Operation and Maintenance Manual

8

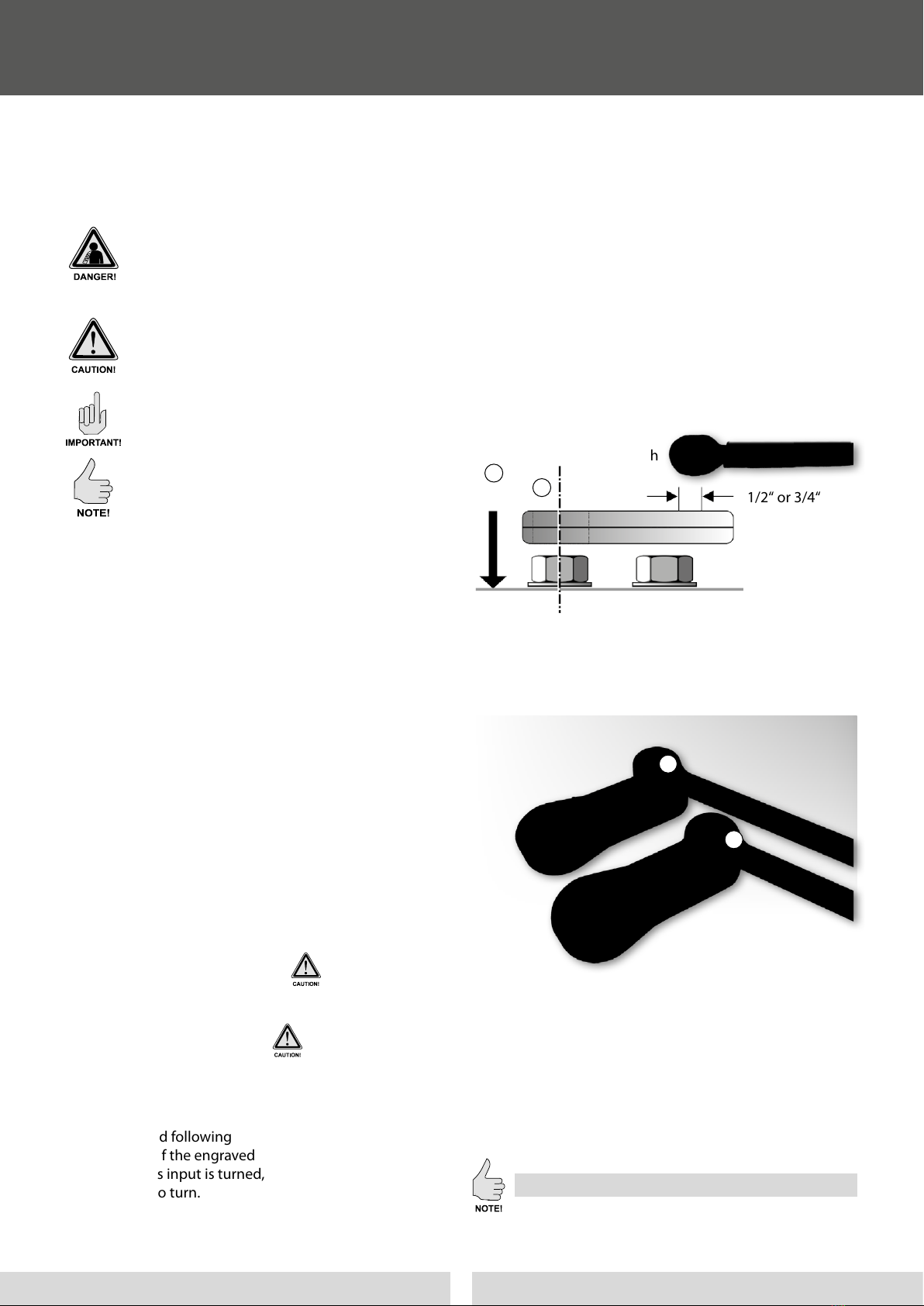

4.2 Tightening or loosening using torque wrench

Select the Link Tool corresponding to the joint.

• Place the alkitronic® M-ML/Norwolf Missing Link / Z series

completely on the nut.

• Position the housing (optional with DMA) against the

reaction point until contact is made.

• Determine whether you have a 4:1 or a 6:1 ratio of your

alkitronic®/Norwolf tool.

• Set the desired torque according to the operation manual

of your Torque Wrench

• Check the rotation direction switch (1) on the torque

wrench to ensure correct rotation (cw = R, ccw = L,

neutral position = O).

