All Paws Pet Wash ADA813 User manual

A

L

L

P

A

W

S

P

E

T

W

A

S

H

2009est.

A

L

L

P

A

W

S

P

E

T

W

A

S

H

2009est.

8642 US Highway 20 Garden Prairie, IL 61038 800.537.8231 www.allpawspetwash.com

Find a Pet Wash Near You! Everything you need for

your pet wash business!

MANUAL

ADA Models

ADA813 & ADA821

800.537.8231

www.AllPawsPetWash.com

*ADA813 Shown

8642 US Highway 20 Garden Prairie, IL 61038

Seller warrants the welded aluminum components for 5 years from date of shipment from our

factory in Garden Prairie, IL.

All other components warranted for 1 year from date of shipment.

Powder coat finish is excluded from all warranties.

Purchaser shall notify seller of defect in writing and return the defective part for repair or

replacement.

All warranty claims are to be handled by the purchaser. The purchaser will return the non-

working part to the factory [8642 US Hwy 20 Garden Prairie, IL 61038] for repair or

replacement. All Paws Pet Wash will ship the repaired or replaced part back to the purchaser.

Purchaser is responsible for the shipping charge to return to seller and seller is responsible

for shipping charge to return to purchaser.

Labor charges are not included.

Any defect or failure caused by mistreatment or neglect is specifically excluded under this

warranty. This includes damages caused by freezing.

Depending on water source, All Paws Pet Wash recommends using a pre-filter.

The seller and purchaser agree that there are no other warranties or representations made by

or on behalf of the seller other than those specifically set forth in this document. Seller will in

no event be liable for special or consequential damages. This agreement shall be governed

by the laws of the State of Illinois and is deemed entered into in the County of Boone, State

of Illinois. The seller and purchaser agree that jurisdiction of any controversy under this

agreement shall be exclusively in the Courts of the County of Boone, State of Illinois.

Purchaser may contact All Paws Pet Wash factory at (800)537-8231.

Keith Caldwell

Date: 1/1/17 - Present

*information subject to change

WARRANTY - ADA 813 & ADA 821

8642 US Highway 20 Garden Prairie, IL 61038

12

• Dog parks

• Campgrounds

• RV parks

• Laundromats

• Gas Stations

• Large Complexes

• Pet Stores

• Groomers

• Kennels

• Pet Friendly Hotels

• Veterinary Hospital

• Car Washes

The ADA Modular buildings are the flagship products of All Paws Pet Wash. It is a piece

of self-serve pet washing equipment that can be implemented and used in many different

industries. These units are built with the quality and precision that our other products have

been built with since 2009. The ADA is built out of the best quality aluminum and is sand blasted

then powder coated for a smooth finish. APPW offers six different treatments as well as a

grooming blow dryer. It provides an affordable way for a customer to wash their pet without

having to worry about messing up their own home or emptying their wallets.

• No ramps easy for pet to enter low wash tub or wash directly on floor

• Six wash cycles (Oat, Tearless, Flea & Tick Shampoos,

Conditioner, Pet Deodorizer, Tub Disinfectant)

• High volume rinse

• Groomer-grade blow dryer

• Accepts quarters, tokens, dollar coins, and 1-20 dollar bills with credit card option.

• Non-slip mat in tub and on floor

• Filtration system to separate hair

• Easy to read directions and push button operation for customers

• Customizable color and decals

• 1/2” or 3/4” Hot/Cold water lines 1/2” NPTF

• Water usage less than 2 gallons per minute

• 220 Volt - 100 amp electric supply

• Weight: Single 813: Approx 2600*

Double 821: Approx 4000*

*Depending on options

• Building numbers refer to dimensions:

single 813 = 8’ x 13’ double 821 = 8’ x 21’

• Tub: 53” long x 26” wide x 6” deep

• Stand alone equipment room enclosed inside the building

• Easy to hook up to utilities

• Sloping tub and sloping floor leads to floor trough under wall

for easy cleaning and drainage of water/hair

• Two inch drain for constant flow through hair strainers

• Ability to bypass payment with washdown switch

• Ability to change price and time to fit any market

• Easy to read directions for customers

• ADA Compliance

OWNER/OPERATOR BENEFITS PARTNER WITH

EQUIPMENT

SPECIFICATIONS

1

8642 US Highway 20 Garden Prairie, IL 61038

Seller warrants the welded aluminum components for 5 years from date of shipment from our

factory in Garden Prairie, IL.

All other components warranted for 1 year from date of shipment.

Powder coat finish is excluded from all warranties.

Purchaser shall notify seller of defect in writing and return the defective part for repair or

replacement.

All warranty claims are to be handled by the purchaser. The purchaser will return the non-

working part to the factory [8642 US Hwy 20 Garden Prairie, IL 61038] for repair or

replacement. All Paws Pet Wash will ship the repaired or replaced part back to the purchaser.

Purchaser is responsible for the shipping charge to return to seller and seller is responsible

for shipping charge to return to purchaser.

Labor charges are not included.

Any defect or failure caused by mistreatment or neglect is specifically excluded under this

warranty. This includes damages caused by freezing.

Depending on water source, All Paws Pet Wash recommends using a pre-filter.

