ALLFASTENERS AFGN50 ProTrax Guide

AFGN50 ProTrax Nailer

PART# 1GN50

SAFETY OPERATION MANUAL

TABLE OF CONTENTS

1. IMPORTANT INFORMATION 2

2. SAFETY WARNINGS 2

3. DANGER WARNINGS 2

4. GENERAL WARNINGS 3

5. SAFETY INSTRUCTIONS - FUEL CELL 5

6. SAFETY INSTRUCTIONS - BATTERY CHARGER 5

7. USE OF - BATTERY AND BATTERY CHARGER 6

8. DISPOSAL OF THE EXHAUSTED BATTERY 7

9. SPECIFICATIONS 7

10. GENERAL OPERATION 9

11. APPLICATIONS 10

12. REMOVAL, INSTALLATION & CHARGING OF BATTERY 10

13. BEFORE OPERATION 12

14. PREPARING & INSERTING THE FUEL CELL 13

15. PREPARING THE BATTERY 14

16. MAGAZINE ASSEMBLY INSTALL 14

17. TESTING THE NAILER 14

18. LOADING NAILS 16

19. REMOVING THE NAILS 17

20. OPERATING NAILER 17

21. NAIL JAM REMOVAL 18

22. ADJUSTING THE NAILING DEPTH 19

23. USING THE HOOK 19

24. MAINTENANCE & INSPECTION 20

25. TROUBLESHOOTING 22

26. ORDERING INFORMATION 23

27. PROPOSITION 65 23

28. DISCLAIMER 23

ALLFASTENERS.COM | 2

1. IMPORTANT INFORMATION

IMPORTANT INFORMATION TO READ BEFORE OPERATING TOOL

Read and understand tool labels and all operating instructions, safety precautions and warnings in this manual

before operating or maintaining this nailer. Failure to follow warnings could result in DEATH or SERIOUS INJURY.

Most accidents that result from the operation and maintenance of nailers are caused by the failure to observe basic safety rules or

precautions. An accident can often be avoided by recognizing a potentially hazardous situation before it occurs, and by observing

appropriate safety procedures.

Basic safety precautions are outlined in the “2. SAFETY WARNINGS” section of this manual.

NEVER use this nailer for applications other than those specified in this manual.

DEFINITIONS OF SIGNAL WORDS

DANGER indicates an imminent hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury

or may cause machine damage.

NOTE emphasizes essential information.

EXPLANATION OF THE FUNCTION OF THE AF GAS NAILER

This tool has a FULL SEQUENTIAL ACTUATION MECHANISM (on the nailer body marked del operator ). First, press the push lever (push

lever is a part of the full sequential actuation mechanism) against work surface; press nailer down and then pull trigger to drive the nail.

Follow the same sequence to continue driving nails after the push lever and trigger have returned back to their start position.

2. SAFETY WARNINGS

IMPORTANT SAFETY INSTRUCTIONS FOR USING NAILER. READ ALL INSTRUCTIONS BEFORE USE.

This nailer is powered by an internal combustion device and shall only be used with dispensers for combustible gas which

are listed in this manual.

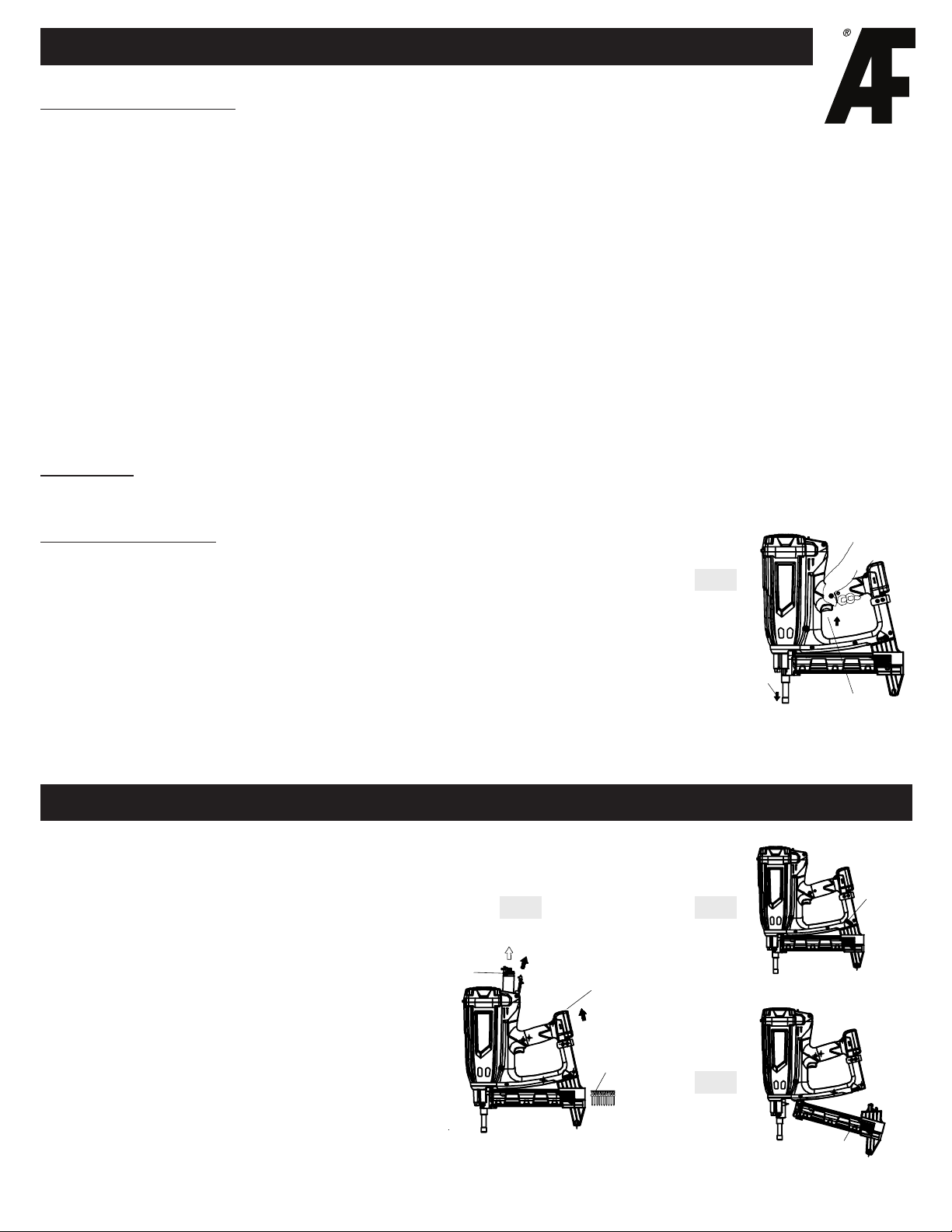

3. DANGER WARNINGS

1. OPERATORS AND OTHERS IN WORK AREA MUST WEAR SAFETY GLASSES WITH SIDE SHIELDS.

When operating the nailer, always wear safety glasses with side shields. Make sure others in work area comply with the

safety precautions and provide protection against flying particles from both the front and back. The employer must enforce

the use of safety glasses by the nailer operator and others in work area.

2. NEVER USE IN PRESENCE OF FLAMMABLE LIQUIDS OR GASES.

This nailer must not be used in a combustible environment or in presence of flammable liquids or gases, e.g. lacquer,

paint, benzine, thinner or gasoline. This nailer produces hot exhaust gases that may ignite and can produce sparks during

operation.

3. DO NOT TOUCH AROUND THE EXHAUST OUTLET.

This nailer produces hot exhaust gases that may be flammable. The push lever and nose will become hot after prolonged or

rapid use. DO NOT touch with bare hands.

4. EXPLOSION AND FIRE HAZARD.

The fuel cell is an aerosol dispenser with flammable contents. Pressured container and propellant will remain in the fuel cell.

Failure to follow instructions may result in explosion or fire.

Explosion and fire hazard continued on page 5.

ALLFASTENERS.COM | 3

3. DANGER WARNINGS (CONT’D)

Keep the nailer, fuel cells and battery away from sunshine and from temperatures exceeding

120°F (50°C). Fuel cell and/or battery may burst, releasing flammable gases if temperature is

too high. DO NOT pierce or burn the container even after use. DO NOT incinerate, refill,

reclaim or recycle the fuel cell cartridge. DO NOT spray near open flame or heat sources.

Keep away from ignition sources. No smoking near materials. Keep out of the reach of children.

120°F

(50°C)

Maximum

4. GENERAL WARNINGS

1. NEVER POINT TOOL AT YOURSELF OR OTHERS IN WORK AREA.

Always assume the nailer contains fasteners. Never point the nailer at yourself or others, whether it contains fasteners

or not. If fasteners are mistakenly driven, it can lead to sever injuries.

2. KEEP FINGERS AWAY FROM TRIGGER WHEN NOT DRIVING FASTENERS TO AVOID ACCIDENTAL FIRING.

To prevent accidental misfire of fastener and injury to yourself or others, never carry the nailer with finger on trigger. Always carry the

nailer by the handle only.

3. ALWAYS WEAR EAR AND HEAD PROTECTION.

Always wear ear protection to further protect from loud noise and ear damage. Always wear head protection to ensure protection

from flying materials or misfire of nailer.

4. USE OUTDOORS OR IN WELL-VENTILATED AREAS.

This nailer should not be used in enclosed or poorly ventilated work areas. This nail creates carbon monoxide exhaust which

is dangerous to health when inhaled. DO NOT inhale.

5. PROPERLY STORE NAILER WITH FUEL CELL AND BATTERY REMOVED.

When not in use, the nailer, fuel cell and battery should be stored by placing pieces individually in tool case. Store case in a dry place,

indoors at temperatures between 41°F (5°C) - 77°F (25°C). Keep the nailer, fuel cell and battery out of direct sunlight and do not leave

in hot vehicle. Keep out of reach of children and lock in storage area when possible.

6. KEEP WORK AREA CLEAN.

Cluttered areas can result in higher risk of injury. Clear all work areas of unnecessary tools, debris, furniture, etc.

7. KEEP UNAUTHORIZED USERS AWAY FROM TOOLS.

Do not let unauthorized users handle nailer, fuel cell or battery. All users must comply with safety requirements and precautions while

operating.

8. DRESS PROPERLY.

Do not wear loose clothing or jewelry as they can be caught in moving parts. Rubber gloves and nonskid footwear are recommended

when working outdoors. Wear protective hair covering to ensure safety against moving parts.

9. CHECK PUSH LEVER BEFORE USE.

Remove fuel cell and battery, and then make sure the push lever operates properly before use. Never use nailer unless the push lever

is operating poorly, otherwise the nailer could drive a fastener unexpectedly. Do not tamper with or remove push lever, otherwise the

push lever may become inoperable or dangerous.

10. KEEP ALL SCREWS AND COVERS TIGHTLY IN PLACE.

Keep all screws and covers tightly mounted and make sure to check their condition periodically. Never use the nailer if parts are

missing or damaged.

