The following safety precautions must be taken when using your air

conditioner.

SAFETY PRECAUTIONS

1. Warning: Prior to repair, disconnect thepower cord.

2. Use properparts: use onlyexact replacement parts.(Also, we recommend replacing parts rather

than repairing them.)

3. Use theproper tools: use the proper toolsand test equipment, and know howto use them. Using

defective tools ortest equipment may cause problems later-intermittentcontact, for example.

4. Power cord:prior to repair, check the power cord andreplace it if necessary.

5. Avoid using anextension cord, andavoid tapping intoa power cord.This practice may result in

malfunction or fire.

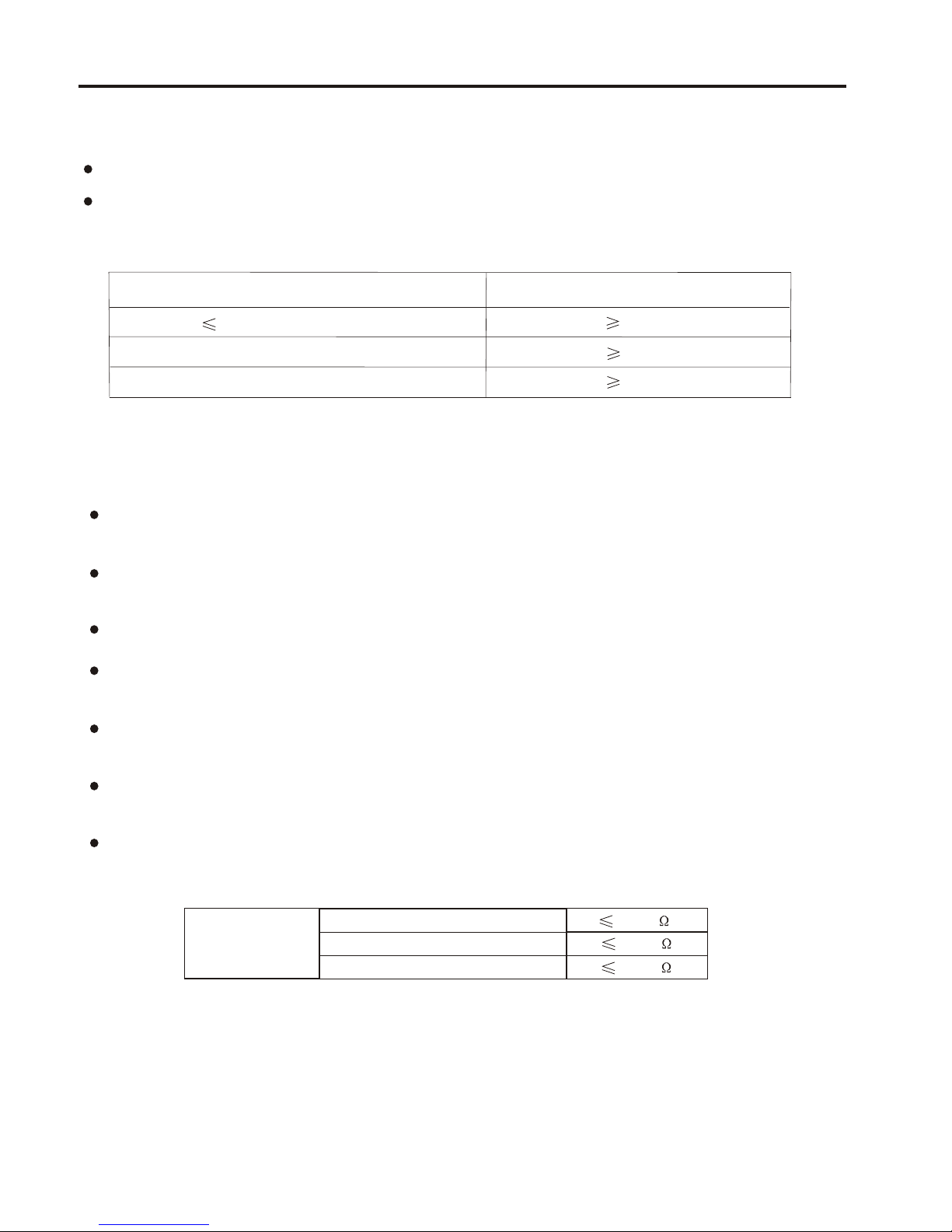

6. Aftercompleting repairs and reassembly, check the insulation resistance.

Procedure: prior toapplying power, measure the resistancebetween the power cord and theground

terminal. The resistance must be greater than 30megohms.

