ALLPOWER APT1016A User manual

tordless

lmpatt

Wrenth

&

Llght

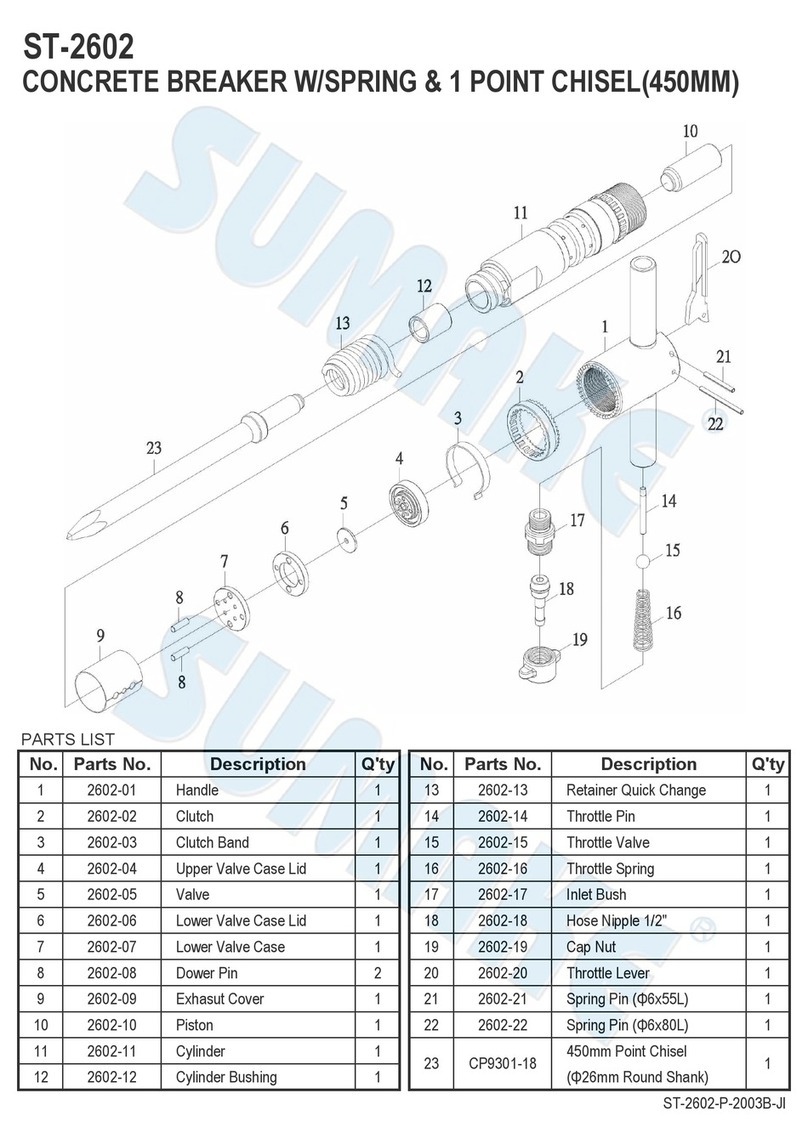

PRODUCT

SPECIFICATIONS

which

may

ignitethe dust or fumes

UNPACKING

Hem

Elscrrlcal Rsqunrements

Drlve

Slls

Trigger

Type

Marlmum Torqus

Sockets

Included

Overall Dtmensluns

Wetgnt

When unpacking,check

to

make

sure all the partsshown onthe

Parts

List on page

13

are

included If any partsare miss~ngor broken, please call All-PowerTools at

the

number

shown on the cover

of

this manual

as

soon

as

posslble

-

Daserlptlon

Power oulput

t9

2

vDc

Power Input

120

VACwo

Hz

Cnarger

Baltery

Type

1

7Ah

NI-Cd

charge

Time.

1

Hour Fasl

Charge

Charqsr

Power Plug

2

Prong Polar~zetl

1R"

Uar#4Dle

Speed

0-2000

RP

M

Reversible

WO

Ft

ILbs.

4

Oty

-

Slzes.

X

.

716'

.15H6",1"

21

L

x

4

318"

W

x

15'

H

14

30PounIls

SAVE

THIS

MANUAL

You

w~llneedth~smanual for the safety warnings

and

precautions,

assembly,

operat~ng,

inspection, rna~ntenanceand clean~ngprocedures, partslisland assembly

d~agrarn.

Keep your invoicewith this manual. Writethe invoice number

on

the insideof the

front

cover Keepthls manual and invoice in

a

safe

and

dry placefor future reference

GENERAL

SAFETY

RULES

A

WARNING!

READ

AND

UNDERSTAND

ALL

INSTRUCTIONS

Failuretofollow all instructionslistedbelow

may

resultin

electric shock,

fire,

andlor serious injury.

