Allmand Maxi-Air MA375-DP T4F User manual

Not for

Reproduction

™

Copyright © 2019 Allmand Bros., Inc.

Holdrege, NE, USA. All rights reserved.

116028

Revision B

Operator’s Manual

Maxi-Air

Towable Compressor

Models MA375-DP T4F, MA400 T4F

en

Not for

Reproduction

2 ALLMAND.COM

Thank you for purchasing this quality-built Allmand™ towable compressor. We are pleased that you’ve placed

your confidence in the Allmand brand. When operated and maintained according to the instructions in this manual,

your Allmand compressor will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with towable

compressors and how to avoid them. Because Allmand does not necessarily know all the applications this towable

compressor could be used for, it is important that you read and understand these instructions thoroughly before

attempting to start or operate this equipment. Save these original instructions for future reference.

Where to Find Us

If you have any questions about the machine, contact your authorized dealer. You can also contact Allmand

Customer Service by phone at (800) 562-1373, or on the Internet at allmand.com.

Knowing the model number of your Allmand towable compressor will make it easy to order maintenance or repair

parts either online or from your local dealer. The model number is generally a number stamped into metal or on a

sticker directly on your product.

Towable Compressor Engine

Model Number _____________________ Model Number ______________________

Revision __________________________ Type Number _______________________

Serial Number ______________________ Code Number _______________________

Date Purchased ___________________

Not for

Reproduction

3

Table of Contents

Operator Safety....................... 4

Features and Controls ................ 11

Set-Up and Installation................ 15

Operation........................... 20

Troubleshooting ..................... 48

Maintenance ........................ 53

Storage and Disposal................. 69

Specifications ....................... 70

Operation Log ....................... 81

Noise Emission ...................... 82

Addendum A - Unit Options............ 86

Not for

Reproduction

4 ALLMAND.COM

Operator Safety

Operator Safety

S-1

This section explains safety cautions for safety work for operation, inspection, maintenance, installation,

movement and transportation. Read these safety requirements carefully and fully understand the contents

before starting the machine.

For your better understanding of the precautions in this manual and on this machine, safety precautions are

classified into “DANGER”, “WARNING” and “CAUTION” message with a warning symbol marked,

according to the degree of hazards.

When one of these messages is found, please take preventative safety measures and carry out “SAFETY

OPERATION AND PROPER MAINTENANCE OF THE MACHINE”.

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe

practices.

IMPORTANT indicates important messages for the performance or durability of the

machine, but will not result in injury.

This manual does not describe all safety items. We, therefore, advise you to pay special attention to all items

(even though they may not be described in the manual) for your safety.

PROPOSITION 65 WARNING

Breathing diesel engine exhaust exposes you to chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

Always start and operate the engine in a well-ventilated area.

If in an enclosed area, vent the exhaust system to the outside.

Do not modify or tamper with the exhaust system.

Do not idle the engine except as necessary

For more information, go to www.P65warnings.ca.gov/diesel

Not for

Reproduction

5

WARNING

Contact with the output terminals and control board

could cause electric shock, resulting in death or

serious injury. Do not open the cover of the output

terminal board during machine operation.

When removing or connecting a connecting cable

for changing load, be sure to switch OFF the circuit

breaker, remove the starter key from the starter

switch, then perform work.

WARNING Contact with rotating parts or

could cause death or serious injury. Keep hands

while machine is in

WARNING Do not open radiator

after operation. Explosive

could cause severe burns,

WARNING Do not touch hot parts.

Never work nearby hot portions of the machine while

it is running.

Parts such as engine, exhaust manifold, exhaust

pipe, muffler and radiator are especially hot. Never

touch these parts, as it could result in serious burns.

Coolant water and engine oil are also very hot and

dangerous to touch. Do not check or add while

machine is running.

WARNING Fire prevention.

Fuel and oils are extremely flammable. Do not bring

ignition sorces near machine when checking or

adding fuel and oils.

Adding fuel and oils should be done outdoors or in a

well-ventilated location.

Refuel after stopping engine, and never leave

fuel near machine. Do not spill. If spilled, wipe up

completely.

Do not fill fuel oil up to cap level. Fuel oil will overflow

due to volume expansion caused by rise of ambient

temperature. Fuel can also spill during machine

movement or transporting.

Parts such as muffler and exhaust pipe can be

extremely hot. Remove twigs, dried leaves, dried

grass, waste paper, etc. from around muffler and

exhaust pipe.

Keep a fire extinguisher available by machine in case

of fire.

WARNING Hang a “Now Checking and under

tag:

Remove starter key from starter switch before

starting inspection, and hang up a “Now Checking

and under Maintenance” tag where it can be easily

Operator Safety

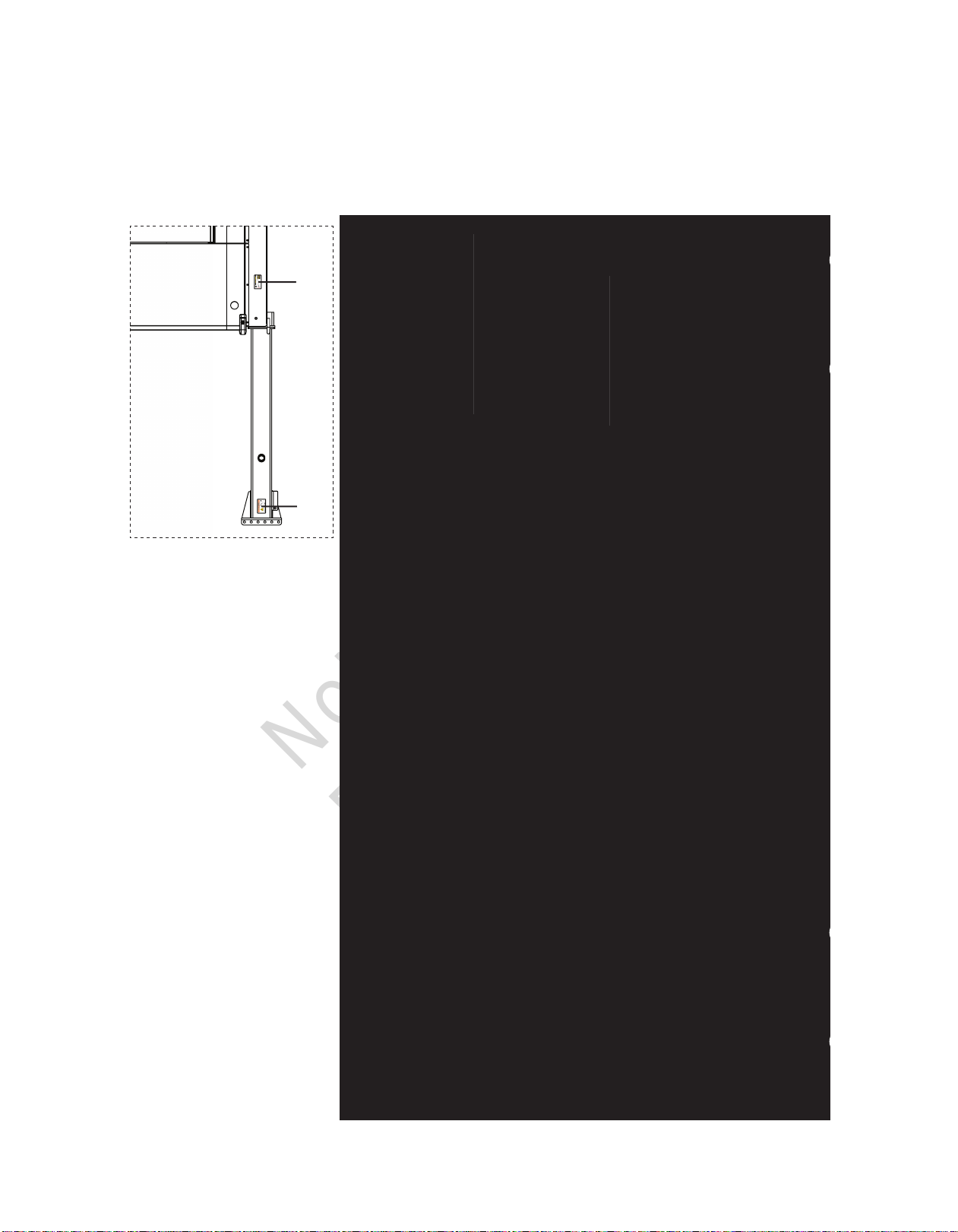

S-2

Please indicate the MODEL / SER.No. on the plate of the machine when making inquiries.

