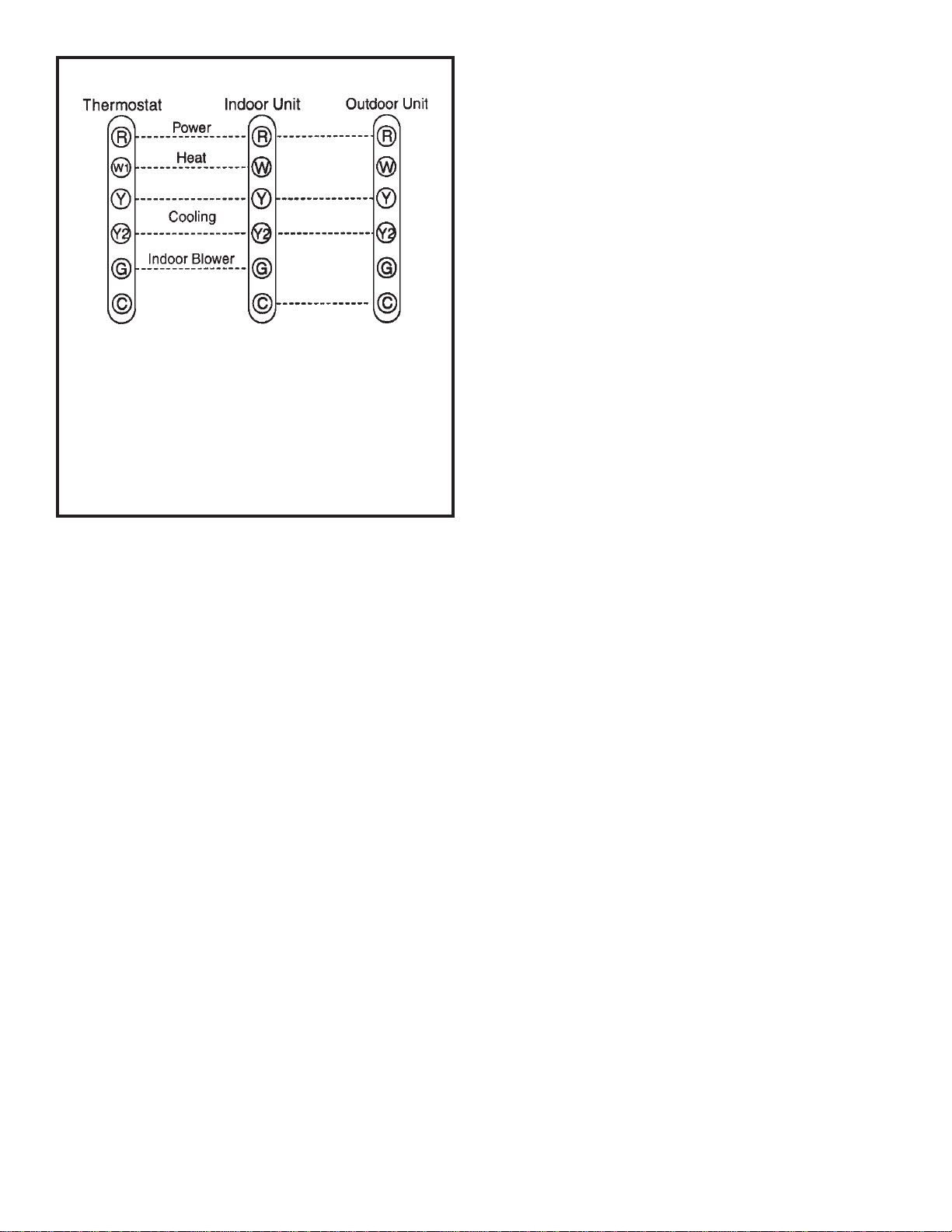

Thermostat Designations

See unit wiring diagram for power supply connections.

If the indoor unit is not equipped with a blower relay, one must

be field supplied and installed.

Do not connect C (common) connection between indoor unit

andthermostatexcept whenrequired bytheindoor thermostat.

Refer to thermostat installation instructions. C (common)

connection between indoor unit and outdoor unit required for

proper operation.