SAVE

THESE

INSTRUCTIONS

I

WORK

AREA

1

1

Keepyour work

area

cleanandwell lit.

Cluttered benchesand

dark

areas

inviteaccidents.

2.

Do

notoperatepower tools inexplosiveatmospheres, such

as

in

the

presence

of

flammableliquids,

gases,

or dust.

Powertools create sparks

Keepbystanders,children,andvisitors

away

whileoperating

a

power

tool.

Distractionscan cause

you

to

lose

control. Protectothers inthe work areafrom

debrissuch as chips and

sparks.

Provide barriersor shields

as

needed

Groundedtools must

be

pluggedintoan outlet properly installdand

grounded

In

accordancewith

all

codesandordinances. Never remove

the

groundingprongor modify

the

plug inany

way.

Po

not use

any

adapter

plugs.

Check

with

a

qualifiedelectricianif

you

are indoubt

as

to whether

theoutlet

is

properly grounded.

If

the

tools should electricallymalfunctlonor

break

down,

groundingprovldesalow resistance

path

to

carry

electrlclty

away

from

the

user.

Doubleinsulatedtools are equippedwith

a

polarized

plug

(oneblade

is

wider thantheother). This

plug

will fit in

a

polarized

outlet

only one

way.

If

theplugdoes not

fit

fully

in

theoutlet, reverse

the

plug. If

It

still does not

fit,

contact

a

qualifiedelectrician

to

install

a

polarized

outlet.

Do

not

change

the

plug inany

way.

Double

lnsulatlon ellmlnates

the

needfor the

three wire grounded power cord and grounded power supply

system

Avoid body contactwith grounded

surfaces

such

as pipes,

radiators,

ranges,

and

refrigerators.

There

IS

an

increased

rlsk of electric shock if your

body

isgrounded

Do not

expose

power toolstorainor

wet

conditions.

Water entering

a

power

toot

will

Increasethe rlsk of electrlc

shock.

Do

not

abuse

the Power Cord. Never

use

the

Power

Cordtocarry thetools

or pullthe Plugfroman

outlet.

Keep

the

Power

Cord

away

from

heat,

oil,

sharp

edges,

or moving

parts.

Replace

damaged

Power

Cords

immedi-

ately.

Damaged

Power

Cords

increasethe risk of electric shock.

When operating

a

power tool outside, use

an

outdoor

extension

cord

marked

"W-A"

or

"W.

These extension cords are rated for outdoor

use,

and

reducethe risk

of

electricshock.

1

PERSONALSAFETY

I

Stay alert.

Watch

what

you

are

doing,

and

use

common sensewhen oper-

sting

a

power tool.

Do

not

use

a

power toolwhlletired or

under

theinflu-

enceoidrugs,alcohol,or medication.

A

momentof mattentionwhileoperat-

ing

power

tools

may

result In serrouspersonal injury

Page

2

Page

3

Dressproperly. Do notwear looseclothingor jewelry. Containlonghair.

Keep

your

hair, clothing, and gloves

away

from movingparts.

Loose

clothes,jewelry,

or

long hair can becaught In moving parts

Avoid accidental starting.

Be

surethe Power Switch

is

off beforeplugging

in.

Carrying powertools with your finger

on

the Power Switch, or plugglng in

powertools w~ththe Power Swltch on, Invites

accidents.

Removeadjusting keysor wrenches beforeturningthe power tool on.

A

wrench or

a

key

that is left attach&

to

a

rotatrngpart

of

the powertool

may

result

in personalinjury.

Do not overreach. Keepproper lootlng and balanceat alltimes.

Proper

footing

and

balanceenables better controlof the powertool inunexpected

situations.

Use

safety equipment. Alwayswear

eye

ANSI-approvedsafety impacteye

goggles.

Dust

mask,

non-skid safety

shoes,

hard hat, or hearing protection

must

be

usedfor appropriate

conditions.

I

TOOL

USE

AND CARE]

Use

clamps(not included) or other practicalways

to

secureandsupport

theworkpieceto

a

stableplatform.

Holdlngthe work by hand or against your

bodyisunstable and

may

lead to lossof control.

Do

notforce the tool. Usethe correct-toolfor your application.

The

correct

tool wrll do

the

job better and safer at the ratefor which it

IS

deslgned

Do

not

use

thepowertool ifthe Power Switch does notturn Iton or

off.

Any tool that cannot

be

controlled with the Power Swltch

IS

dangerousand must

be replaced.

Disconnectthe Power Cord Plugfromthe power sourcebdore makingany

adjustments,changing

accessories,

or

storingthetool.

Such preventive

safety measuresreduce

the

risk

ot

starting thetool accidentally.

Storeidletools

out

of reachof childrenand other untrainedpersons.

Tools

are dangerous inthe handsof untrained users.

Maintaintoolswithcare.

Keep

toolsclean anddry.