7. Make surethat the grounds are adequate.

8. Make surethat the installation conditions are satisfactory. Relocate the unit if necessary.

9. Keep childrenaway from the unit while itis being repaired.

10. Be sureto clean the unit and itssurrounding area.

1

2

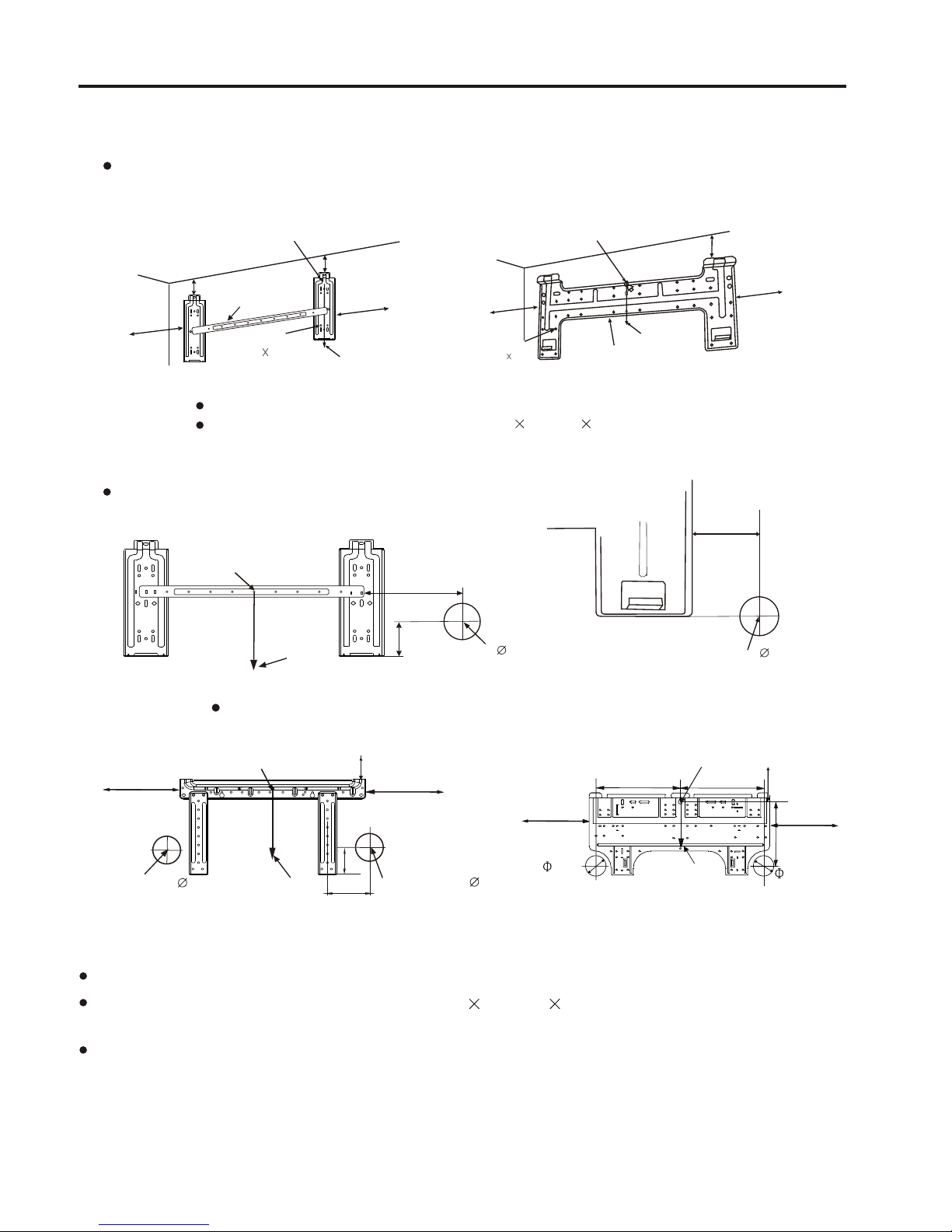