11. DO NO LOAD FASTENERS WITH TRIGGER OR PUSH LEVER DEPRESSED.

When loading fasteners in to the nailer 1) DO NOT depress the trigger, 2) DO NOT depress the push lever and 3) Keep the nailer

pointed downward.

12. KEEP FACE, HANDS AND FEET AWAY FROM FIRING HEAD DURING USE.

Never place your face, hands or feet closer than 8 inches (20mm) from the firing head. A serious injury can occur if the fasteners are

deflected by the work surface, or are driven away from the point of entry.

ALLFASTENERS.COM | 4

4. GENERAL WARNINGS (CONT’D)

13. PLACE NAILER PROPERLY ON WORK SURFACE.

Do not drive fasteners on top of other fasteners or with the nailer at too steep of an angle. The fasteners could

ricochet and cause injury.

14. DO NOT DRIVE FASTENERS INTO THIN BOARDS OR NEAR CORNERS AND EDGES OF WORK SURFACE.

By doing so, the fasteners could be driven through or away from the work surface and cause injury to operator or others.

15. NEVER DRIVE FASTENERS FROM BOTH SIDES OF A WALL AT THE SAME TIME.

By doing so, the fasteners could be driven into and through the wall causing injury to operator or others on opposite side of wall.

16. CHECK FOR LIVE WIRES.

Avoid the risk of severe electrical shock by checking for live electrical wires that may be hidden by walls, floors or ceilings. Turn off

the breaker switch to ensure there are no live wires.

17. DO NOT OVERREACH.

Keep proper footing and balance at all times. Do not operate the nailer while on scaffolding or ladders.

18. NEVER USE NAILER WHICH IS DEFECTIVE OR OPERATING ABNORMALLY.

If the nailer appears to be operating abnormally, making strange noises or otherwise appears to be defective, stop using it

immediately and call Allfasteners, LLC. at 1-800-577-3171 for further instructions.

19. TAKE FUEL CELL AND BATTERY OUT OF NAILER WHEN:

1) Doing maintenance and inspection; 2) Clearing a jam; 3) It is not in use; 4) Leaving work area; 5) Moving it to another location;

6) Handing it to another person

Never attempt to clear a jam or repair on the nailer unless you have taken fuel cell and battery out of the nailer as well as removed all

remaining fasteners from tool. The nailer should never be left unattended with people who are not an authorized operator. By doing

so, risk of injury is higher.

20. KEEP ALERT.

Operate the nailer only in good physical and mental state. Do not operate the tool when you are tired, under the influence of

alcohol, drugs or medication that may make you drowsy.

21. HANDLE NAILER CORRECTLY.

Operate the nailer according to this manual. Never allow the tool to be operated by children, individuals unfamiliar with its operations

or unauthorized personnel.

22. NEVER USE THIS TOOL FOR APPLICATIONS OTHER THAN THOSE SPECIFIED IN THIS MANUAL.

See section 11.

23. HANDLE GAS NAILER CAREFULLY.

Do not drop the nailer or strike it against hard surfaces. DO NOT scratch or engrave nailer. Handle tool with care.

24. MAINTAIN NAILER WITH CARE.

Keep the nailer clean and lubricated for more efficient and safe performance.

25. USE ONLY PARTS, ACCESSORIES OR FASTENERS SUPPLIED OR RECOMMENDED BY ALLFASTENERS.

Unauthorized parts, accessories or fasteners may void your warranty and can lead to malfunction or result in injury. If tool requires

service or repair, contact Allfasteners, LLC at 1-800-577-3171 for further instructions.

26. NEVER MODIFY OR ALTER TOOL.

Doing so may cause it to malfunction and personal injuries may occur.

DANGER

FUEL CELL, FUEL AND PROPELLANT ARE FLAMMABLE UNDER PRESSURE.

ALLFASTENERS.COM | 5

5. SAFETY INSTRUCTIONS - FUEL CELL

EXPLOSION / FIRE HAZARD

User must follow all instructions to avoid fire and explosion when handling dispensers with combustible gases. This includes

transportation, storage, disposal and inserting/removing fuel cell in and out of tool.

DO NOT SMOKE WHEN HANDLING FUEL CELL.

WARNING

DO NOT INHALE THE CONTENTS FROM FUEL CELL.

In case of inhalation: person affected should be taken to open air and placed in a comfortable position. If condition does

not improve with fresh air, seek professional medical help immediately.

EXPANDING GASES CAUSE LOW TEMPERATURES. FLUID GASES MIGHT CAUSE INJURIES WHEN IN CONTACT WITH SKIN AND

EYES.

In case of contact with skin: wash the contacted surface carefully with warm water and soap. If condition does not clear or worsens, seek

professional medical help immediately.

In case of contact with eyes: locate work site eye wash station and rinse open eyes with running water. If condition does not improve or

worsens, seek professional medical help immediately.

Store in well-ventilated area.

Store in temperatures between 41°F (5°C) - 77°F (25°C).

Do not store under the direct sunlight or in a vehicle.

Do not expose to an open flame and/or sparks.

Do not refill, reclaim or recycle the fuel cell.

Dispose of according to local regulations for aerosol products. Do not dispose of fuel cell with other scrap or recycling.

Keep out of reach of children.

6. SAFETY INSTRUCTIONS - BATTERY CHARGER

WARNING

DEATH OR SERIOUS BODILY INJURY COULD RESULT FROM IMPROPER OR UNSAFE USE OF BATTERY CHARGERS. TO AVOID

THESE RISKS, FOLLOW THE BASIC SAFETY INSTRUCTIONS BELOW. READ ALL INSTRUCTIONS BEFORE USE.

This manual contains important safety and operating instructions for battery charger included with the AFGN50 ProTrax Nailer.

Before using battery charger, read all instructions and cautionary markings on 1) Nailer, 2) Battery charger and 3) Battery.

To reduce risk of injury, only use rechargeable battery included with the AFGN50 ProTrax Nailer. Other types or brands of batteries

may burst, causing personal injury and damage. If replacement part is needed, contact Allfasteners, LLC at 1-800-577-3171 for

further instructions.

Do not expose battery charger to rain or snow.

Use of any kind of attachment is not recommended. Could result in a risk of fire, electric shock or injury to user.

To reduce risk of damage to electric plug and cord, when disconnecting battery charger, disconnect by pulling on plug not cord.

Make sure cord is placed so that it will not be stepped on, tripped over, or otherwise subjected to damage or stress.

An extension cord should not be used unless absolutely necessary. Use of improper extension cord could result in a risk of fire and

electric shock. If extension cord must be used, make sure that: 1) Blades of extension cord are the same number, size and shape as

those of plug on battery charger; 2) Extension cord is properly wired and in good electrical condition; 3) Wire size is large

enough for AC ampere rating of battery charger as specified in table 1 on page 6.

DO NOT operate battery charger with damaged cord or plug. This should be repaired immediately.

ALLFASTENERS.COM | 6

6. SAFETY INSTRUCTIONS - BATTERY CHARGER (CONT’D)

RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS FOR BATTERY CHARGER

AC INPUT RATING AMPERES AWG SIZE OF CORD

EQUAL TO OR

GREATER THAN BUT LESS THAN

LENGTH OF CORD IN FEET (METER)

2.5 (7.5) 50 (15) 100 (30) 150 (45)

0 2 18 18 18 16

2 3 18 18 16 14

3 4 18 18 16 14

TABLE 1 - RECOMMENDED SIZE OF EXTENSION CORDS FOR BATTERY CHARGER

If the input rating of the battery charger is given in watts rather than amperes, the corresponding ampere rating is to be determined by dividing the wattage

rating by the voltage rating.

For example: 1,200 watts / 120volt - 10 amperes.

DO NOT operate battery charger if it has received a sharp blow, been dropped, or otherwise damaged in any way; take it to a

qualified service technician before use.

DO NOT disassemble battery charger; take it to a qualified service technician when service or repair is required. For further

information, contact Allfasteners, LLC at 1-800-577-3171 for service options. Incorrect reassembly may result in a risk of electric

shock or fire.

To reduce risk of electric shock, unplug charger from receptacle before attempting any maintenance or cleaning. Removing battery

will not reduce this risk.

Please read this manual before using the battery charger.

7. USE OF - BATTERY AND BATTERY CHARGER

YOU MUST CHARGE THE BATTERY BEFORE YOU USE THE NAILER. BEFORE USE OF BATTERY AND BATTERY CHARGER, BE SURE

TO READ ALL INSTRUCTIONS AND CAUTIONARY STATEMENTS IN THE MANUAL.

Remember: Use only battery that is included with the AFGN50 ProTrax Nailer. Other types or brands of battery may burst and cause injury.

WARNING

Improper use of the battery or battery charger can lead to serious injury. To avoid these injuries:

DO NOT disassemble the battery.

DO NOT incinerate the battery, even if it is damaged or completely worn out. The battery can explode when exposed to fire.

DO NOT short-circuit the battery.

DO NOT insert any objects into the battery charger’s air vents. Electric shock or damage to the battery charger may result.

DO NOT charge outdoors. Keep the battery away from direct sunlight and use only where there is low humidity and good ventilation.

DO NOT charge when the temperature is below 50°F (10°C) or above 104°F (40°C).

DO NOT connect two battery chargers together.

DO NOT insert foreign objects into the hole of the battery or the battery charger.

DO NOT use a booster transformer when charging.

DO NOT use an engine generator or DC power to charge.

DO NOT store the battery or battery charger in places where temperatures may reach or exceed 104°F (40°C).

MUST operate charger on standard household electrical power (120 volts). Using the charger on any other voltage may overheat

and damage the charger.

MUST wait at least 15 minutes between charges to avoid overheating the charger.

ALLFASTENERS.COM | 7

7. USE OF - BATTERY AND BATTERY CHARGER (CONT’D)

MUST disconnect the power cord from its receptacle and cut off the charger power when the charger is not in use.

8. DISPOSAL OF THE EXHAUSTED BATTERY

WARNING

DO NOT dispose of the exhausted battery. Incineration of the battery may result in explosion. The product you have

purchased contains a rechargeable battery and IS RECYCLABLE. At the end of its life span, under various state and

local laws, it may be illegal to dispose of this battery into the municipal waste system. Check with your local solid

waste officials for details in your area for recycling options or proper disposal.

EMPLOYER’S RESPONSIBILITY

Ensure that this manual is available to operators and personnel performing maintenance.

Enforce proper safety regulations and ensure that tool is used only when operators and others in work area are wearing

eye and ear protection.

Keep nailer in safe working order and perform maintenance when needed.

Ensure that tool needing repair is not used at any time for work or job site purposes.

