Allegro ABR521 User manual

MODEL : ABR521

SERVICE MANUAL

P/NO : 3829RGN004P APRIL, 2005

MODEL : ABR521

VCR+DVD RECORDER

1-1

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS ............. 1-2

SERVICING PRECAUTIONS .................................................................................................. 1-3

THE STEPS FOR CHANGE THE OPTION CODE ........................................................... 1-4

UP-DATING PROGRAM ........................................................................................................... 1-5

SPECIFICATIONS ...................................................................................................................... 1-7

1-2

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original

design be modified or altered without permission from ALLEG O Electronics

Corporation. All components should be replaced only with types identical to

those in the original circuit and their physical location, wiring and lead dress

must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire haz-

ard. These components are indicated by the letter “x” included in their compo-

nent designators and are required to maintain safe performance. No deviations

are allowed without prior approval by ALLEG O Electronics Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes

into the set is not delayed until the new service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized modi-

fications will not only void the warranty, but may lead to property damage or

user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to

alert the service personnel to important safety information in the

service literature.

The lightning flash with arrowhead symbol within an equilateral tri-

angle is intended to alert the service personnel to the presence of

noninsulated “dangerous voltage” that may be of sufficient magni-

tude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an equi-

lateral triangle is intended to convey to the service personnel the

following fuse replacement caution notice:

CAUTION: FO CONTINUED P OTECTION AGAINST ISK

OF FI E, EPLACE ALL FUSES WITH THE SAME TYPE AND

ATING AS MA KED NEA EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the fol-

lowing:

FIRE AND SHOCK HA ARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items trans-ported to and

from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields,

strain reliefs, power supply cords, and other hardware have been reinstalled

per the original design. Be sure that the safety purpose of the polarized line

plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign par-

ticles.

4. Check for physical evidence of damage or deterioration to parts and compo-

nents, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a high current device or a resistor rated

at 1 watt or more. Lead tension around protruding metal surfaces must be

avoided.

6. After reassembly of the set, always perform an AC leakage test on all

exposed metallic parts of the cabinet (the channel selector knobs, antenna

terminals, handle and screws) to be sure that set is safe to operate without

danger of electrical shock. DO NOT USE A LINE ISOLATION T ANS-

FO ME DU ING THIS TEST. Use an AC voltmeter having 5000 ohms per

volt or more sensitivity in the following manner: Connect a 1500 ohm, 10

watt resistor, paralleled by a .15 mfd 150V AC type capacitor between a

known good earth ground water pipe, conduit, etc.) and the exposed metal-

lic parts, one at a time. Measure the AC voltage across the combination of

1500 ohm resistor and .15 mfd capacitor. everse the AC plug by using a

non-polarized adaptor and repeat AC voltage measurements for each

exposed metallic part. Voltage measured must not exceed 0.75 volts MS.

This corresponds to 0.5 milliamp AC. Any value exceeding this limit consti-

tutes a potential shock hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting

shelf space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where

dew is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that

might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must

follow the factory-approved mounting instructions. A product mounted to a

shelf or platform must retain its original feet (or the equivalent thickness in

spacers) to provide adequate air flow across the bottom. Bolts or screws

used for fasteners must not touch any parts or wiring. Perform leakage tests

on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilt-

ed position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small cast-

ers across thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous conse-

quences to home and family.

A.C. Voltmeter

1500 OHM

10 WATT

Place this probe

on each exposed

metal part.

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

0.15uF

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

1-3

SERVICING PRECAUTIONS

CAUTION: Before servicing the VC + DVD ECODE cov-

ered by this service data and its supplements and addends,

read and follow the SAFETY PRECAUTIONS. NOTE: if

unforeseen circumstances create conflict between the fol-

lowing servicing precautions and any of the safety precau-

tions in this publications, always follow the safety precau-

tions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the VC + DVD ECODE AC power cord

from the AC power source before:

(1) emoving or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this VC + DVD

ECODE or any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this VC + DVD ECODE

and / or any of its electrical assemblies unless all solid-

state device heat sinks are correctly installed.

6. Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation resis-

tance between each blade of the attachment plug and acces-

sible conductive parts (Note 1) should be more than 1M-

ohm.

Note 1: Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor compo-

nent or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commer-

cially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate an electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec-

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil,or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static elec-

tricity sufficient to damage an ES device.)