Properly malntained

tools wlth

a

sharpcutting edge are less likelyto bind and are easier to control

Do

not

use

a

damagedtool

Tag

damaged tools "Do not use"until repaired.

7

Check for misalignment or binding

oi

moving

parts,

breakageof

parts,

and

any

other

conditionthat

may

affw

thetool's operation.

ll

damaged,

have

the

tool serviced

before

using.

Many accidents are caused by poorly

main-

tainedtools.

8.

Use only accessoriesthat are recommended

by

the manufacturer

for

your

model.

Accessoriesthat

may

be suitablefor one tool may becomehazardous

when usedon another tool.

1.

Tool service

musl

be performedonly

by

qualified repair personnel.

Service

or ma~ntenanceperformedby

unqualified

personnelcouldresult

in

a

risk

of

Injury

2.

When servicing

a

tool, useonly

identical

replacement parts. Follow

instructionsinthe

'lnspecfion,

Maintenance,

And

Cleaning"9ectionof this

manual.

Useof unauthorrzed

parts

or

failure

lo

follow maintenancernstructions

may create

a

risk of electr~cshock or injury.

SPECIFIC SAFETY RULES

1

Maintain

a

safeworking environment.

Keep

the

work

areawell lit.

Make

sure

there isadequate surroundingworkspace. Always keepthe work

area

free

of

obstruct~ons,grease, oil, trash,

and

other debris.

Do

not

use

the lmpactWrench

In areas near flammablechemicals, dusts, and vapors.

Do

not usethis product

In

a

damp or wet location

2

Maintainlabelsand nameplatesonthe

Impact

Wrench.

These carry

Importantinformation. If unreadable

or

mlssing,contact Harbor FreightTools for

a

replacement.

3

When usingthe

lmpact

Wrench, always maintainafirmgrip on thetool

with

bothhands.

4.

Do not usethe lmpactWrench or Charger

(39)

il

It

has

been dropped, dam-

agd,

leftoutdoors,or immersedInliquid.

5.

Do

notchargethe Battery

(37)

when

the

temperature isbelow

50

degr-s

Fahrenheitor above

104

degrees Fahrenheit.

6.

Do notshake, drop, or strlke

the

Battery

(37).

7.

To avoidelectrical shock, do not pullor carry the Charger

(38)

by

Its

Power Cord or pull

the

Power Cord around sharp corners

or

edges.

Do

not

Page

4

Page

5

unplugthe Charger

by

pulling

on

the Power Card. Keep the Power Cord

away

from heated surfaces

8.

To

avoid electrical shock,

do

not

handle

the

Charger

(391,

its

Power

Cord Plug,

or

the

lmpact

Wrench

with

wet

hands.

9

Keepthe Handle

of

the ImpactWrench dry, clean,

free

from

oil and

grease.

10.

Avoid

unintentional

starting.

Make

sure you are preparedto begin work

beforeturningon the lmpact Wrench.

11.

Never

leave

the

Charger

(39)

unattendedwhen

it

is

plugged

into

an

eltxtrical

outlet.

Makesure to unplug itfrom its electricaloutlet before leaving

12

Atways

turn

off

the

ImpactWrench

and

unplugthe Charger

(39)

from

its

electricaloutld

before

changingaccessoriesor performingany inspec-

tion, maintenance,

or

cleaning procedures.

13.

Always

switch

to

a

fresh

Battery

(37)

when tool performance

begins

to

diminish.

Severe heat is

most

destrucllveto a Battery The more heat gener-

ated,

the

faster the Battery loses power.

A

Batterythat gets too hot can be per-

manentlydamaged Never over-dischargea

Battery

by

usingthe tool even after

tool performance is decreasing. Never attemptto d~scharge

a

tool's Battery

by

continuing to pull the tool'strigger When tool performance beg~nsto diminish,

stop

thetool, rechargethe Battery, and usethefresh Batteryfor optimal perfor-

mance

14.

Battery

(37)

leakage

may

occur under extreme

usage

or temperature condl-

tions.

If Batteryflurd comes In contact with skin, wash with

soap

and water and

rinsewith lemon juice and vinegar If the fluid comes into contact with the eyes,

flush with water for several minutes and contact

a

doctor immediately.

15.

Never burnthe Battery,

as

it

can

explode

in

a

fire.

Do not chargethe lmpact

Wrench wlth a leaking Battery. Contact local solid waste authorities for instruc-

tions on correctdisposal or recyclingof the Battery.

16.

1

BWARNING!

I

Peoplewth pacemakers should consult ther physican(s)

beforeusing

this

product. Operation

of

electrical equipment in close proximity

to

a

heart pacemakercouldcause interference or failure of the pacemaker

17.

1

WARNING!

lThewarnings, precautions,and instructionsdiscussedinthis

manualcannot cover all ~ossibleconditionsand s~tuationsthat

may

occur The

operator must understandthat common sense and cautionare factors, which

cannot be built intothis product, but must

be

supplied

by

the operator.