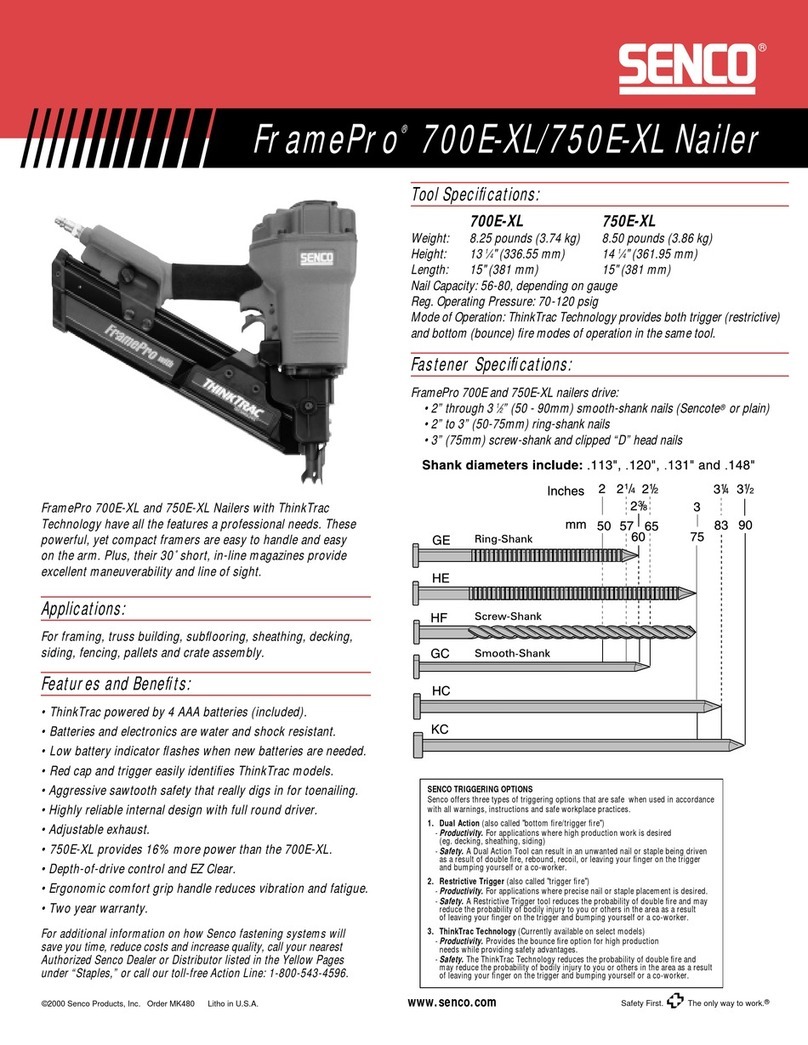

9. SPECIFICATIONS

Type AFGN50 ProTrax Nailer

Type of Power Piston Reciprocating

Applicable Nails See Table 3 Below. “Available Nails”

Nail Capacity 33 Nails (3-Strip)

Ambient Temperature 23°F (-5°C) to 120°F (50°C)

Dimensions 17.24” (L) x 14.55” (H) x 4.80” (W); 438mm (L) x 370mm (H) x 122mm (W)

Weight 9.50lbs. (4.2kg) Including Battery

Cycle Rate 1-2 Nails/Second

Battery Pack Li-on 7.2V

TABLE 2 - GAS CONCRETE NAILER

PLASTIC STRIP NAILS MIN MAX

0.256in (6.5mm) 0.256in (6.5mm)

0.102in (2.6mm) 0.118in (3.0mm)

TABLE 3 - AVAILABLE NAILS (CONT’D ON PAGE 8)

0.59in (15mm)

1.57in (40mm)

ALLFASTENERS.COM | 8

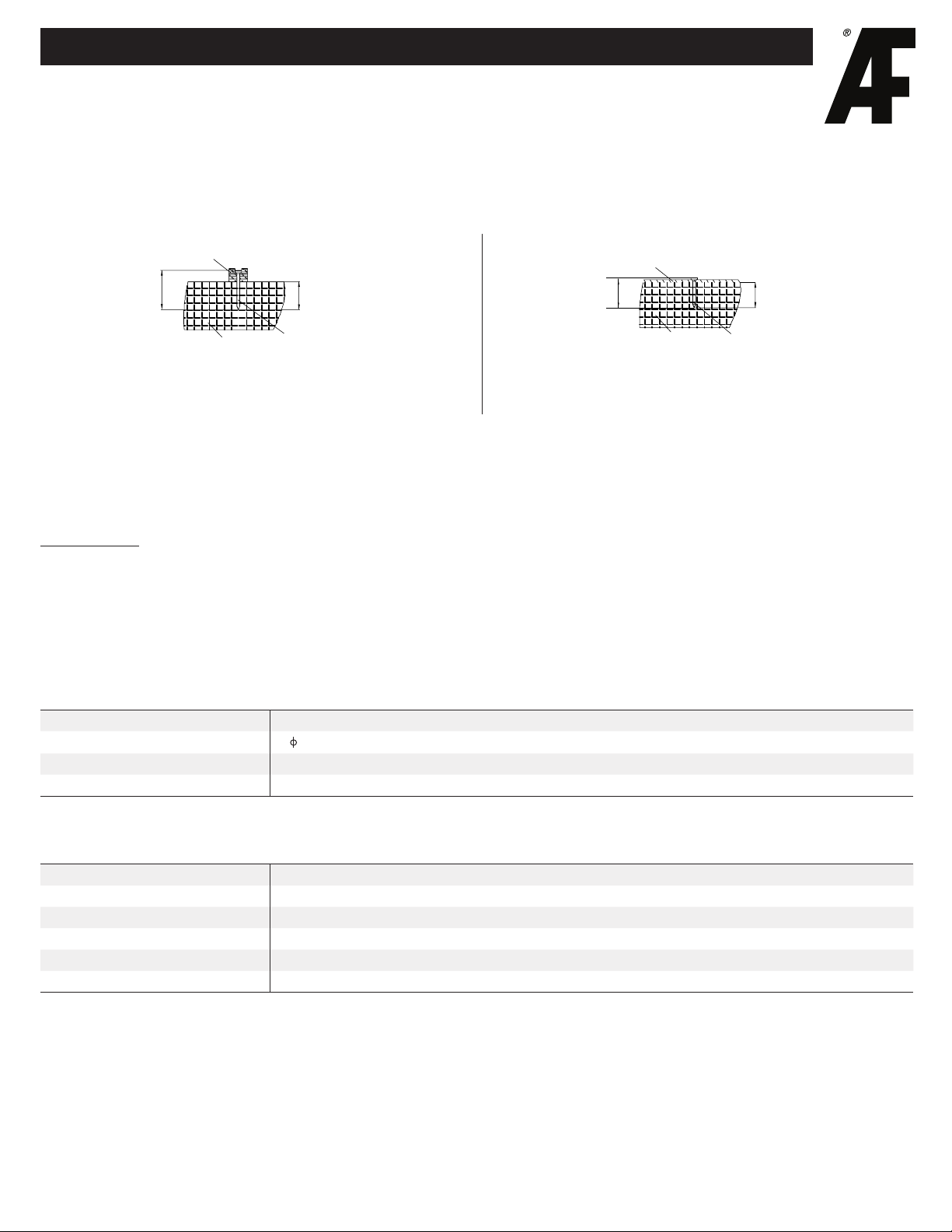

9. SPECIFICATIONS (CONT’D)

wood

suitable length

fire into concrete length

nail length

concrete

sheet steel

suitable length

concrete

nail length

fire into concrete length

WARNING

Be sure to use only Allfasteners branded pins/nails as mentioned in the sizes above. The use of any other nails can

result in tool malfunction or nail breakdown and could cause serious injury. Only nails shown in the table above can

be driven with the AFGN50 ProTrax Nailer. See section 26 for sizes and ordering information.

Fuel Cell/Model Number 1GNF

Size 31.5mm x 154mm

Pressure 16-18 Bar.

Temperature Range 23°F (-5°C) - 120°F (50°C)

TABLE 5 - FUEL CELL

Input Power Source AC110 ~ 240V / 50~60Hz / 0.35A

Charge Time About 2.5hrs

Charging Voltage DC 7.2V

Charging Current DC 0.7A

Charger Weight 0.15Kg

Adapter Weight 0.085Kg

TABLE 6 - CHARGER (INCLUDED WITH 1GN50)

Choose the suitable nail length. Over length nails will cause the nail to bend or nail head immersion

on the work surface.

Nail should be embedded into the concrete by 1/2” to 3/4”.

Add the thickness of the material to be fastened to the concrete embedment to find the correct length nail to use.

Nails through wood into concrete length is 15-20mm .

Nails through sheet steel into concrete length is 12-20mm

(sheet steel thickness not greater than 3mm).

ALLFASTENERS.COM | 9

10. GENERAL OPERATION

NOTE: The information contained in this manual is designed to assist you in the safe operation of the

AFGN50 ProTrax Nailer. Some illustrations in this manual may show details or attachments that differ

than those on your own tool.