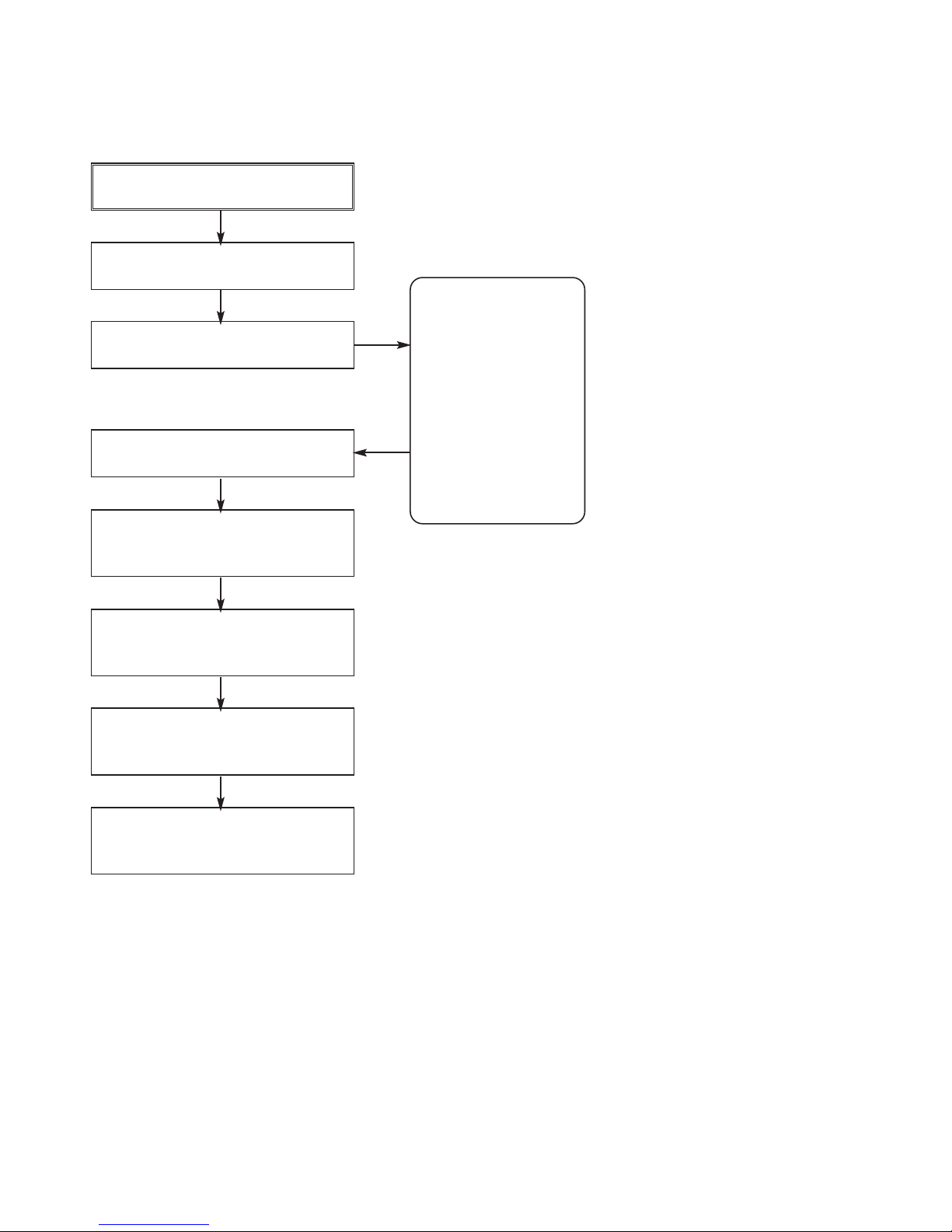

1-4

THE STEPS FOR CHANGE THE OPTION CODE

Push Switch POWE ON/ OFF

at remocon or timer keyborad

Select DVD MODE at the set

use remocon or timer keyborad

Push EC+ PLAY

at timer keyboard

Use remocon and push ENTE

Use Direction Key at

remocon (LEFT/ IGHT)

for select the position of option

Use Direction Key

at remocon (UP/ DOWN)

for change the option

After finish edit code of option

push ENTE at remocon

For finishing and intialized

the option code push

EC + EJECT at remocon

Note : This procedure must be done when IC304(On digital Board) or Digital Boardassy

ABR521

NAME HEX

OPT1 F2

OPT2 55

OPT3 53

OPT4 55

OPT5 17

OPT6 B8

OPT7 20

OPT8 00

Press “Enter” key

to Save and Exit

DETECT NEW EEP OM (OPTION EDIT SC EEN)