I

-

.-

SYMBOLOGY

PRODUCT

FEATURES

Dl

@

NOIc

For additional informationregardingthe parts

listed

in the following

pages,

refer

to

the

Assembly

Diagram

on

page

73.

Double

InsulaZed

Canadlan

StandaKls

Association

Underwriters

hb~~t~rit%i,

1°C.

1.

-1

Always

make

sure

the

Trigger (36) of the

lmpact

Wrench is in

its

"OFF"

posit~on,the Battery

(37)

is

removedfrom the lmpactWrench, and

the

Charger

(39)

is

unpluggedfrom its electical

outlet

prior

to

making

any

adjust-

mentsto thetool. {See

Figure

I),

next

paqe.)

2.

Irigaer

(361:

The

Trigger

is

operated

manually

simply by squeezingthe Trigger

to

turn

on

the

lmpact

Wrench and releasingpressure on the Triggerto turn

off

the

lmpact Wrench.

(See

Figure

D.)

V

,

3.

ForwaKYReverseSwitch

(32):

The

ForwardlReverseSwitchallowsyou tochange

the rotatronal

direct~on

of the lmpact Wrench. For

a

clockwise

rotation,move

the

ForwardIReverseButton

to

the

right.

For

a

counterclockwiserotation, movethe

ForwardIReverseButtonto the

left.

To avoiddamageto the lmpact Wrench,

always wait untll

the

tool completely

stops

beforechanging rotationaldirections.

(See

Flgure

P.)

Volts

Alternating

Current

4.

112"

Drlve lmpact

Head

m:

The

1/2"

lmpact Headfeatures

a

spring

and

ball

to

securely

hold

a

socket.

The

lmpact Headacceptsall sizes of standard

and

metric

sockets

having

a

1

/2

drlve.

(See

Figure

D.)

Page

6

FIGURE

C

A

Amperes

no

K!2&m'n*

No Load

Revollnions

1

per Minute(RPM)