A plate stamped with the model and serial number is attached to the side of the machine.

Each illustrated figure (Fig.) has a number

(for instance, A130375) at the right bottom.

This number is not a part number, but it is used only for

our reference number.

A130375

A VIN plate is also located on the left side of the machine.

Not for

Reproduction

6 ALLMAND.COM

Operator Safety

S-3

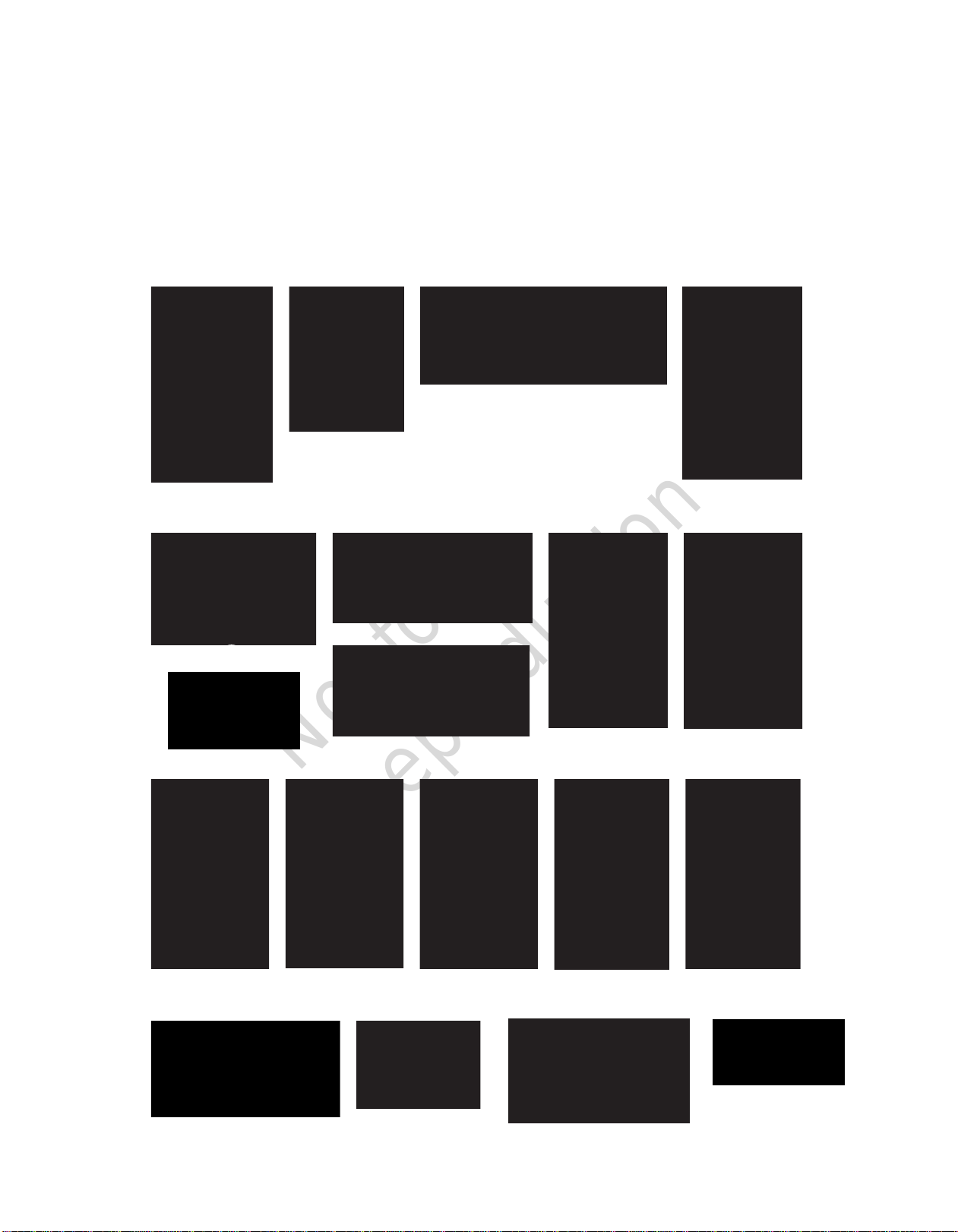

Safety Warning Labels

The following safety warning labels are attached to the machine. If damaged or missing, contact your

dealer for replacements.

A

BCD

E

F H I

J K LM N

O

P

G

R

Q

E1

Not for

Reproduction

7

Operator Safety

S-4

Location of safety warning labels

A180276E

G

F

E

BC D

L

M

N

O

H

I

A

P

Receiver tank portion sticking position

Shroud portion sticking positi

on

K

J

Operator Safety

S-4

Location of safety warning labels

A180276E

G F E

B C D

L

M

N

O

H

I

A

P

Receiver tank portion sticking position

Shroud portion sticking positi

on

K

J

R

Q

E1 E1 E1 E1

Not for

Reproduction

8 ALLMAND.COM

Operator Safety

S-5

Compressed air from this machine contains poisonous

materials. Absorption of the compressed air can cause

serious injury. Never provide this compressed air for human

respiration.

This machine is not designed to be used for working

chambers pressurized by compressed air such as

respiratory air provided to persons working inside wells and

tunnels such as pneumatic engineering method and

pneumatic caisson method. Should this machine stop

operation due to trouble, it can cause death and serous

injury to the working persons. Refrain from using the

compressed air for such pneumatic engineering method or

pneumatic caisson method.

Read each instruction plate which is displayed in the

manual or on the machine carefully, understand its content

and follow the indications thereof.

Do not modify the machine without prior approval. The

safety may be compromised, functions may be

deteriorated, or the machine life may be shortened.

Never use the machine for the purpose of compression of

gases other than air, or as a vacuum pump. Otherwise,

serious accidents may occur.

Never blow compressed air directly at people. Scattered

impurities, dust, or foreign objects in the compressed air

may cause skin and eyes to be seriously injured.

As compressed air contains toxic gas etc., compressed air

should not be used to be blown or sprayed against food

etc.

Keep hands off from the rotating portion or belts while

running. It could cause serious injuries if hands should be

caught in.

TR0201-1

A080001

TR0086

TR0092

TR0304

Not for

Reproduction

9

Operator Safety

S-6

As part of pre-start safety checks, always confirm that there

is no residual pressure in the tank by carefully opening the

service valve, even if the pressure gauge on the screen

indicates 0PSI.

Note residual pressure in the separator receiver tank could

force both extremely hot compressed air and oil to jet out

and you may be scalded or seriously injured.

W011

Not for

Reproduction

10 ALLMAND.COM

Operator Safety

S-7

When cleaning dust accumulated in such devices as the

air-filter, by blowing compressed air, wear safety glasses,

etc. to protect your eyes.

Be sure to stop the engine, and let the coolant water

sufficiently cool down before draining it.

If the drain valve is opened before the coolant water is

cooled enough, hot water could jet out, and it could cause

scalding.

Be sure to perform the periodic checks of compressor oil

and oil separator.

Neglecting checks could cause overheat of the oil, resulting

in a fire.