BURNING DISC

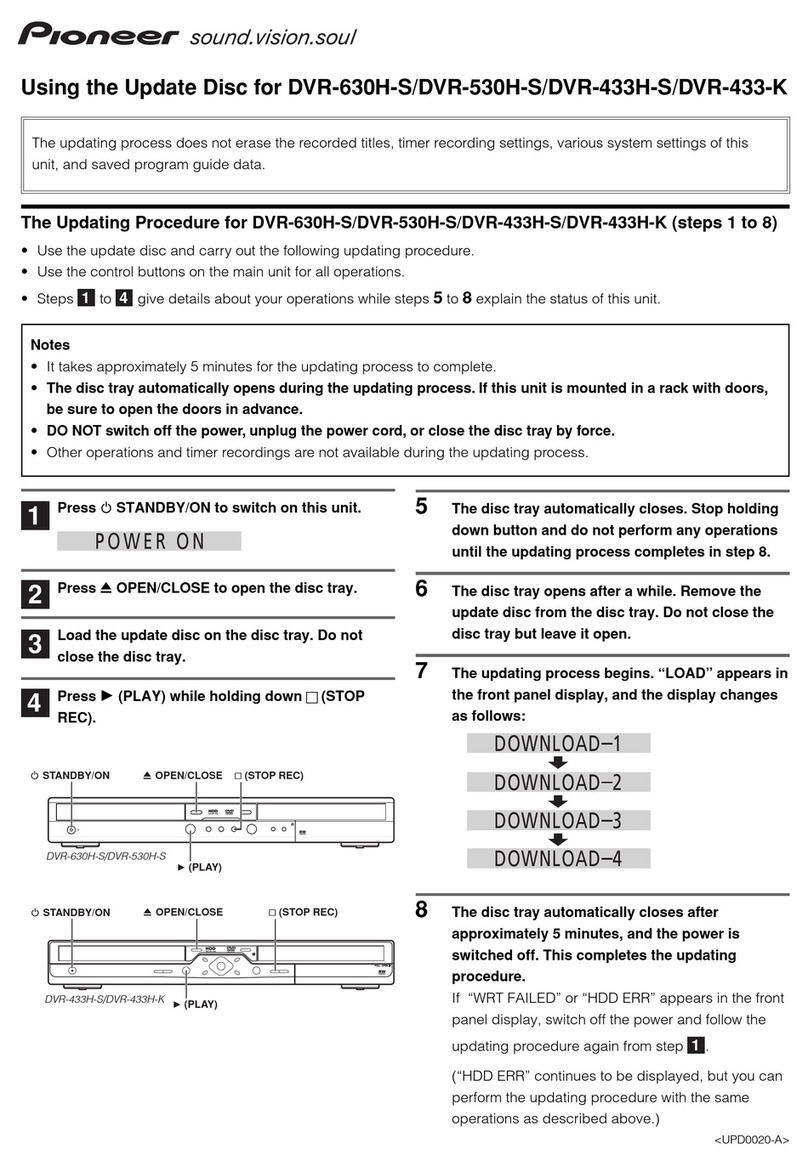

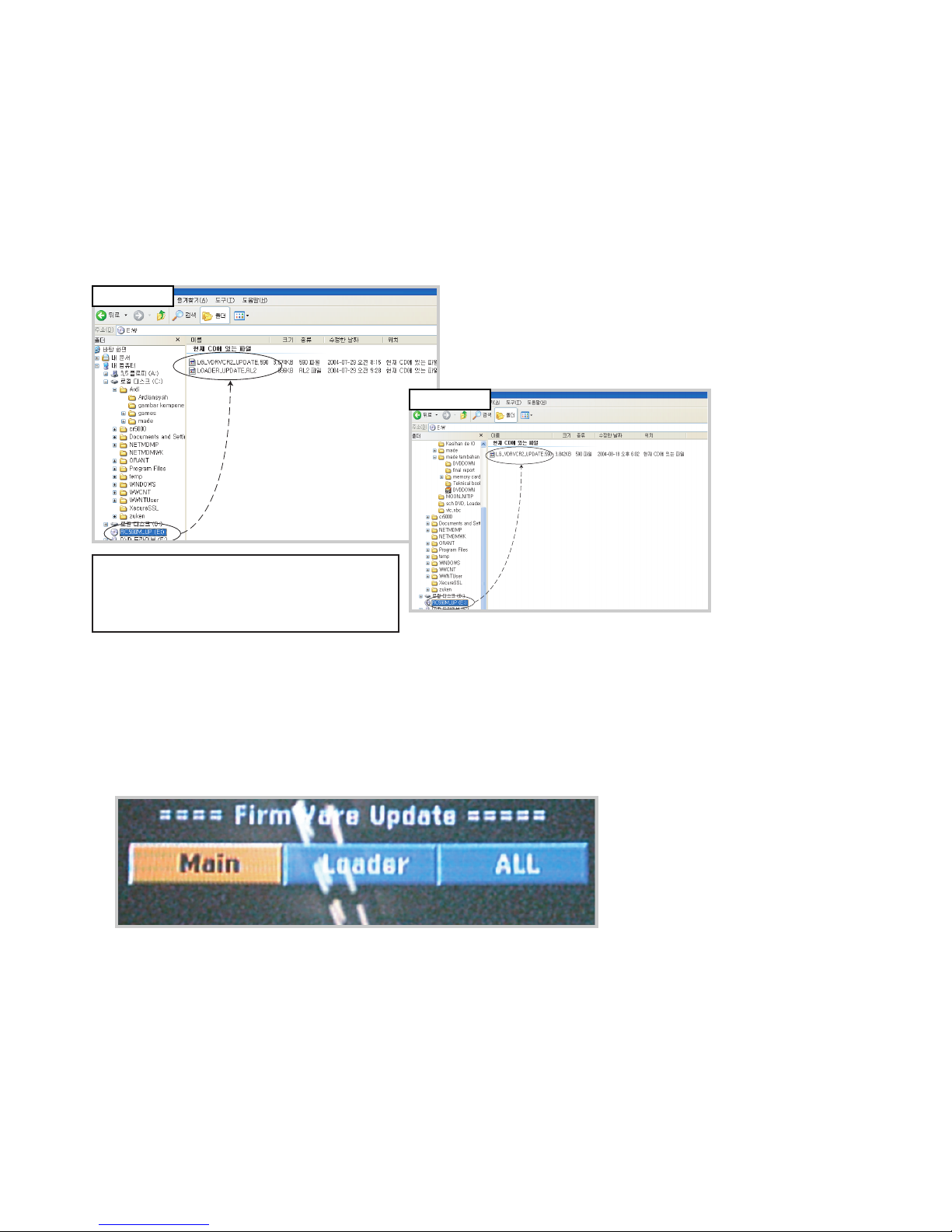

• For up-dating the DVD program using the disc, it must burning the disc which include the DVD software.

• For recorder combi set which using the disc downloader program are DVD Program and Loader Program.

• In 2nd generation for recorder combi can download the DVD program and Loader program one by one, or all

together.

• If you format like number 1 you’ll see capture like (figure 1)

• And you have three choice:

1. Main. It’s mean if you chose this it’ll up-dating only DVD prgram.

2. Loader.It’s mean if you chose this it’ll up-dating only Loader program.

3. ALL. It’s mean if you chose this it’ll up-dating DVD and Loader program.

• If you format like number 2 you’ll not see capture like figure 1 that give you choices, you have no choice only

update DVD program

1-5

UP-DATING PROGRAM

* There is two way to format disc DVD Program

1. DVD and LOADE program format in one

disc

2. Only DVD program format in one disc

(Figure 1)

Number 1

Number 2

1-6

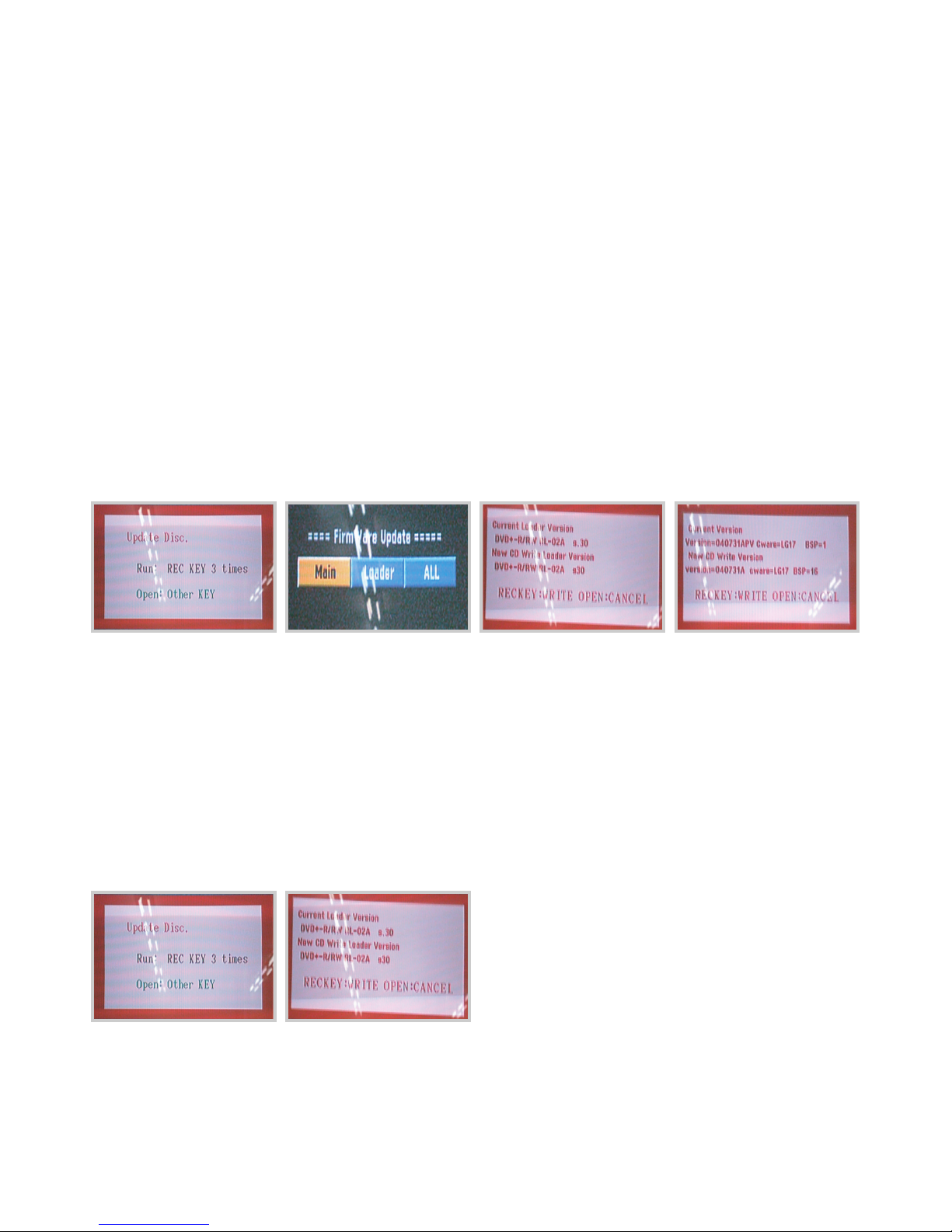

DVD UPGRADE INSTRUCTION

FORMAT NO 1

1. Press POWE KEY to turn on.

2. After booting, insert the upgrade disc, and you will see massage like [FIGU E 1]

3. Press “ EC” key (front or remote) 3 times and you will see as [FIGU E 2] with remote Chose one of them

then Press enter

4. For update both of them [MAIN & LOADE ] we chose “ALL” and first you will see [FIGU E 3] DVD update

→Check the “Current Version” and “ New CD Write Version” and press “ EC” key.