The seller and purchaser agree that there are no other warranties or representations made by

or on behalf of the seller other than those specifically set forth in this document. Seller will in

no event be liable for special or consequential damages. This agreement shall be governed

by the laws of the State of Illinois and is deemed entered into in the County of Boone, State

of Illinois. The seller and purchaser agree that jurisdiction of any controversy under this

agreement shall be exclusively in the Courts of the County of Boone, State of Illinois.

Purchaser may contact All Paws Pet Wash factory at (800)537-8231.

Keith Caldwell

Date: 1/1/17 - Present

*information subject to change

WARRANTY - ADA 813 & ADA 821

8642 US Highway 20 Garden Prairie, IL 61038

12

• Dog parks

• Campgrounds

• RV parks

• Laundromats

• Gas Stations

• Large Complexes

• Pet Stores

• Groomers

• Kennels

• Pet Friendly Hotels

• Veterinary Hospital

• Car Washes

The ADA Modular buildings are the flagship products of All Paws Pet Wash. It is a piece

of self-serve pet washing equipment that can be implemented and used in many different

industries. These units are built with the quality and precision that our other products have

been built with since 2009. The ADA is built out of the best quality aluminum and is sand blasted

then powder coated for a smooth finish. APPW offers six different treatments as well as a

grooming blow dryer. It provides an affordable way for a customer to wash their pet without

having to worry about messing up their own home or emptying their wallets.

• No ramps easy for pet to enter low wash tub or wash directly on floor

• Six wash cycles (Oat, Tearless, Flea & Tick Shampoos,

Conditioner, Pet Deodorizer, Tub Disinfectant)

• High volume rinse

• Groomer-grade blow dryer

• Accepts quarters, tokens, dollar coins, and 1-20 dollar bills with credit card option.

• Non-slip mat in tub and on floor

• Filtration system to separate hair

• Easy to read directions and push button operation for customers

• Customizable color and decals

• 1/2” or 3/4” Hot/Cold water lines 1/2” NPTF

• Water usage less than 2 gallons per minute

• 220 Volt - 100 amp electric supply

• Weight: Single 813: Approx 2600*

Double 821: Approx 4000*

*Depending on options

• Building numbers refer to dimensions:

single 813 = 8’ x 13’ double 821 = 8’ x 21’

• Tub: 53” long x 26” wide x 6” deep

• Stand alone equipment room enclosed inside the building

• Easy to hook up to utilities

• Sloping tub and sloping floor leads to floor trough under wall

for easy cleaning and drainage of water/hair

• Two inch drain for constant flow through hair strainers

• Ability to bypass payment with washdown switch

• Ability to change price and time to fit any market

• Easy to read directions for customers

• ADA Compliance

OWNER/OPERATOR BENEFITS PARTNER WITH

EQUIPMENT

SPECIFICATIONS

1

Problem: No water pressure flow in the wash tub.

Solution: Check water flow from incoming water line. Check pressure gauge on water column

in cabinet of APW. The unit requires 40-50 PSI to function properly. If you have sufficient flow

form the incoming water line, and 40-50 PSI of required pressure, you will need to adjust the

flow screw [Reference image on page 3 / #4 Inside Cabinet]. Start by counting the number of

turns it takes to close the screw when tightening (clockwise). The flow at the wash tub should

not be very low. Now loosen the screw (turning counter-clockwise) approximately 1 ¾- 2

turns, which should increase the flow. Keep in mind the more you loosen the flow screw to the

left the more you will increase the flow, but will be decreasing the suction for the shampoo.

Problem: One of the shampoos or treatments in not flowing correctly.

Solution: With the sprayer in the on and locked position, select the soap or treatment that’s

malfunctioning. If everything is working properly, you should have a low pressure flow with

soap and water. If you’re not receiving any soap along with the water, head to the equipment

room and locate the soap containers. Screw off the cap of the soap or treatment that’s mal-

functioning and examine the suction strainer. Make sure the screen is clean, if not, run the

suction strainer under some clean water. Next, examine the clear tube running from the soap

to the water column. If you are getting air bubbles in the tube, the soap is flowing but your

concentrate may be too diluted to see the soap coming out of the sprayer. If you are still

having issues you can increase the flow by loosening the material volume screw.

Problem: Vacuum is running, but has no suction.

Solution: Check the hose for obstruction. With the vacuum cleaner off, use the water

flush valve and flush the vacuum. Make sure water is flowing out of the vacuum. Once

completed, run the vacuum and check for suction. If you still do not have suction, you will

need to remove and clean the vacuum motor and filter. You can also remove the black drain

hose from the check valve at the bottom of the vacuum and then turn on the vacuum. At this

point feel if you are achieving suction back threw the check valve. If you are the check valve

flap is not sealing tight and needs to either cleaned or replaced. Clean the filters as needed.

Problem: Water is not pumping out of the hair strainer tank.

Solution: The pump float switch is stuck. Simply unlodge the pump float. Rinse out tank as

needed.

Problem: Floor pumps are not functioning correctly.

Solution: Ensure that hair is not clogging the release hole at the base of the floor pump tube.

If clear, spray water directly at the probes to remove any excess film build-up. When film

accumulates, the build-up will not allow the probes to function properly.