Waste liquid from the machine contains harmful material.

Do not discharge it onto the ground or into the river, lake or

sea. Such material will contaminate the environment.

Be sure to use a container to hold the waste liquid from the

machine.

Be sure to follow the designated regulations when

disposing of oil, fuel, coolant (antifreeze), filter, battery or

other harmful materials.

The engine of this machine and electrical parts many electronic devices have been

installed. If you perform welding work, remove the connector of the electronic control

equipment. Application of excessive current to electronic controls can cause

equipment malfunction.

M003

H990432

W004-1

A100285

Not for

Reproduction

11

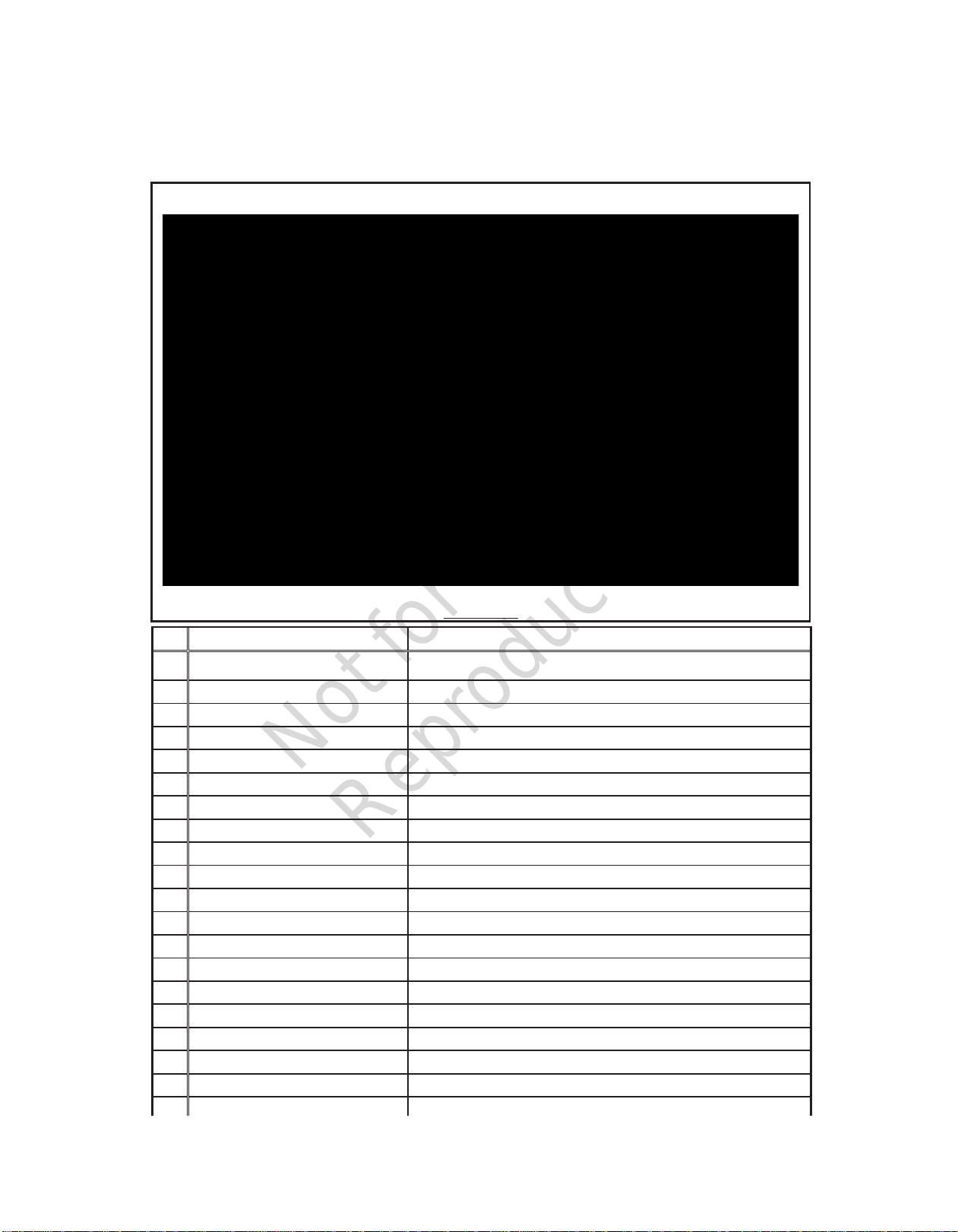

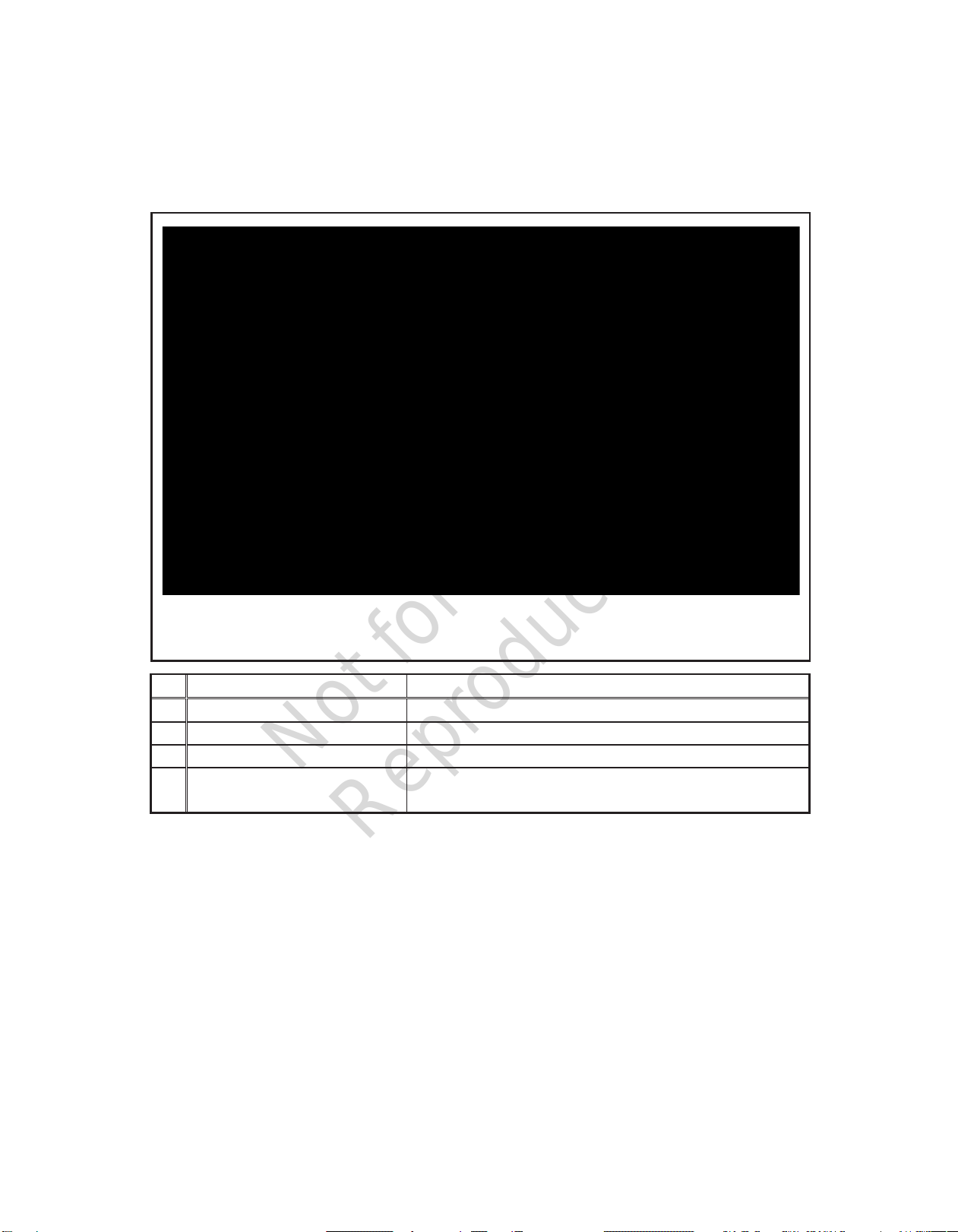

Features and Controls

1-1

Internal Components

A180429

No.