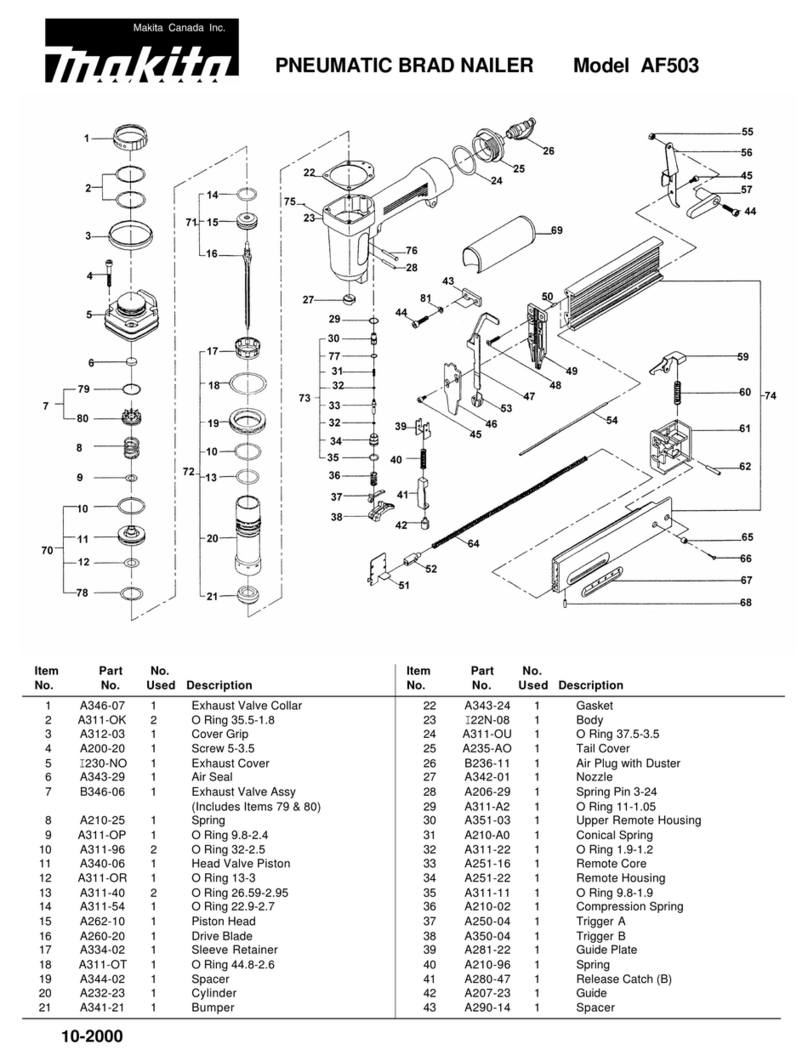

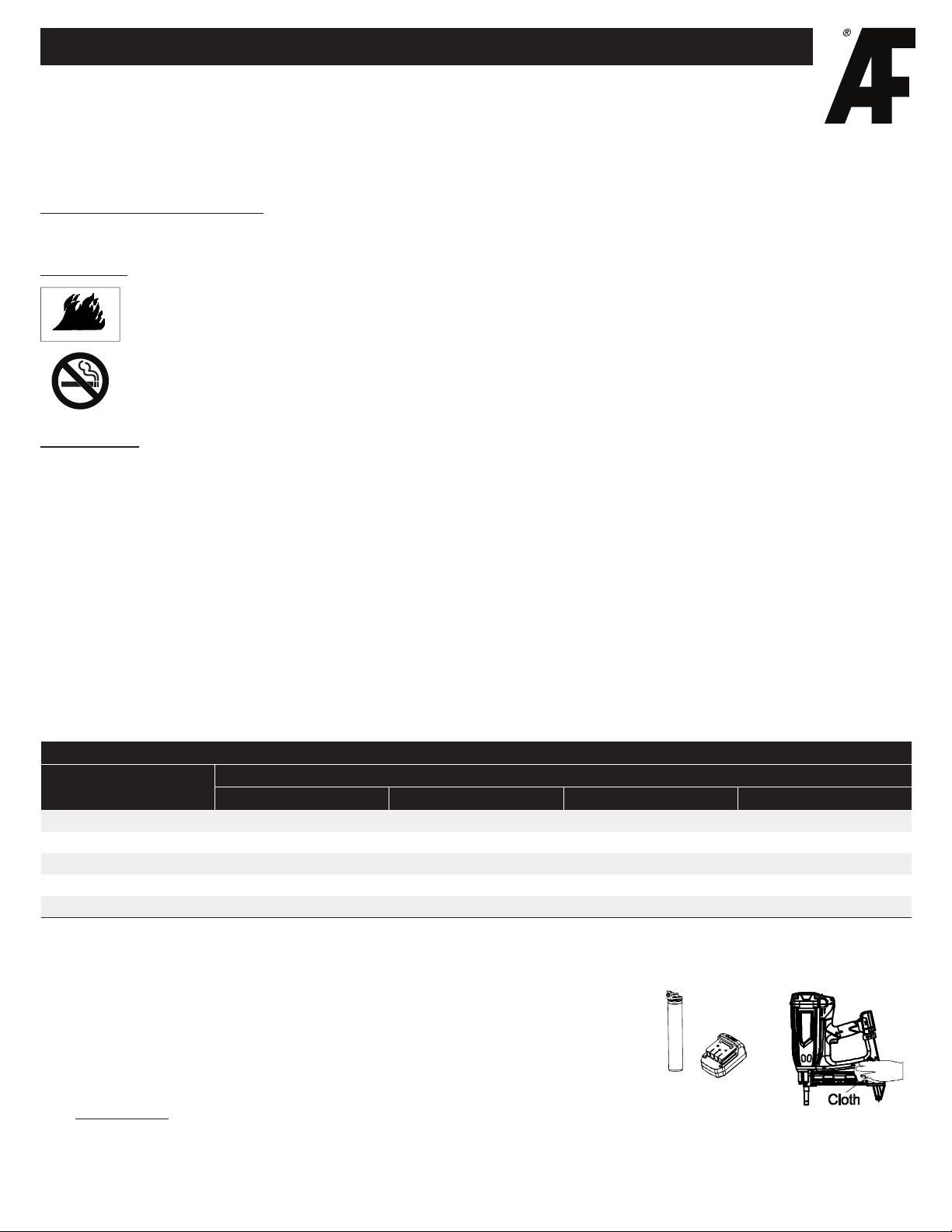

NAME OF PARTS

1. AFGN50 ProTrax Nailer (Part# 1GN50)

2. Battery Pack (Included with 1GN50)

3. Battery Charger - Adapter and Charger Base (Included with 1GN50)

4. Accessories (See Notes for What is Included or Sold Separately)

5. Nail/Pin Options (Sold Separately)

6. Fuel Cell Options (Sold Separately)

Top Cover

Piston

Piston Assembly

Knob

Firing Head Magazine

Lock-Knob

Trigger

Battery Pack

Handle

Fuel Cell

Cell Cover

Latch

Latch

Battery Pack

Charger Base

Pilot Lamp

Battery Installation

Connection Receptacle

Air Vent

Power Cord

Connection Plug

Adapter

Power Plug

1 2

3

ALLFASTENERS.COM | 10

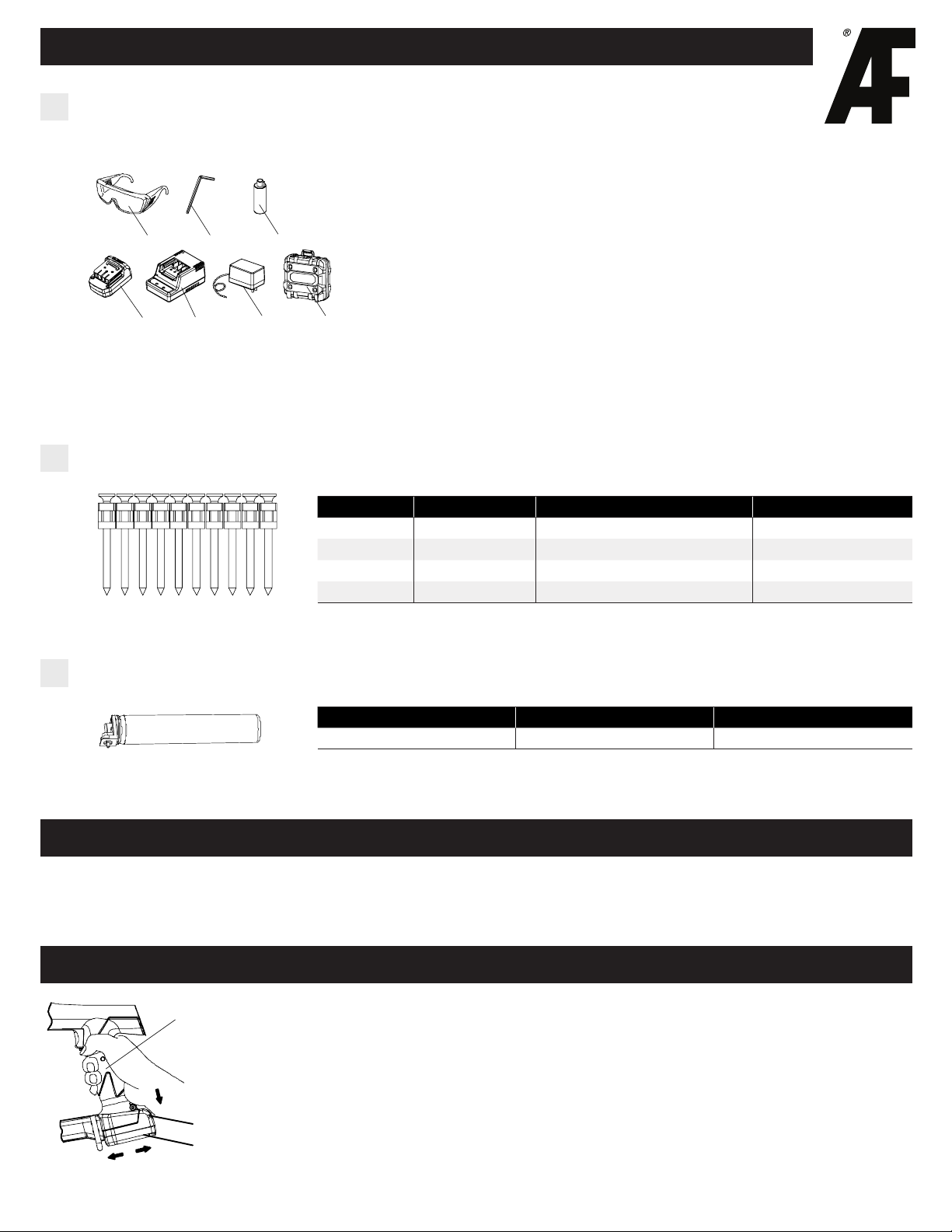

()

4NOTE: Accessories other than those shown below can lead to malfunction and may

result in injury.

A. Safety Glasses

(Sold Separately but Recommended. See AF Part# 13SB140S)

B. Allen Wrench for M5 Screws (Sold Separately)

C. Lubricant Oil (Included with 1GN50)

D. Battery (Included with 1GN50)

E. Battery Charger (Included with 1GN50)

F. Adapter (Included with 1GN50)

G. Case (Included with 1GN50)

H. Cleaner (Optional. Not Pictured. Sold Separately)

5

A B C

D E F G

PART # SIZE DESCRIPTION QTY/BOX

1GN012 1/2 x 0.120 AF Gas Nailer Pins + 1 Fuel Cell 1000/Box + 1 Fuel Cell

1GN034 3/4 x 0.102 AF Gas Nailer Pins + 1 Fuel Cell 1000/Box + 1 Fuel Cell

1GN100 1 x 0.102 AF Gas Nailer Pins + 1 Fuel Cell 1000/Box + 1 Fuel Cell

1GN114 1-1/4 x 0.102 AF Gas Nailer Pins + 1 Fuel Cell 1000/Box + 1 Fuel Cell

Nail/Pin Options (Sold Separately. See AF Part Numbers Listed Below.)

6

PART # DESCRIPTION QTY/BOX

1GNF AF Fuel Cell for 1GN50 10/Box

Fuel Cell Option (Sold Separately. See AF Part Numbers Listed Below.)

11. APPLICATIONS

Suggested applications suitable for connecting substrates and work surfaces: Metal (sheet, section and wire netting, etc.), wood,

engineering plastics, and plywood connecting into concreted, brick and metal plate.