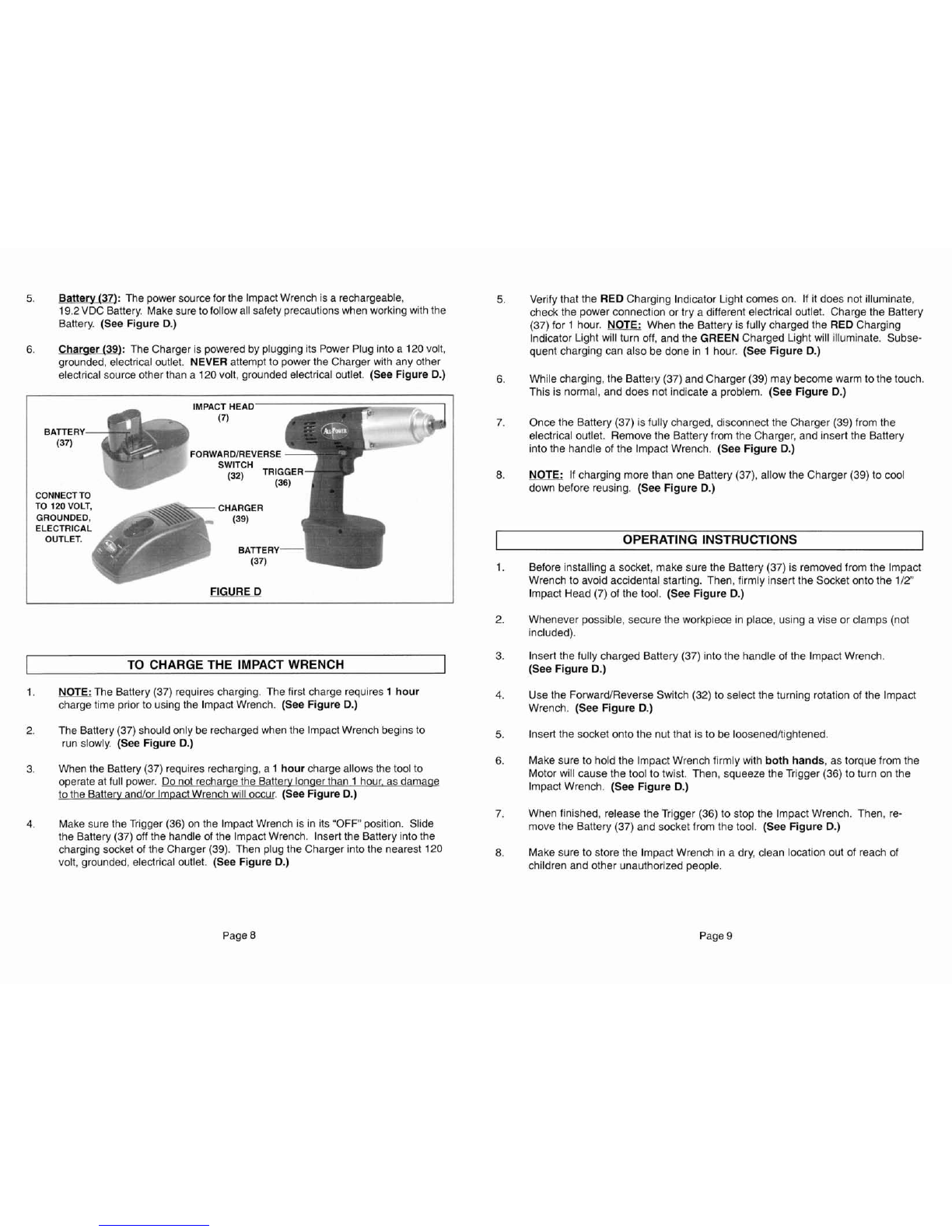

5.

Battery

i37):

The powersourcefor

the

ImpactWrench is

a

rechargeable,

5.

Verify that the

RED

Charging IndicatorUght

comes

on. If it does not iliuminate,

19.2VDC

Battery.

Make

sureto follow all

safety

precautionswhen

working

withthe check the power connection or try a different electrical outlet. Charge the Battery

Battery.

(See

Figure

D.)

(37)

for

1

hour.

NOTE:

When the

Battery

isfully charged the

RED

Charging

IndicatorLight

WIH

turn off, and the

GREEN

Charged L~ghtwill illuminate. Subse-

6.

Charger

(39):

The Charger ispoweredbypluggingits Power

Plug

into

a

120

volt, quent charglngcan also

be

done in

1

hour.

(See

Figure

D.)

grounded,electricaloutlet.

NEVER

attempt to powerthe Charger wlth any other

electrical source other than a

120

volt, grounded electrical outlet.

(See

Figure

D.)

6.

While charging,the

Battery

(37)

andCharger

(39)

may

becomewarm tothetouch.

Thls isnormal, and does not lndicate

a

problem.

(See

Figure

D.)

CONNECT

TO

ELECTRICAL

FIGURED

TO

CHARGE

THE

IMPACT

WRENCH

1.

NOTE:

The Battery(37) requirescharging. The first charge requires

1

hour

c'hargetime prior

to

usingthe ImpactWrench.

(See

Figure

D.)

2.

The Battery

(37)

shouldonly be rechargedwhen the lrnpactWrench beginsto

runslowly.

(See

Flgure

D.)

3.

When the

Battery

(37)requires recharging, a

1

hour

charge allows thetool to

operate

at

full power.

Do

not recharge

the

Batterylonaerthan

1

hour,

as

darna~

tothe Batteryand/or ImpactWrench

will

occur.

{SeeFigure

0.)

4.

Make

sure theTrigger

(36)

on the lmpactWrench

rs

In its

"OFF'

position. Slide

the Battery

(37)

oft the handle

of

the lmpactWrench. Insertthe

Battery

intothe

charglng

socket of the Charger

(39).

Then plugthe Charger !ntothe nearest

120

volt, grounded, electrical outlet.

(See

Figure

D.)

7.

Oncethe Battery

(37)

isfully charged, disconnect the Charger

(39)

from the

electrical outlet. Removethe Batteryfrom the Charger,and insertthe Battery

intothe handle of the ImpactWrench.

(See Figure

0.)

8.

NOIE

If

charging morethan one Battery

(37),

allow the Charger

(39)

to cool

down beforereusing.

(See Figure

D.)

I

OPERATING

INSTRUCTIONS

I

I.

Before installing

a

socket,

make

sure the

Battery

(37)

is removedfrom the lmpact

Wrench to avold accidental starting. Then, firmly insertthe Socket

onto

the

112"

lmpact Mead

(7)

of

the tool.

(See

Figure

D.)

2.

Whenever possible, secure the workpiece inplace, using

a

vise or clamps (not

included).

3,

Insertthe fully charged Battery

(37)

intothe handle of the ImpactWrench.

(See Figure

D.)

4.

Usethe Forward/ReverseSwitch

(32)

to select the turning rotationof the lmpact

Wrench.

(See Figure

D.)

5,

Insertthe socket onto the nutthat isto be loosenedhightened

6.

Make sure to holdthe

Impact

Wrench firmly wlth

both

hands,

as

torque from the

Motor will cause the tool

to

twist. Then, squeezethe Trlgger

(36)

to turn on the

lmpact

Wrench.

(See Figure

D.)

7.

When finished, releasethe Trigger

(36)

to stop the ImpactWrench. Then, re-

movethe Battery

(37)

and

socket from the tool.

(See Figure

D.)

8.

Make sure to store the lmpactWrench in

a

dry, clean locationout of reach of

chlldren

and

other unauthor~zedpeople.