Description

Function

A Safety valve

For releasing compressed air to the atmosphere when the pressure rises higher

than the rated pressure in the system.

B

Air filter (For compressor air-end)

Filtering device for filtering dust floating in intake air.

C

Air filter (For engine)

Filtering device for filtering dust floating in intake air.

D

Sedimenter

For separating coolant from fuel in the system.

E

Fuel pre-filter

For removing dust and water mixed in fuel.

F

Fuel filter

For filtering foreign matter and dust mixed in fuel.

G

Fuel air-bleeding electromagnetic pump

For automatically bleeding air from fuel pipes in the system.

H

Reserve tank

For checking coolant level and supplying it.

I

Compressor oil filter

For filtering compressor oil in the system.

J

By-pass valve

For keeping compressor oil at optimum temperature in the system.

K

Oil cooler

For cooling compressor oil in the system.

L

Fuel tank drain valve

For draining condensates from fuel tank.

M

Fuel tank

For storing fuel.

N

Engine oil filler port

For supplying and replenishing engine oil to engine.

O

Engine oil filter

For filtering engine oil in the system.

P

Engine oil level gauge

For checking engine oil level.

Q

Separator receiver tank

For separating air and oil from compressed air in the system.

R

Separator receiver tank drain valve

For draining condensed water from separator receiver tank.

S

Compressor oil filler port

For supplying or adding compressor oil.

T

Compressor oil level gauge

For checking compressor oil level.