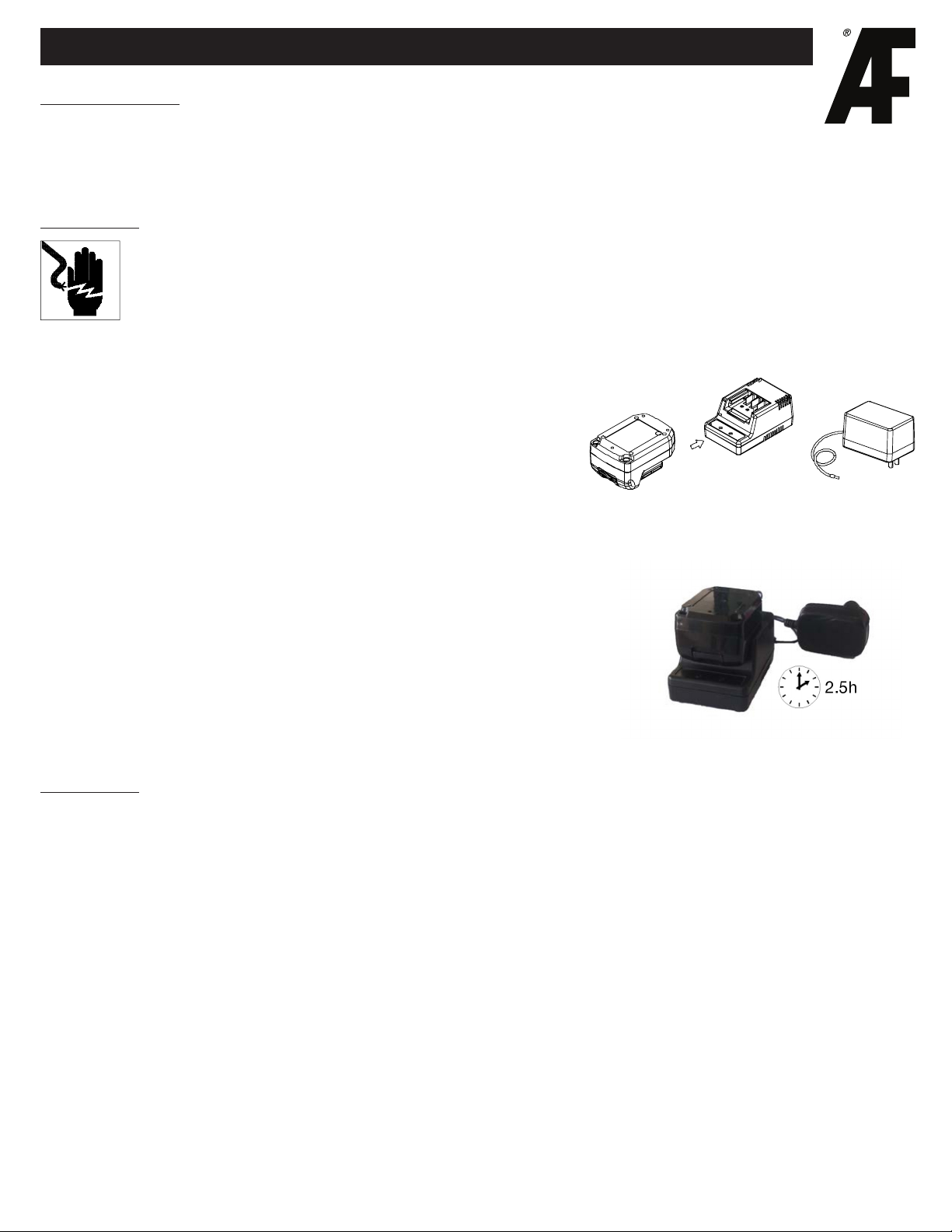

12. REMOVAL, INSTALLATION & CHARGING OF BATTERY

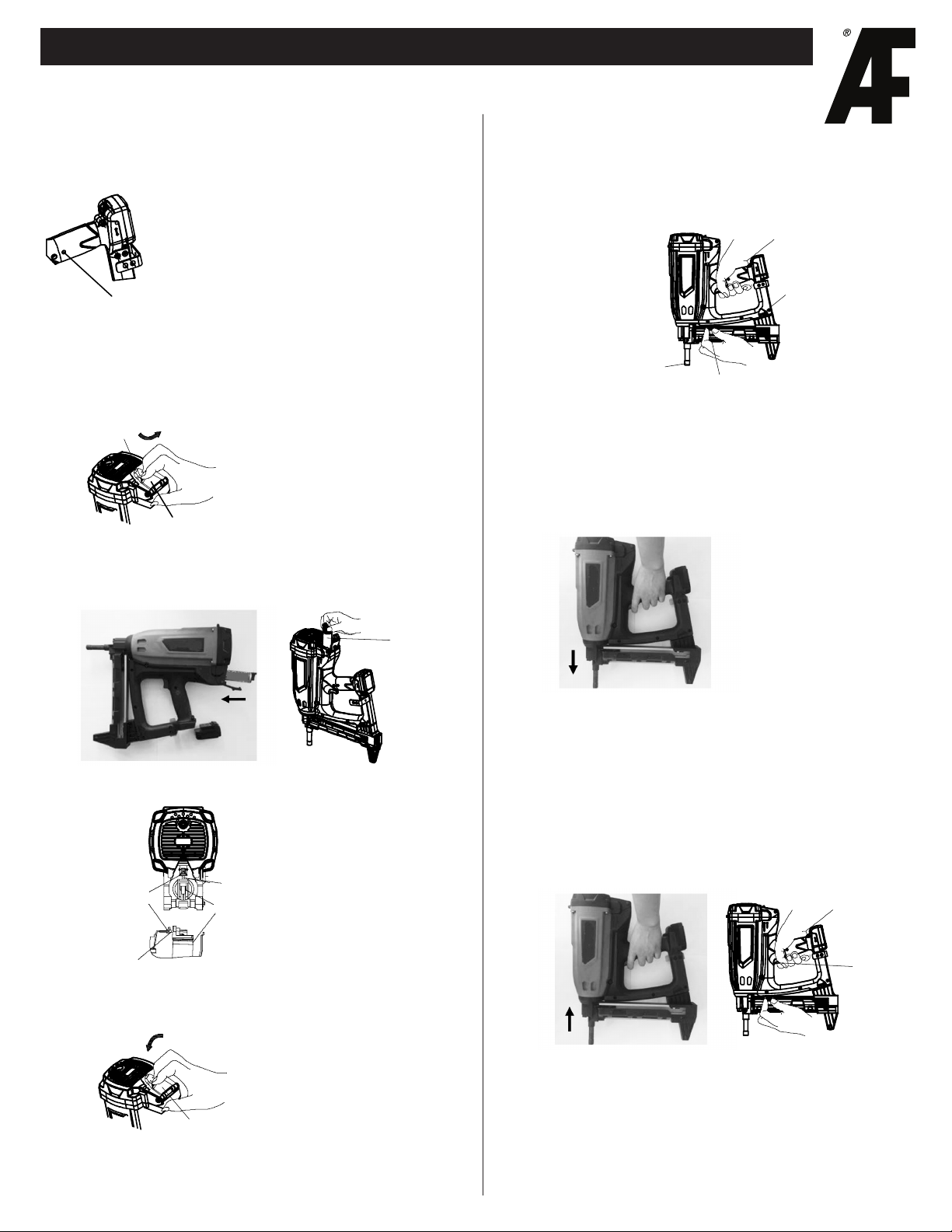

1. How to install the battery: Align the battery with the groove in tool handle and

slip into place. Always insert all the way until it locks in place with a click. If not

inserted properly, it may accidentally fall out of tool, causing injury to operator or

surrounding persons.

2. How to remove the battery: Press the 2 buttons on side of battery and withdraw

battery from tool handle.

Handle

Push Direction

Latch

Battery Pack

Insert Pull Out

10. GENERAL OPERATION (CONT’D)

ALLFASTENERS.COM | 11

() 12. REMOVAL, INSTALLATION & CHARGING OF BATTERY (CONT’D)

CHARGING METHOD

NOTE: Before plugging into the receptacle, make sure the following is reviewed.

The power source voltage requirements is stated on the nameplate.

The cord is not damaged.

WARNING

DO NOT charge at voltage higher than indicated on the name plate. If charged at voltage higher than indicated, the

charger could burn up.

DO NOT use the electrical cord if damaged. Have it repaired immediately.

ONLY use 1GN50 battery and 1GN50 battery charger is only to be used with each other. Do not use other types or

brands of chargers and batteries with 1GN50 products as charger may become inoperable, damaged or battery may

burst.

Steps for charging:

1. Insert the battery into the charger base. Make sure it contacts the bottom of

the charger base.

2. Insert the adapter’s connection plug into the receptacle of the charger base.

3. Insert the adapter’s power plug into the power source.

4. Charging:

When the plug of the charger adapter has been inserted into the power source,

charging will commence and the green pilot light will flicker.

When battery is fully charged, green pilot light will remain on.

Charging takes roughly 120 minutes at 70°F (20°C).

If the pilot light flickers red during charging, this indicates charging failure and

battery should be removed and power source

should be disconnected.

NOTE: The battery charging time becomes longer when temperature is lower or

the voltage of the power source is too low. When the green pilot light does not

come on, even after three hours has passed after the start of charging, contact

Allfasteners, LLC. at 1-800-577-3171 for further instruction.

5. Disconnect battery charger from power source once fully charged.

CAUTION

DO NOT pull the plug out of the power source or out of the charger/adapter by pulling on the cord. Make sure to

grasp adapter plug when removing from receptacle to avoid damaging adapter.

6. Remove the battery from the battery charger. Supporting the charger base the one hand, pull out the battery from the charger base

with the other hand.

Regarding electric discharge in case of new batteries, etc.

As the internal chemical substance of new batteries and batteries that have not been used for an extended period is not activated, the

electric discharge might be low when using the first to second time. This is temporary and normal time required for charging will be

restored by recharging 2-3 times.

How to make the battery perform longer:

DO NOT recharge the batteries after they become completely exhausted. When you find the power pilot light change from green to

red on the nailer handle, stop the operation of the tool and recharge its battery. If you continue to use the nailer and exhaust the

electric current, the battery may become damaged and its life span will become shorter.

Avoid recharging at high temperatures. A rechargeable battery will be hot immediately after use. If a battery at high temperatures is

recharged immediately after use, its internal chemical substance will deteriorate, and the battery life will be shortened. Leave the

battery and recharge it after it has had time to cool.

ALLFASTENERS.COM | 12

() 12. REMOVAL, INSTALLATION & CHARGING OF BATTERY (CONT’D)

13. BEFORE OPERATION

Read section titled “2. SAFETY WARNINGS” and make sure all is reviewed before use.

WORKING ENVIRONMENT

WARNING

No flammable gas, liquid or other flammable objects at work site.

Use outdoor or well-ventilated areas. DO NOT inhale.

Keep the nailer, fuel cell and battery away from sunshine and temperatures exceeding

120°F (50°C).

Keep away from ignition sources. No smoking.

Clear the area of children or unauthorized personnel.

COLD WEATHER CARE

DO NOT store the nailer, fuel cell and battery in a cold weather environment. Keep the nailer, fuel cell and battery in a warm area

until beginning work.

If the nailer, fuel cell and battery are already cold, bring it into a warm area and allow the tool to warm up before use. Observe

temperature and limit maximum 120°F (50°C). DO NOT expose to an open flame and/or sparks.