Page

8

Page

9

INSPECTION, MAINTENANCE,AND CLEANING

1

PARTS

LIST

&

ASSEMBLY

DIAGRAM

1.

/7\

WARNING!

Always lettheTrigger (36) rest

in

Its

"OFF"

position, remove

the Battery

(37)

from

the

tool,

and

unplug

the

Charger

(39)

from

itselectrical

outlet

before performing

any

inspection,

maintenance, orcleaning.

2.

Beforeeach use: Inspectthe general

condition

of the lrnpact Wrench. Check for

misalignment

or

bindingof movingparts,

cracked

or brokenparts, leaking Battery,

damaged Charger wiring, chipped or broken sockets,and

any

other conditionthat

may

affect

its safe operation.

If

abnormal

noise

or vibration occurs,

have

the prob-

lemcorrected before further

use.

Do

not

use

damagedequipment.

3.

Daily: With

a

cleancloth, removealldirt, grease,

and

oil from the lrnpactWrench.

Po

not immersethe ImpactWrench in any liquids.

4.

It

may

becomenecessary

at

sometime

to

replaceor cleanthetwo CarbonBrushes

(29)

when the Motorperformancedecreases,

or

stopsworkingcompletely.

To

replacetheCarbonBrushes:

Remwe

thetwo Brush Holder Caps

(28).

Then,

removethetwo Carbon Brushes

(291,

keeprng

track of the orientationand location

of

each.

If either Carbon Brush is worn more

than

halfway, replace

both

Carbon

Brushes. If the Carbon Brushes are just dirty, however, they may be cleaned by

rubbingthem with a pencil eraser. If

cleaning

and

replacing

used

brushes,try to

installthem inthe

same

holdersand

in

thesamedirectiontheywere removed.When

installingtheCarbonBrushes, makesurethe carbonportionof theCarbonBrushes

contactthe Motor'sRotor

and

thatthespnngsface

away

from

the

Motor. Also,

make

surethe springsoperatefreely. After replacementor cleaning,replace

the

twoBrush

Holder Caps.

NOTE:

New

Carbon Brushestend

to

arc

or spark when f~rst

used

untilthey wear

and

conformtothe Motor'sRotor.

5.

/!l

CAUTION!

All maintenance, service, or repairs not listed

in

this manual

are onlyto

be

attempted

by

a

qualified servicetechnician.

PLEASE READ

THE

FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDEDTHE PARTS LlST AND

ASSEMBLY

DIAGRAM IN THIS MANUAL

AS

A REFERENCE

TOOL

ONLY. NEITHER THE MANUFACTURER

OR

DISTRIBUTOR

MAKES

ANY REPRESENTATION

OR

WARRANTY OF ANY KIND

TO

THE BUYER THAT

HE

OR

SHE

IS

QUALIFIED TO MAKE ANY REPAIRS TO

THE

PRODUCT,

OR THAT

HE

OR

SHE IS

QUALIFIEDTO REPLACE

ANY

PARTS

OF

THE

PRODUCT

IN FACT,

THE

MANUFACTURERAND/OR

DlSTRlBUTOR EXPRESSLY STATES THAT

ALL

REPAIRS

AND

PARTS REPLACEMENTSSHOULD

BE

UNDERTAKEN

BY

CERTIFIED

AND

LlCENSEDTECHNIC1ANS.AND NOT

BY

THE

BUYER.

THE BUYER

ASSUMES ALL RISK

AND

LIABILITY ARISING OUT OF HIS

OR

HER REPAIRS TO THE ORIGINAL

PRODUCT

OR

REPLACEMENTPARTSTHERETO. OR ARISING OUT

OF

HIS OR HER INSTALLATION

OF

REPLACEMENTPARTSTHERETO

APT1

Ol6A-A-22-TB

I

Master

sham

I

APT1011 Sw~tch

APT1

0

16A-A-23-T

R

I

Screw

1

APT1011

Battery

clan

APT1

0Z6A-A-24-TB

I

Right

body

1

?ar

lamlc

gear

f

lhght

head

NOTE:

Some

parts

are

listed

and

shown

for

illustration purposes

only,

and

are

not

aavilableindividually

as

replacement

parts.