5. The DVD update will be on progress.And when finish update MAIN Version it’s automatically continue to

Update Loader Version and You will see [FIGU E 4]

→Check the “Current Version” and “New CD Write Version “ and Press “ EC” key once more

6. The LOADE update will be on progress. And tray will open.

7. emove the disc and wait until finish

8. The tray will be close and open automatically after completing “UNDE UPDATE” 100%

9. Turn off the unit

10. Turn on again the unit is operation with new software

FORMAT NO 2

1. Press POWE KEY to turn on.

2. After booting, insert the upgrade disc, and you will see massage like [FIGU E 1]

3. Press “ EC” key (front or remote) 3 times

4. The DVD update will be on progress.

→Check the “Current Version” and “New CD Write Version “ and Press “ EC” key once more

5. The tray will be open automatically after completing “UNDE UPDATE” 100%

6. emove the disc andTurn off the unit

7. Turn on again the unit is operation with new software

[FIGURE 1] [FIGURE 2] [FIGURE 3] [FIGURE 4]

[FIGURE 1] [FIGURE 2]

1-7

SPECIFICATIONS

General

Power requirements AC 120V, 60 Hz

Power consumption 35W

Dimensions (approx.) 430 X 78.5 X 354 mm (w x h x d)

Mass (approx.) 5.7 kg

Operating temperature 5°C to 35°C

Operating humidity 5 % to 90 %

Television system NTSC color system

ecording format NTSC

System

Laser Semiconductor laser, wavelength 650 mm

Video head system Double azimuth 4 heads, helical scanning

Signal system NTSC

Recording

ecording format DVD+ W/+ Video format

ecordable discs DVD- eWritable, DVD- ecordable, DVD+ eWritable, DVD+ ecordable

ecordable time Approx. 1 hour (XP mode), 2 hours (SP mode), 4 hours (LP mode),

6 hours (EP mode)

Video recording format

Sampling frequency 27MHz

Compression format MPEG 2

Audio recording format

Sampling frequency 48kHz

Compression format Dolby Digital

Playback

Frequency response DVD (PCM 48 kHz): 8 Hz to 22 kHz, CD: 8 Hz to 20 kHz

DVD (PCM 96 kHz): 8 Hz to 44 kHz

Harmonic distortion Less than 0.008% (AUDIO OUT connector)

Dynamic range More than 95 dB (AUDIO OUT connector)

Inputs

F IN F input, 75 ohms

VIDEO IN 1.0 Vp-p 75 ohms, sync negative, CA jack

AUDIO IN 0 dBm more than 47 kohms, CA jack (L, )

DV IN 4 pin (i.LINK/IEEE 1394 standard)

S-VIDEO IN (Y) 1.0 V (p-p), 75 Ω, negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75 Ω

Outputs

S-VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75 Ω

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync, CA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, CA jack x 2

Audio output (digital audio) 0.5 V (p-p), 75 Ω, CA jack x 1

Audio output (analog audio) 2.0 Vrms (1 KHz, 0 dB), 600 Ω, CA jack (L, ) x 1

* Design and specifications are subject to change without notice.

* Manufactured under license from Dolby Laboratories. “Dolby”, “Pro Logic” and the double-D symbol are trademarks of

Dolby Laboratories.

* DTS and DTS Digital Out are registered trademarks of Digital Theater Systems, Inc.

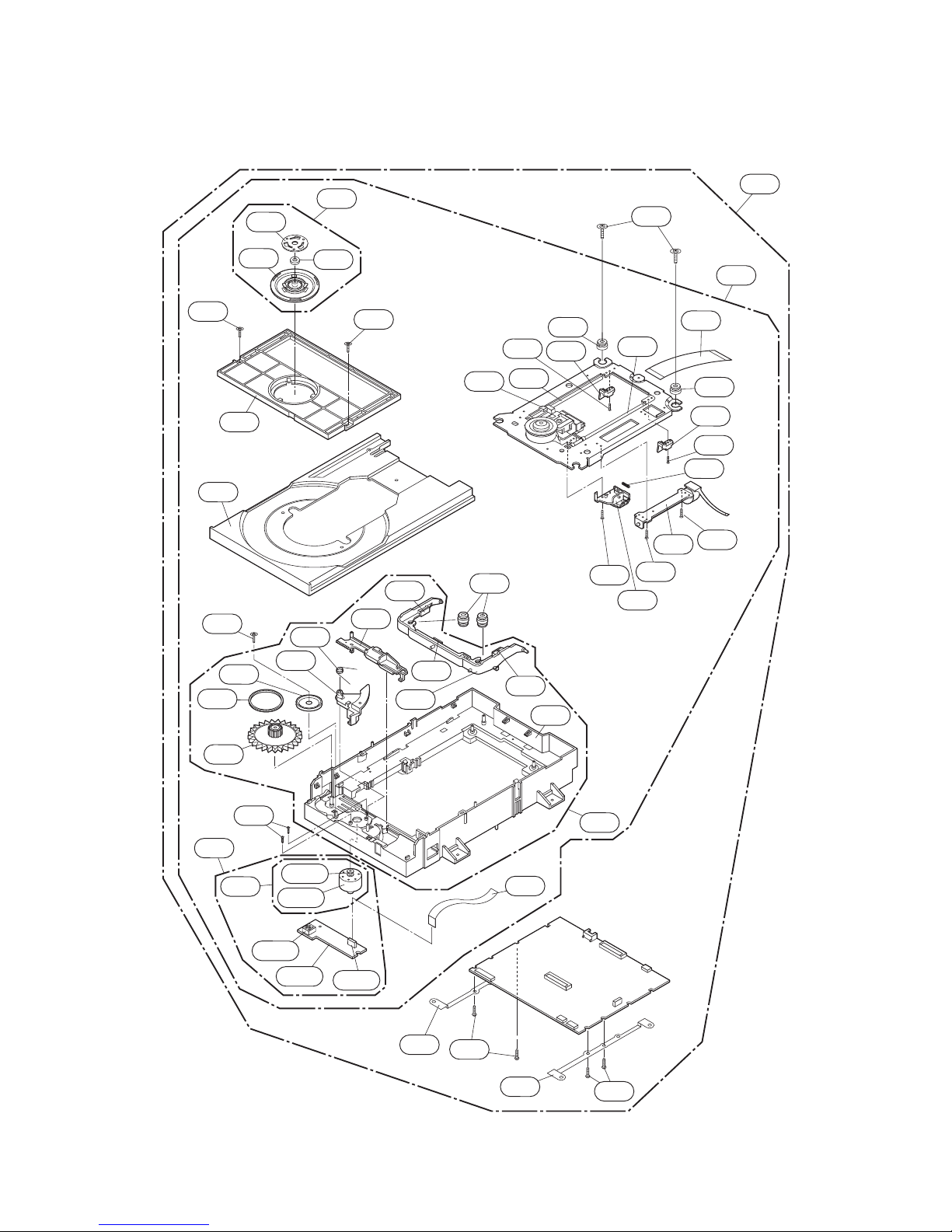

2-1

SECTION 2

EXPLODED VIEWS

CONTENTS

EXPLODED VIEWS .....................................................................................................................2-2

1. Cabinet and Main Frame Section ...........................................................................................2-2

2. Deck Mechanism Section (RL-05) ..........................................................................................2-3

3. Packing Accessory Section ....................................................................................................2-4