Common Problems & Solutions

TROUBLESHOOTING

Please Note: Due to ongoing product changes, sales literature descriptions of product features

and options may not reflect current product offering. Please verify at the time order is placed.

1. Equipment

2. Plumbing

3. Electrical

3

4

5

1. Set-Up

2. Testing

6 -7

8

CONTENTS

I. OVERVIEW page 3-5

page 6-8

II. OPERATION

III. DAILY MAINTENANCE SCHEDULE page 9

IV. SECURITY

V. TROUBLESHOOTING page 11

VI. ADA WARRANTY INFORMATION page 12

page 10

11

2

Equipment Room

ADA Modular Building (813)

A

B

C

D

E

F

G

1

2

3

4

5

6

7

8

8

9

10

12 13

11

a

a

b

b

d

c

1Water Column

20 Gal. Water Heater

removable pin / padlock

• All of the sales from your washes will end up in one place, behind the spray control system.

The spray control system opens on the back side and is accessed via the equipement room.

To access the back end of your control system, open your door and remove the pin keeping

the panel in place. For additional security, install a padlock like shown in the image below.

Spray Control System

Front Back (Inside Cabinet)

IV. SECURITY

10 3

Building

A. Wash Tub

B. Spray Control

C. Sprayer

D. Vacuum

E. Dryer

F. Vending Machine (optional)

G. Equipment Room

Equipment Room

1. Water Column

a. Pressure Gauge

b. Solenoid Valves

c. Flow Screw

d. Relay Board

2. Back of Spray Control

3. Soaps and Treatments

4. Trough

5. Water Filter

6. Electrical Panel (100 Amp)

7. Heating/AC

8. 20 Gal. Water Heater

a. Temp. Blending Valve

b. Pressure Relief Valve

9. Shelf for Storage

10. Washdown & Test Buttos

11. Vacuum

12. Hair Strainer

13. Discharge Pump

1. Equipment

I. OVERVIEW

sensors

discharge pump

incoming water line

regulator

Oatmeal Shampoo

Tearless Shampoo

Conditioner

Flea & Tick Treatment

Pet Deodorizer

Tub Disinfectant

• Every ADA Modular Building comes with a trough which runs

through the equipment room. The floor in the building is

sloped toward the equipment room allowing gravity to carry

excess water under the wall and into the trough. Once the

sensors detect that theres a collection of water in the trough,

the discharge pump will kick on, draining the trough.

• In this example, the blue pipe is the

incoming water line. It runs through the

pressure regulator which adjusts the

overall pressure of the incoming water.

Pressure can be adjusted by turning

the bolt on top of the regulator. After

passing through the regulator, water

passes on to the water filter and then

through the water heater. After being

heated, the water then runs to the

water column.

• Insert suction strainers leading from selenoid valves into appropriate soap and

treatment containers.

2. Plumbing

I. OVERVIEW (cont.)

49

The following are general, suggested guidelines for daily, weekly, monthly, and bimonthly

maintenance on your All Paws Pet Wash self serve pet wash vending station. You may find

more applicable methods of maintenance in the daily operation of your personal unit.

DAILY MAINTENANCE

WASH AREA

• Rinse wash tub - Open equipment room door, reel out 20ft hose to swing/sliding door of

wash bay. Spray down wash bay walls, floor and tub towards equipment room wall.

• Clean glass if needed - Spray glass with Glass Stripper starting from the top and work your

way to the bottom.

• Skim trough for solid debris - Using a small hair strainer, skim the trough to collect larger

pieces of debris, hair and other particles to avoid clogged floor pumps.

EQUIPMENT AREA

• Rinse Vacuum - Open equipment room door, walk in and turn water valve counter-clockwise

to allow water to be flushed through vacuum for a duration of five seconds. Turn valve clock

wise to OFF.

• Dump hair strainer - Open equipment room door, walk in towards back corner and grab

strainer by brown handle. Dump into an external trash receptacle.

• Check soap levels - Open equipment room door, walk in and locate soaps. Use the guide

illustrated on this page to determine necessary fill-ups. Remember to use the ratio of 20:1

water to concentrate. Refer to the label on your 2.5 gallon jug for more information.

*Depending on water hardness, water to soap ratios may need adjusting.

WEEKLY MAINTENANCE

• Check filter on blow dryer, clean as needed - Filter is located on the back side of dryer. You

will need a philips head screwdriver to gain access to the filter.

• Check operation of spray control - Push diagnostic button in equipment room to run test on

all functionality of pet wash.

• Check the two HVAC filters if applicable - Slide filters up by grabbing lower section and

lifting up then pulling out.

• Check under rubber mats in wash tub (floor and tub) - Depending on climate, remove

rubber mat and hang dry nearby.

MONTHLY MAINTENANCE SCHEDULE

• Rinse the hair strainer - Remove excess hair and clean the strainer.

• Clean glass with Glass Stripper - Work in Glass Stripper with microfiber towel. Rinse with

water afterwards.

AS NEEDED MAINTENANCE SCHEDULE

• Check and replace incoming water filter every six months

• Clean bill, coin and credit card equipment

III. DAILY MAINTENANCE SCHEDULE

12

4

3

5

7

6

8

5

Electrical Box

This box contains the electrical components that drive the spray

controls. This box also contains the washdown and output test

switches, used for maintenance and testing.