Page

10

Page

11

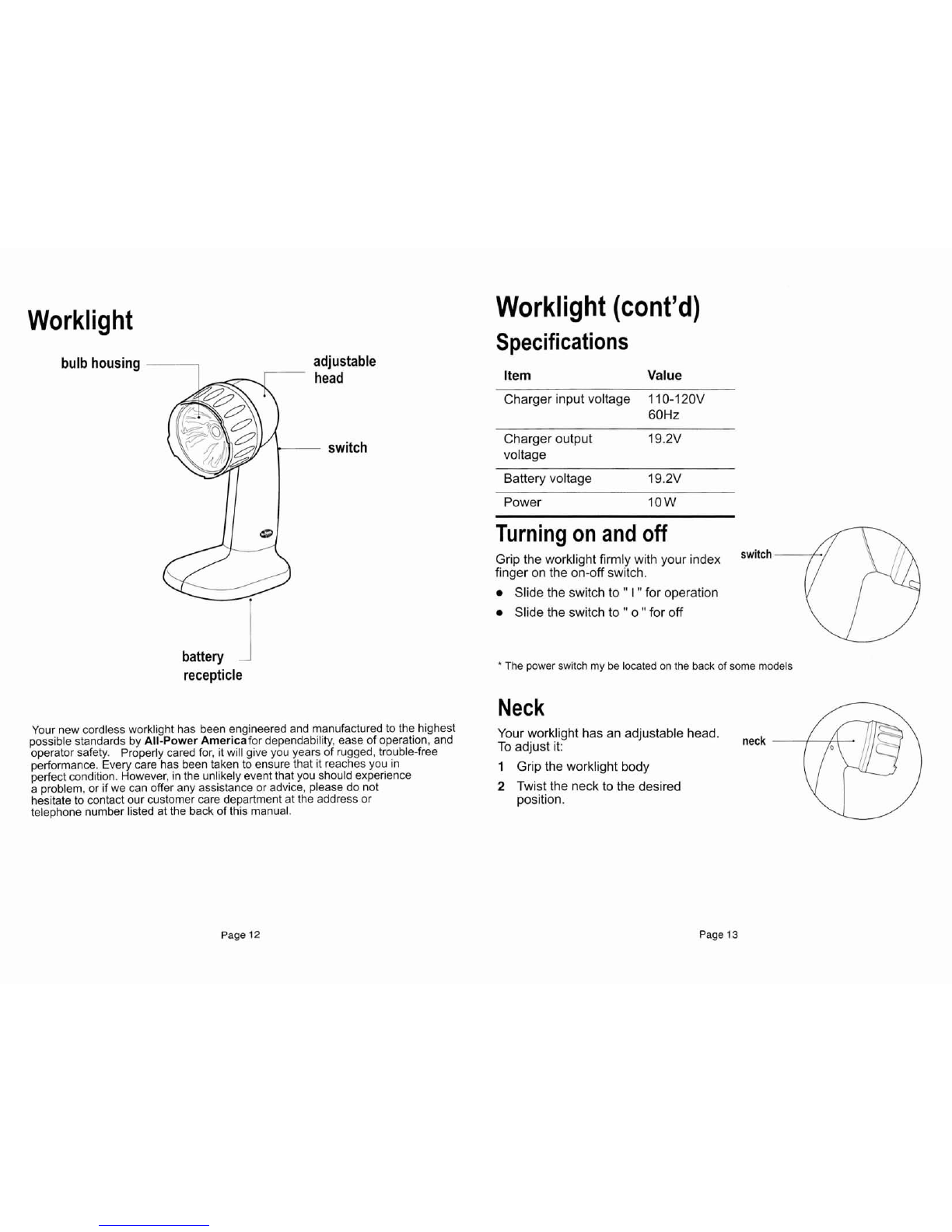

Worklight

bulb

housing

battery

1

recepticle

adjustable

head

Worklight

(cont'd)

Specifications

Item

Value

Charger

input

voltage

1

10-120V

-

switch

Charger output

19.2V

voltage

Your new cordless worklight

has been

engineered and manufactured

to

the

highest

possible

standards by

All-Power

Americafor dependability, ease

of

operation, and

operator safety. Properly

cared

for,

it will

give

you years

of

rugged, trouble-free

performance.

Every

care

has

been

taken

to ensurethat itreaches

you

in

perfect condition. However, in

the

unlrkelyevent that you

should

experience

a

problem,

or

if

we

can

offer any assistance or advice, please

do

not

hesitate to contact our customer care department at the address or

telephone number listed

at

the

back

of

this manual.

Battery

voltage

19.2V

Power

10W

Turning

on

and

off

Gripthe work'lightfirmly with your

index

switch-t

finger on the

on-off

switch.

Slide

the

switch

to

"

I

"

for

operation

Slide

the

switch

to "

o"

for

off

//I

*

The

power

switch

my

be

located

on

the

back

of

some

models

Neck

Your

worklight

has

an

adjustable

head,

neck

To adjust it:

1

Grip

the

worklight

body

2

Twist

the

neck

to

the

desired

position.

Page

12

Page

13

Worklight

(cont'd)

Changing

the

bulb

CAUTION:

ALWAYS

REMOVE

BATTERY

BEFORE

CHANGING

THEBULB.

To

change

the bulb:

I

Remove

the lens cover

assembly

by turning it

counterclockwise.

2

Remove

the

bulb

from

its

spring mounting.

3

Insert

a

new

bulb.

