Operation and Maintenance Manual

8

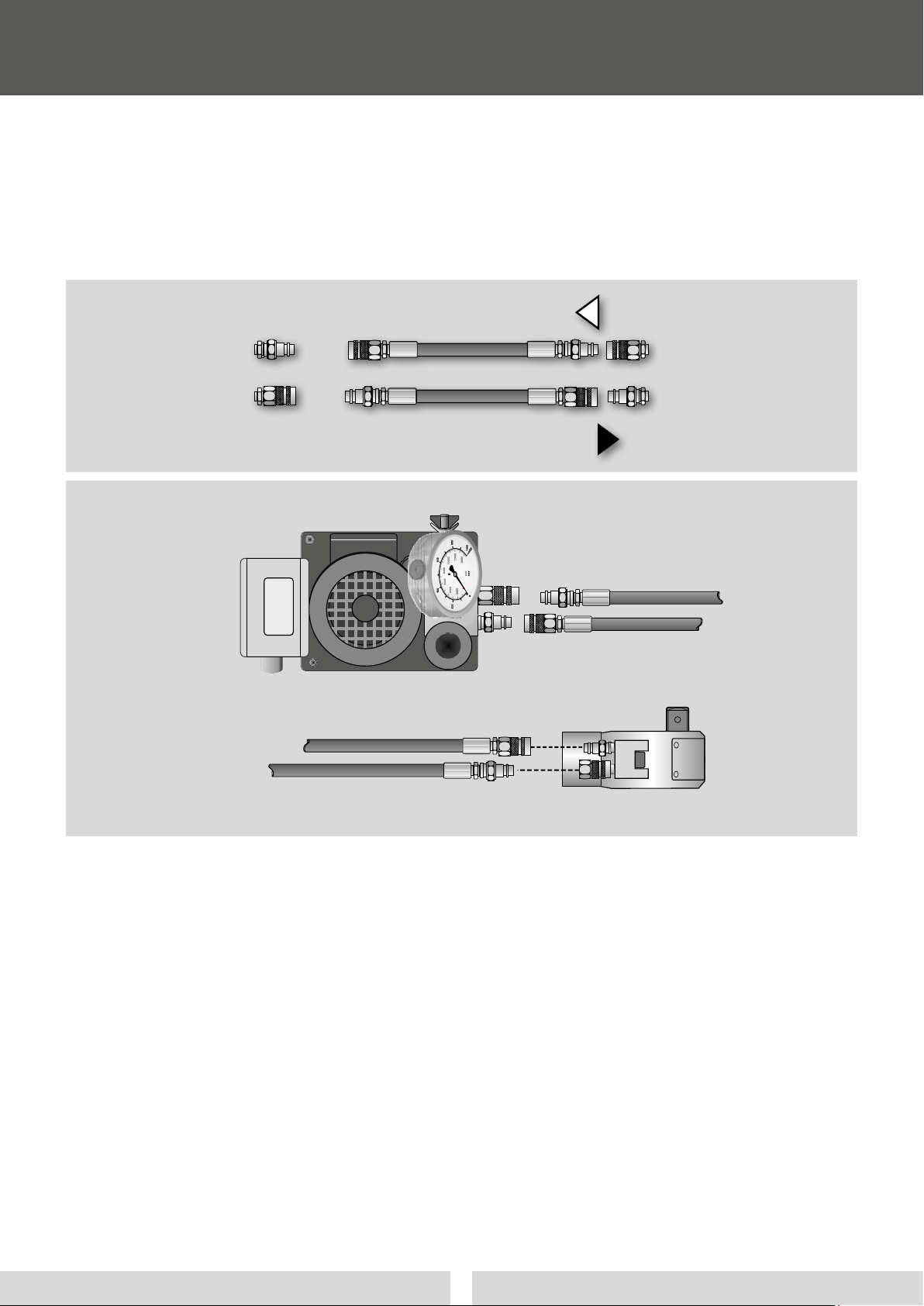

4.3 Change of direction of rotation / wrench change

Switch o the pump by pressing the black button

(2), see remote control Fig. 2, page 7.

Relieve the pressure on the LEVA

Hydraulic Pump !

Press the manual override

on the top of the solenoid valve.

Disconnect the LEVA Hydraulic pump from the

power supply (pull the plug).

Adjust the hydraulic wrench according to the de-

sired direction of rotation and connect it to the

pump (LOOSEN or TIGHTEN screw connection, see

the instructions for use of the hydraulic wrench).

Reconnect the LEVA Hydraulic Pump to the power

supply. Press the white button (1) on the remote

control to switch it on, Fig. 2, page 7.

When changing a torque wrench, a torque setting accord-

ing to point. 4.1, page 7 is to be achieved.

5. Functional Test

5.1 Visual inspection

Check the connections see point 9,

Fig. 6a / b, page 10 - correct connection diagrams.

5.2 Check for leaks and contamination

The high pressure hoses and all couplings, ttings

and connections must be checked for integrity

and cleaned if necessary.

Dirt particles in the hydraulic system lead to mal-

functions and breakdowns. Check the hydraulic

parts for leaks, defective components must be

replaced professionally.

5.3 Compliance with time limits

To ensure torque precision, an accuracy check of

the pressure gauge must be carried out with the

help of a test pressure gauge for a given occasion,

but no later than annually.

The oil level and oil quality must be checked regu-

larly. In the case of frequent use, we recommend

changing the oil annually (for oil type, see techni-

cal data).

Authorized personnel must also have the LEVA

Hydraulic Pump checked for electrical safety and

mechanical defects at least once a year. With high

loads / stress / operating hours at shorter intervals.

5.4 Requirements for hydraulic hoses

For safety reasons, replace all hydraulic hoses with

normal requirements after 5 years at the latest

(additionally a maximum of 2 years storage time).

With increased requirements (multi-shift opera-

tion, short cycle times, hand-held tools) after only

2 years. Additional regulations from the legislator

(DIN 20 066 / BGR 237) must be observed.

The operating and service requirements specied

in these instructions for use must be observed.

6. After use

After the work has been completed, depressurize the

LEVA Hydraulic Pump and disconnect the pump

from the power supply.

Remove hydraulic hoses and multipliers and keep

all components dry and clean.

(See also the following descriptions)

6.1 Storage

Keep the LEVA Hydraulic Pump dry and clean in

the alkitronic® transport case or in another seal-

able container.

Moisture leads to oxidation on the housing as well

as on internal parts. Consequences can include

malfunctions and further damage.

Hydraulic hoses

When storing, make sure that the hydraulic

hoses are removed and the ends of the hoses

and connecting parts (couplings / nipples) are

closed with the protective caps.

Store in a cool, dry and low-dust condition.

Avoid direct sunlight and UV radiation, ozone-

forming lighting xtures (e.g. uorescent light

sources, mercury vapor lamps) and storage

temperatures below -10 °C.

Hydraulic hoses must not come into contact

with acids, alkali, solvents.

Store tension-free and lying at. When stored

in rings, the minimum bending radius specied

by the manufacturer must not be undercut

•

•

•

•

•

Magnetic

valve