CAUTION

This nailer may not drive completely when at low temperature and fuel cell loses the required propellant force; or at high

temperatures when the fuel cell can “overdose”.

DO NOT use the nailer in the rain, snow or where excessive moisture is present.

The AFGN50 ProTrax Nailer is not recommended for use at altitudes above 5,000 feet (1,500m) or in temperatures below 23°F (-5°C).

120°F

(50°C)

Maximum

CAUTION

When the battery charger has been continuously used, it will become hot, thus constituting the cause of

failures. Once the charging has been completed, give 15 minutes rest until the next charging.

If the battery is recharged when it is warm (due to battery use or exposure to sunlight), the pilot light may not turn on and

the battery will not be recharged. In such case, let the battery cool before charging.

If the battery charger does not work while the battery is mounted correctly, it is probable that the battery or charger is

malfunctioning. If this occurs, contact Allfasteners, LLC at 1-800-577-3171 for further instruction.

7. Install battery into tool to use.

ALLFASTENERS.COM | 13

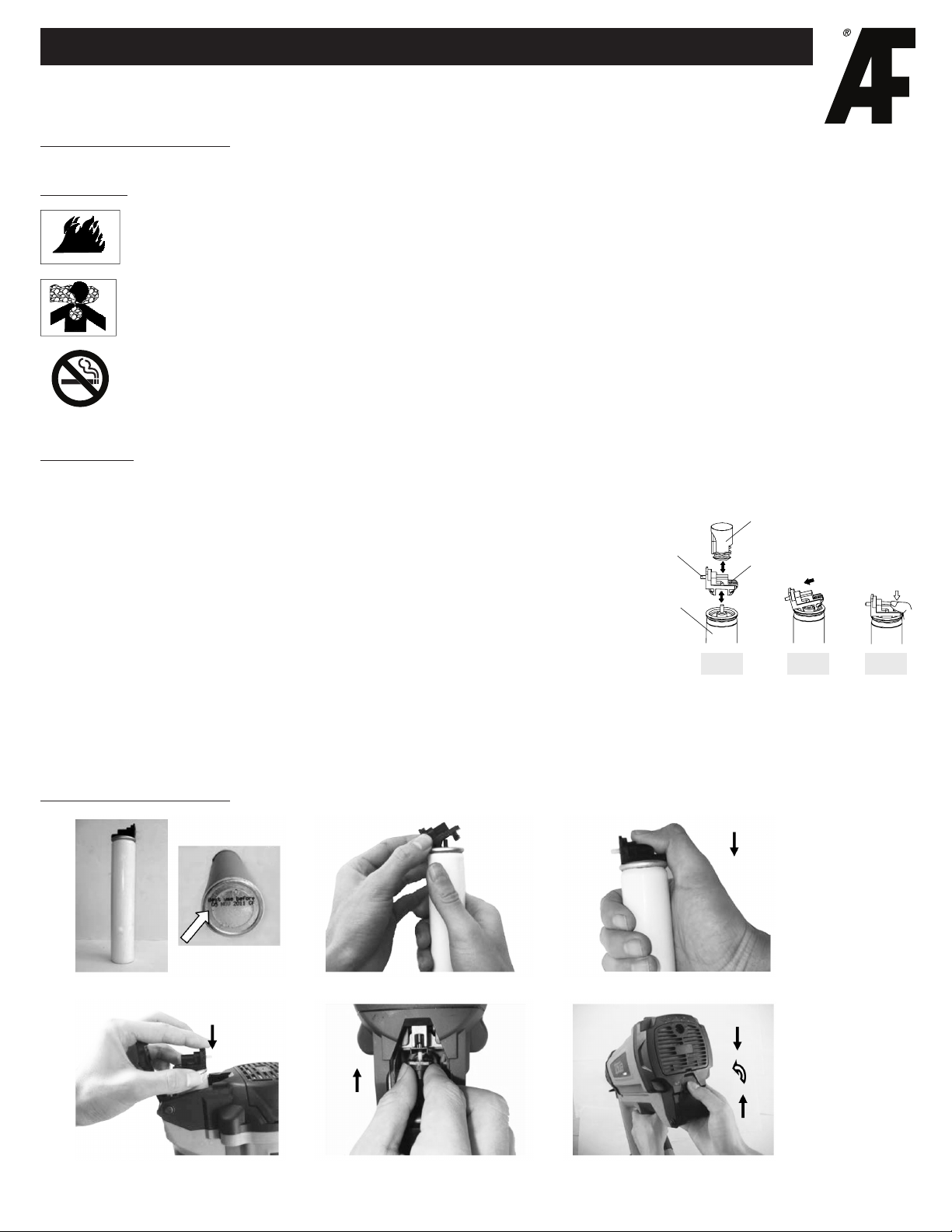

() 14. PREPARING & INSERTING THE FUEL CELL

Read section titled “5. SAFETY INSTRUCTIONS - FUEL CELL” before moving forward.

PREPARING THE FUEL CELL

DANGER

The fuel cell is flammable

Keep away from ignition sources.

DO NOT spray toward an open flame or heat source.

DO NOT smoke when handling fuel cell.

Keep stem of fuel cell away from face and skin. Expanding gases cause low temperatures. DO NOT come in contact

with these gases.

DO NOT inhale.

Keep out of reach of children.

CAUTION

If the gas leaks form the metering valve or the gas cartridge (after attaching the metering valve), replace with a new

metering valve.

DO NOT attempt to reuse the metering valve. Replace with new metering valve.

To attach the metering valve to the fuel cell:

1. Separate the metering valve and the cap from the gas cartridge. (14.1).

2. Stem downward, putting the metering valve incline forward to the

bowl cover. (14.2)

3. Press downward on the rear of the metering valve until it seals with no

gas leakage. (14.3)

4. Check the metering valve: Press the metering valve stem on the fuel cell two or

three times against a stationary object and release. If gas is not dispersed, fuel cell

is empty and replace it.

5. Observe safety regulations. The fuel cell is not ready to insert into the nailer.

INSTALLING THE FUEL CELL

Cap

Stem

Fuel Cell

Metering Valve

14.1 14.2 14.3

ALLFASTENERS.COM | 14

() 15. PREPARING THE BATTERY

Read section titled “6. SAFETY INSTRUCTIONS - BATTERY CHARGER” before moving forward.

You must charge the battery before use. The charging method for the battery is show under “CHARGING METHOD” of the

“12. REMOVAL, INSTALLATION & CHARGING” section of this manual.