Figure 4

Refrigerant Piping

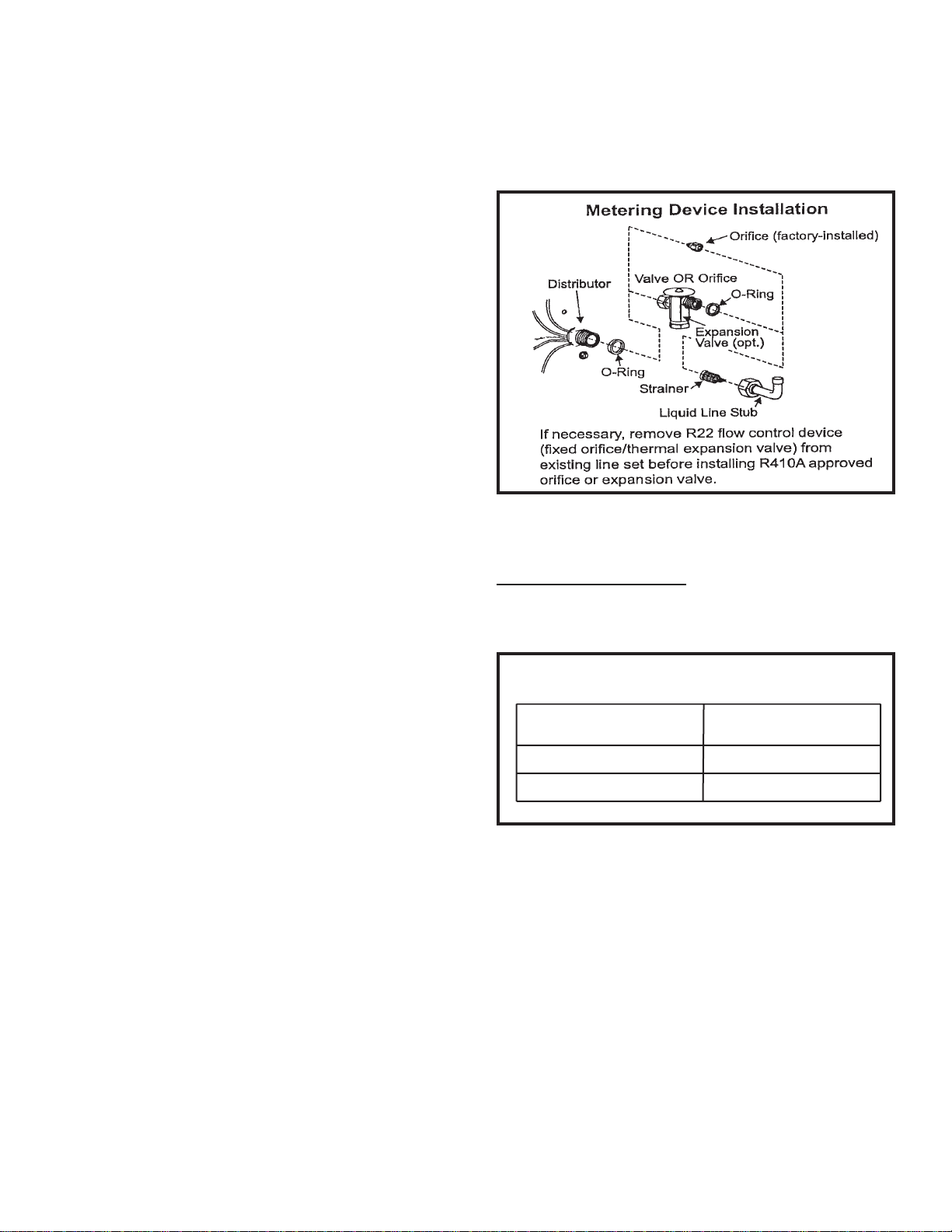

If the 4SCU18LT unit is being installed with a new indoor

coilandline set,the refrigerant connectionsshould bemade

asoutlinedinthis section. If anexistinglineset and/or indoor

coilwill beused tocomplete the system, refer tothis section

as well as the section that follows entitled - Flushing

Existing Line Set and Indoor Coil.

If this unit is being matched with an approved line set or

indoor coil which was previously charged with R-22

refrigerant, the line set and coil must be flushed prior to

installation. Iftheunit is being used withand existingindoor

coilwhich was equipped with a liquid line which served as a

meteringdevice(RFCI),the liquid linemustbereplaced prior

to the installation of the 4SCU18LT unit.

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (sweat connections) to the indoor coil

(flare or sweat connections).