Back of Spray Control

These are the components that are

responsible for relaying input selections on

the control panel and handling payment.

Activates 2 minute timer.

Resets with each button push.

When light is on, timer is active.

Activates all outputs in

sequence for 1 second each.

3. Electrical

1

2

Relay Board 3

Electrical Panel 4

Button Board

Coin Acceptor

6

Dixmor Timer

5

7

Bill Acceptor

8

I. OVERVIEW (cont.)

Cabinet Electrical Components

The relay board controls the treatment and

soap solenoids as well as the water column.

The electrical panel divides an electrical

power feed into subsidiary circuits, while

providing a protective fuse or circuit breaker

for each circuit in a common enclosure.

BS4 APW/ADA

Serial #:

LED7 OR #5 - HORN POS+

LED7 B1 #4 - NEG -

LED7 WHITE/BLACK #9 CC

IDX - X-10 / SLUGBUSTER 3 - P-8

3

MEI- BILL ACCEPTOR

DIXMOR - LED 7

IDX X-10

(or) Slugbuster III

yellow

MEI

black

LED7 #7

red

IDX X-10

(or) Slugbuster

black

MEI

white

LED 7 #6

green

IDX X-10

red / green

(or) Slugbuster

blue

LED7 #1 coin com.

grey

LED7 #2 coin cont.

brown

IDX X-10

red / green

MEI

orange

MEI

brown

LED7 #8 MEI

yellow / black

24VAC L

blue

24VAC N

white

Button Board J4 - Vend timed load

blue

GROUND

LED7 #10 Timed Load

white

1 2 3 4 5 6 7 8 9 10

MOUNTING

SCREW

JUMPER

under

validator

MOUNTING

SCREW

BS4

LED 7 #5

orange

LED 7 #4

blue

HORN 12 VDC

10

9

8

7

6

5

4

3

2

1

TIMEDLOAD

CCW/Bk

BillValidator

24VAC HOT IN

24VAC COM. IN

HORNPOS. +

HORNNEG. -

+12VDC OUT

COINSIGNAL

COINCOM.

DIXMOR LED7

WHITE

WHITE/BLACK

YELLOW/BLACK

RED

GREEN

ORANGE

BLUE

BROWN

GREY

SET

MODE

INV.

SEEOPERATING AND PROGRAMMING INSTRUCTIONS

ATWWW.DIXMOR.COM

To transformer

cabinet

Button Board connector

J4 Vend Timed Load

Parker Engineering Slugbuster

SBIII mod P.83

Black

Yellow

Blue

Purple

(not connected)

24VAC Com.

24VAC Hot

Coin Signal

Counter Pulse

(tucked in harness

shrink tube)

SEC 3.7AMP

Breaker on Transformer

PRI 3AMP

Breaker on Cabinet

IDX X-10 or Slugbuster III, MEI, LED7

Wiring Diagram decal

located on back of

button board panel.

FILL UP

FULL

Pressure Gauge

Temperature Blending Valve

Included Allen Wrench

Pressure Relief Valve

Pipe Plug

II. OPERATION

1. Set-Up

• Begin by checking your water pressure on the gauge located on the

water column. 45 PSI is your target (+/- 5 PSI). If you need to adjust

the PSI, you can do so by tightening or loosening your regulator screw

on the incoming water line (See image on Page 3)

• Locate the Washdown switch located on the electrical box and press

it. The green light will illuminate. The Washdown switch allows for

operation without payment. This is primarily used for maintenance

and cleaning. The unit will only operate for two minutes before

turning off unless another button (i.e. Rinse or Tearless Shampoo)

is pressed. If the unit turns off before your maintenance is complete,

press the Washdown switch again to reactivate the two minute timer.

Filling Your Soap Containers

• All Paws Pet Wash recommends a dilution ratio of 20:1 for our soap concentrates. This

means that for every ounce of concentrate in your jug, you need to add 20 oz of water. If

this ratio isn’t followed properly, you may end up with soap too viscous to syphon properly.

*Depending on water hardness, water-to-soap ratio may need to be adjusted.

• Fill all six of your soap containers to the “FULL” line on the label. Once your soap mixtures

fall below the “BELOW LINE”, fill them up again to assure proper operation of your APW unit.

Adjust the Temperature Blending Valve

• Located on the water heater, the blending valve is used to

adjust the water to an appropriate temperature. Use the

attached allen wrench to loosen the knob. The knob will pop

out allowing for adjustment. Once the temperature is adjusted

to the appropriate temperature, tighten the hex screw.

Anytime water supply is shut off, turn off breaker to water heater and bleed hot water prior to resuming use.

67

II. OPERATION (cont.)

Bleeding Air from Hot Water Heater

• Before use of your pet wash, it is important to bleed the air from your hot water heater.

Failure to bleed air can cause failure of heating element.

• Locate the pressure relief valve on your water heater.

It’s a brass colored valve with an aluminum lever

extending from it, pointed towards the floor. With the

incoming water supply valve open (feeding water into

unit) pull lever on pressure relief valve open until water

is running out of release tube and onto the floor.

• Water heater is ready for use.

Priming Floor Pump

• Priming the floor pump before use of your pet wash will ensure your floors don’t flood after

the trough fills up. There are two methods for priming your pump:

Method One: Remove pipe plug on top of pump.

Fill with water until full and water is

running out of pump.

Method Two: Remove tube running from pump to

floor trough. Using a garden hose,

pour water down tube and into pump.

• To avoid clogged pumps, use a small hair strainer to skim

the top of the trough water to collect larger pieces of

debris, hair and other particles to avoid clogged floor pumps.

Syphoning Soaps

• Begin by tightening the flow screw with a small flat-head screwdriver.

Tighten by turning clockwise until snug. DO NOT over tighten the

flow screw!

• Next, select the first soap to be syphoned, the Oat Shampoo.

Press the Oat Shampoo button on the Spray Control located on the

front of your APW.

Before begining this process, insert suction strainers into containers! (Ref. page 4)

FILL UP

FULL

Pressure Gauge

Temperature Blending Valve

Included Allen Wrench

Pressure Relief Valve

Pipe Plug

II. OPERATION

1. Set-Up

• Begin by checking your water pressure on the gauge located on the

water column. 45 PSI is your target (+/- 5 PSI). If you need to adjust

the PSI, you can do so by tightening or loosening your regulator screw

on the incoming water line (See image on Page 3)

• Locate the Washdown switch located on the electrical box and press

it. The green light will illuminate. The Washdown switch allows for

operation without payment. This is primarily used for maintenance

and cleaning. The unit will only operate for two minutes before

turning off unless another button (i.e. Rinse or Tearless Shampoo)

is pressed. If the unit turns off before your maintenance is complete,

press the Washdown switch again to reactivate the two minute timer.

Filling Your Soap Containers

• All Paws Pet Wash recommends a dilution ratio of 20:1 for our soap concentrates. This

means that for every ounce of concentrate in your jug, you need to add 20 oz of water. If

this ratio isn’t followed properly, you may end up with soap too viscous to syphon properly.

*Depending on water hardness, water-to-soap ratio may need to be adjusted.

• Fill all six of your soap containers to the “FULL” line on the label. Once your soap mixtures

fall below the “BELOW LINE”, fill them up again to assure proper operation of your APW unit.

Adjust the Temperature Blending Valve

• Located on the water heater, the blending valve is used to

adjust the water to an appropriate temperature. Use the

attached allen wrench to loosen the knob. The knob will pop

out allowing for adjustment. Once the temperature is adjusted

to the appropriate temperature, tighten the hex screw.

Anytime water supply is shut off, turn off breaker to water heater and bleed hot water prior to resuming use.

67

II. OPERATION (cont.)

Bleeding Air from Hot Water Heater

• Before use of your pet wash, it is important to bleed the air from your hot water heater.

Failure to bleed air can cause failure of heating element.

• Locate the pressure relief valve on your water heater.

It’s a brass colored valve with an aluminum lever

extending from it, pointed towards the floor. With the

incoming water supply valve open (feeding water into

unit) pull lever on pressure relief valve open until water

is running out of release tube and onto the floor.

• Water heater is ready for use.

Priming Floor Pump

• Priming the floor pump before use of your pet wash will ensure your floors don’t flood after

the trough fills up. There are two methods for priming your pump:

Method One: Remove pipe plug on top of pump.

Fill with water until full and water is

running out of pump.

Method Two: Remove tube running from pump to

floor trough. Using a garden hose,

pour water down tube and into pump.

• To avoid clogged pumps, use a small hair strainer to skim

the top of the trough water to collect larger pieces of

debris, hair and other particles to avoid clogged floor pumps.

Syphoning Soaps

• Begin by tightening the flow screw with a small flat-head screwdriver.

Tighten by turning clockwise until snug. DO NOT over tighten the

flow screw!

• Next, select the first soap to be syphoned, the Oat Shampoo.

Press the Oat Shampoo button on the Spray Control located on the

front of your APW.

Before begining this process, insert suction strainers into containers! (Ref. page 4)

12

4

3

5

7

6

8

5

Electrical Box

This box contains the electrical components that drive the spray

controls. This box also contains the washdown and output test

switches, used for maintenance and testing.

Back of Spray Control

These are the components that are responsible for relaying

input selections on the control panel and handling payment.

Activates 2 minute timer.

Resets with each button push.

When light is on, timer is active.

Activates all outputs in

sequence for 1 second each.

3. Electrical

1

2

Relay Board 3

Electrical Panel 4

Button Board

Coin Acceptor

6

Dixmor Timer

5

7

Bill Acceptor

8

I. OVERVIEW (cont.)

Cabinet Electrical Components

The relay board controls the treatment and

soap solenoids as well as the water column.

The electrical panel divides an electrical

power feed into subsidiary circuits, while

providing a protective fuse or circuit breaker

for each circuit in a common enclosure.

8

Sprayer Lock

Rinse Pressure Soap Pressure

• Turn on the sprayer to get the water flowing. Lock the sprayer

in the “on” position and place in tub to keep the water flowing.

• In your cabinet, you should see the soap from the Oat Shampoo

begin the fill the line leading from the container up to the

solenoid valves.

• Once the soap is flowing out of the sprayer, return to the Spray Control on the front of your

APW and select Rinse. After a few moments of Rinse time, select the next soap to get it

flowing. Repeat this process for all 6 treatments.

• After all of your soaps are flowing correctly, return to the flow screw and loosen the screw

two full turns. If your soap is not flowing properly, double check your PSI reading.

2. Testing

• Once all of your treatments have been syphoned from the containers up to the selonoid

valves, it’s time to test your APW. Start the sprayer, lock it in the “on” position and place

it in the tub.

• Work your way down through all of the soaps

and treatments on the spray control board while

switching to “Rinse” inbetween each soap or

treatment. While the system is on Rinse, only

water should be coming from your sprayer.

When you switch to a soap or treatment, you

should notice a decrease in water pressure and

some foaming coming from the sprayer. Place

your hand under your sprayer to double check

the foaming soap.

For more information or help on set-up, please visit our OWNERS HUB

online at www.AllPawsPetWash.com or visit our YouTube page.

Password for OWNERS HUB is: Pawtastic! (Case senstive, include the exclamation point)

II. OPERATION (cont.)

Please Note:

Rinse pressure

is stronger

than soap &

treatment

pressure!

sensors

discharge pump

incoming water line

regulator

Oatmeal Shampoo

Tearless Shampoo

Conditioner

Flea & Tick Treatment

Pet Deodorizer

Tub Disinfectant

• Every ADA Modular Building comes with a trough which runs

through the equipment room. The floor in the building is

sloped toward the equipment room allowing gravity to carry

excess water under the wall and into the trough. Once the

sensors detect that theres a collection of water in the trough,

the discharge pump will kick on, draining the trough.

• In this example, the blue pipe is the

incoming water line. It runs through the

pressure regulator which adjusts the

overall pressure of the incoming water.

Pressure can be adjusted by turning

the bolt on top of the regulator. After

passing through the regulator, water

passes on to the water filter and then

through the water heater. After being

heated, the water then runs to the

water column.

• Insert suction strainers leading from selenoid valves into appropriate soap and

treatment containers.

2. Plumbing

I. OVERVIEW (cont.)

49

The following are general, suggested guidelines for daily, weekly, monthly, and bimonthly

maintenance on your All Paws Pet Wash self serve pet wash vending station. You may find

more applicable methods of maintenance in the daily operation of your personal unit.

DAILY MAINTENANCE

WASH AREA

• Rinse wash tub - Open equipment room door, reel out 20ft hose to swing/sliding door of

wash bay. Spray down wash bay walls, floor and tub towards equipment room wall.

• Clean glass if needed - Spray glass with Glass Stripper starting from the top and work your

way to the bottom.

• Skim trough for solid debris - Using a small hair strainer, skim the trough to collect larger

pieces of debris, hair and other particles to avoid clogged floor pumps.

EQUIPMENT AREA

• Rinse Vacuum - Open equipment room door, walk in and turn water valve counter-clockwise

to allow water to be flushed through vacuum for a duration of five seconds. Turn valve clock

wise to OFF.

• Dump hair strainer - Open equipment room door, walk in towards back corner and grab

strainer by brown handle. Dump into an external trash receptacle.

• Check soap levels - Open equipment room door, walk in and locate soaps. Use the guide

illustrated on this page to determine necessary fill-ups. Remember to use the ratio of 20:1

water to concentrate. Refer to the label on your 2.5 gallon jug for more information.

*Depending on water hardness, water to soap ratios may need adjusting.

WEEKLY MAINTENANCE

• Check filter on blow dryer, clean as needed - Filter is located on the back side of dryer. You

will need a philips head screwdriver to gain access to the filter.

• Check operation of spray control - Push diagnostic button in equipment room to run test on

all functionality of pet wash.

• Check the two HVAC filters if applicable - Slide filters up by grabbing lower section and

lifting up then pulling out.

• Check under rubber mats in wash tub (floor and tub) - Depending on climate, remove

rubber mat and hang dry nearby.

MONTHLY MAINTENANCE SCHEDULE

• Rinse the hair strainer - Remove excess hair and clean the strainer.

• Clean glass with Glass Stripper - Work in Glass Stripper with microfiber towel. Rinse with

water afterwards.

AS NEEDED MAINTENANCE SCHEDULE

• Check and replace incoming water filter every six months

• Clean bill, coin and credit card equipment

III. DAILY MAINTENANCE SCHEDULE

Equipment Room

ADA Modular Building (813)

A

B

C

D

E

F

G

1

2

3

4

5

6

7

8

8

9

10

12 13

11

a

a

b

b

d

c

1Water Column

20 Gal. Water Heater

removable pin / padlock

• All of the sales from your washes will end up in one place, behind the spray control system.

The spray control system opens on the back side and is accessed via the equipement room.

To access the back end of your control system, open your door and remove the pin keeping

the panel in place. For additional security, install a padlock like shown in the image below.

Spray Control System

Front Back (Inside Cabinet)

IV. SECURITY

10 3

Building

A. Wash Tub

B. Spray Control

C. Sprayer

D. Vacuum

E. Dryer

F. Vending Machine (optional)

G. Equipment Room

Equipment Room

1. Water Column

a. Pressure Gauge

b. Solenoid Valves

c. Flow Screw

d. Relay Board

2. Back of Spray Control

3. Soaps and Treatments

4. Trough

5. Water Filter

6. Electrical Panel (100 Amp)

7. Heating/AC

8. 20 Gal. Water Heater

a. Temp. Blending Valve

b. Pressure Relief Valve

9. Shelf for Storage

10. Washdown & Test Buttos

11. Vacuum

12. Hair Strainer

13. Discharge Pump

1. Equipment

I. OVERVIEW

Problem: No water pressure flow in the wash tub.

Solution: Check water flow from incoming water line. Check pressure gauge on water column

in cabinet of APW. The unit requires 40-50 PSI to function properly. If you have sufficient flow

form the incoming water line, and 40-50 PSI of required pressure, you will need to adjust the

flow screw [Reference image on page 3 / #4 Inside Cabinet]. Start by counting the number of

turns it takes to close the screw when tightening (clockwise). The flow at the wash tub should

not be very low. Now loosen the screw (turning counter-clockwise) approximately 1 ¾- 2

turns, which should increase the flow. Keep in mind the more you loosen the flow screw to the

left the more you will increase the flow, but will be decreasing the suction for the shampoo.

Problem: One of the shampoos or treatments in not flowing correctly.

Solution: With the sprayer in the on and locked position, select the soap or treatment that’s

malfunctioning. If everything is working properly, you should have a low pressure flow with

soap and water. If you’re not receiving any soap along with the water, head to the equipment

room and locate the soap containers. Screw off the cap of the soap or treatment that’s mal-

functioning and examine the suction strainer. Make sure the screen is clean, if not, run the

suction strainer under some clean water. Next, examine the clear tube running from the soap

to the water column. If you are getting air bubbles in the tube, the soap is flowing but your

concentrate may be too diluted to see the soap coming out of the sprayer. If you are still

having issues you can increase the flow by loosening the material volume screw.

Problem: Vacuum is running, but has no suction.

Solution: Check the hose for obstruction. With the vacuum cleaner off, use the water

flush valve and flush the vacuum. Make sure water is flowing out of the vacuum. Once

completed, run the vacuum and check for suction. If you still do not have suction, you will

need to remove and clean the vacuum motor and filter. You can also remove the black drain

hose from the check valve at the bottom of the vacuum and then turn on the vacuum. At this

point feel if you are achieving suction back threw the check valve. If you are the check valve

flap is not sealing tight and needs to either cleaned or replaced. Clean the filters as needed.

Problem: Water is not pumping out of the hair strainer tank.

Solution: The pump float switch is stuck. Simply unlodge the pump float. Rinse out tank as

needed.

Problem: Floor pumps are not functioning correctly.

Solution: Ensure that hair is not clogging the release hole at the base of the floor pump tube.

If clear, spray water directly at the probes to remove any excess film build-up. When film

accumulates, the build-up will not allow the probes to function properly.

Common Problems & Solutions

TROUBLESHOOTING

Please Note: Due to ongoing product changes, sales literature descriptions of product features

and options may not reflect current product offering. Please verify at the time order is placed.

1. Equipment

2. Plumbing

3. Electrical

3

4

5

1. Set-Up

2. Testing

6 -7

8

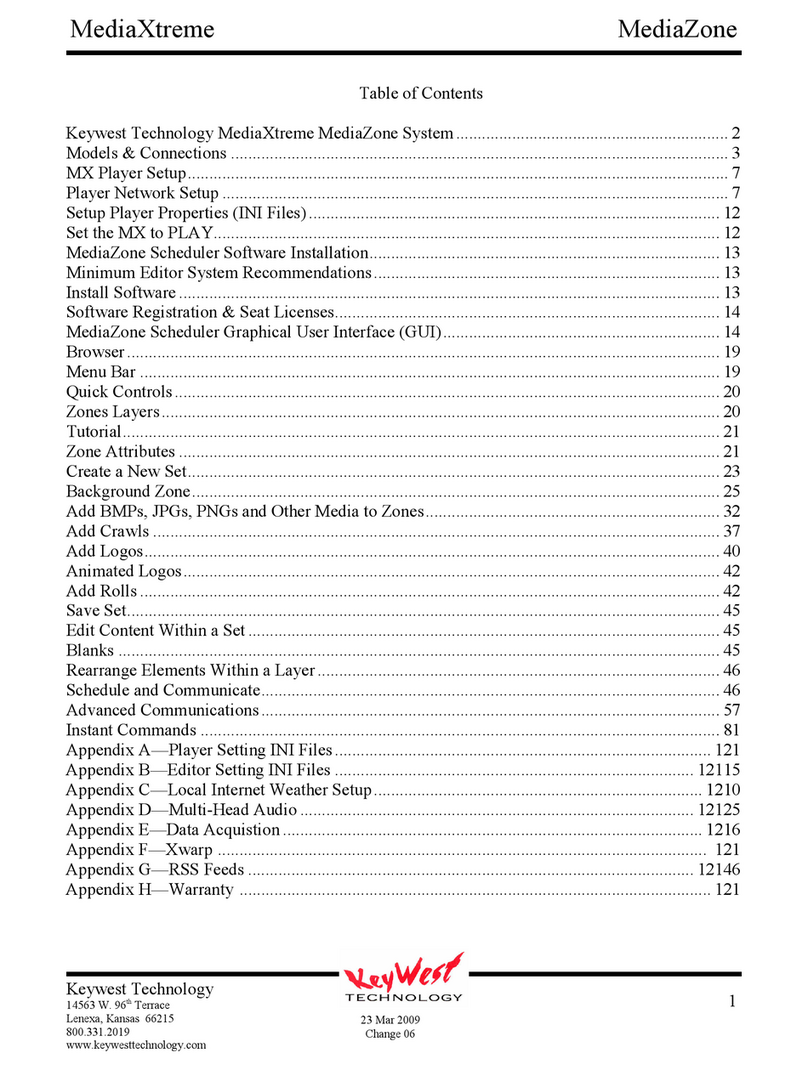

CONTENTS

I. OVERVIEW page 3-5

page 6-8

II. OPERATION

III. DAILY MAINTENANCE SCHEDULE page 9

IV. SECURITY

V. TROUBLESHOOTING page 11

VI. ADA WARRANTY INFORMATION page 12

page 10

11

2

8642 US Highway 20 Garden Prairie, IL 61038

Seller warrants the welded aluminum components for 5 years from date of shipment from our

factory in Garden Prairie, IL.

All other components warranted for 1 year from date of shipment.

Powder coat finish is excluded from all warranties.

Purchaser shall notify seller of defect in writing and return the defective part for repair or

replacement.

All warranty claims are to be handled by the purchaser. The purchaser will return the non-

working part to the factory [8642 US Hwy 20 Garden Prairie, IL 61038] for repair or

replacement. All Paws Pet Wash will ship the repaired or replaced part back to the purchaser.

Purchaser is responsible for the shipping charge to return to seller and seller is responsible

for shipping charge to return to purchaser.

Labor charges are not included.

Any defect or failure caused by mistreatment or neglect is specifically excluded under this

warranty. This includes damages caused by freezing.

Depending on water source, All Paws Pet Wash recommends using a pre-filter.

The seller and purchaser agree that there are no other warranties or representations made by

or on behalf of the seller other than those specifically set forth in this document. Seller will in

no event be liable for special or consequential damages. This agreement shall be governed

by the laws of the State of Illinois and is deemed entered into in the County of Boone, State

of Illinois. The seller and purchaser agree that jurisdiction of any controversy under this

agreement shall be exclusively in the Courts of the County of Boone, State of Illinois.

Purchaser may contact All Paws Pet Wash factory at (800)537-8231.

Keith Caldwell

Date: 1/1/17 - Present

*information subject to change

WARRANTY - ADA 813 & ADA 821

8642 US Highway 20 Garden Prairie, IL 61038

12

• Dog parks

• Campgrounds

• RV parks

• Laundromats

• Gas Stations

• Large Complexes

• Pet Stores

• Groomers

• Kennels

• Pet Friendly Hotels

• Veterinary Hospital

• Car Washes

The ADA Modular buildings are the flagship products of All Paws Pet Wash. It is a piece

of self-serve pet washing equipment that can be implemented and used in many different

industries. These units are built with the quality and precision that our other products have

been built with since 2009. The ADA is built out of the best quality aluminum and is sand blasted

then powder coated for a smooth finish. APPW offers six different treatments as well as a

grooming blow dryer. It provides an affordable way for a customer to wash their pet without

having to worry about messing up their own home or emptying their wallets.

• No ramps easy for pet to enter low wash tub or wash directly on floor

• Six wash cycles (Oat, Tearless, Flea & Tick Shampoos,

Conditioner, Pet Deodorizer, Tub Disinfectant)

• High volume rinse

• Groomer-grade blow dryer

• Accepts quarters, tokens, dollar coins, and 1-20 dollar bills with credit card option.

• Non-slip mat in tub and on floor

• Filtration system to separate hair

• Easy to read directions and push button operation for customers

• Customizable color and decals

• 1/2” or 3/4” Hot/Cold water lines 1/2” NPTF

• Water usage less than 2 gallons per minute

• 220 Volt - 100 amp electric supply

• Weight: Single 813: Approx 2600*

Double 821: Approx 4000*

*Depending on options

• Building numbers refer to dimensions:

single 813 = 8’ x 13’ double 821 = 8’ x 21’

• Tub: 53” long x 26” wide x 6” deep

• Stand alone equipment room enclosed inside the building

• Easy to hook up to utilities

• Sloping tub and sloping floor leads to floor trough under wall

for easy cleaning and drainage of water/hair

• Two inch drain for constant flow through hair strainers

• Ability to bypass payment with washdown switch

• Ability to change price and time to fit any market

• Easy to read directions for customers

• ADA Compliance

OWNER/OPERATOR BENEFITS PARTNER WITH

EQUIPMENT

SPECIFICATIONS

1

A

L

L

P

A

W

S

P

E

T

W

A

S

H

2009est.

A

L

L

P

A

W

S

P

E

T

W

A

S

H

2009est.

8642 US Highway 20 Garden Prairie, IL 61038 800.537.8231 www.allpawspetwash.com

Find a Pet Wash Near You! Everything you need for

your pet wash business!

MANUAL

ADA Models

ADA813 & ADA821

800.537.8231

www.AllPawsPetWash.com

*ADA813 Shown

This manual suits for next models

1

Table of contents