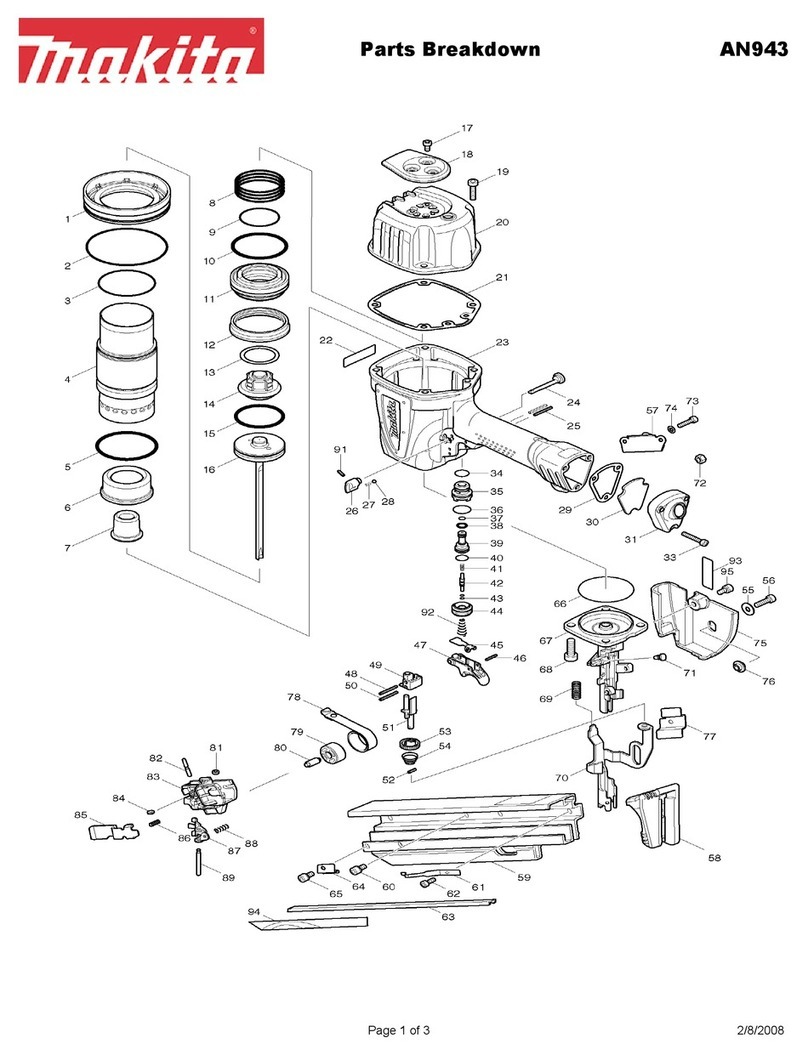

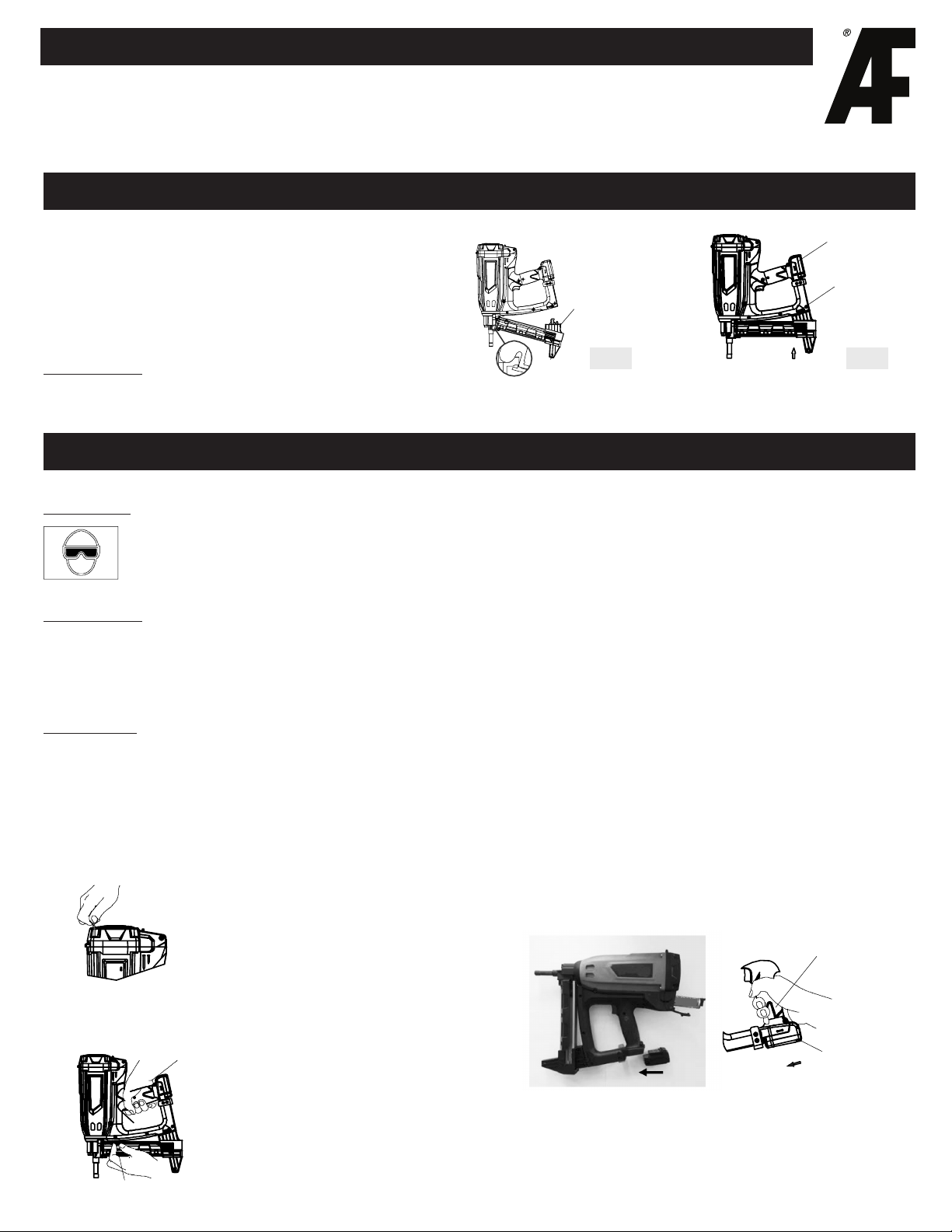

16. MAGAZINE ASSEMBLY INSTALL

1. REMOVE FUEL CELL AND BATTERY FROM NAILER.

2. Fit on magazine assembly. Insert magazine

into the nail seat. See drawing 16.A.

3. Lock magazine into nail seat by turning

the lock knob. See drawing 16.B.

WARNING

Never use the AF Gas Nailer after taking off the magazine.

17. TESTING THE NAILER

DANGER

Operators and others in work area MUST wear safety glasses with side shields that conform to safety

regulation specifications.

WARNING

Never use nailer unless push lever is operating properly.

The machine employs a preventative mechanism for unloading operation.

The machine enters a state where the push lever cannot be pushed up. This takes place when the magazine is not loaded with nails or

when the remaining number of nails becomes less than 2 or 3.

CAUTION

Use caution not to throw the push lever tip onto any object.

Before actually beginning the nailing work, test the nailer by using the checklist located on page 14. Conduct the tests in the following

order. If abnormal operation occurs, stop using the tool and contact Allfasteners, LLC. at 1-800-577-3171 for further instructions.

16.A 16.B

Magazine

Assembly

Lock Magazine

Assembly

Battery Pack

Lock Knob

1. REMOVE FUEL CELL AND BATTERY FROM NAILER.

ALL SCREWS MUST BE TIGHTENED.

THE PUSH LEVER AND TRIGGER MUST MOVE

SMOOTHLY when pulling back the feeder knob.

2. Install the battery. DO NOT operate the push lever or trigger

while installing the battery. Make sure the battery indicator

light is flashing green. If the battery indicator light is flashing

red, the battery does not have enough power and it needs to

be charged.

Trigger

Nail Feeder

Handle

Battery Pack

Insert

ALLFASTENERS.COM | 15

BATTERY INDICATOR LIGHT

Flashing GREEN: Enough power remaining (the light turns

steady during operation). Flashing RED: Insufficient power

remaining (the light turns steady during operation).

3. INSERT FUEL CELL INTO NAILER.

Pull the latch and open the cell cover.

Insert the fuel cell into the nailer.

Insert the stem of fuel cell into the hole of the adapter

Close the cell cover.

Lock up the latch.

4. Remove the finger from the trigger and press the nailer

mouth against the work surface, while pulling backward

on the feeder knob. Motor fan will start.

THE NAILER SHOULD NOT OPERATE.

5. Separate the nailer mouth from the work surface. Next,

point the nailer mouth downward, pull the trigger and

then wait in that position for 5 seconds or longer.

If there is a burst, this means the push lever is not

replacing properly, the cylinder may not have opened

and the nailer is an anomaly.

THE NAILER WILL NOT OPERATE.

6. Depress the nailer mouth against the work surface in

a downward position and pull the trigger.

THE NAILER SHOULD OPERATE.

() 17. TESTING THE NAILER (CONT’D)

Battery Indicator Light

Latch

Cell Cover

Fuel Cell

Fuel Cell

Stem

Stem

Adapter

Cell Cover

Do not Pull the Trigger

Nail Feeder

Depress nailer

mouth against

the work surface

Pull the

Trigger

ALLFASTENERS.COM | 16

() 17. TESTING THE NAILER (CONT’D)

7. If no abnormal operation is observed, you may load nails into the nailer. Drive nails into the work surface that is

the same type to be used in the actual application.

THE NAILER SHOULD OPERATE.

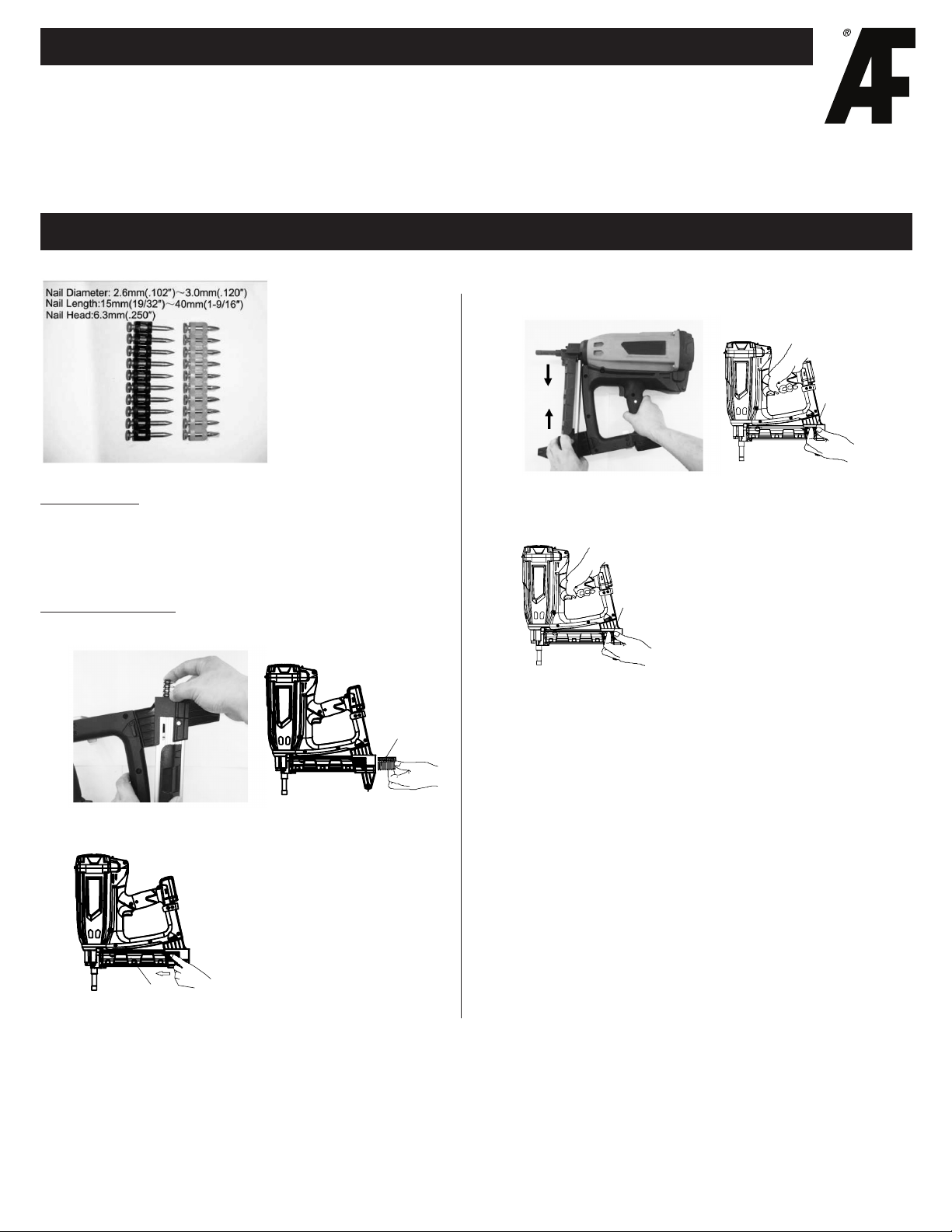

18. LOADING NAILS

WARNING

When loading nails into nailer: 1) DO NOT depress trigger,

2) DO NOT depress nailer mouth and 3) Keep the nailer

pointed downward.

NAIL FEEDING STEP

1. Insert nails into the back of the magazine.

2. Hand slide the nails forward in the magazine.

3. Pull the nail feeder a little past the back of the nails.

Loosen the feeder knob and allow nail feeder to automate

against the nails.

NOTE:

Gently push the feeder knob to bring the nail feeder to the

end of the magazine, loosen the feeder knob and let the

nail feeder slowly move forward against the nail

Use nail strip of more than 4 nails.

The nailer is now ready to operate.

Magazine

Nail Feeder

Plastic

Strip Nails

Nail Feeder

ALLFASTENERS.COM | 17

() 19. REMOVING THE NAILS

1. Pull the feeder knob backward to leave the nails some

distance and press the knob of the nail feed.

The nails will fall back on end of magazine catch location.

2. Using your finger, press the catch and let

the nails drop into the palm of your hand.

Catch

20. OPERATING NAILER

Read section titled “2. SAFETY WARNINGS” before operating tool.

DANGER

Operators and others in work area MUST wear safety glasses with side shields that conform to safety

regulation specifications.

Never use in presence of flammable liquids or gases.

DO NOT touch around the exhaust outlet with bare hands. The push lever and nose will become hot

after prolonged or rapid use.

DO NOT allow the movement of the push and pull lever with hands. This could cause accidental firing

and possible injury.

Explosion and fire hazard. Keep away from sunshine and temperatures exceeding 120°F (50°C).

Keep away from ignition source.

No smoking.

WARNING

NEVER POINT tool at yourself or others in work area.

Keep fingers AWAY from trigger when driving nails to avoid accidental firing or injury.

Use outdoor or well-ventilated work area.

DO NOT inhale its contents.

DO NOT use the electrical cord if damaged. Have it repaired immediately.

Never place your face, hands or feet closer than 8 inches (200mm) from firing head when operating.