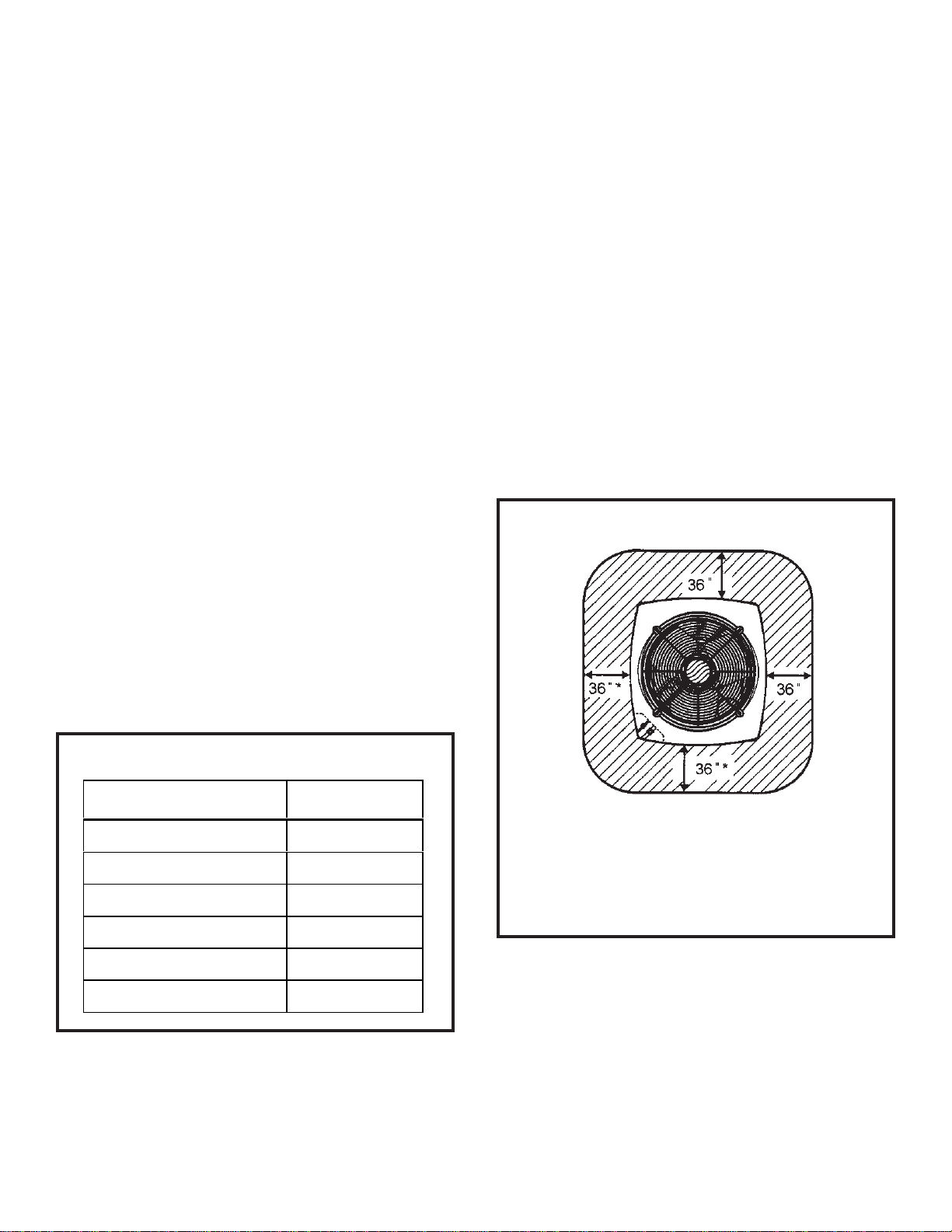

Select line set diameters from Table 2 to ensure that oil

returns to the compressor. Size vertical suction riser to

maintain minimum velocity at minimum capacity.

Recommended line length is 50’ or less. If more than 50’

line set is required, contact Technical Services. Table 2

showsthediameters forline sets upto 100’althoughvertical

lift applications and trapping requirements need to be

reviewed with Technical Services for line sets over 50’.

