Supply/Return Button

The LoFlo Balometer® Capture Hood is in supply

mode when turned on. This is indicated on the

display with the supply indicator . To take return

air measurements, press the supply/return button

on the front of the meter. Return air mode will be

indicated on the display with the return indicator

.

Significant errors may result if:

Instrument is not in proper mode.

Fabric hood is not used with vent open

mode.

Vent Closed/Vent Open Modes

When the instrument is turned on, it is in the vent

closed mode . When the vent closed indicator

is on, the vents must be closed to take the

measurement. Close the vents by loosening the

thumbscrew and sliding the vent baffle to the fully

closed position and locking the vent in place

again.

The vent open mode is indicated with the vent

open indicator on the LCD . Open the vents by

loosening the thumb screw and sliding the vent

baffle to the fully open position and locking it into

place again. Then press and hold the handle

switch for more than 3 seconds to switch the

LoFlo Balometer® Capture Hood to the open vent

mode.

The vent open mode was developed for higher

volume rates on larger diffusers; the 2' x 2' or 650

mm x 650 mm hood should always be used with

vent open mode.

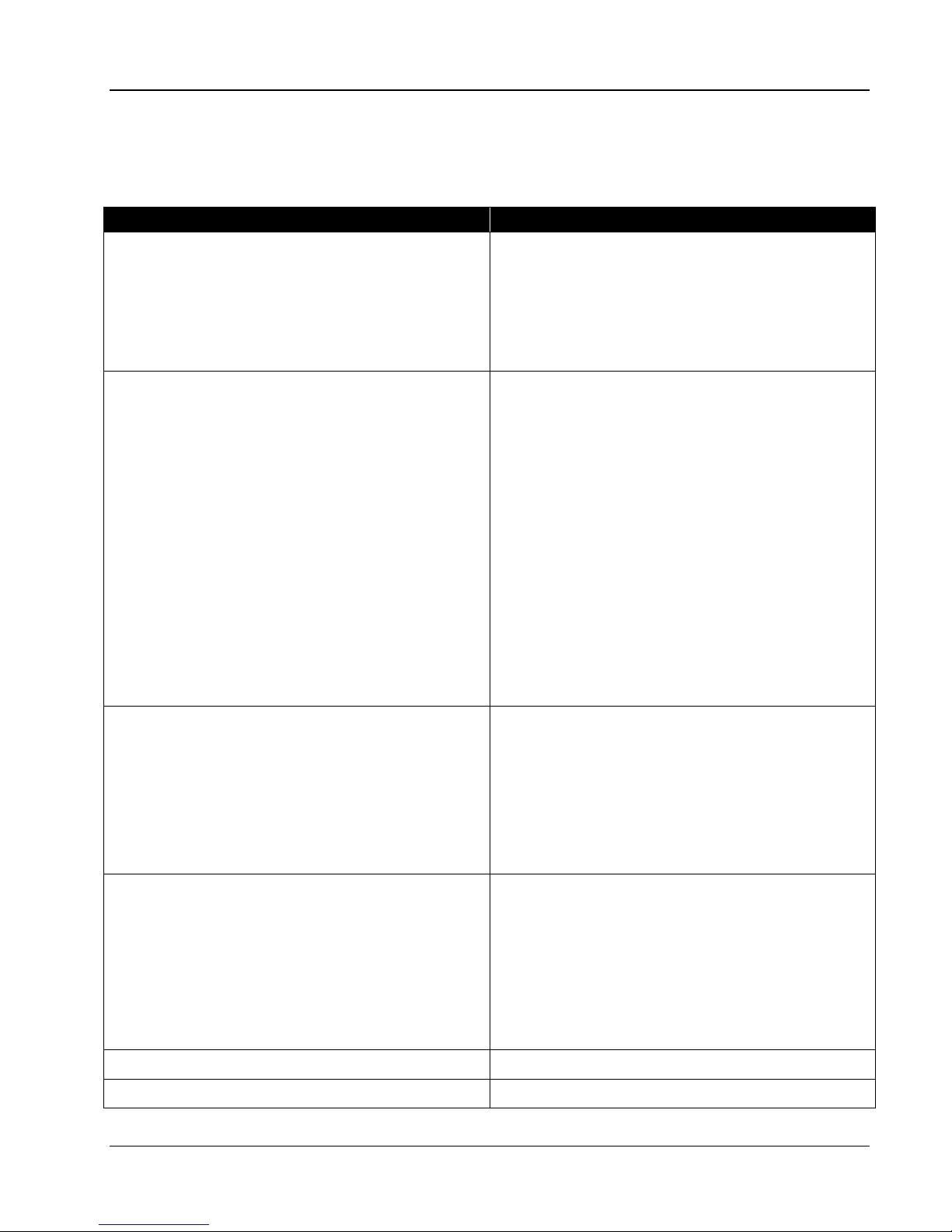

1-Point Measurement Mode

The default mode of the LoFlo Balometer®

Capture Hood is the 1-point measurement mode.

If you are in 2-point measurement mode, simply

turn the instrument off and turn back on.

The 1-point measurement mode is described in

the Getting Started section earlier in this manual.

This is the faster, simpler way to take

measurements.

Use Vent Closed Mode for measurements

between:

10 to 150 cfm (17 to 255 m3/h, 4.7 to 71 l/s).

NOTE: In Vent Closed Mode, volume rates

below 8 cfm (13 m3/h, 3.6 l/s) are displayed as

0; volume rates above 517 cfm (879 m3/hr, 244

l/s) are displayed as Or.

Use Vent Open Mode for measurements between:

150 to 500 cfm (255 to 850 m3/h, 71 to 236 l/s)

NOTE: In Vent Open Mode, volume rates

below 150 cfm (255 m3/h, 71 l/s) are displayed

as Ur; volume rates above 517 cfm (879 m3/h,

244 l/s) are displayed as Or.

2-Point Measurement Mode—Supply

Only

To activate the 2-point measurement mode, turn

the instrument off. While pressing the handle

button, turn the instrument back on. The 2-point

mode indicator will show.

The 2-point measurement mode takes both vent

open and vent closed measurements to calculate

a resistance-compensated volume flow rate.

The process starts with the vents closed and the

display showing the vent closed indicator.

1. Place the LoFlo Balometer® Capture Hood

over the diffuser to be measured and press

the handle switch once to take the vent closed

measurement.

2. The instrument stores that reading.

3. The display will now show the open vent

indicator and you should open the vents.

NOTE: Make certain you are using a fabric

hood when in 2-point mode.

4. Again place the LoFlo Balometer® Capture

Hood over the diffuser to be measured and

press the handle switch to take the vent open

measurement.

5. The instrument calculates and displays the

compensated reading.

6. The numeric display will flash; press the

handle switch again and the instrument will

display the vent closed indicator. Close the

vents.

7. Return to Step 1 to take another resistance

compensated reading.

NOTE: Return to 1- point measurement mode

at any time by turning the power off and on.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com