A B C D E F G H I J K

T S R Q P O N M L

MA400 T4F

Features and Controls

Not for

Reproduction

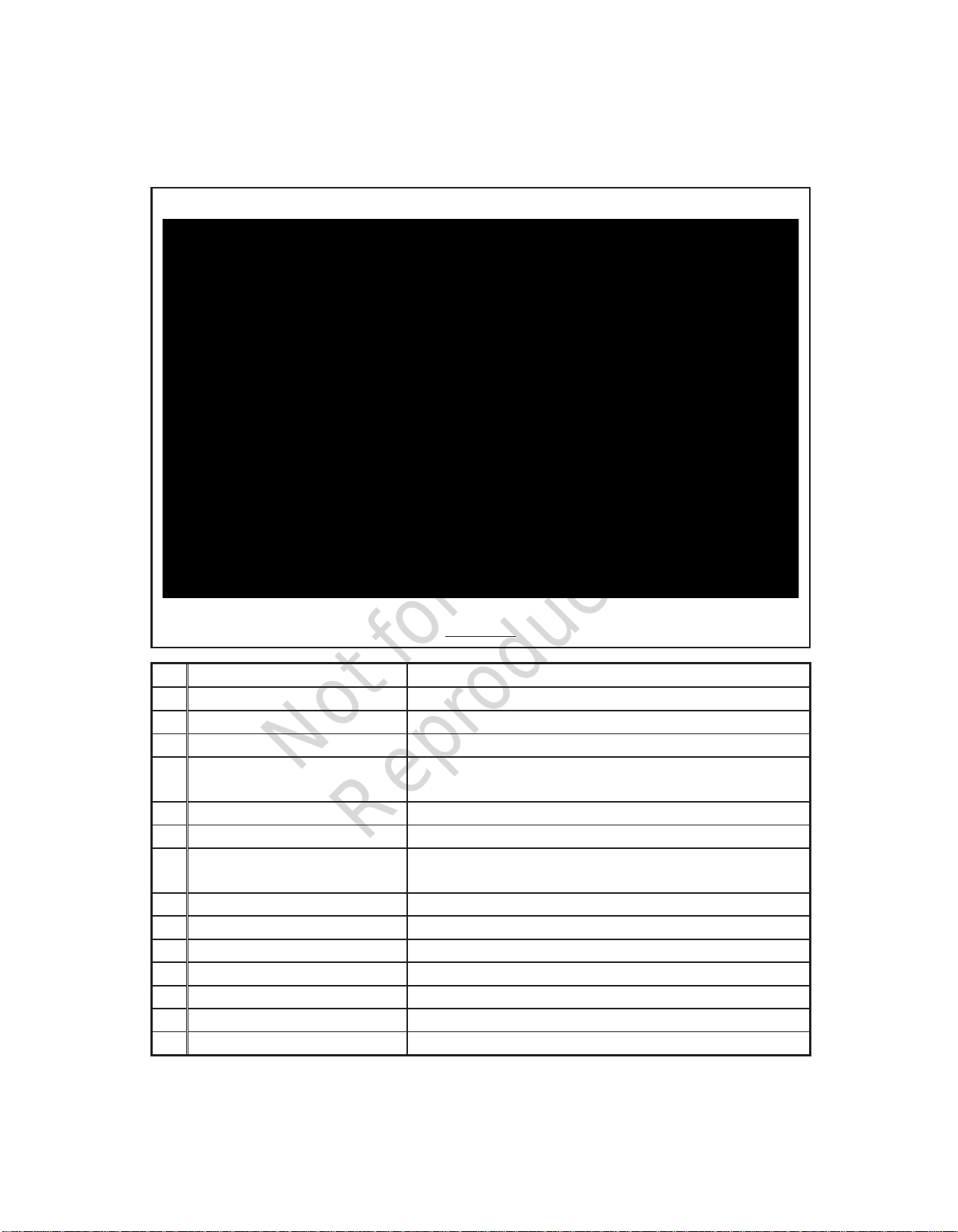

12 ALLMAND.COM

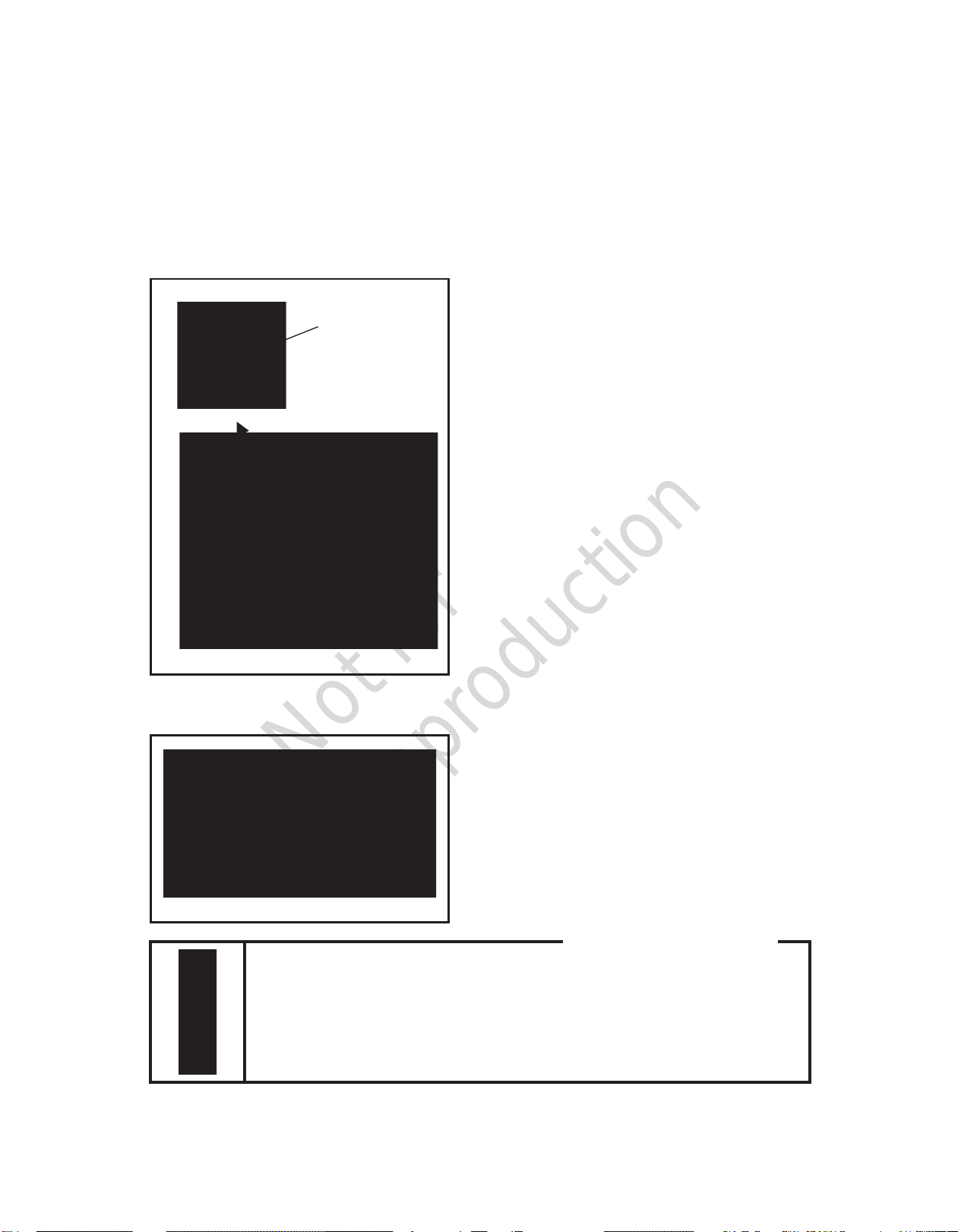

Features and Controls

1-2

A180430

MA400 T4F

No.

Description

Function

A

SCR (Selective Catalytic Reduction)

Selective reduction-type catalyst that uses DEF as a reducing agent.

B

Radiator

For cooling the coolant for engine in the system.

C

Engine

For driving the compressor air-end in the system.

D

Solenoid valve for unloader spring

chamber

For reducing loads during start-up.

E

Pressure regulator

For controlling full load and unload operation.

F

Solenoid valve for starting unload

For reducing load at start-up.

G Pressure control valve

For keeping the pressure in receiver tank constantly higher than a certain level in

the system.

H

Compressor air-end

For compressing air in the system.

I

Battery

For electrically starting engine.

J

DEF tank

Container for DEF

K

Engine oil drain valve

For draining engine oil.

L

Oil cooler drain valve

For draining compressor oil from oil cooler and oil line.

M

Radiator drain valve

For draining engine coolant.

N

DPF (Diesel Particulate Filter)

Apparatus for removing harmful components contained in the exhaust gas.

A B C D E F G H

N M L KJI

Not for

Reproduction

13

Features and Controls

1-3

A180431

MA375-DP T4F

No.

Description

Function

A

SCR (Selective Catalytic Reduction)

Selective reduction-type catalyst that uses DEF as a reducing agent

B

Radiator

For cooling the coolant for engine in the system

C

Engine

For driving the compressor air-end in the system

D

Solenoid valve for unloader spring

chamber

For reducing loads during start-up

E

High pressure regulator

Pressure regulator used to control air pressure during high pressure operation

F Pressure switching solenoid valve

Equipment for switching the operating pressure between low pressure and high

pressure

G

Low pressure regulator

Pressure regulator used to control air pressure during low pressure operation

H

Solenoid valve for starting unload

For reducing load at start-up

I Pressure control valve

For keeping the pressure in receiver tank constantly higher than a certain level in

the system

J

Compressor air-end

For compressing air in the system

K

Battery

For electrically starting engine

L

DEF tank

Container for DEF

M

Engine oil drain valve

For draining engine oil

N

Oil cooler drain valve

For draining compressor oil from oil cooler and oil line

O

Radiator drain valve

For draining engine coolant

P

DPF (Diesel Particulate Filter)