2-2

EXPLODED VIEWS

1. Cabinet and Main Frame Section

283

28

284

469

286

457

A43

285

A48

274

261

452

261

261

266

263

264

468

265

465

32

26

A44

3

A

457

47

257

256

255

469

463

25

463

463

469

A52

A6

457

278

457

A5

A47

A54

276

469

323

321

469

A46

2-3

2. Deck Mechanism Section (RL-05)

1001

A001

A60

1434 1434 1025

1025

1030

1432

1038 1029

1432

1021 1432

1432

1032

1033

1011

1019

1020

1019

1009

1012

1013

1435

1014

1016

1015

1017

1018 1018A

1018B

1018C

1018E 1018D

1006

1436

10241433

1029

1027

1027

1005

1026

1003 1002

A004

A002

1041

1042

1434

1434

A000

1437

2-4

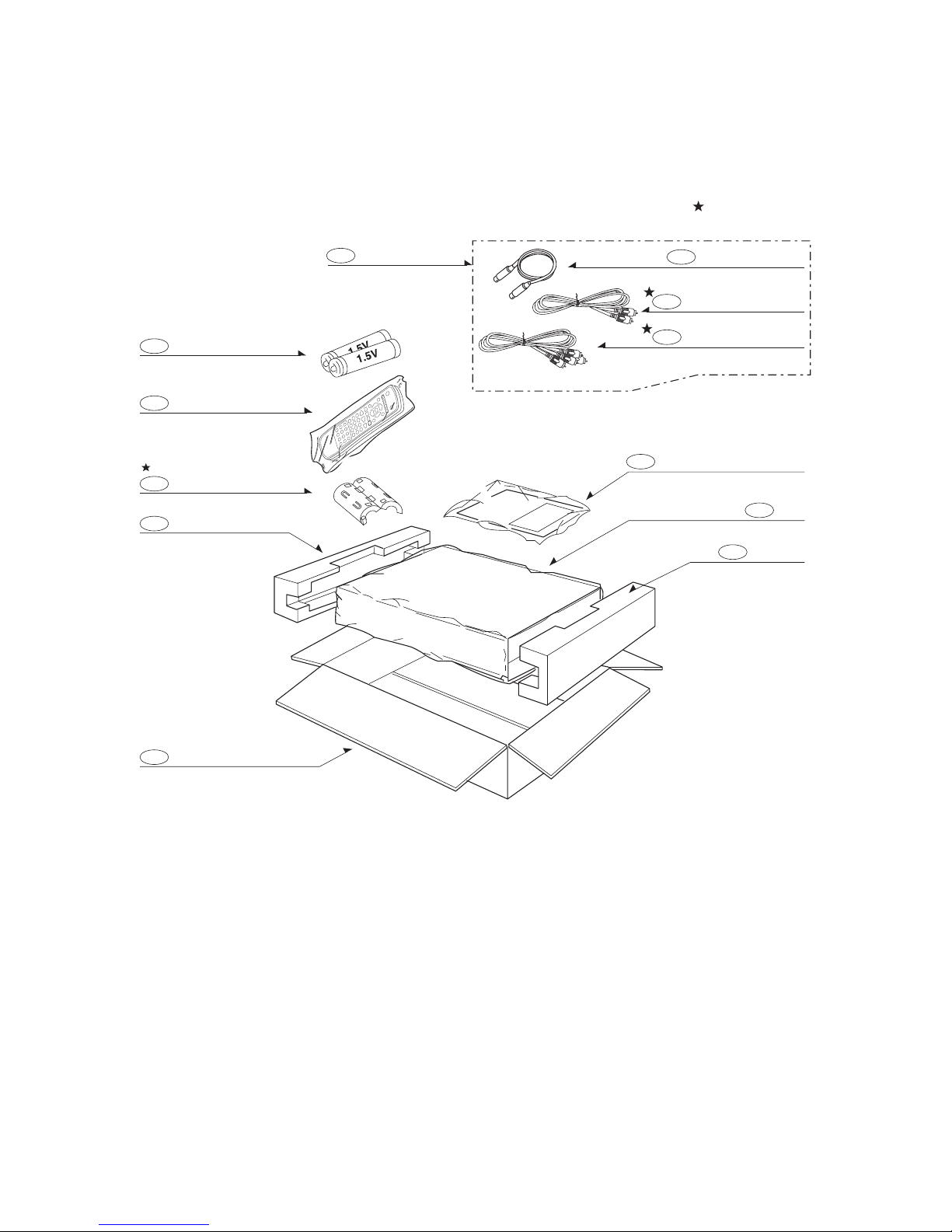

3. Packing Accessory Section

BATTERY

808

BAG

804

PACKING

803

806

INSTRUCTION ASSEMBLY

CABLE(COAXIAL)