DO NOT drive nails on the top of other nails or with nailer at too steep of an angle; nails could ricochet

and cause injury

DO NOT drive fasteners into thin boards or near corners and edges of work surface. By doing so, the

fasteners could be driven through or away from the work surface and cause injury to operator or others.

Never drive fasteners from both sides of a wall at the same time. By doing so, the fasteners could be

driven into and through the wall and cause injury to operator or others on opposite side of wall.

Never use nailer which is defective or operating abnormally.

120°F

(50°C)

Maximum

Nail Feeder

Feeder Knob

Catch

ALLFASTENERS.COM | 18

() 20. OPERATING NAILER (CONT’D)

WARNING (CONT’D)

DO NOT use nailer as hammer.

Disconnect battery and fuel cell from nailer when: 1) It is not in use; 2) Leaving a work area; 3) Moving it to another

location; or 4) Handing it to another person.

Be careful of unwanted fasteners. If the nailer will not operate normally in a temperature below 23°F (-5°C), push lever downward

against the work surface, quick press nailer 2-3 times, pulling trigger. The nails should be driven then. Or use tool after warming in

indoor temperatures for at least 30 minutes.

This nailer is equipped with a FULL SEQUENTIAL ACTUATION MECHANISM. Explanation of FULL SEQUENTIAL ACTUATION

MECHANISM nailing operation is:

First, press the push lever against the work surface.

Next, press nailer downward.

Then, pull the trigger to drive a nail.

The machine employs a preventative mechanism for unloading operation. The machine cannot be pushed up in place. This takes place

when the magazine is not loaded with nails or when the remaining number of nails becomes less than 2 or 3.

CAUTION

Use caution not to press push lever tip against the work surface when the push lever

cannot be pushed up in place.

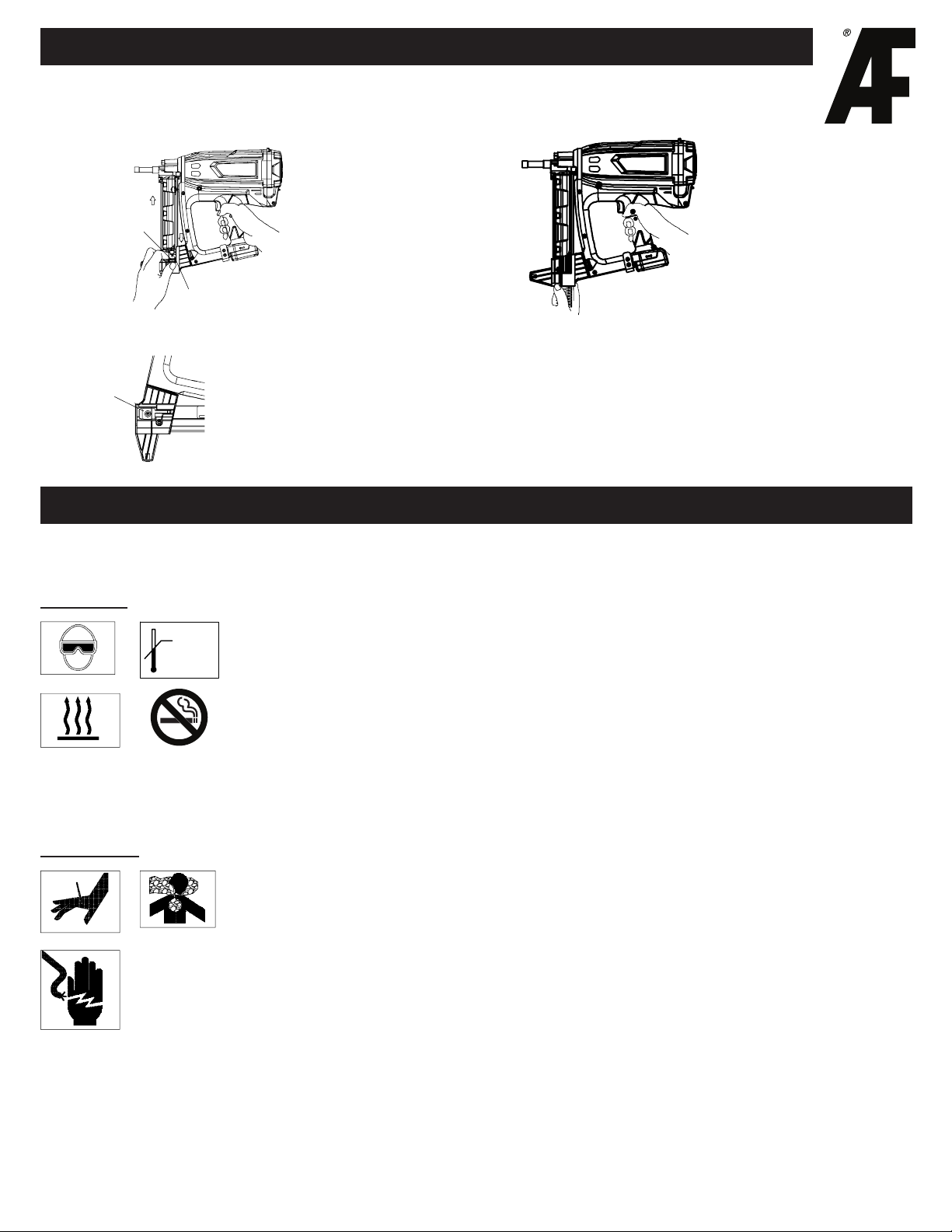

METHODS OF OPERATION

This nailer is equipped with the push lever and does not operate unless the nailer mouth

is depressed upward into the top center position. It is an intermittent operation (trigger fire) only.

See drawing 20.A.

1. Position the nail outlet on the work surface with finger off trigger.

2. Depress the nailer mouth firmly until it is completely depressed.

3. Pull and squeeze the trigger to drive a nail.

4. Remove finger off the trigger.

To continue nailing in a separate location, move the nailer along the work surface, repeating above steps 1-4 as required.

Trigger

nailer mouth

against the

workpiece firmly.

21. NAIL JAM REMOVAL

1. Remove the fuel cell and battery. See drawing 21.A

2. Remove all nails.

3. Turn the lock knob to loosen the magazine.

See drawing 21.B

4. Take off the guard and magazine assembly.

Remove the jammed nails. See drawing 21.C.

5. Lock magazine assembly by turning the lock knob.

See photos on page 19.

Fuel Cell

Battery Pack

Plastic strip nails

Lock Bolt

In the firing process, nail jam malfunction may occur. Remove the nail jam according to the following steps:

21.A 21.B

21.C

20.A

Nailer Mouth

Against the Work

Piece Firmly

Trigger

Fuel Cell

Battery Pack

Plastic

Strip Nails

Lock

Bolt

Magazine Assembly

ALLFASTENERS.COM | 19

() 21. NAIL JAM REMOVAL (CONT’D)

23. USING THE HOOK

CAUTION

Using the hook will allow the operator to hang the nailer on work belt, scaffolding, etc.

This nailer hook can be used on the left or right, side by side mounting as shown

in 23.A and 23.B.

Follow these steps to access and use hook feature:

1. Use accessory wrench (M5) to loosen and pull out two screws.

2. Pull out the hook and reverse insert if needed.

3. Insert the screws and tighten. The screws must be tightened to avoid the hook from falling off and causing damage to the nailer

or injury to user.

If the tool falls, there is a risk of malfunctions or damaged parts can occur. It is recommended that you also use fall preventing wires,

clasps, lanyards, etc.

23.A 23.B

To assure that each nail penetrates the same depth, be sure the nailer is always held firmly

against the work surface. If nails are driven too deep or shallow into the work surface, adjust

the nailing depth by following the steps below.

1. Remove the fuel cell and the battery from the nailer. See drawing 22.A.

2. Turn the nob. See drawing 22.B.

If nail depth is too deep, turn the knob clockwise. If nail depth is too

shallow, turn the knob anticlockwise. See drawing 22.C.

3. Connect the fuel cell and the battery to the nailer.

ALWAYS WEAR SAFETY GLASSES.

4. Perform a nailing test.

22.A

22.B

21.C

Fuel Cell

Battery Pack

Plastic strip nails

Fuel Cell

Battery Pack

Plastic

Strip Nails

Knob

Knob

clockwise

anticlockwise

Knob

Clockwise

Knob

Anticlockwise

22. ADJUSTING THE NAILING DEPTH

ALLFASTENERS.COM | 20

NOTE:

The information contained in this manual is designed to assist you in the safe maintenance of the AFGN50 ProTrax

Nailer.

Some illustrations in this manual may show details or attachments that differ from those on your own nailer.

MAINTENANCE AND INSPECTION

Read section titled “2. SAFETY WARNING” before operating tool.

DANGER

Never use and test in presence of flammable liquids or gases.

Keep away from ignition source

No smoking.

() 24. MAINTENANCE & INSPECTION

WARNING

Remove fuel cell, battery and all nails from nailer when 1) Daily cleaning, 2) Maintenance and inspection or 3) Clearing

a jam.

1. Daily Cleaning

Must regularly clean nailer including removal of the internal accumulation of smears, carbon and dust. This will help ensure the

normal operation of tool and extend nailer working life. Cleaner sold separately.

Follow the AFGN50 ProTrax Tool Cleaning & Maintenance Guide, which include steps and methods to clean the AFGN50 ProTrax

Nailer.

AF Gas Nailer cleaning time intervals depends on the nailer operating environments and the firing quantity of nails per week.

If using in a dirty environment full of debris ad firing large quantities of nails per week, nailer cleaning intervals will be shorter.

Below is the cleaning intervals table for reference. If according to the cleaning time intervals, you still find the nailer is extremely

dirty, the cleaning intervals should be shortened. If you find the nailer is very clean, extend cleaning time intervals.

CLEANING TIME INTERVALS

FIRING QUANTITY PER WEEK

OPERATION ENVIRONMENT

VERY DIRTY DIRTY COMMON CLEAN

1000 1 Week 2 Weeks 1 Month 2 Months

2000 1 Week 2 Weeks 1 Month 1.5 Months

4000 1 Week 2 Weeks 3 Weeks 3 Weeks

6000 1 Week 1 Week 2 Weeks 2 Weeks

8000 1 Week 1 Week 2 Weeks 2 Weeks

NOTE: After completion of each cleaning, user must drip lubricant oil on nailer in places indicated in the AFGN50 ProTrax Nailer Tool Cleaning & Maintenance

Guide. If you have further questions pertaining to the cleaning, operating procedures and methods of the AFGN50 ProTrax Nailer, contact Allfasteners, LLC.

at 1-800-577-3171.

2. Inspecting the magazine.

REMOVE FUEL CELL AND BATTERY.

Clean the magazine. Remove the dust which may have accumulated in the magazine.

Lubricate it with the proper designated lubricant oil (Sold Separately).

CAUTION

Check that the nail feeder slides smoothly by pulling it with your finger. If it does not slide

smoothly, nails can be driven at an irregular angle and cause injury.

This manual suits for next models

1

Table of contents