4

Replacelens

cover.

5

Reinsert

battery.

Maintenance

Clean the tool with

a

rag

dampened

with

cleanwater.

Do

not

use

chemicals or soap.

Do

not allowwater to

get

inside

the

tool.

Make

sure the

vent

passagesremain

clear

of

dust and

debris

to

avoid

overheating

the

tool.

Store

the

tool in

a

clean

dry

place.

m

All repairs

must

be

performed

by

a

qualified electrician.

a

Opening

the

tool

voids

the

warranty.

6

Check

for

correct operation.

Page

14

Page

15

Limited

Warranty

All-Power Arncricawarrants to the original purchaser who uses the product in

a

consumer application (personal, residential or household

usage)

that all products

covered under this warranty are free from defects in material and workmanship for

one year from the date

of

purchase. All products covered by this limited

warranty

which

arc

used in commercial applications (i-e.incomeproducing) arewarranted to

be

free

of

dcfects in material and workmanship for

90

days

from the date of original

purchase. Products covered under this warranty include air compressors, air tools,

service parts, pressure

washers,

and generators.

All-Power America will repair or replace, at All-Power America's soleoption,

products or components which have failed within the warranty period. Service will

be

scheduled according to the nonnal work

flow

and

business hours at the servicc

center

location, and the availabit

ity

of

replacement parts. All decisions of All-

Power America with regard

so

this limited warranty shall

be

final.

This warranty gives you specific legal

rights,

and you

may

also have other rights

which

vary

from state to state.

RESPONSIBILITY

OF

ORIGINAL

PURCHASER

(initial User):

m

To process a

warranty

claim on this product,

DO

NOT

return item to the

retailer.The product must be evaluated

by

an

Authorized Warranty Service

Center. For the location of the nearest Authorized Warranty Service Center

contact the retailer or place of purchase.

m

Retain original

cash

register sales receipt as proof of purchase for warranty

work.

Use reasonable care

in

the operation and maintenance ofthe product

as

described in the Owners Manual(s).

Deliver or

ship

the product

to

the

nearest Authorized Warranty Service Center.

Freight costs,

if

any, must be paid

by

the purchaser.

*

Air cemprcssors with

60

and

80

gallon tanks will

be

inspected at the site

of

installation.Contact the nearest Authorized Warranty

Servicc

Center that

provides on-site service calls for service call arrangements.

Limited

Warranty

(cont'd)

THIS

WARRANTY

DOES

NOT

COVER:

a

Merchandise sold

as

reconditioned,

used

as

rental equipment, or floor

or

display models.

Merchandise that has

become

damaged or inoperative because

of

ordinary

wear, misuse, cold, heat, rain, cxcessive humidity, freeze damage, use

of

improper chemicals, negligence, accident, failure to operate the product

in

accordance with the instructionsprovided in the Owners Manual(s) supplied

with

the product, improper maintenance, the use of accessories or attachments

not

recommended by All-Power America

,

orunauthorized repair

or

alterations.

Repair and transportation costs of merchandise determined not to be defective.

Costs associated with assembly, required oil, adjustmcnts or other installation

and start-up costs.

Expendable parts or

accessories

supplied with the product which are expected

to become inoperative or unusable after

a

reasonable period

of

use.

Merchandise soldby All-Powcr America which

has

been manufactured

by

and

identified asthe product of another company, such as gasoline engines. The

product manufacturer's warranty,

if

any,will apply.

ANY

INCIDENTAL,

INDIRECT

OR

CONSEQUENTIAL

LOSS,

DAMAGE,

OR

EXPENSE

THAT

MAY

RESULT

FROM

ANY

DEFECTS,

FAILURE

OR

MALFUNCTION

OF

THE

PRODUCT

IS

NOT

COVERED

BY

THIS

WARRANTY.

Some states

do

not allow thccxclusion, so it

may

not apply to

you.

IMPLIED

WARRANTIES,

INCLUDING

THOSE

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE,

ARE

LIMITED TO

ONE

YEAR

FROM

THE

DATE

OF

ORIGINAL

PURCHASE.

Some states

do

not

allow limitations on how long

an

implied warranty lasts,

so

the above

limitations

may

not apply to you.

e

If

the purchaser does not receive satisfactoryresults from the Authorized

Warranty

Service

Center,the purchaser should contact All-Power

America.

Page

16

Page

17

Table of contents

Popular Power Tools manuals by other brands

GRAPHITE PRO

GRAPHITE PRO 59GP300 instruction manual

DeWalt

DeWalt DCS354 user manual

ODU

ODU 080.000.062.000.000 instruction manual

Ryobi

Ryobi XIW-3100 Owner's operating manual

Campbell Hausfeld

Campbell Hausfeld DG460300CK S Operating instructions and parts manual

Hitachi

Hitachi N 3804AB3 Instruction and safety manual