810 CABLE ASS'Y RF

801

REMOCON

900

FILTER

826

BOX CARTON

802

PACKING

803

811

812

PLUG ASS'Y 1WAY

PLUG ASS'Y 2WAY

OPTIONAL PARTS

3-1

SECTION 3

ELECTRICAL

CONTENTS

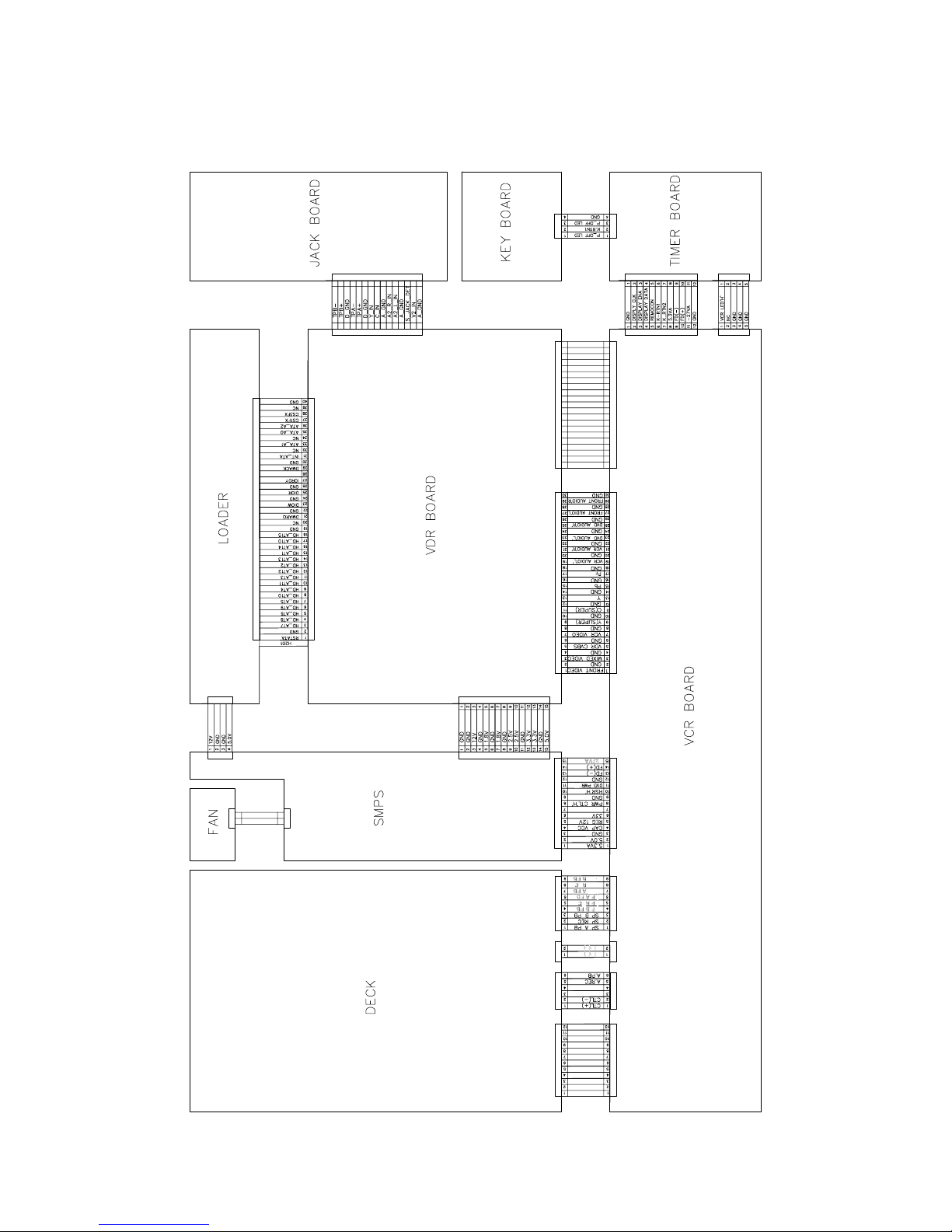

OVERALL WIRING DIAGRAM..............................3-2

VCR PART

ELECTRICAL ADJUSTMENT

PROCEDURES............................................................3-3

VCR ELECTRICAL TROUBLESHOOTING

GUIDE.............................................................................3-4

1. POWE (SMPS) CI CUIT .......................................3-4

2. SYSTEM/KEY CI CUIT ..........................................3-7

3. SE VO CI CUIT.....................................................3-8

4. Y/C CI CUIT..........................................................3-11

5. HI-FI CI CUIT .......................................................3-15

6. TUNE /IF CI CUIT...............................................3-18

BLOCK DIAGRAMS................................................3-20

1. POWE (SMPS) BLOCK DIAG AM......................3-20

2. AVCP BLOCK DIAG AM ......................................3-22

3. SYSTEM BLOCK DIAG AM.................................3-24

4. JACK BLOCK DIAG AM ......................................3-26

5. STUNE /MTZ BLOCK DIAG AM.........................3-28

6. AVCP BLOCK DIAG AM ......................................3-30

CIRCUIT DIAGRAMS..............................................3-32

1. POWE (SMPS) CI CUIT DIAG AM ...................3-32

2. TU/IF CI CUIT DIAG AM ....................................3-34

3. A/V CI CUIT DIAG AM........................................3-36

4. HI-FI CI CUIT DIAG AM .....................................3-38

5. SYSTEM CI CUIT DIAG AM...............................3-40

6. JACK CI CUIT DIAG AM ....................................3-42

7. TIME CI CUIT DIAG AM( 2 TOOL ) .................3-44

8. TIME CI CUIT DIAG AM( 3 TOOL, 8 TOOL ) ..3-46

9. TIME CI CUIT DIAG AM( 4 TOOL ) .................3-48

10. TIME CI CUIT DIAG AM( 6 TOOL ) ...............3-50

11. TIME CI CUIT DIAG AM( 7 TOOL ) ...............5-52

• WAVEFO MS .........................................................3-54

• CI CUIT VOLTAGE CHA T ...................................3-56

PRINTED CIRCUIT DIAGRAMS.........................3-58

1. VC P.C.BOA D...................................................3-58

2. SMPS P.C.BOA D ...............................................3-60

3. JACK P.C.BOA D ................................................3-62

4. KEY P.C.BOA D .................................................3-64

5. TIME P.C.BOA D .............................................3-64

VDR PART

VDR ELECTRICAL TROUBLESHOOTING

GUIDE...........................................................................3-66

1. POWE (SMPS) CI CUIT .....................................3-66

2. NO COMPONENT VIDEO SIGNAL WHEN

PLAYING DISC......................................................3-68

3. NO COMPOSITE / S-VIDEO SIGNAL WHEN

PLAYING DISC......................................................3-69

4. NO TV, EXTE NAL INPUT VIDEO SIGNAL.........3-70

5. WHEN PLAYING DISC, NO AUDIO OUTPUT ......3-71

6. NO TUNE AUDIO OUTPUT ................................3-71

7. NO OPTICAL / DIGITAL OUTPUT ........................3-71

8. NO EXTE NAL INPUT 1, 2 AUDIO ......................3-72

9. NO EXTE NAL INPUT 3 AUDIO ..........................3-72

BLOCK DIAGRAMS................................................3-73

1. VD SET TOTAL BLOCK DIAG AM....................3-73

2. VD MAIN H/ W BLOCK DIAG AM.....................3-74

3. POWE BLOCK DIAG AM ..................................3-75

4. AUDIO IN/ OUT BLOCK DIAG AM ......................3-76

5. CPU & CONT OL EGISTE

BLOCK DIAG AM.................................................3-77

6. VIDEO IN/ OUT BLOCK DIAG AM ......................3-78

7. DV 1394 IN/OUT BLOCK DIAG AM ....................3-79

8. MEMO Y CA D IN/ OUT BLOCK DIAG AM ......3-80

CIRCUIT DIAGRAMS..............................................3-81

1. BGA 308P CI CUIT DIAG AM.............................3-81

2. DD & B TO B CONNECTO

CI CUIT DIAG AM ..............................................3-83

3. POWE , FLASH, CONNECTO CI CUIT

DIAG AM ..............................................................3-85

4. ST, CONT OL/STATUS_ EG., ATAPI,

HOST_CPLD, LATCH CI CUIT DIAG AM ..........3-87

5. VIDEO_IN, VIDEO_OUT CI CUIT DIAG AM......3-89

6. DV1394, HDMI CI CUIT DIAG AM .....................3-91

7. AUDIO IN/OUT CI CUIT DIAG AM .....................3-93

• WAVEFO MS .........................................................3-95

• CI CUIT VOLTAGE CHA T ...................................3-97

PRINTED CIRCUIT DIAGRAMS.........................3-99

1. VD P.C.BOA D(TOP VIEW) ...............................3-99

2. VD P.C.BOA D(BOTTOM VIEW).....................3-101

3-2

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

SPD.F

GND

INTR/PROG

NC

GND

RADIO'H'

AMP ON

VDR REDET

NC

NC

NC

VDR CLK

DATA(VCR-VDR)

DATA(VDR-VCR)

VDR ENA

AMP CLK

AMP RX

AMP TX

AMP READY

AMP MUTE

NC

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

P6603

P6602

PM601PN302

PN302

PN301

PN301

PMD01PMD02

PN304

CON401

CON401

PPM01

P101

P3D01P3D03

P104

P103

P103

P104

P3D02

P3D02

PMC01

PMC01

P3D03 P3D01

PN303

PM602

PM603 P6M01

13.5VA(DRUM)

A/E(-)

A/E(+)

CFG

CAP.VCC

SERVO VCC

CAP.REV'H'

I-LIMIT

MOTOR GND

S.GND

DRUM VCC(13.5VA)

CAP.CTL

L/M CTL

DPG/DFG

DRUM CTL

8.7V

GND

1

21

2

R493

OVERALL WIRING DIAGRAMS

3-3

ELECTRICAL ADJUSTMENT PROCEDURES

1. Servo Adjustment

1) PG Adjustment

• Adjustment And Specification

• Test Equipment

a) OSCILLOSCOPE : NTSC SP TEST TAPE

MODE

PLAY

• Adjustment Procedure

a) Insert the SP Test Tape and play.

b) Connect the CH1 of the oscilloscope to the H/SW and CH2 to the “VC VIDEO” TP for the VC .