Apparatus for removing harmful components contained in the exhaust gas

A B C D E F G H I J

P O N MLK

Not for

Reproduction

14 ALLMAND.COM

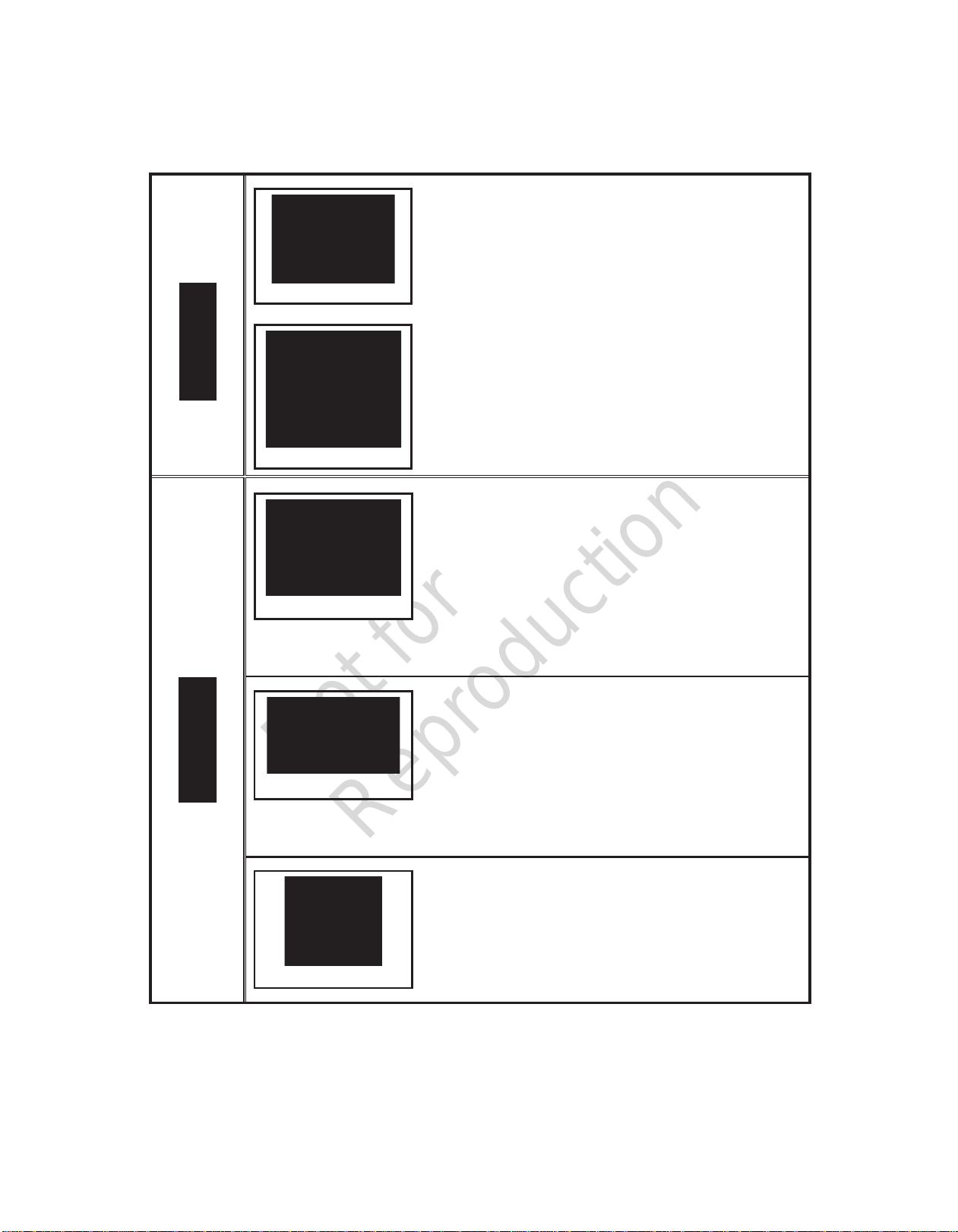

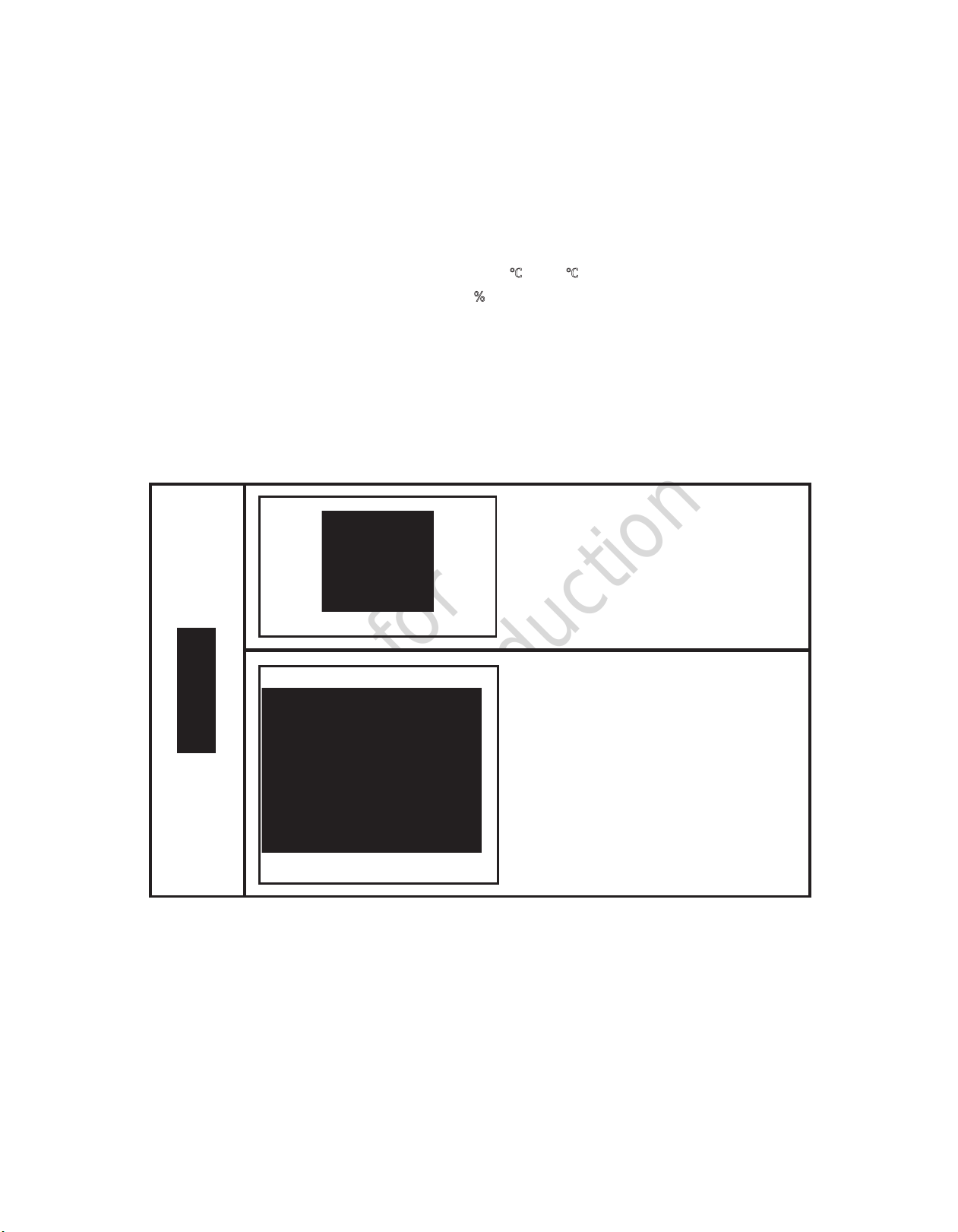

Features and Controls

1-4

After cooler type

Only options available on standard units are shown in the following figure.

No.

Description

Function

1

Drain separator

For separating water from compressed air cooled through after cooler

2

After cooler

For cooling compressed air

3

Drain port of air pipe

For draining condensate from drain separator

4 Drain warming valve

For preventing freezing of water separated through drain separator when

exhausting it

A180431

D C B A

Not for

Reproduction

15

Set-Up and Installation

2-1

Transportation

When loading and unloading the machine, make sure to use the lifting bail provided on the center of the

machine top.

Lifting

1. Before lifting the machine, make sure to check the lifting

bail [A] for any cracks or loosened bolts.

2. Connect the hook [B] of the crane or shackle to the

lifting bail eye fitted at the top center of the machine.

Make sure there is no person standing around the

machine. Then perform the hoisting operation.

3. Select a truck or a crane with a capacity sufficient for the

size and weight of the machine. See “Specifications.”

4. Any crane operations must be performed by a qualified

crane operator.

Mounting the machine on a truck bed

Fasten the machine with ropes [A] as shown, and

securely fix it on the truck bed.

Place one set of chocks [B] against the wheels. Pull the

parking brake lever firmly after the machine is loaded on

the truck bed.

Never stand under the machine when lifted. Death or serious injury could result.

Lifting the machine while still in operation could result in death or serious injury, or

serious equipment damage.

Transportation warnings

A160749

A160750

A

B A

B

A

Lifting bail

Set-Up and Installation

Not for

Reproduction

16 ALLMAND.COM

Set-Up and Installation

2-2

Towing

Before towing the machine, make sure to check the following:

Proper tire pressure.

Tire lug nuts are not loose.

Tires are not worn or damaged.

Make sure that the end of the drawbar is securely connected to the coupler of the

towing vehicle, to prevent disconnection while the machine is being towed.

Make sure there is no damage to the towing vehicle or the drawbar of the machine.

Make sure to keep your hands away from any part of the coupling device when

coupling or uncoupling.

Make sure to drive the towing vehicle safely. Avoid dangerous situations or

conditions on the road.

Failure to obey the above instructions could result in death or serious injury, or

serious equipment damage.

Warnings for towing the machine

Not for

Reproduction

17

Set-Up and Installation

2-3

Installation conditions

The machine must be parked on a firm, level surface.

The machine must be parked perpendicular (on a right angle) to a slope.

The machine must not be parked on a slope more than 15°

The machine should be operated in the following conditions:

Ambient temperature-------------- -5°F to 104°F (-15℃to +40℃)

Humidity------------------------------ Less than 80%

Altitude--------------------------------

Lower than1,500m above sea level

Operating the machine in conditions other than those stated above could result in death or serious

injury, or serious equipment damage.

The machine must be installed in an environment where fresh air is always available. Avoid temperature

extremes and excessive humidity.

If more than two machines are placed together in operation, keep enough distance so that the exhaust

from one machine does not affect the other.

Keep enough space around the machine for inspection and maintenance access.

Exhaust gas from the engine is poisonous. It

could cause death or serious injury if inhaled.

Avoid using the machine in an insufficiently

ventilated building or tunnel.

Do not position the exhaust gas outlet in

direction of a person or a house.

When installing the machine in a tunnel or

other enclosed space, make sure to provide

a supply of fresh air and adequate ventilation.

Make sure to install an exhaust pipe that

leads to an outdoor location. Make sure to

check any seams in the exhaust pipe for

leaks.

Do not position the exhaust gas outlet in the

direction of a house.

Exhaust from the engine is harmful. Avoid

positioning it in the direction of passers-by.