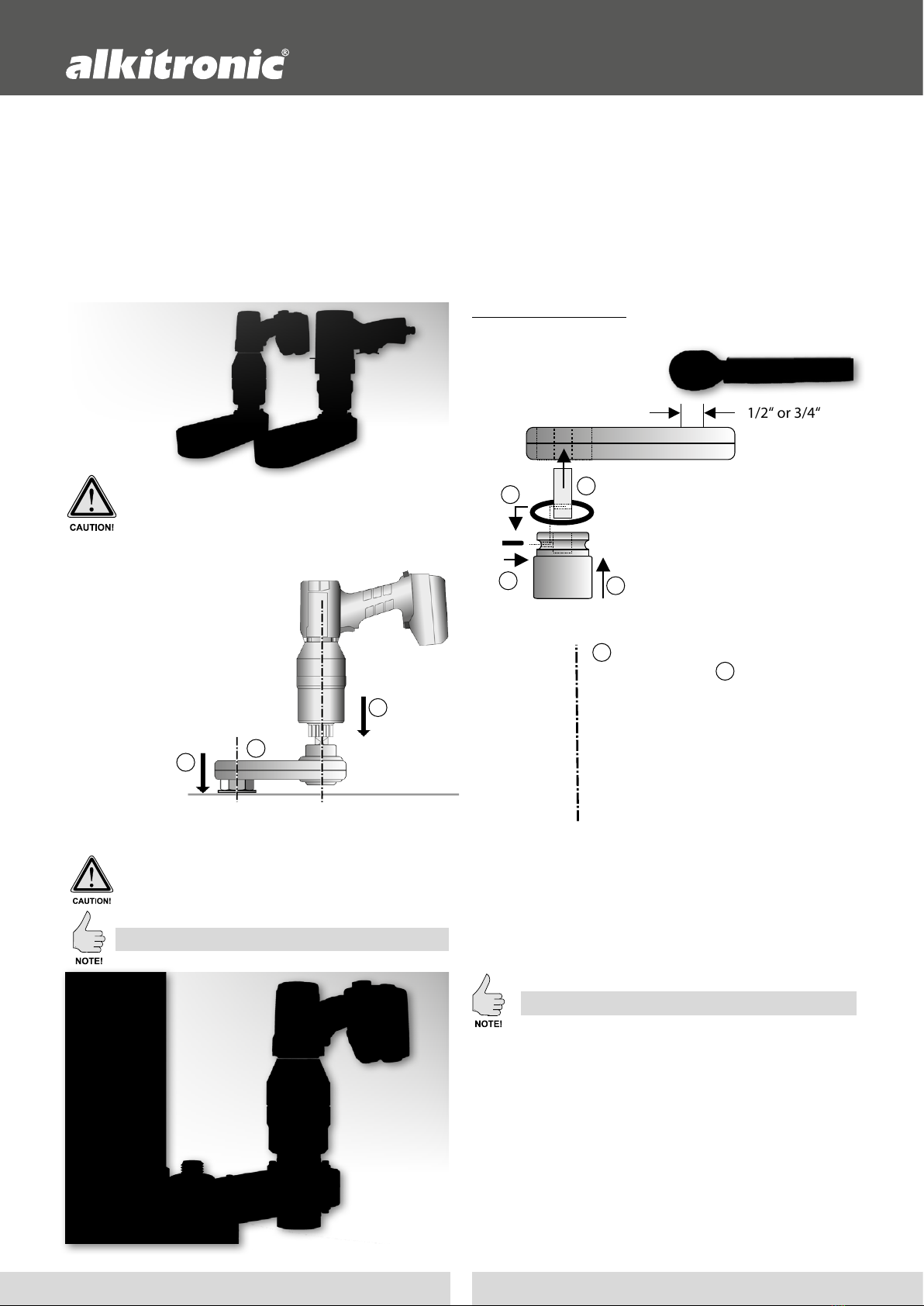

4.3 Tightening or loosening using torque multipliers

Select the alkitronic® / Norwolf XCE Link corresponding to

the joint.

• Place the XCE Link completely on the nut.

• Position the housing (optional with DMA) against the

reaction point until contact is made.

• Determine whether you have a 3:1 or 4:1 ratio of your

alkitronic® / Norwolf XCE Link.

• Set the desired torque according to the operation manual

of your electric or pneumatic driven Torque Multiplier.

Drive Ratio Input max Output

Nm Nm

1/2“ 4:1 340 1360

3/4“ 4:1 815 3260

3/4“ 6:1 815 4890

Models: alkitronic® M-ML/Missing Link / Z series

Drive Ratio Input max Output

Nm Nm

3/4“ 3:1 1150 3450

1“ 3:1 2440 7320

3/4“ 4:1 1150 4600

1“ 4:1 2440 9760

Models: XCE Link

The rotation direction (1) of the Torque Wrench

must be in agreement with the engraved arrow

“TURN” (2) on the Missing Link / Z series.

The rotation direction of the Torque Multiplier must

be in agreement with the engraved arrow “TURN”

(Fig. 11/ 2) on the XCE Link.

The rotation is changed by reversing the XCE Link

by 1800. Insert the multiplier in the splined hub.

To loosen the bolt connection, the Torque Multiplier

drive direction

must be in agreement with the en-

graved arrow“TURN” on the

XCE Link.

The rotation is changed by reversing the Missing Link

by 1800. Insert the Torque Wrench. To loosen the bolt

connection, the direction of rotation must match

the engraved arrow “TURN” on the Missing Link

.

1

2

• Position the

TorqueWrench

on the drive and apply contin-

uous force until the application is tightened satisfactorily.

Make certain the final torque is transmitted to the

bolt connection. The tool does not stop until its

Rachet Drive Lever reaches the final position.

retract automatically. While retracting, you will hear 1-3

“clicks” indicating that the tool has reset itself. Repeat this

procedure once or twice and if no audible clicks are heard on

retraction, at this point, the pre-set torque is achieved with

an accuracy of ± 8%.

Repositioning the Missing Link / Z series on the next bolt joint.

Fig. 10

Fig. 11 2

3

• Insert the Torque Multiplier into the splined hub (3).

Energy supply depends on the type of drive. Turn on

machine.

• Keep pressing the start button of the electric or pneumatic

multiplier until the drive stops turning and pre-set pres-

sure is reached.

Repositioning the

XCE Link

on the next bolt joint.

Loosening

Loosening

You cannot turn the nut any further: Retain the

tension on the Torque Wrench. Switch the return

twist lock on the Torque Wrench to neutral position

without using force. The Rachet Drive Lever will