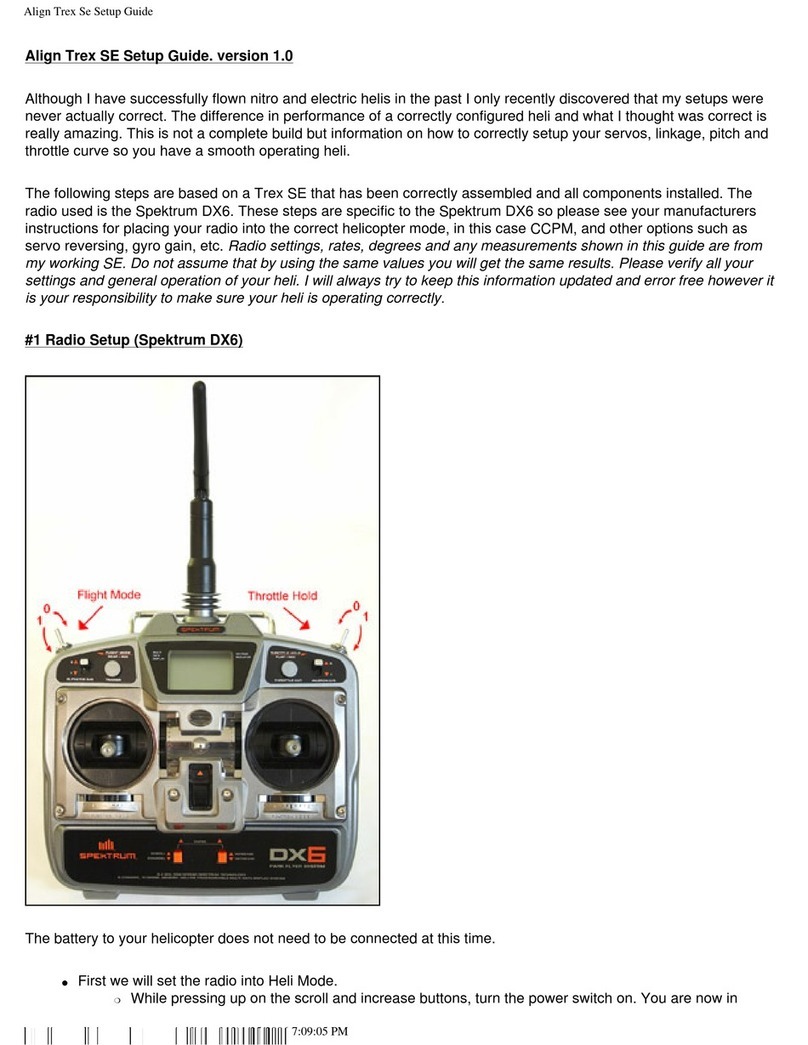

Align Trex SE User manual

Align

Align Super Combo T-Rex 700E F3C KX018E06T User manual

Align

Align Trex 250 Combo KX019001TA User manual

Align

Align Combo T-REX 550E User manual

Align

Align T-Rex 500 ESP KX017011T User manual

Align

Align TREX 700E V2 User manual

Align

Align T-REX 250PRO DFC KX019011T User manual

Align

Align T-rex 450SE KX015042TA 3K User manual

Align

Align T-Rex 700E Combo User manual

Align

Align T-Rex 500CF User manual

Align

Align T-rex 450SE User manual

Align

Align T-REX 450X User manual

Align

Align T-Rex 700E Combo User manual

Align

Align T-REX 700E F3C V2 KX018E11T User manual

Align

Align Trex 700 Electric conversion User manual

Align

Align Trex600 ESP KX016013T User manual

Align

Align T-REX500 User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions