Allegro MicroSystems APEK4964 User manual

APEK4964

A4964 Sensorless Sinusoidal Drive BLDC Controller

Evaluation Board User Manual

Introduction

This user manual describes the operation and use of the

APEK4964 evaluation board for the A4964 automotive,

programmable BLDC controller. The A4964 is a flexible

sensorless, sinusoidal motor controller that drives an external

three-phase N-channel MOSFET bridge for easy implemen-

tation of a BLDC motor driver. The A4964 can be used as

a standalone controller or it can be used in a system with a

microcontroller, providing communication to a central ECU

and intelligent fault and status handling. The A4964 can

provide the supply and watchdog for the microcontroller,

as well as a physical interface between a LIN bus network

or a supply level PWM signal and the microcontroller. The

A4964 can be easily put to sleep or woken up using software

commands or signal inputs. In the sleep state, the power

consumption can be reduced to a low level.

The motor can be driven using a number of modulation

options, from full three-phase sinusoidal drive to two-phase

trapezoidal drive and includes overdrive options in the sinu-

soidal mode.

Commutation between the phases is independent of any

position sensor and rotor position detection is achieved by

monitoring the motor back-emf (bemf). The integrated sen-

sorless startup scheme provides highly programmable startup

options, allowing the A4964 to operate over a wide range of

motor and load combinations. It also includes forward and

reverse pre-rotation (windmill) detection and synchroniza-

tion.

Several operational modes are available, including duty-

cycle (voltage) control, current (torque limit) control, and

closed-loop speed control. Operating mode and control

parameters can be altered through an SPI-compatible serial

interface.

Integrated diagnostics provide indication of undervoltage,

overtemperature, and power bridge faults and can protect

the power switches under most short-circuit condition. By

monitoring the contents of the status register in the A4964

via the serial interface, any fault conditions present can eas-

ily be identified.

The A4964 is fully described in its datasheet, which should

be read in conjunction with this user manual.

December 9, 2022

Table of Contents

Introduction ........................................................................... 1

Evaluation Board Features......................................................... 2

Evaluation Board Connections .................................................... 2

Power Connections .............................................................. 2

Load Connections ................................................................ 3

Control Connections ............................................................. 3

Software Installation................................................................. 3

GUI General Overview.............................................................. 4

Bridge PWM ....................................................................... 4

Speed Control..................................................................... 5

Motor Commutation .............................................................. 5

Motor Control...................................................................... 6

System ............................................................................. 6

Diagnostics ........................................................................ 7

Register Display .................................................................. 7

Action Buttons..................................................................... 8

Setting Up for First Time Use .................................................... 10

Set Supply Current to Minimum.............................................. 10

Interface the GUI ............................................................... 10

Controlling the Motor with the GUI.............................................. 10

Automatic Tuning for Speed Control Mode .................................... 10

Tuning Parameters for Speed Control.......................................... 12

Alignment ........................................................................ 12

Untuned Parameters for Ramp and Closed-Loop Sequence ........... 13

Ramp ............................................................................. 13

Coast ............................................................................. 14

Closed Loop Control ........................................................... 14

Speed Loop Gains.............................................................. 14

Position Loop Gains............................................................ 15

Phase Advance ................................................................. 15

Bemf Sensing ................................................................... 15

Tuning Parameters for Current Control and Open Loop Voltage Control ... 16

Appendix A: Evaluation Board Schematic ..................................... 17

Appendix B: Evaluation Board Layout.......................................... 18

Appendix C: Evaluation Board Components .................................. 19

Appendix D: Settings.............................................................. 20

APEK4964-UM, Rev. 4

MCO-0001338

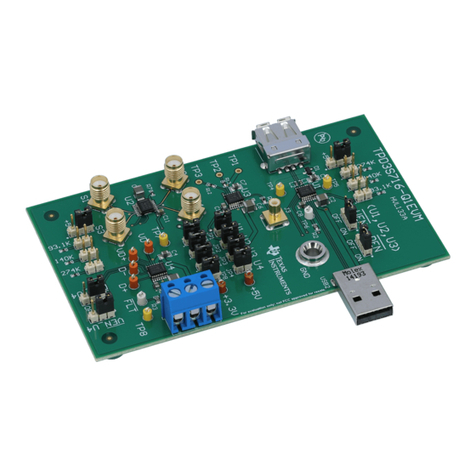

Figure 1: A4964 Evaluation Board

2

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

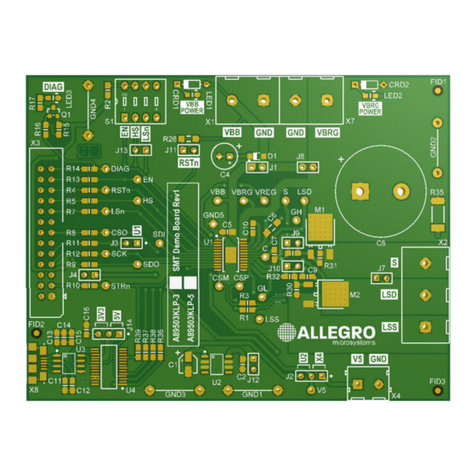

Evaluation Board Features

The evaluation board is a two-sided FR4 surface-mount board,

as shown in Figure 1. This board includes the necessary passive

components and connections to provide a complete interface

between the required microcontroller and a three-phase BLDC

motor using the A4964. The board can also be run without a

microcontroller with a suitably programmed A4964 sample. The

board requires a single DC power supply between 5.5 V and 50 V.

The board does not include any reverse battery or transient clamp

circuits. The motor is connected to the board through a high-cur-

rent three-way connector and the main supply is connected to the

board through a high-current two-way connector. Additionally, a

USB cable is provided, together with a graphical user interface

(GUI) for users to control the motor, to program many of its inte-

grated features, and to read back diagnostic information via the

serial interface. A microcontroller is included on the evaluation

board to provide improved serial interface communication perfor-

mance between the PC and the A4964. In particular, this allows

the A4964 to be continuously interrogated for data log informa-

tion and to display that information in real time in the GUI. This

should not discourage users from using their own microcontroller

to communicate directly with the A4964, and a suitable micro-

controller connection is available.

The power section of the evaluation board is designed to dem-

onstrate the functionality of A4964 and has limited load current

capability. In the supplied configuration, the board can provide a

continuous motor current of ~10 A and a peak motor current of

~20 A for short period in normal room temperature conditions.

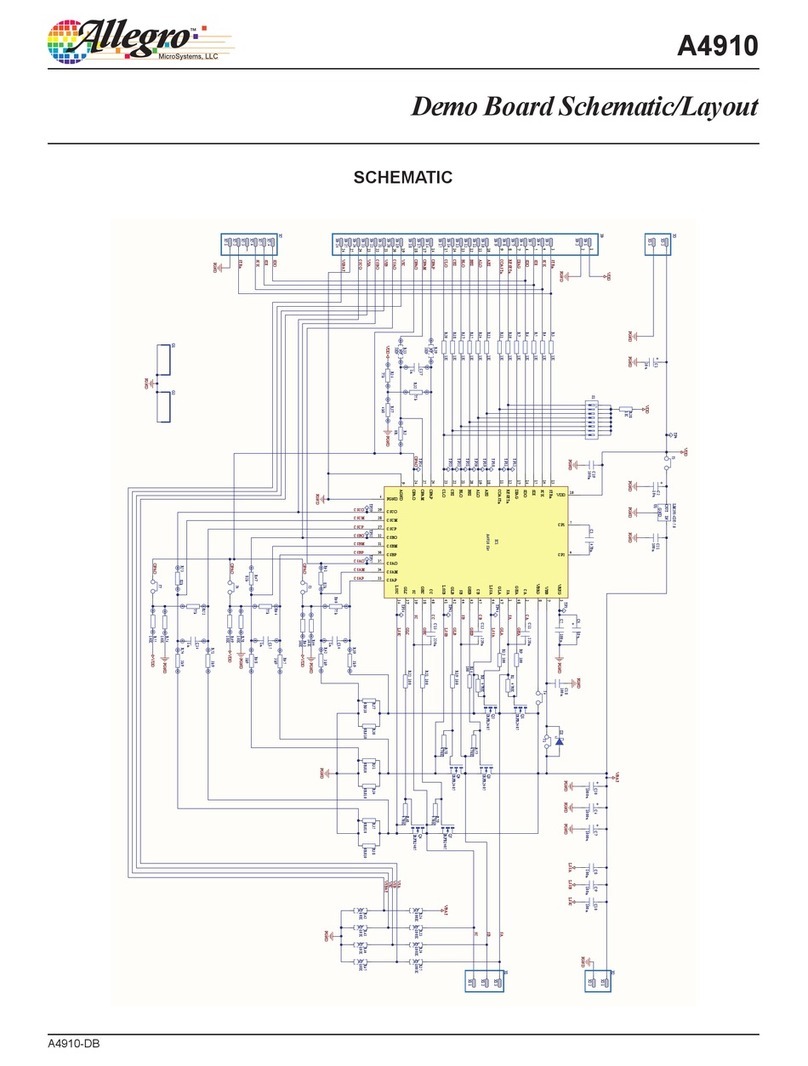

Circuit Description

The circuit diagram for the evaluation board is shown in Appen-

dix A. This provides the basic components required to use the

A4964 to drive a motor. The motor can be controlled via the

serial interface, by using the on-board PWM generator, or via

an externally supplied PWM signal input on the LIN terminal.

The serial interface control signals can be generated by the GUI

provided or by a user-provided processor or controller attached to

the SPI connector on the board.

The maximum current limit for the board is determined by the

sense resistors. Two 20 mΩ sense resistors in parallel are pro-

vided on the board, giving 10 mΩ total sense resistance. The

maximum possible current is limited by this resistor to 20 A. The

current limit can be changed by changing the sense resistor value

using the equation:

ILIM – VILIM

RSENSE

where RSENSE is the sense resistor value,

VILIM is the internally generated threshold voltage, and

ILIM is the limitation current value.

It is recommended to keep the maximum current limit below

20 A for this evaluation board. Lower current limits (higher sense

resistor values) can be useful for higher accuracy control of lower

power motors. The full circuit schematic is shown in Appendix A,

and the component placement and board layout is shown in

Appendix B. The function, specification, and selection criteria for

the components are listed in Table 2 in Appendix C.

Evaluation Board Setup and Operation

In order to run a motor using the evaluation board, the following

items are required:

• USB cable

• A4964 demo board

• External motor supply (5.5 to 50 V)

• USB cable driver and software

• A4964 Serial control GUI software

• Windows® based PC

A typical connection diagram to interface the GUI is provided in

Figure 2. The USB cable and GUI provided is not the only inter-

face option to control the A4964 to drive the motor. The A4964

evaluation board can also be used in conjunction with an exter-

nal microcontroller using serial interface communication or the

control can be done in standalone mode by using the LIN input as

described previously.

Figure 2: Connection Diagram to Interface the GUI

Evaluation Board Connections

The A4964 evaluation board has six connectors: a two-way screw

connector for the main supply, a two-way connecter that provides

the logic supply output from the A4964, a three-way screw con-

nector for the motor connection, a two-way screw connector for

LIN terminal for standalone mode control, a USB connector to

interface to the GUI, and a 16-pin IDC cable connector to inter-

face to an external microcontroller.

Power Connections

Power for the motor phases is provided through the two-way

screw connector X1. A positive supply, between 5.5 and 50 V,

is connected to X1, labelled VBB. The supply return is labelled

3

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

GND at X1. The power source for the motor phase current must

be capable of providing the necessary continuous input current at

the required input voltage to drive the motor up to the board cur-

rent limit plus any inrush current. The motor supply voltage must

not exceed 50 V in any conditions or permanent damage may

occur to the A4964, other components on the board and possibly

the motor. The current limit of the supply should initially be set to

twice the maximum operating current for the motor being driven.

The A4964 can provide logic voltage levels of either 5 V or 3.3 V

to different target devices such as external MCU through X2

connector as long as the provided current does not exceed 70 mA.

The logic level of the target device must be connected to the X2

connector at the point, labelled VLR, and the return path must be

connected to X2, at a point labelled GND.

Load Connections

A three-phase BLDC motor is connected through the three-way

screw terminal, X5, labelled SA, SB, and SC. The current to drive

the motor is provided via the three-phase MOSFET bridge from

the main supply connected to X1.

Control Connections

The serial interface communication between the A4964 and the

Windows® based GUI is provided using a standard USB to micro

USB cable by connecting the micro USB end to the connector X7

on the evaluation board and the standard USB connector to the

target PC (see Software Installation section for further details).

If an external microcontroller is to be used to communicate

directly with the serial interface of the A4964, then the signals

STRn, SCK, SDI, SDO, and GND must be connected to termi-

nals 18, 22, 24, 26, and 16 of the connector X3 respectively. In

this case, the jumpers J4, J5, J6, and J7 must be removed.

If standalone control of the motor is required, an externally

generated PWM signal can be applied to connector X4 at a LIN

terminal. The positive signal level must be connected to the

point labelled LIN and the return path must be connected to the

point labelled GND. The duty cycle of the PWM signal would

then determine the demand input. In standalone mode, the DIAG

terminal can also be shorted to the LIN terminal to shut down the

system in case any fault condition exists.

Software Installation

A USB cable is provided for users to operate the A4964 evalua-

tion board from a Windows® based desktop or laptop PC using

the A4964 serial control GUI. Hardware drivers must be installed

for the USB cable before use. A driver installer can be down-

loaded for the correct Windows version from the drivers page on

the FTDI website at ftdichip.com/FTDrivers.htm.

The detailed installation guides for the hardware driver can be

found through the support page on the FTDI website.

When hardware drivers are successfully installed, a virtual COM

port will appear in the Device Manager as shown in Figure 3.

Figure 3: Windows Device Manager

Allegro also provides a A4964 serial control GUI, which can be

used to operate the evaluation board through the USB cable. The

GUI is a standalone executable file, named A4964SerialVxpx.exe,

where xpx is the version number. The latest versions can be

accessed on the Allegro support website at registration.allegro-

micro.com. This GUI can be run directly on a Windows-based

PC without installation. A screenshot of the GUI when running is

shown in Figure 4.

Figure 4: GUI – Main Window

When running, the GUI will continuously check the communica-

tion between the PC and the USB cable. If the hardware driver

for the cable is successfully installed, the “SPI Status” window

in the GUI will display “OKAY!” when the cable is connected

between the PC and the evaluation board. If the cable is discon-

nected, or the driver has not been installed correctly, then the

“SPI Status” window will display “False!”.

4

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

GUI General Overview

The main window of the GUI is shown in Figure 4. Various set-

tings such as type of control, fault detection, etc., can be config-

ured in the GUI. Settings are grouped based on their functionality

in seven pop-up windows marked with red rectangle in Figure 4.

The summary of each configuration option is provided in this

user manual; however, if a detailed explanation of any parameter

is required, it can be easily found in the datasheet by searching

the relevant title.

For example, after clicking on the Bridge PWM button, the

window shown in Figure 5 will open. Then, if further informa-

tion about “Modulation Mode” is required, the title “Modulation

Mode” can be searched in the A4964 datasheet in order to obtain

full details about it.

Bridge PWM

The first pop-up window is the Bridge PWM (Figure 5).

Figure 5: GUI – Bridge PWM Section

The “Modulation Mode” setting defines the number of phases

that are turned on at the same time. For three-phase, all of the

phases will be driven with PWM signal, whereas for two-phase,

one of the phases is always driven low and two other phases are

driven with PWM signal. The two-phase modulation results in

lower switching loss; however, with three-phase modulation,

torque ripple is reduced, resulting in less audible noise at low

power outputs. Both trapezoidal and sinusoidal driving mode

are available in the A4964, which can be selected in the “Drive

Mode” setting. If higher driving capability is required than is

available in sinusoidal mode, the “Overmodulation” setting can

be used.

The frequency of the applied PWM signal can be controlled in

the “PWM Fixed Period” setting, and the alignment of PWM sig-

nals in the three phases can be done by using the “PWM Mode”

setting.

In order to avoid short circuit in the phase of the power MOSFET

bridge, a dead time is required between generating a low or high

side turn-off signal and a complementary turn-on signal. The

duration of the dead time can be selected using the “Dead Time”

setting.

In order to reduce the radiated and conducted electromagnetic

emission (EM), the dither frequency scheme can be used. By

stepping the PWM frequency in a triangular pattern, the EM

energy associated with the switching can be spread across a spec-

trum more effectively. The amount, duration, and the number of

steps can be controlled using “PWM Dither Freq Step”, “PWM

Dither Dwell Time”, and “PWM Dither Step Count” accordingly.

More information about dither frequency scheme can be found in

the datasheet.

In some applications, in order to comply with the EMC emis-

sion regulation, it is necessary to control the rate of change of

the phase voltage. This can usually be achieved by controlling

the FET gate charge and discharge rate. In the A4964, the slew

rate control can be used to control the FET charge and discharge

rate. The amount of the charging current applied to the gate of

the FET is controlled by two parameters, labelled IR1 and IR2.

For the duration defined by TR, the current defined by IR1 is

initially applied to the FET. Usually IR1 is set to maximum, and

turn-on duration is set to last long enough to reach the Miller

region. Once the duration TR ends, the current IR2 is sourced to

the gate of the FETs. IR2 is usually set lower than IR1 to increase

the duration of Miller region, which would therefore result in a

slower rise of the phase voltage. When the FET reaches a fully

on-state, the drive output will change from current mode to volt-

age mode in order to maintain the MOSFET in the fully on-state.

The turn-off sequence follows the same procedure in the reverse

manner, and the amount of sinking currents are determined by

IF1 and IF2. The duration of IF1 in this case is determined by

TF. More information about slew rate control can be found in the

datasheet.

The maximum current limit can be set for the system with the

help of current limit configuration. The amount of current going

through the motor can be determined by measuring the voltage

across the sense resistor, which are connected to Terminal CSP

and CSM as shown in Figure 2. Each time the output of the gate

driver changes, the current limit blank time is triggered. The

duration of blank time can be controlled by modifying OBT.

If at the end of the blank time voltage across the sense resistor

is higher than the current threshold limit defined by VILIM, all

the high-side outputs are turned off, and the phase current will

circulate through the low-side switches. This state is maintained

until the next PWM period starts. VILIM can be calculated using

the following equation:

VILIM = VMIT × VISC

where VMIT is the maximum threshold of the sense amplifier,

which can be set by MIT variable, and

VISC is the current limit scale defined by VIL.

5

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

For example, if VMIT is set to 200 mV and VISC to 1/16, then

the maximum allowed voltage across the sense resistor is equal

to 12.5 mV. The current limit can be disabled by clicking on the

System window and disabling DIL as shown in Figure 10.

Speed Control

In this section of the GUI, the parameters relating to acceleration,

deceleration, underspeed, and overspeed threshold can be modified.

Figure 6: GUI – Speed Control Section

The acceleration and deceleration profile that can be achieved

with the A4964 is shown in Figure 7. The linear speed rise, or

constant acceleration, is limited by the product of SGL and the

gain SG. Once the motor reaches speed = reference speed – SGL,

the acceleration will be limited by SG only. For deceleration,

there is an additional variable limiting the acceleration, which is

labelled DF. During deceleration, some current may flow back to

the supply, resulting in the rise of voltage to a dangerous level.

Therefore, introduction of this new variable into the deceleration

profile gives more feasibility in terms of control.

In order to mitigate the impact of any transient disturbance of the

power supply voltage on the motor control, voltage compensation

DV can be used. For supply voltages between 7 to 19 V, the com-

pensation should be set to 12 V, and for voltage ranges between

14 to 38 V, compensation should be set to 24 V.

Voltage compensation only affects open- and closed-loop speed

control and does not have any impact on the closed-loop current

control. More information about control modes are provided in

the Motor Control section.

The minimum and maximum achievable speed can be set by

the underspeed (SL) and overspeed (SH) threshold. If the motor

speed is below the underspeed threshold or above the overspeed

threshold, a loss of synchronization occurs, the fault LOS (shown

in the content of status register in Figure 4) will flag, and the

motor will stop by shutting down the FETs M1-M6 (shown in

Figure 2). More information about LOS can be found in the

datasheet.

Figure 7: Acceleration and Deceleration Prole

The electrical motor reference speed used in speed control mode

is the product of “Resolution”, SR, and “Demand Input”, DI. For

example, if SR is 0.2 Hz and DI is 100, then the reference speed

attempted by the controller to be achieved is equal to 20 Hz.

Motor Commutation

Figure 8: GUI – Motor Commutation Section

The content of motor commutation pop-up window is shown in

Figure 8. The parameters in this section affect the closed-loop

control and must be properly tuned in order to allow smooth

operation of the motor. The A4964 uses motor bemf for control

and the “BEMF Window” and “Sampling” settings are used to

achieve this.

In addition, to allow the motor to operate beyond the base speed

with the same supply voltage, field weakening must be per-

formed. This is accomplished by tuning parameters in the “Phase

Advance” section. Further information about control gain adjust-

ment, bemf sensing, and phase advance are provided in this user

manual in the Setting Up for First Time Use section.

6

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Motor Control

Figure 9: GUI – Motor Control Section

This section of the GUI focuses on startup configuration. If there

is loss of synchronization in the system, RSC can be used to

restart the system if enabled. RSC can also restart the system in

cases where there is a supply or logic undervoltage.

Before applying the closed-loop speed control, there is a startup

sequence that consists of an alignment, followed by an open-

loop commutation with increasing speed and a short motor coast

period. The content of each of the startup sequences can be tuned

and modified to achieve smooth and consistent startup. The

startup sequence is discussed in detail in the last section of this

user manual.

There are some occasions where the motor may still be rotating

due to a previous running state or load condition. In these cases,

it is possible to use the windmill start feature to bypass the startup

sequence. The windmill startup conditions can be further studied

in the datasheet.

The motor rotation direction can also be controlled by modifying

“Rotation Direction”, DIR. If electromagnetic brake is required,

the “Brake Function”, BRK, can be used to enable all low-side

FETs and disable all high-side FETs. By enabling all low-side

FETs, the current continues to flow within the phases due to

bemf, creating torque against the rotational direction of the motor

and therefore forcing the motor to stop.

The motor constant (KM) is used to determine the application of

correct duty cycle to the bridge if windmilling or coast mode are

enabled. KM is related to the motor bemf constant and can be cal-

culated based on the following equations depending on the setting

for voltage compensation (DV).

KM =

⎧

⎪

⎨

⎪

⎩

642.4

VBB

×Kemf

npp

, DV = 0

53.5 × Kemf

npp

, DV = 1 or 3

53.5 × Kemf

npp

, DV = 2

where Kemf is the motor bemf constant in unit of v×s / rad, and

npp is the number of pole pairs.

System

Figure 10: GUI – System Section

In this pop-up window, several features of the device—such as

logic regulator and driver output voltage—can be modified. In

addition, the type of control to be applied—such as speed or cur-

rent control—can be selected. If the A4964 is used in conjunction

with a microcontroller, the watchdog can be used to determine if

the microcontroller is operating in an adverse state.

When watchdog is enabled, the input waveform to the WDOG

terminal must follow a certain configuration, which is explained

in the datasheet. If a watchdog failure occurs, the MRSTn termi-

nal output, which is an active-low signal, can be used to disable

or reset the microcontroller. A watchdog failure also disables all

the switches and can put the device to sleep depending on the

choice of settings. If the watchdog feature is not used, it should

be disabled in order to allow correct operation of the A4964

device. This can be done by masking the WD bit in the main

menu of the GUI shown in Figure 4.

There are three control modes in the A4964: closed-loop speed

control, closed-loop current control, and open-loop voltage con-

7

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

trol mode, which can be set by defining the CM bit.

There are two ways to set the demand input (speed reference) for

the A4964 in the closed speed control mode. The first method is to

define the required demand input in the GUI as shown in Figure 4.

In this case, serial interface communication is used and therefore

the “Operating Mode” OPM shown in Figure 10 must be set to

SPI. The other method is to apply duty cycle to the LIN input. In

this case, the OPM must be set to PWM (standalone mode). More

information about the LIN interface can be found in the datasheet.

When operating in closed-loop current control mode, the current

limit bit, DIL, must be enabled. In this case, the “Current Limit-

ing!” status in the main window of the GUI, shown in Figure 4,

will be shown in red if the current hasn’t reached to the defined

limit. Otherwise, it will be shown in green. In closed-loop speed

control or voltage control mode, if the current limit is enabled, the

“Current Limiting!” status will be red if the current has reached the

limit and it will be gray if the current is not at the limit.

As discussed previously, one way to put the device into sleep is

to use watchdog. Another method is to make a logic low to high

transition on the GTS bit. More information on sleep state and

how to wake up the device can be found in the datasheet.

Diagnostics

Figure 11: GUI – Diagnostic

The setting in the diagnostic register should be adjusted properly

in order to increase the reliability of the overall system and to

prevent possible damage to the A4964 as well as other components

such as FETs. The ESF bit, if set to “Stop on fail”, will disable all

the A4964 outputs in several conditions such as overtemperature,

drain-to-source overvoltage, and power supply (VBB) undervoltage.

The list of failures that can result in disabling the outputs when

ESF is set to “Stop on fail” can be found in the datasheet.

The drain-to-source voltage threshold VT provides protection for

the system in case any short circuit occurs in the bridge FETs.

When VDQ is set to “Debounce”, if the measured voltage across

FETs is higher than VT when they are fully on, all the outputs

will be disabled after the condition has persisted for the duration

VQT. If VDQ is set to “Blank”, the comparison of voltage across

the FET and overvoltage threshold VT is ignored once the output

is turned on for the duration defined by VQT. When VQT ends, if

the voltage across the FETs is higher than the threshold VT, then

the outputs will be disabled if ESF is set to “Stop on fail”.

The DIAG terminal on the A4964 evaluation board can provide

important information, such as motor electrical speed, and low-

or high-level signals in case of fault conditions. The output of the

DIAG pin depends on the setting of DGS. For example, if DGS

is set to “Active low fault flag”, then the DIAG will output a low

signal in case any fault occurs. If it is set to FG, it will then out-

put the motor speed, and so on. More information on the different

types of output waveforms depending on the setting of the DGS

can be found in the datasheet.

When CKS is set to “High impedance”, the SDO terminal output

works as it would during normal serial interface communica-

tion. When CKS is set to “Divided system clock”, it will output

the square waveform at a ratio of clock frequency when no data

is being transmitted (STRn = 1). This generated waveform will

allow more precise calibration of the timing settings, if required.

Register Display

Figure 12: GUI Register Display

The register display, shown in Figure 12, provides the hexadeci-

mal values of the present contents of the registers. Once all reg-

8

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

ister values have been tuned to a specific motor and load, these

settings may be written to the non-volatile memory (NVM) inside

the A4964. These values will then be used as the default power-

up values and can be used to avoid reprogramming the registers

at each power-on. This can then permit the A4964 to operate in a

standalone mode with only a PWM control input.

To write the present register values into NVM, the main sup-

ply should first be increased to at least 24 V before clicking on

the “Write NVM” button. The NVM write status box will then

display “Programming!” and the DSR selection pop-up window

will appear, asking “Would you like to set DSR=1”. The DSR bit

is not selectable in any other window and can only be set to 0 or

1 when writing to NVM. Click “Yes” or “No” and writing to the

NVM will commence. If NVM is updated successfully, then the

NVM write status box will display “success!”. If there are any

problems such that NVM is not updated successfully, then the

NVM write status box will display “Failed!”. If this occurs, check

that the supply voltage is above 24 V and the A4964 is active

and communicating with the GUI. Once any problems have been

resolved, click again on the “Write NVM” button.

Action Buttons

Clear

The “Clear” button will remove all the previous fault condition

shown in the “Status” section of Figure 4. If “Clear” is pressed

and there is no fault in the system, the content of the status

register should be shown in green. If the fault still exists, the cor-

responding fault will be shown in red.

Run

By pressing the “Run” button, the output of the A4964 is enabled

and the motor will start running if the settings are configured

properly.

Load Default

This button provides a quick way to set all parameters to their

datasheet default values. After clicking the “Load Default” but-

ton, all the selections in the drop-down menus and the display

buttons will be set to default values defined as the power-on reset

values in the datasheet. These values will then be written to the

A4964 mounted on the board if it is active.

Load

Clicking on the “Load” button allows loading previously con-

figured parameters into the GUI and as well updating the A4964

with these new parameters. The previously configured parameters

are in a text file with the “.rst” extension. Successful loading

occurs if the A4964 device is powered on and the USB connec-

tion between A4964 and PC exists at the time of the loading.

When the A4964 is initially powered up and the POR bit is set,

the content of registers from A4964 will be loaded into the GUI.

Also, if the GUI window is opened after the A4964 is powered

up, the contents of the registers in the GUI will be again updated

with A4964 register values. Thereafter, each time a parameter

is changed in the GUI, the register values of the A4964 will be

automatically updated with the changes.

If the USB is connected after the A4964 is powered up and the

GUI window is opened, the registers content from A4964 will not

be loaded into the GUI and vice versa. In this case, the register

values of the GUI and A4964 can be different, and therefore the

options “Update GUI » IC” and “Update IC » GUI” which are

described next can be useful.

Update GUI » IC

This option allows the contents of the GUI to be uploaded to

the A4964. By default, the contents of the GUI are loaded to the

A4964 whenever a parameter is changed. This option ensures that

the current contents of all registers in the GUI are loaded to the

A4964 and is useful for cases where the USB cable is discon-

nected and connected.

Update IC » GUI

When power is first applied to the A4964, the register parameter

settings that are saved in NVM will be loaded to the GUI. If the

GUI window is opened after the A4964 is powered up, the pres-

ent contents of registers from the A4964 will be loaded to the

GUI. This option ensures that the current contents of all A4964

registers are loaded to the GUI and is useful for cases where the

USB cable is disconnected and connected.

Save

The settings of operating parameters in the GUI can be saved to a

text file (with the file extension “.rst”) for future testing. To save

the parameters, click “Save”, input the file name in the pop-up

window, and choose a folder where the configuration file will be

saved. Then click “Save” in the pop-up window.

Demand Input

By increasing or decreasing the demand input, the user can alter

the motor reference speed or current limit depending on the con-

trol mode operation.

The motor electrical reference speed in closed-loop speed control

mode is equal to demand input (DI) multiplied by resolution SR.

For example, if demand input is equal to 200 and resolution is

equal to 0.8 Hz, then the motor electrical speed should be equal

to 160 Hz at steady state.

The amount of current limit in current control mode is defined by

the following equation:

9

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

ILIM – VILIM

RSENSE

where Rsense is the sense resistor.

In this case, demand input sets VILIM as a ratio of the maximum

threshold of VMIT. VMIT can be set by modifying the variable

MIT that can be found in the “Bridge PWM” section of the

GUI. For example, when demand input is 256 and VMIT is set to

200 mV, VILIM will be 50 mV.

Motor Status

Should there be any fault during operation of the A4964, the

“Status” section of the GUI will provide information about the

type of the fault. Some of the faults that are shown in the “Status”

are overtemperature, supply undervoltage, regulator undervolt-

age, etc. Once a specific type of fault occurs, the associated fault

will be marked in red and if there is no fault, it will be marked in

green.

When the A4964 is initially powered, the bits VLU, VRU, VSU,

WD, SE, POR, and FF will be shown in red. If watchdog is not

used, the WD bit must be masked as previously discussed. The

other faults can be cleared by clicking on the “Clear” button.

However, if the aforementioned faults genuinely exist in the sys-

tem and is not due to initial power on, even after clicking on the

“Clear” button, the fault will still be shown in the status section,

and its source must be removed from the system in order to clear

the fault in the GUI.

Capture

Data acquisition is possible by pressing the “Capture” button. The

data acquisition window will provide information about motor

speed, average supply current, supply voltage, chip temperature,

demand input, applied bridge peak duty cycle, and applied phase

advance. To ensure correct reading for motor speed and average

supply current, the number of pole pairs and sense resistor value

must be configured correctly. The information in the capture win-

dow is updated at approximately 700 ms intervals; however, this

strongly depends on the operating system and number of applica-

tions opened in the system background.

10

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Setting Up for First Time Use

Before operating the evaluation board for the first time, it should

be set into a safe condition to avoid overcurrent stress to any

components or attached load. The jumpers should be in their

default position as shown in Table 1, and switch S1 should be in

the “On” position.

Set Supply Current to Minimum

Before connecting the supply for the first time, ensure the supply

current limit is set to a low value to avoid unexpected current

caused by any component or load problems.

After connecting the power supply to VBB (connector X1), the

power supply current should be approximately 15 mA at 12 V

without any motor connected.

Interface the GUI

Table 1: Default Jumper Connections

Jumper Terminal Details Default

Setting

J1 Supply Voltage to VBB input Short

J2 VLR output to on board connector Short

J3 Supply Voltage to VBB (bypass diode) Short

J4 Clock signal for SCK input Short

J5 Signal from master device to SDI Short

J6 Strobe signal from STRn to the target device Short

J7 Signal output from SDO to master device Short

J8 Signal from DIAG to LED Short

J13 Signal from VBB to on Board 5 V regulator Short

Once the supply voltage and current have been checked, the

board can be connected to the PC that has the GUI installed. The

procedure for proper installation of the USB driver as well as

the GUI has already been discussed in the Software Installation

section. The connection can be done by connecting one end of the

provided micro USB to the PC and the other end to the evaluation

board (connector X7). After connecting the two devices together,

open the GUI software. If the connection has been successful, the

“SPI status” window indicates “OKAY!” as shown in Figure 13,

otherwise it will indicate “False!”.

There is one more step needed before setting up the control

parameters of the motor in the GUI and connecting the motor to

the board. Since watchdog is not used when interfacing the GUI,

it must be masked in order to avoid the device going into sleep

mode or disabling the output as discussed in section “System”. In

order to mask the watchdog, simply checkmark the “WD” bit as

shown in Figure 13, then press the “Clear” button. If the opera-

tion is successful, all the text under the “Status” and “Readback

Register” should be shown in green and the WD will be grayed

out as shown in Figure 13. At this point, the motor can be con-

nected and it is now possible to configure the control setting to

run the motor.

Figure 13: GUI – Main Window

Controlling the Motor with the GUI

A number of example settings to run motors for different appli-

cations are provided in Appendix D. Once the desired setting is

determined, open a blank text file (e.g., using Notepad), copy

and paste the determined setting into the file. Next, save the file

with the “.rst” extension. In the main window of the GUI, click

“Load”, locate the file and open it. At this point, the GUI should

be updated with the new parameters and the GUI then updates the

A4964 with these parameters automatically.

Click the “Run” button and the motor should start to operate. If

the motor started successfully, further tuning may not be needed,

and the speed can be further increased or decreased by changing

the DI. The A4964 GUI also provides an automatic tuning fea-

ture, which can be used to adjust the control setting gains should

the user prefer not to use the provided files. If in both cases,

loading the file or using automatic tuning feature, there is startup

problem, the guidelines provided in the Tuning Parameters

for Speed Control section can be followed and with minimum

changes, the motor should be able to run.

Automatic Tuning for Speed Control Mode

The A4964 GUI provides an automatic tuning feature to adjust

the gains for the closed-loop speed control. To use the automatic

tuning feature, first ensure that the board is powered, and the PC

is connected to the GUI via the USB connection. Then click on

the “Load Default” button to load the registers with the default

values and mask the watchdog bit WD as shown in Figure 13 if

watchdog is not used. The parameters that are changed during

automatic tuning is shown and marked in Figure 14.

Once the default values are loaded in the GUI, click on the

“Automatic Tuning” button. The pop-up window shown in

Figure 14 should open.

11

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Figure 14: Automatic Tuning Window

In order to start tuning, two important motor parameters (rated

speed (no load) and number of pole pairs) are required which

can be easily found in the specific motor datasheet. The user

then must provide the desired acceleration and PWM switching

period. It should be noted that if fast acceleration is required, the

current limiting function may have to be disabled by setting the

DIL bit to 1. To do this in the GUI, click on the “System” tab and

set “Current Limit” to “Disabled”. Once all the parameters are

defined, click on the “SET” button to ensure the “Set Maximum

Speed” window is updated with the latest motor rated speed and

then click on the “Start Tuning” button. A new pop-up message

will appear to confirm all the parameters are configured prop-

erly as shown in Figure 15. By clicking “Yes”, the gains will be

adjusted accordingly. Next, by clicking on the “RUN” button in

the main window of the GUI, the motor should be able to run.

If there is doubt about any of the parameters, click “No”, fix the

values, and click on “Start Tuning” again.

Figure 15: Automatic Tuning Message

The only parameter that must be tuned in the “Auto Tuning”

window is the desired acceleration. If the requested acceleration

is too high and is more than the capability of the motor, there can

be a startup problem. It is recommended to start with a low accel-

eration profile and increase it step by step until the motor can no

longer fulfil the desired acceleration. In rare cases where it is not

possible to start up the motor with any of the provided accelera-

tion profiles, a small adjustment to the control gain settings will

be necessary for which the guidelines provided in the next section

can be used.

12

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Tuning Parameters for Speed Control

Figure 16: Startup Sequence

The startup sequence summary is shown in Figure 16. In order to

achieve successful startup of the motor, the parameters for each

of the sequences must be modified and tuned. Before starting the

parameter tuning, load the default setting (shown in Appendix D)

to ensure the initial settings are set properly and only the relevant

parameters that require tuning are changed.

Alignment

The first settings that must be tuned for the specific type of motor

are those related to alignment. This is used to move the rotor to a

known position before initiating a forced commutation sequence

to start the motor. This function is helpful for motor and loads

with high inertia. Consider a simplified drawing of typical BLDC

as shown in Figure 17.

Figure 17: Illustration of rotor movement

The winding of phase A is energized to form a magnetic pole

shown in orange in Figure 17a. The blue and orange colors indi-

cate magnetic poles of different polarities. The rotor starts rotat-

ing clockwise as shown in Figure 17a until its blue magnetic pole

is fully aligned with the stator, which is shown in Figure 17b. At

this point, in order to further rotate the rotor, phase B of the stator

must be commutated. However, for example, for the duration

of phase A turn-on, it is not possible for the rotor to fully align

itself with the stator due to its high inertia. Thus, it is placed at

the location shown in Figure 17c. At this point, by commutating

phase B, rather than moving clockwise, the rotor will try to rotate

counterclockwise, causing disturbance in the motor performance.

Therefore, the alignment function in the A4964 helps placing the

rotor into a known position in order to achieve correct commuta-

tion sequence in the next startup stage, which is ramp.

The state flow diagram to tune the parameters for alignment is

shown in Figure 18. Depending on the position of the rotor and

its inertia, the parameters relating to alignment (HT, HD, and

HR) must be tuned.

These parameters can be found in the “Motor Control” section of

the GUI as shown in Figure 9. For example, if the inertia is high

and initial rotor position is far from the known position, the hold

time, HT, must be increased to provide more time for the rotor

to move to the desired position. Increasing the peak duty dur-

ing alignment parameter, HD, and reducing the alignment duty

cycle ramp time, HR, results in faster movement of the rotor to

the known position, which can be used if a long hold time is not

desired. It should be noted that during alignment, once the motor

reaches the known position, it will remain in that position until

HT ends and the ramp sequence begins.

If there are any problems with tuning the parameters in this sec-

tion, the motor will start vibrating and juddering at a certain posi-

tion. For example, if HT is set to 3 seconds and motor juddering

is observed after 2 seconds of running the motor, it means that the

parameters in the alignment section must be tuned.

Otherwise, if the motor vibration occurs after three seconds, the

problem is due to other untuned parameters in the next sequences

of startup. The worst-case condition is if the rotor is 180˚ far from

the known position and motor inertia is high. In this case, longer

HT, larger value of HD, and lower value of HR is required in

order to allow the rotor reach to the known position and achieve

robust startup. It should be noted that a high value of HD can also

result in motor vibration, and so if the motor starts to vibrate, this

value must be reduced.

Figure 18: State Flow Diagram for Alignment Sequence

Tuning Parameters

13

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Untuned Parameters for Ramp and Closed-Loop

Sequence

The untuned parameters in both ramp and closed-loop sequence

can result in stopping of the motor. In order to check at which stage

of startup this had occurred, the waveform of the signal FG must be

observed. The FG signal provides the electrical speed of the motor

and can be measured by connecting a probe to the point labelled

DIAG. The DIAG provides several measurements. To ensure that it

provides motor electrical speed, click on “Diagnostic” in the main

window of the GUI and set the DIAG output, DGS, to FG. Once

done, run the motor and observe the waveform of FG. Measure

the frequency of the signal FG on the oscilloscope. An example

of frequency measurement is shown in Figure 19. If the measured

frequency is higher than the value defined by parameter SF2, it

is confirmed that the ramp sequence is implemented successfully

and tuning must be done for the parameters of the closed-loop

sequence. If the motor stops or judders before the frequency

reaches the value defined by SF2, it indicates the parameters for

the ramp sequence are not well tuned. SF2 is among the parameters

that must be tuned for the ramp sequence and the importance of it

is discussed in the next section.

Figure 19: Frequency Measurement of the Signal FG

Ramp

The next important startup sequence after alignment is ramp. The

parameters to be tuned for this sequence are SF1, SD1, SF2, SD2,

SFS, and STS, which are provided in “Motor Control” section of

the GUI as shown in the Figure 9. In order to implement sensor-

less closed-loop motor control, measurement of the bemf signal is

required. The bemf signal level is equivalent to the motor speed.

Therefore, the purpose of the ramp sequence is to push the motor

speed high enough to be able to measure bemf effectively before

entering the closed-loop sequence.

When the ramp sequence begins, sinusoidal or trapezoidal

(depending on the choice of drive mode) waveforms are applied

to stator phases to create rotating magnetic fields that allow the

motor to rotate. The initial frequency of the waveforms and the

peak applied duty cycle are determined by the parameters SF1

and SD1. For two-phase modulation, the peak applied duty cycle

at zero-degree position for each phase, is defined as:

Phase A = (SD1 ÷ 2) %

Phase B = 0 Phase C = SD1 %

For three-phase modulation, the peak applied duty cycle for each

phase at zero-degree position is defined as:

Phase A = 50 %

Phase B = 50 – (SD1÷ 2) % Phase C= 50 + (SD1÷ 2) %

The applied frequency will then increase to the final value

defined by SF2, and the duty cycle by which the phases will be

modulated will increase to a final value defined by SD2. This

increase is done in steps, where duration of steps is determined

by STS and the amount of frequency increasing in each step is

determined by SFS. Figure 20 illustrates the waveform of applied

duty cycle with respect to time for a three-phase sinusoidal mod-

ulation. It should be noted that the applied duty cycle is equiva-

lent to the amount of phase voltage. With time advancement, it

can be noted that the peak duty cycle and frequency of the signal

increases. This increase continues until the frequency of the

signal has reached the value defined by SF2, after which the next

sequence (coast or closed-loop control) will initiate depending on

the configuration, which will be discussed later.

Figure 20: Ramp Sequence, Illustration of Duty Cycle

with Respect to Time

Tuning the Parameters for Ramp

The state flow diagram to tune parameters for the ramp sequence

is provided in Figure 21. In order to tune parameters for ramp,

one should realize the interdependency between the applied duty

cycle and frequency. Consider Figure 17 once again. If high fre-

quency step is applied to the phases, it means the rotor must also

react to the applied frequency, or otherwise it will lose synchro-

nism. In order for the rotor to react to the high-frequency step, a

high duty cycle step is also required. Higher duty cycle results in

higher phase voltages.

This creates stronger magnetic poles in each phase and therefore

results in faster acceleration of the rotor. However, it should be

noted that for the high inertia motors, a high-frequency step may

not be possible, as even the highest applied duty cycle step may

14

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

still not result in fast enough acceleration of the rotor compared

to the applied frequency.

To tune, start with low values of SF1 and SD1. This should avoid

any sudden oscillation in the rotor if its inertia is low. Also, start

with a low frequency step SFS but set the duration of step STS

to a high value. Usually, motor manufacturers provide the motor

voltage (bemf) constant. If the motor has low-voltage constant,

a higher value of SF2 is needed and vice versa. For motors with

high inertia, SD2 must be high. If the inertia is low, SD2 must be

low. Once the successful ramp sequence is achieved, the fre-

quency step SFS can be increased and the step time STS can be

reduced to achieve the desired acceleration during ramp.

If there is a problem for startup in this sequence, the motor usu-

ally starts rotating initially and then it begins to slip and lose

synchronism if the parameters are not set properly.

Coast

During coast, all switches are turned off for a very short duration,

which allows full measurement of bemf signal and detection of

zero-crossing point. This mode is useful for a high inertia motor

where it is harder to detect bemf due to lower acceleration and

therefore speed during ramp. It should also be noted that for very

low inertia motors, the coast mode can completely stop the motor,

therefore causing disturbance in the turn-on sequence. If a high

inertia motor is used, it is recommended to enable coast mode. If

the inertia is low, however, it is recommended to disable it. Coast

mode can be enabled or disabled by changing the bit STM in the

“Motor Control” section in Figure 9.

Figure 21: State Flow Diagram for

Ramp Sequence Tuning Parameters

Closed-Loop Control

The last important part for the startup configuration is tuning the

parameters for the closed-loop speed control. The parameters

that must be tuned in closed-loop control are provided in sec-

tions “Motor Commutation” and “Speed Control”. The state

flow diagram to tune the parameters in this section is provided in

Figure 22.

Figure 22: State Flow Diagram for

Close-Loop Tuning Parameters

Speed Loop Gains

Tuning the parameters for the closed-loop speed control fol-

lows the same logic as the ramp section. The acceleration during

closed-loop speed control is limited by the two parameters SGL

and SG. Higher gains can be used for low inertia motors and low

gains should be used for high inertia motors to achieve stable

performance. In addition to SGL and SG, a deceleration factor

DF is added to increase control loop versatility during decelera-

tion. If slow deceleration is required, the deceleration factor can

be increased.

15

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Position Loop Gains

The position loop gains CP, CI, CPT, and CIT also must be tuned

properly for smooth speed control. If low gains are used, the esti-

mated motor position can lag behind the actual motor position,

therefore causing disturbance in the motor control due to late

commutation. On the contrary, if high gains are used, the esti-

mated motor position can be further ahead from the actual motor

position, which can again result in disturbance in the performance

of the motor. It is recommended to set CPT = CP and CIT = CI.

Figure 22 provides a diagram, which demonstrates how to tune

these parameters.

Phase Advance

Phase advance serves two purposes: to improve efficiency of the

system and to allow the motor to go beyond the base speed. The

state flow diagram to tune parameters for phase advance is shown

in Figure 23.

Figure 23: State Flow Diagram for

Phase Advance Tuning Parameters

The efficiency improvement by using phase advance can be

understood by observing Figure 24 and Figure 25. In Figure 24,

the waveforms of phase current and voltage are shown without

application of phase advance. It should be noted that the phase

voltage signal is averaged to make the impact of phase advance

clearer. Due to the inductance of the windings in the stator, when

phase voltage is applied, there will always be a short delay in

the rise of the current. The bemf signal is synchronized with the

signal FG, as shown in Figure 24. If at a point, the bemf zero

crossing occurs, the current will not be zero and there will be

a sudden spike at the phase voltage. This occurs because at the

point of bemf zero-crossing, both bridge FETs are in tri-state,

meaning the voltage seen at the phase is due to the voltage spike

in the coil inductance and center tap voltage only. This effect

results in distortion in both phase voltage and current and thus

leads to harmonic losses and a less efficient system. However,

with the introduction of phase advance, which shifts the current

waveform with respect to bemf, it is possible to align bemf zero-

crossing with phase current zero-crossing as shown in Figure 25.

By shifting the current waveform by 7 degrees, it can be noticed

at the point the bemf zero-crossing occurs when the current is

zero. Therefore, this results in a less distorted current and voltage

waveform, leading to a more efficient system.

Figure 24: Phase Current and Voltage Waveform

with No Phase Advance

Figure 25: Phase Current and Voltage Waveform

with 7-Degree Phase Advance

There are cases where even with the application of 100% duty

cycle, the desired speed cannot be achieved. In these cases,

phase advance can be used to force the motor to go beyond the

base speed. The bemf of the motor depends on motor speed and

voltage constant. In the best-case scenario, bemf can be equal to

phase voltage (no load condition).

Therefore, since the phase voltage is fixed, the only way to go

beyond the base speed is to reduce the voltage constant. By shift-

ing the current with respect to bemf, a field is created in the stator

that opposes the permanent magnet field. This results in a reduc-

tion of flux density, and therefore a reduction of voltage constant.

Reduction of voltage constant allows an increase of speed beyond

16

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

the base value. However, it should be noted that in this case, due

to weakening of the field, there is less torque available, and if the

motor is heavily loaded, it can result in a disturbance in motor

performance.

There are two modes of phase advance operation, manual and

automatic, which can be set using the parameter PAM. To adjust

phase advance in manual mode, initially set PA to zero degrees.

Record the waveform of the phase current at a falling edge of FG.

Check if there is any sudden current change. If there is, change

the phase advance slightly until a clean waveform without any

distortion is achieved. If automatic phase advance operation is

used, the phase advance is adjusted automatically to achieve

better efficiency. To achieve automatic phase advance success-

fully, it is important to set PA to 0 and to have each phase going

high-impedance (both high-side and low-side MOSFETs in the

off-state) for a minimum of approximately 50% of the program-

mable dead time, DT[5:0].

Bemf Sensing

The next important parameter to be tuned is the bemf window.

In order to detect bemf, the applied signal to the phases should

be stopped. The duration of bemf measurement is defined by

the bemf window. For low-speed motors, a small bemf window

should be sufficient; however, at higher speeds the bemf window

must be extended to allow detection of the zero-crossing point,

which is used for closed-loop speed control. The increase in the

bemf window results in more reliable control performance at high

speed at the expense of a less sinusoidal waveform. The number

of times the window is opened in each electrical cycle depends on

bemf sampling BS. If BS is set to 1, only one window will open,

and it is only for phase A. If BS is set to 2, two window will open

for phase A only. If BS is 3, one window will open for each of the

phases, and finally if BS is 6, two windows will open for each of

the phases. The higher the number of bemf sampling, the more reli-

able the control can be at the cost of more disturbance in sinusoidal

waveform across all phases. The bemf filter time is used for wind-

mill and it must be tuned only if windmill is used.

Tuning Parameters for Current Control and Open

Loop Voltage Control

In both control modes, the first two sequences, which are align-

ment and ramp, remain the same as speed control. In open-loop

control mode, DI defines the applied duty cycle to the system

after the first two sequences. In current control mode, the error

between measured current across the sense resistor and the refer-

ence current, defined by DI, defines the duty cycle applied to the

phases. For positive error, the duty cycle continues to increase

until the reference current is achieved and vice versa for the nega-

tive error. In both cases, the position loop gains must be adjusted

properly using the same method as shown in the last section, and

speed loop gains no longer have any impact in any of the two

modes. Therefore, in these two control modes, there are no addi-

tional parameters that must be tuned. The desired control mode

can be selected in the GUI by clicking on “System” and then

modifying “Motor Control Mode”, CM.

17

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

APPENDIX A: EVALUATION BOARD SCHEMATIC

Figure 26: A4964 Evaluation Board Schematic

18

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

APPENDIX B: EVALUATION BOARD LAYOUT

Figure 27: Top Board Layout

Figure 28: Bottom Board Layout

19

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

APPENDIX C: EVALUATION BOARD COMPONENTS

Table 2: Component Function, Specification, and Selection Criteria

Component Value Type Notes

C1 10 µF (25 V) X7R Ceramic Capacitor Decoupling capacitor used for 5 V regulator output. Used to provide inrush current for

diagnostic LED.

C2 100 nF (63 V) X7R Ceramic Capacitor Decoupling capacitor used for 5 V regulator input. Used to provide ripple current

required by the regulator.

C3 470 nF (63 V) X7R Ceramic Capacitor Local decoupling capacitors for near VBB pin of A4964 to provide high switching

currents.

C5 10 µF (25 V) X7R Ceramic Capacitor Output decoupling capacitor used for VREG voltage. Used to reduce VREG output

voltage ripple.

C6, C7 1000 µF (63 V) Electrolytic Capacitor

Motor supply decoupling capacitor. Provides a local low-impedance source to

compensate for any supply wiring inductance. This capacitor provides ripple current

pulses to the motor phase. Selected to be able to handle maximum motor phase

ripple current.

C8 1 µF X7R Ceramic Capacitor

VLR output decoupling capacitor. Provides a local low-impedance source to

compensate for any supply wiring inductance. Provides ripple current pulses to VCC.

Selected to be able to handle maximum VCC load ripple current.

C9, C10, C14 220 nF (25 V) X7R Ceramic Capacitor Bootstrap capacitors used to turn on high-side FETs.

C11, C12, C13 100 nF (63 V) X7R Ceramic Capacitor

Local supply decoupling capacitors for VBB supply pins. Provide high-frequency

switching currents to the motor phase. Mounted as close as possible to VBB

terminals on A4964.

C15 220 pF (50 V) X7R Ceramic Capacitor Local decoupling capacitors for LIN interface.

D1 0.2 A 60 V Diode Provides arbitrary path from supply voltage to A4964.

LED1 High-Efficiency

Red LED Red High-efficiency LED to indicate the power supply has been applied to the device.

LED2 High-Efficiency

Red LED Red

Low-current high-efficiency red LED. Indicates when the FAULTn output is low.

Provides fault indication when FAULTn is in default condition. R18 limits current

through this LED to about 2 mA.

R2, R3, R4, R5,

R6, R7, R8, R9,

R10, R11, R12

1 kΩ 0805 Chip resistor Logic signal current limit resistors. Provide some protection for logic inputs of A4964.

R13 10 kΩ 0805 Chip resistor Current limit resistor. Prevent current flow from 5 V regulator to DIAG pin.

R14, R16, R17,

R25 R26, R27 100 Ω 0805 Chip resistor Filter resistors for gate of the FETs.

R15 47 kΩ 0805 Chip resistor Current limiting resistor. Used to limit current flowing from DIAG pin to base of

transistor Q1.

R18 2.2 kΩ 0805 Chip resistor Current-limiting resistor for LED2.

R19, R20, R21,

R28, R29, R30 274 kΩ 0805 Chip Resistor Used as protection to turn off FETs in case A4964 device is fully turned off.

R31, R32, R33,

R38, R39 0 Ω 0805 Chip Resistor Jumper resistors used to provide interface between communication devices.

R41, R42 20 mΩ 2512 Chip Resistor 5 V LDO on-board regulator for on-board parts.

U2 USB port

protection Used to avoid flow of current back to USB port and limit current from USB device.

U3 PIC device Microcontroller that provides serial interface.

U4 FTDI Chip

U5 LDO LM2936HVMA-5.0 5 V LDO on-board regulator for on-board parts.

CRD1 E202 Current regulator to control current going to LED1.

20

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

APPENDIX D-1: GUI DEFAULT SETTINGS

The GUI default settings are loaded via the DEFAULT button and

can be used as a starting point when tuning the register settings.

Once the default settings are loaded into the GUI, the register

settings can be retuned using the guidelines provided in this user

manual.

To load the default settings into the GUI, follow the instructions

below:

1. Open GUI, ensure that A4964 is supplied with power and

USB connection exists between PC and A4964.

2. Click on the “Load Default” button in the main window of

the GUI.

3. At this point, the GUI is loaded with the settings and it auto-

matically updates the register of A4964 with these values.

The part number is: A4964 Config[0] is: 0CC Con-

fig[1] is: 001

Config[2] is: 028

Config[3] is: 001

Config[4] is: 001

Config[5] is: 001

Config[6] is: 0FE

Config[7] is: 07E

Config[8] is: 07F

Config[9] is: 001

Config[10] is: 001

Config[11] is: 021

Config[12] is: 021

Config[13] is: 006

Config[14] is: 070

Config[15] is: 3C2

Config[16] is: 038

Config[17] is: 04F

Config[18] is: 085

Config[19] is: 021

Config[20] is: 1EF

Config[21] is: 007

Config[22] is: 086

Config[23] is: 00F

Config[24] is: 0FE

Config[25] is: 289

Config[26] is: 001

Config[27] is: 001

Config[28] is: 201

Config[29] is: 180

Config[30] is: 102

RShunt is: 00A Npp is: 006

Table of contents

Other Allegro MicroSystems Motherboard manuals

Allegro MicroSystems

Allegro MicroSystems ASEK-1335-T-KIT User manual

Allegro MicroSystems

Allegro MicroSystems A4910 Quick start guide

Allegro MicroSystems

Allegro MicroSystems A89503 User manual

Allegro MicroSystems

Allegro MicroSystems ASEK31300 User manual

Allegro MicroSystems

Allegro MicroSystems ACS732 User manual