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW, and then check the distance (time dif-

ference), which is from the selected A(B) Head point of the H/SW signal to the starting point of the ver-

tical synchronized signal, to 6.5H ± 0.5H (416µs, 1H=64µs).

• PG Adjustment Method

a-1) Playback the SP standard tape

b-2) Wait for 3seconds with F/P “ EC” key and “PLAY” key presseed at the same time. < Digitron[ - - ] >

c-3) epeat the above step(No.b-2), then it finishes the PG adjusting automatically. < Digitron[ PG ] >

d-4) Stop the playback, then it goes out of PG adjusting mode after mony the PG data.

• CONNECTION

• WAVEFORM

V.Out

H/SW(TP) /C T K JIG KEY 6.5 ± 0.5H

MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

H/SW

(TP)

TP

(VCR

VIDEO)

(CH2)

(CH1)

OSCILLOSCOPE

CH1 CH2

R/C KEY

H/SW

(TP)

VCR BOARDVDR BOARD

"VCR VIDEO" TP

VCR PART

H/SW

Composite

VIDEO

6.5H(416µs)

3-4

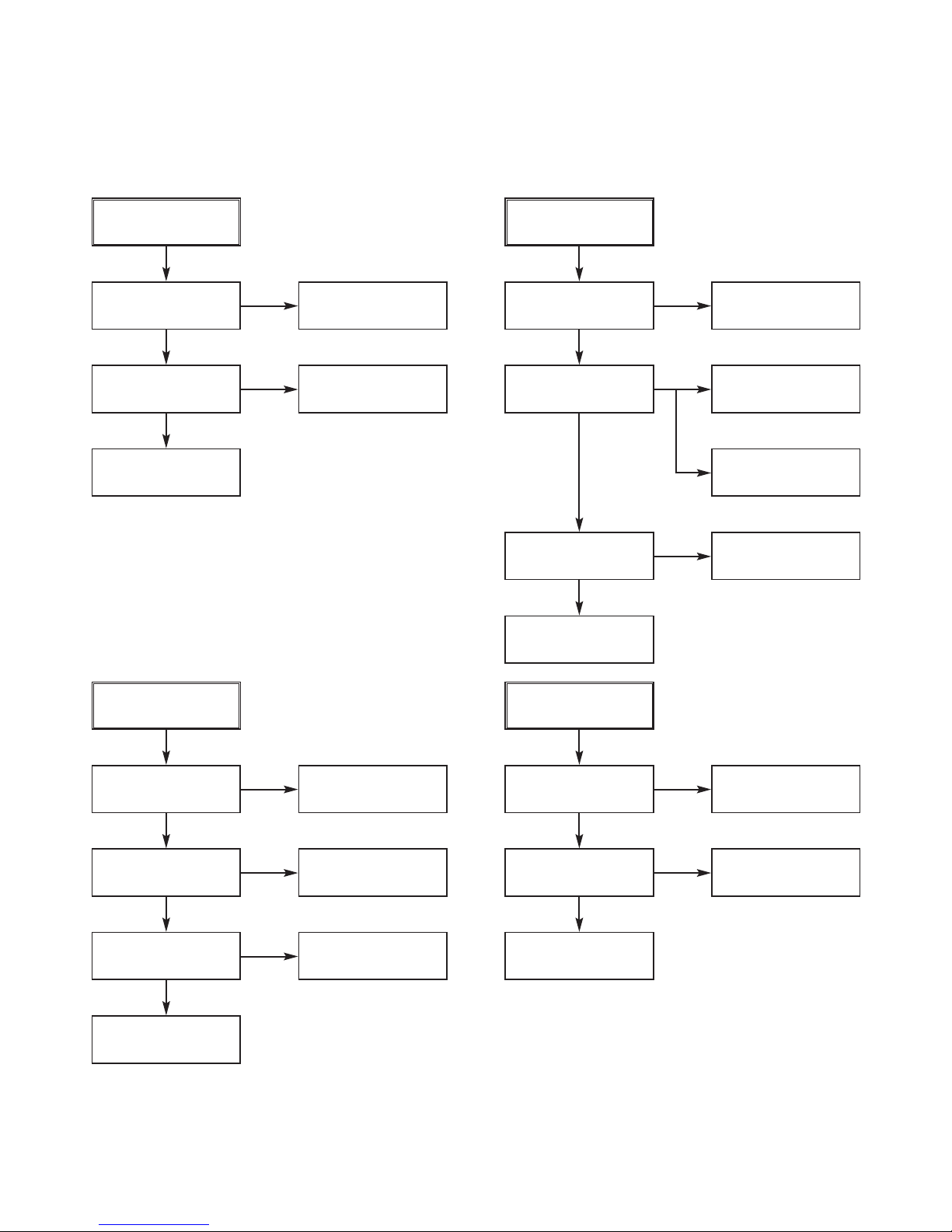

VCR ELECTRICAL TROUBLESHOOTING GUIDE

1. Power(SMPS) CIRCUIT

NO 5.3VA.

eplace the F101

(Use the same Fuse)

Is the F101 normal?

Is the TH01

Normal?

Is the BD101

Normal?

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

eplace the BD101

eplace the TH01

Is the D102

normal?

Check or eplace

the D102

eplace the D121

eplace the IC103

eplace the D126

eplace the D129

eplace the D130

eplace the D127

eplace the D128

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Is the Vcc (14V - 17V)

supplied to IC101 Pin7?

NO

Is the D121

normal?

Is there about 2.5V

at the IC103 Pin1?

Is the D126

normal?

Is the D129

normal?

Is the D130

normal?

Is the D127

normal?

Is the D128

normal?

YES

Power Line of Main

PCB(VC ) is short

3-5

VCR ELECTRICAL TROUBLESHOOTING GUIDE

No 12VA

Check or eplace

the D126

Is the Vcc(13V)

supplied to C130?

Check or eplace

the Cap / Drum

Is the D132

Normal?

NO

NO eplace the D132

YES

YES

(To Cap, Drum Motor )

No EG 12V

Check or eplace

the D126

Check the ‘PW CTL

“H”’signal from µ-com

Check the 33V Line

eplace the Q126

Is the Vcc(13V) sup-

plied to Q126Collector?

Is the Vcc(33V) sup-

plied to Q126 Base?

Is the Q126 Nomal?

Check or eplace

the D126

NO

NO

NO

YES

YES

YES

NO VFD

Check or eplace

the 107

Is the 107

Normal?

Is the D128

Normal?

NO

Check or eplace

the D128

Check or eplace

the ZD151

NO

NO

YES

Is the ZD151

Normal?

Check or eplace

the D127

YES

YES

No 33V

Check or eplace

the D130

Is the Vcc(33V) sup-

plied to Q123 Emittor?