PC002

A150835

Exhaust pipe

Use an air blower

for taking in air

○

Exhaust gas

×

A150836

○

×

Private house

Set-Up and Installation

2-3

Installation conditions

The machine must be parked on a firm, level surface.

The machine must be parked perpendicular (on a right angle) to a slope.

The machine must not be parked on a slope more than 15°

The machine should be operated in the following conditions:

Ambient temperature-------------- -5°F to 104°F (-15℃to +40℃)

Humidity------------------------------ Less than 80%

Altitude--------------------------------

Lower than1,500m above sea level

Operating the machine in conditions other than those stated above could result in death or serious

injury, or serious equipment damage.

The machine must be installed in an environment where fresh air is always available. Avoid temperature

extremes and excessive humidity.

If more than two machines are placed together in operation, keep enough distance so that the exhaust

from one machine does not affect the other.

Keep enough space around the machine for inspection and maintenance access.

Exhaust gas from the engine is poisonous. It

could cause death or serious injury if inhaled.

Avoid using the machine in an insufficiently

ventilated building or tunnel.

Do not position the exhaust gas outlet in

direction of a person or a house.

When installing the machine in a tunnel or

other enclosed space, make sure to provide

a supply of fresh air and adequate ventilation.

Make sure to install an exhaust pipe that

leads to an outdoor location. Make sure to

check any seams in the exhaust pipe for

leaks.

Do not position the exhaust gas outlet in the

direction of a house.

Exhaust from the engine is harmful. Avoid

positioning it in the direction of passers-by.

PC002

A150835

Exhaust pipe

Use an air blower

for taking in air

○

Exhaust gas

×

A150836

○

×

Private house

Set-Up and Installation

2-3

Installation conditions

The machine must be parked on a firm, level surface.

The machine must be parked perpendicular (on a right angle) to a slope.

The machine must not be parked on a slope more than 15°

The machine should be operated in the following conditions:

Ambient temperature-------------- -5°F to 104°F (-15℃to +40℃)

Humidity------------------------------ Less than 80%

Altitude--------------------------------

Lower than1,500m above sea level

Operating the machine in conditions other than those stated above could result in death or serious

injury, or serious equipment damage.

The machine must be installed in an environment where fresh air is always available. Avoid temperature

extremes and excessive humidity.

If more than two machines are placed together in operation, keep enough distance so that the exhaust

from one machine does not affect the other.

Keep enough space around the machine for inspection and maintenance access.

Exhaust gas from the engine is poisonous. It

could cause death or serious injury if inhaled.

Avoid using the machine in an insufficiently

ventilated building or tunnel.

Do not position the exhaust gas outlet in

direction of a person or a house.

When installing the machine in a tunnel or

other enclosed space, make sure to provide

a supply of fresh air and adequate ventilation.

Make sure to install an exhaust pipe that

leads to an outdoor location. Make sure to

check any seams in the exhaust pipe for

leaks.

Do not position the exhaust gas outlet in the

direction of a house.

Exhaust from the engine is harmful. Avoid

positioning it in the direction of passers-by.

PC002

A150835

Exhaust pipe

Use an air blower

for taking in air

○

Exhaust gas

×

A150836

○

×

Private house

Not for

Reproduction

18 ALLMAND.COM

Set-Up and Installation

2-4

Make sure to install wheel chocks [A] on both

sides of both tires. Failure to do so could

result in death or serious injury.

Make sure to place a safety fence around the

machine, to prevent unauthorized access to

the machine.

Service valve

A160694

A160751

A

安全护拦

Installation notes

Placing safety fence in position

A120199

Safety fences

Bore of service valve: 20A(R3/4B)×2

[Taper male screw]

Bore of service valve: 50A(Rc2B)×1

[Taper female screw]

Not for

Reproduction

19

Set-Up and Installation

2-5

Piping or air hoses connected to the service

valves of this machine must meet or exceed

the discharge pressure of the machine.

Connect piping or air hoses to the service

valves of this machine firmly before operation,

and check during operation. A loose

connection could separate and result in death

or serious injury.

Close the service valves and relieve

remaining pressure before removing piping or

air hoses. Remaining pressure in the piping

or air hoses could result in death or serious

injury.

Read the operator manuals supplied with any

tools or equipment used in conjunction with

this machine.

Do not operate the machine with service

valves and relief valve open unless

connected to piping or air hoses.

High-pressurized air directly from the service

vales could result in death or serious injury.

If the machine must be temporarily operated

with the valve open, mount a silencer to

reduce noise, and wear hearing protection to

prevent hearing damage.

A partially open service valve could result in

equipment damage and air leaks. Make sure

the service valve is fully closed or fully open.

A150841

○

○

×

Partially open

Fully closed Fully open

Cautions of service valve

TR0088

Warnings of hose attachment and removal

TR0303A

Operation with discharge port

(compressed air supply port) opened is prohibited

D003

Not for

Reproduction

20 ALLMAND.COM

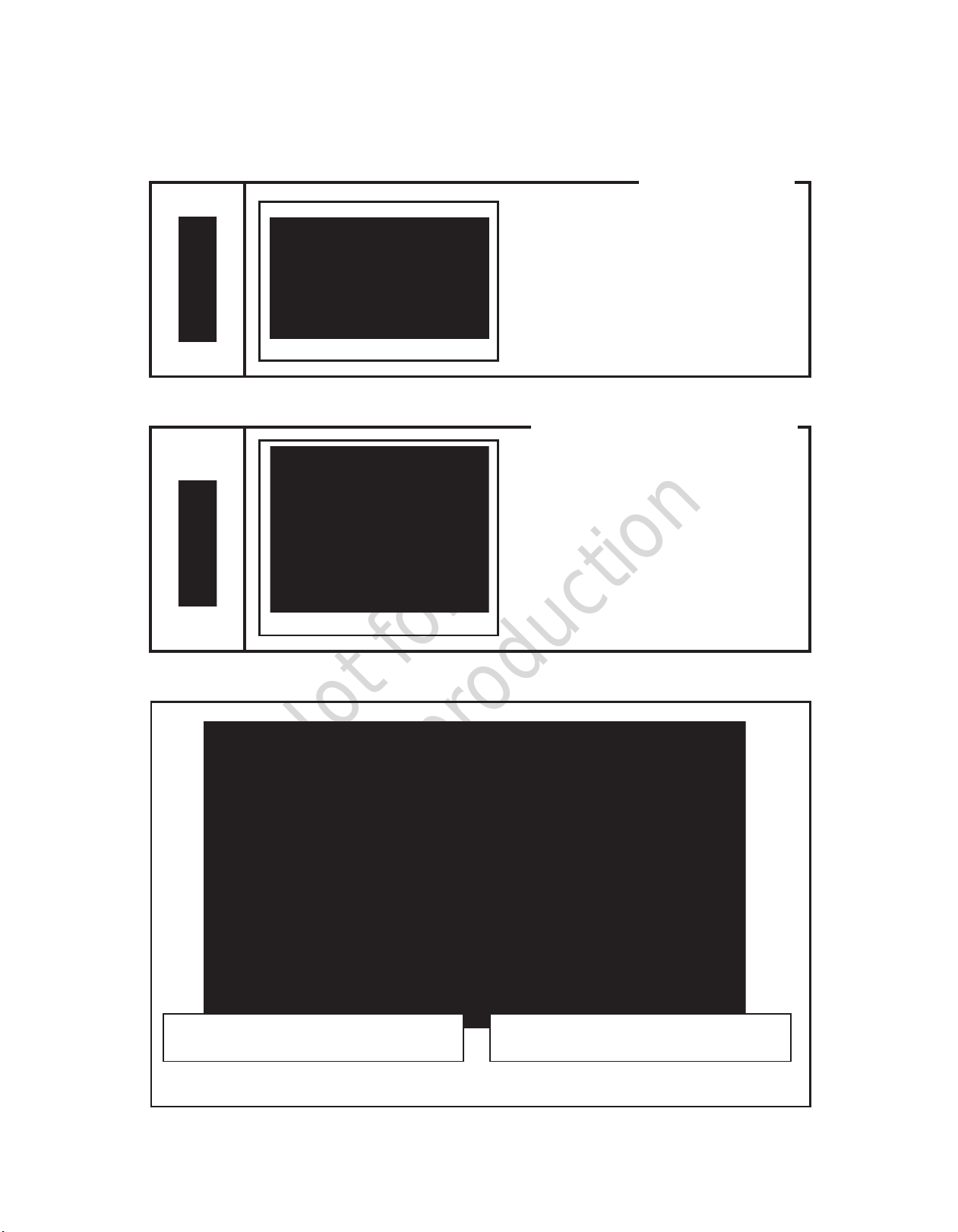

Operation

3-1

Instrument Panel

Each display of the operation panel is illustrated as follows.