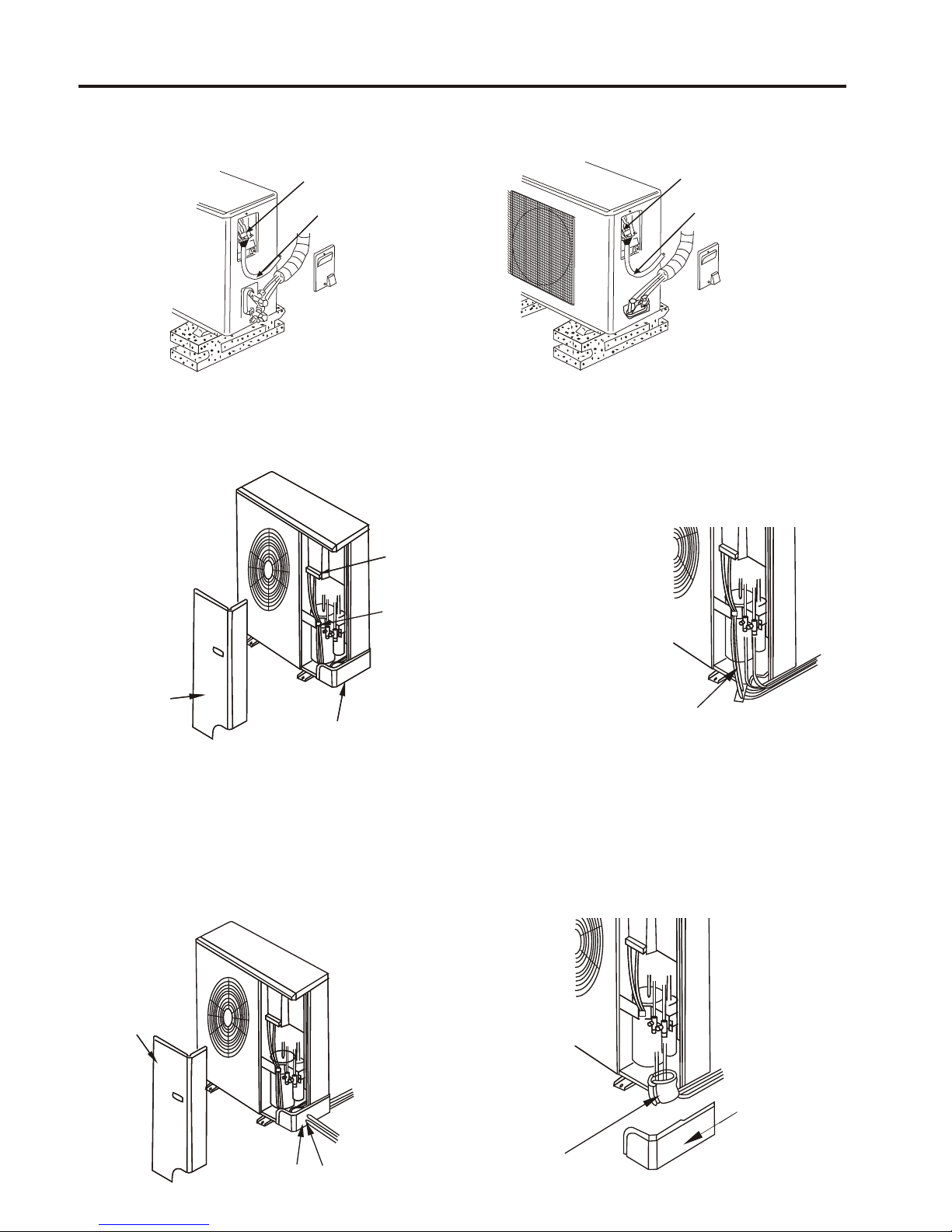

Location of indoor unit

A place solid enough to bear the weight of the unit and not cause any shake.

Good ventilation, less dust, far from direct rain and sunshine.

Avoid places close to inflammable gas leakage.

Keep the air inlet and outlet at a far distance from the blockage.