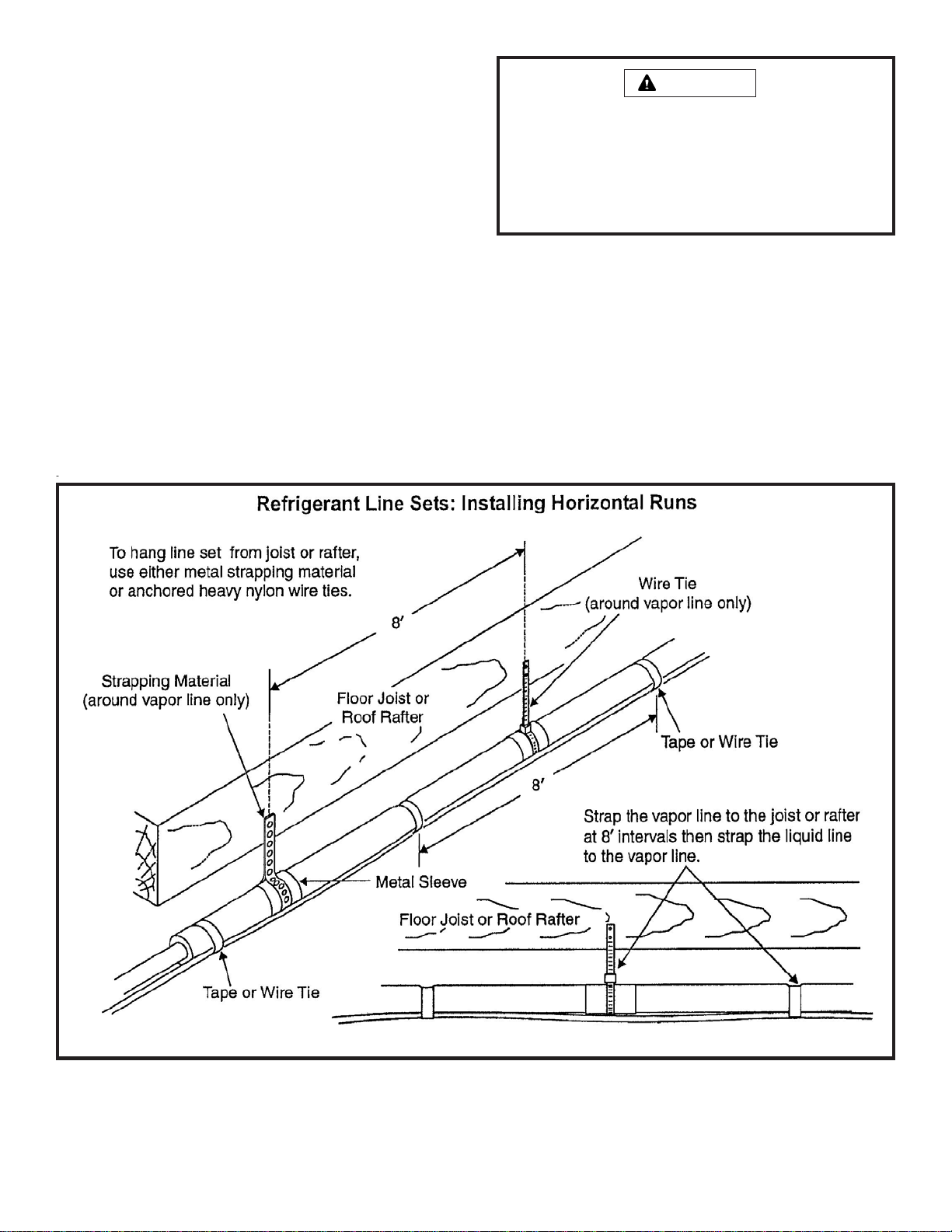

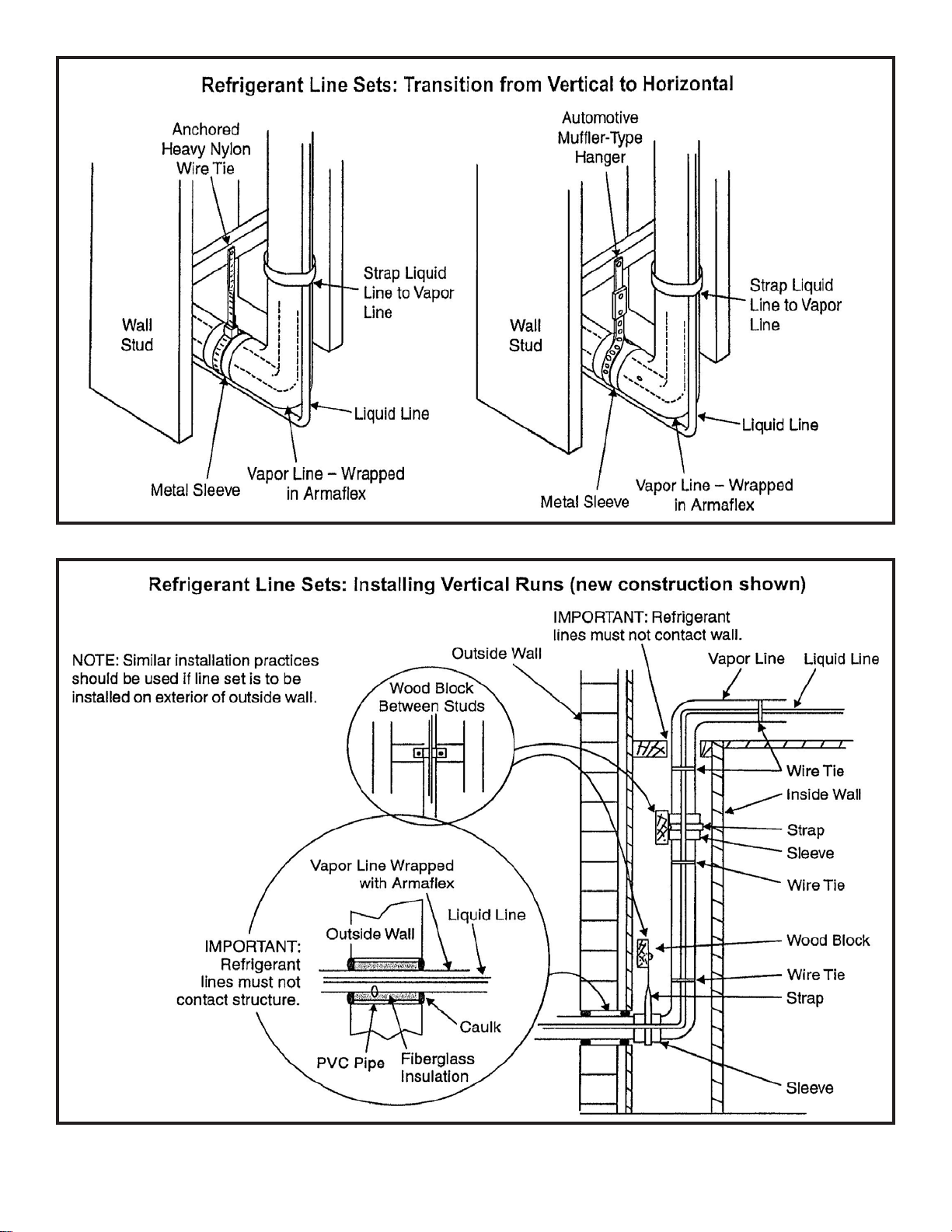

Installing Refrigerant Line

During the installation of an air conditioning system, it is

important to properly isolate the refrigerant line to prevent

unnecessary vibration. Line set contact with the structure

(wall, ceiling, or floor) may cause objectionable noise when

vibration is translated into sound. As a result, more energy

or vibration can be expected. Close attention to line set

isolation must be observed.

Following are some points to consider when placing and

installing a high-efficiency outdoor unit:

1. Install line voltage power supply to unit from a properly

sizeddisconnectswitch. Anyexcesshigh voltagefield wiring

should be trimmed or secured away from the low voltage

field wiring.

2.Groundunitatunitdisconnectswitchortoanearthground.

To facilitate conduit, a hole is in the bottom of the control

box. Connect conduit to the control box using a proper

conduit fitting. Units are approved for use only with copper

conductors. 24V Class II circuit connections are made in

the low voltage junction box. Refer to Figure 4 for high

voltagefield wiring diagram. Acomplete unit wiring diagram

is located inside the unit control box cover.

3.Installroomthermostaton an insidewall that isnotsubject

to drafts, direct sunshine, or other heat sources.

4. Install low voltage wiring from outdoor to indoor unit and

from thermostat to indoor unit (See Figure 5).

5. Do not bundle any excess 24V control wire inside control

box. Run control wire through installed wire tie and tighten

wire tie to provide low voltage strain relief and to maintain

seperation of field-installed low and high voltage circuits.

506254-01 Page 4 of 25Issue 0912