Read and fully understand the explanations and be sure to operate safely:

A180427

[START] button

Start operation by holding

the button for 1 second.

[CONTROL POWER] switch

Switch to start and stop

the unit.

Switch to change high pressure

mode and low pressure mode.

Touch Screen

Display operation conditions

and set each parameter.

PRESSURE SELECTOR switch

(MA375-DP T4F only)

Operation

This manual suits for next models

1

Table of contents

Other Allmand Air Compressor manuals

Popular Air Compressor manuals by other brands

SMC Networks

SMC Networks CRP10 Series Operation manual

Bambi

Bambi VT75 Operator's handbook

Stanley

Stanley DN 200-10-5 instruction manual

ULTIMATE SPEED

ULTIMATE SPEED UMK 10 C2 Operation and safety notes translation of the original instructions

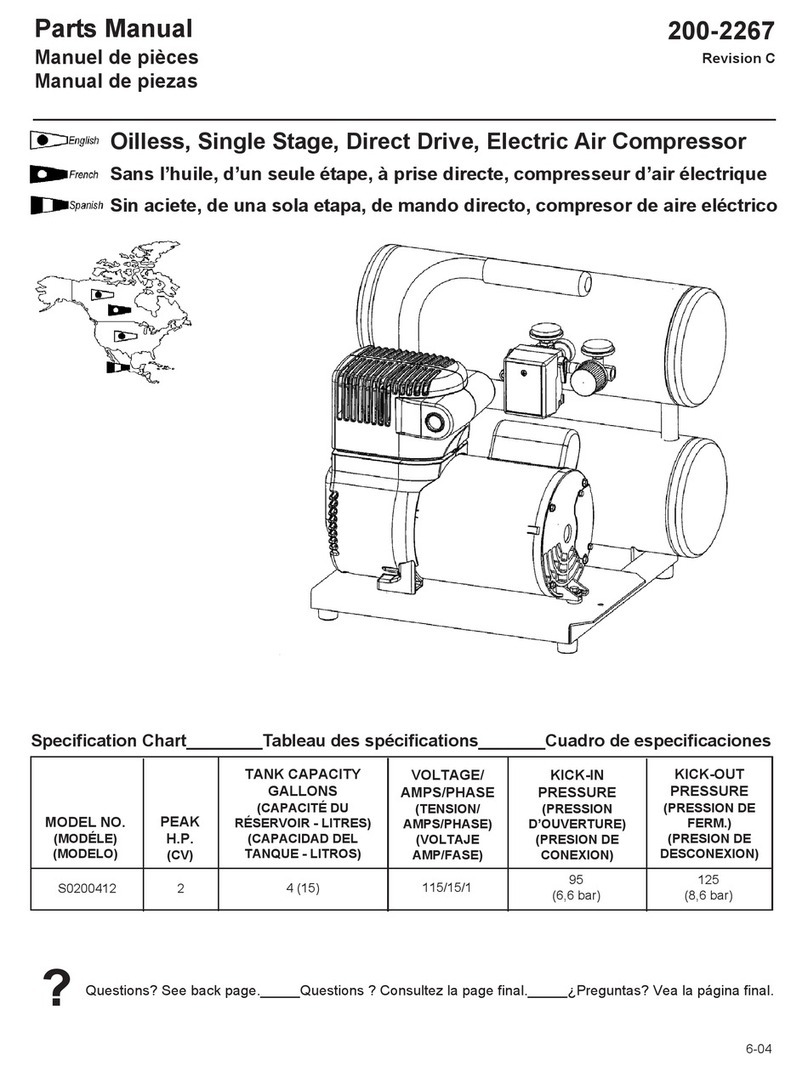

Powermate

Powermate S0200412 parts manual

MODE

MODE HS08-6 Series instruction manual

Parkside

Parkside PKO 400 A1 operation and safety notes original operating instructions

Campbell Hausfeld

Campbell Hausfeld Vertical Operating instrctions

Bitzer

Bitzer ST-150-2 technical information

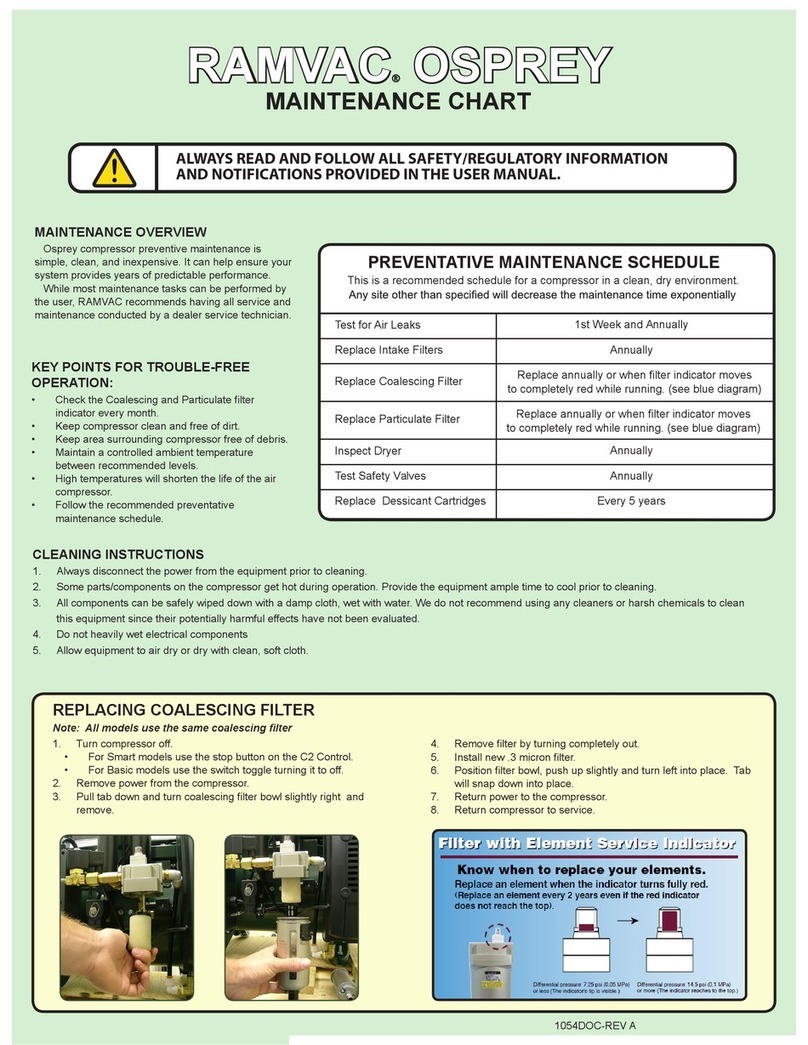

RAMVAC

RAMVAC OSPREY Maintenance chart

California Air Tools

California Air Tools 4610AC-22050 owner's manual

darda

darda BP2 product manual