Is the Q123 Base

‘H’?

NO

Check the ‘PW CTL

“H”’signal from µ-com

NO

YES

Check or eplace

the Q123

YES

3-6

VCR ELECTRICAL TROUBLESHOOTING GUIDE

No 28V (HS )

Check or eplace

the D129

Is the Vcc(30V) supplied

to Q120 Collector?

Is the Vcc(33V) supplied

to Q121 Collector?

Is the Vcc(30V) sup-

plied to Q120 Base?

NO

NO Check or eplace

the ZD153

NO

Check the ‘HS “H”

signal from µ-com

Check or eplace the

Q121/Q122 & 33V line

YES

YES

Check or eplace

the Q120

YES

3-7

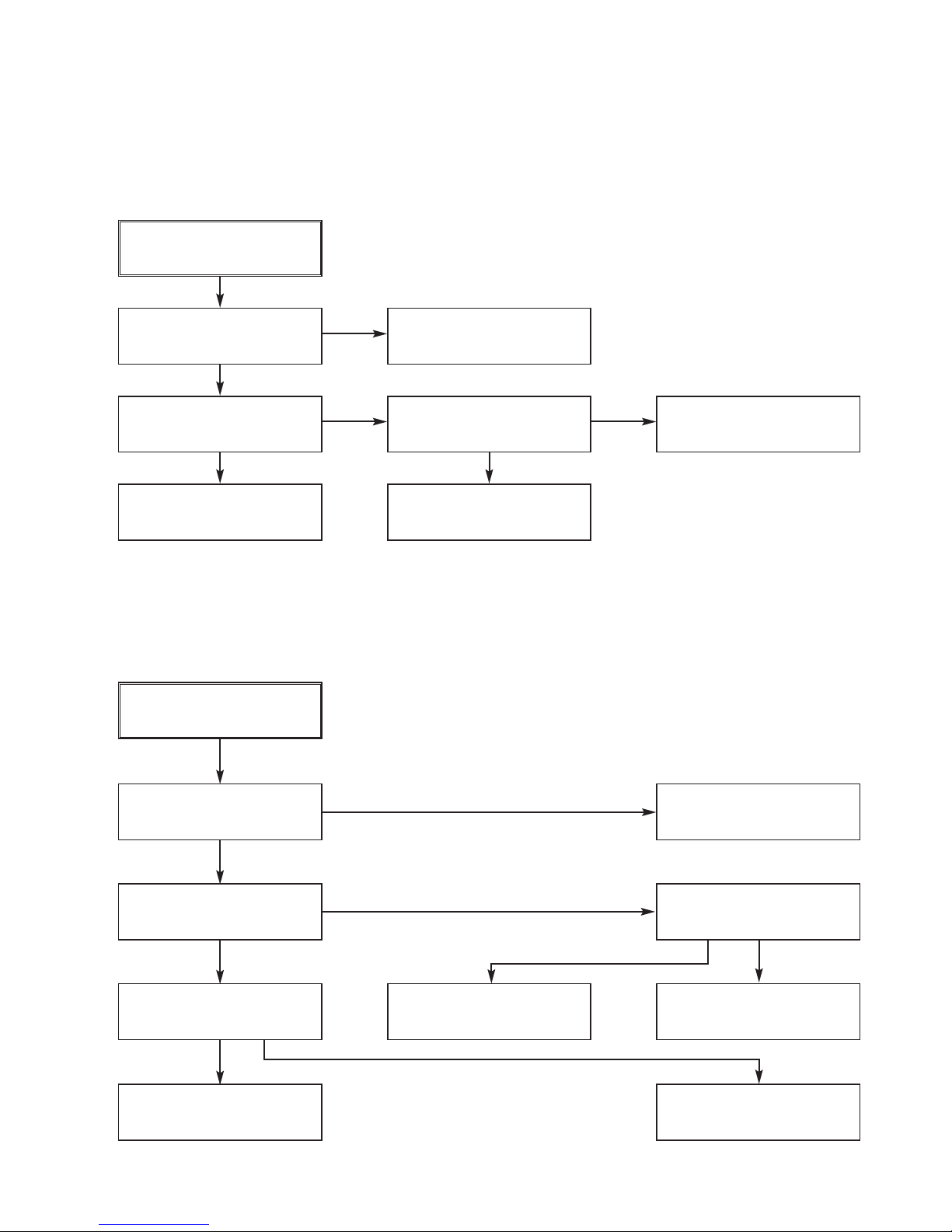

2. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

(2) The unstable loading of a Cassette tape

Auto Stop

Does the H/SW waveform

appear at IC501 Pin18?

Do the T-UP eel Pulses

appear at IC501 Pin80?

Is 12V applied to PMC01

Pin8?

Check the Drum Motor

signal.

Check the Power Circuit.

Check the power.

Is 5.0V applied to the

531?

efer to SMPS 5.3VA

troubleshooting.

Check IC501

Pins22, 23, 24, 25.

Does 5.0V appear at the

S501?

eplace the T/UP eel

Sensor ( S501).

Check the CST SW and

the peripheral circuitry.

eplace the IC501.

The unstable loading of a

Cassette tape

Does the “H” signal appear

at IC501 Pin58 during

inserting the CST ?

Does the “L” signal appear

at IC501 Pin10 while

inserting the CST?

Check the Deck

Mechanism.

Note : Auto stop can occur because Grease or Oil has dried up

YES

YES YES

YES

YES

YES

NO

NO

NO

NO

NO

NO NO

YES

VCR ELECTRICAL TROUBLESHOOTING GUIDE

3-8

3. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Does the Noise level of the

screen change

periodically?

Do the CTL pulses appear

at IC501 Pin97?

Is adjusting the height of

the CTL Head accurate?

eadjust the height of the

CTL Head.

eplace the IC501.

efer to “When the Y signal

doesn’t appear on the

screen in PB Mode”.

Does the CFG waveform

appear at the IC501 pin87?

On tracking, do the CTL

pulses move?

Does the Video Envelope

waveform appear at IC501

Pin9?

eplace IC501.

YES

YES

YES

NO NO

NO

NO

(2) When the Drum Motor

(2) doesn’t run. Do the DFG Pulses appear

at PMC01 Pin11?

eplace the Cap M.

Aren’t the foil patterns and

the Components between

IC501 Pin 90 and PMC01

Pin11 shorted?

eplace the IC501.

efer to “(2)

No 12VA of Power section”

Do the Drum PWM Pulses

appear at IC501 Pin76?

Aren’t the foil patterns and

the Components between

IC501 Pin76 and PMC01

Pin12 shorted?

Do the DFG Pulses appear

at IC501 Pin90?

Do the Drum PWM Pulses

appear at IC501 Pin76?

Are the connecting patterns and the Components

between IC501 Pin76 and PMC01 Pin12 shorted?

When the Drum Motor

doesn’t run,

Does 12V appear at

PMC01 Pin8?

Does 2.8V appear at

PMC01 Pin12?

Check the connector

(PMC01) and the Drum

Motor Ass’y.

NO

YES

YES

YES

NO

NO

NO

NO

NO

YES

YES

YES

VCR ELECTRICAL TROUBLESHOOTING GUIDE

Table of contents