Keep the height distance between the indoor and outdoor unit at most 5m.

Mount on the wall solid enough to bear the weight of the unit and not cause any shake.

Avoid direct sunshine.

A place easy for condensate drain and easy for connecting with the outdoor unit.

Keep a far distance away from the fluorescent lamp, it may influence the operation of remote controller.

Location of outdoor unit

Keep at least 1m away from the TV radio and other home appliances.

A place where the air discharged out of the outdoor unit or the operation noise will not annoy your

neighbours.

No blockage near the outdoor unit.

Avoid places close to inflammable gas leakage.

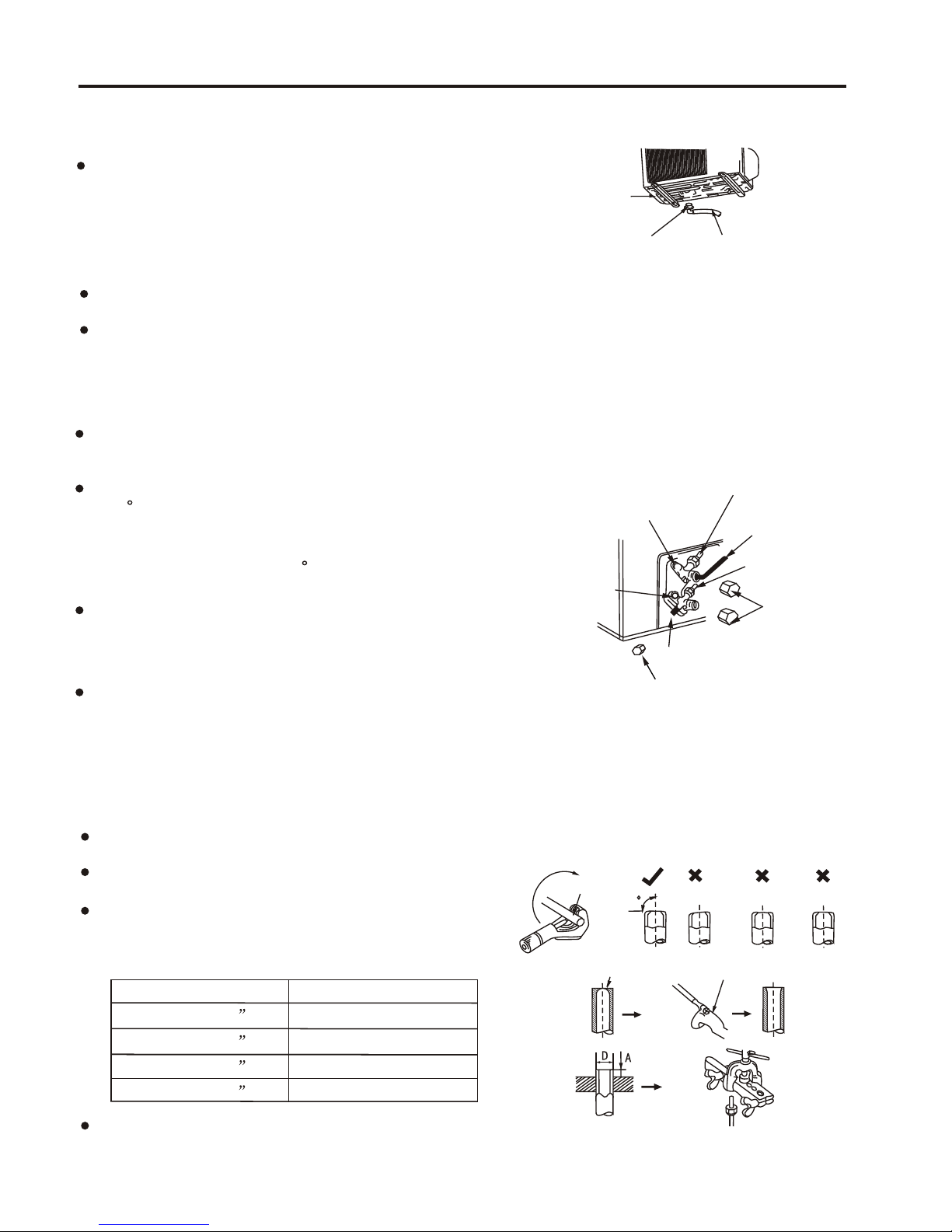

Selecting area for installation

INSTALLATION

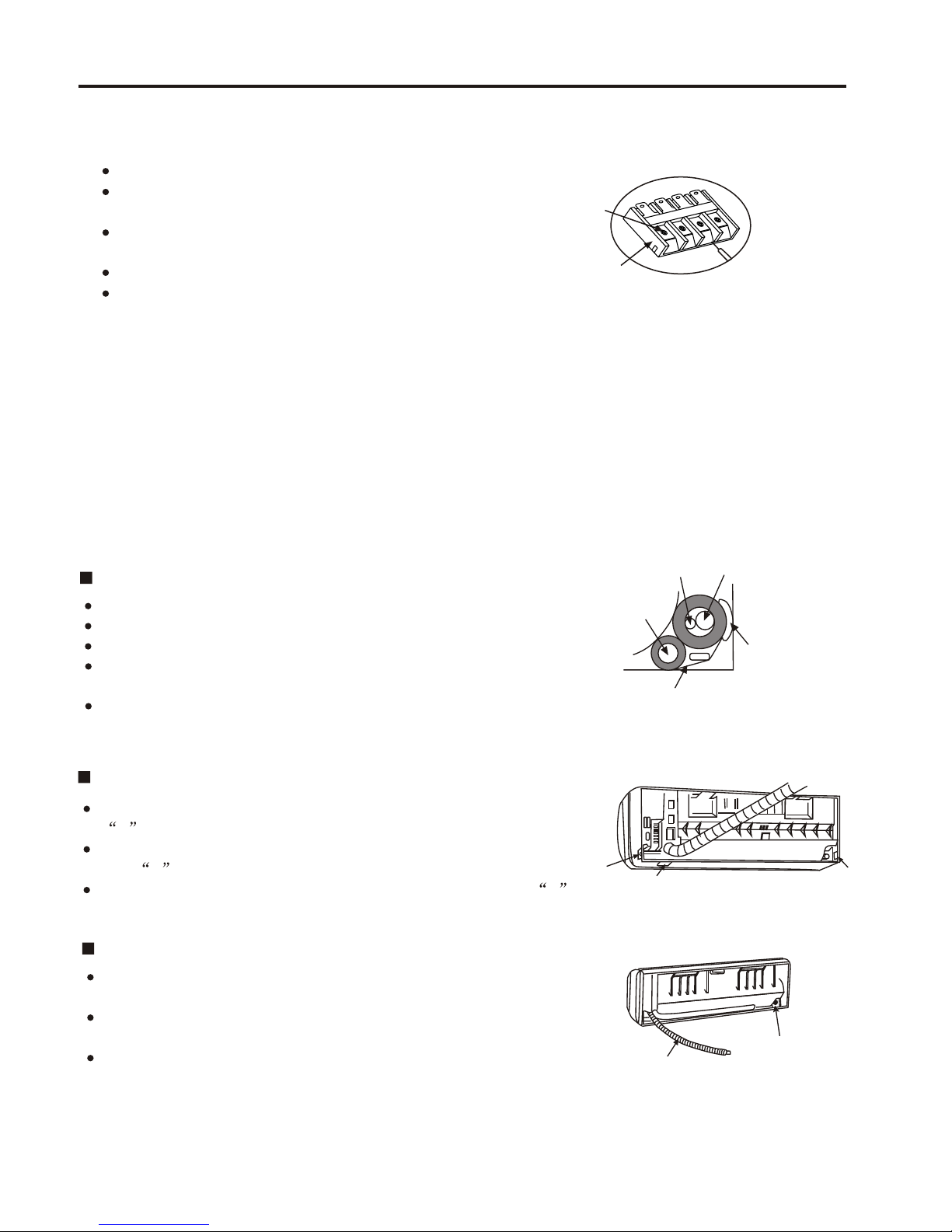

Select an area for installation that is suitable to the customer’s needs.

It is harmful to the air conditioner if it is used in the following environments: greasy areas (including area

near machines). Salty area such as coastal areas, areas where sulfuric gas is present such as hot spring

areas. Contact your dealer for advice.

Caution:

2