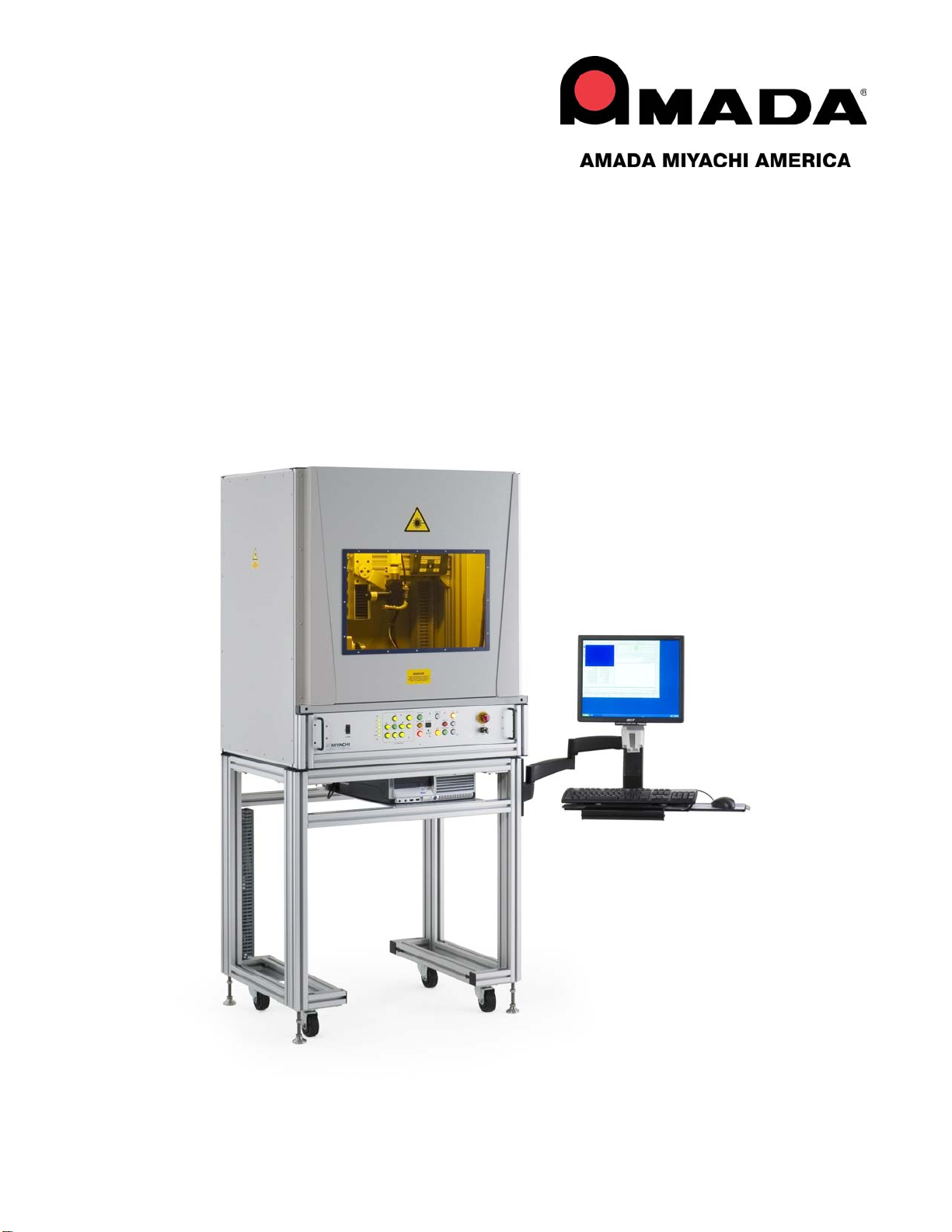

DELTA LASER WORKSTATION – VERTICAL DOOR OPTION

990-850 1

CONTENTS

General.......................................................................................................................................................ii

Revision Record ......................................................................................................................................ii

CDRH Compliance Statement................................................................................................................iii

Workstation Laser Safety ....................................................................................................................... iv

Workstation Specifications.....................................................................................................................vi

Laser Safety Labels (See Figures Included and Appendix) ...................................................................vi

Section I. General Description................................................................................................................ 2

Description............................................................................................................................................... 2

Delta Laser Workstation Dimensions (Figure 1A).................................................................................. 3

Workstation Facility Requirements (Figures 1A) ................................................................................... 3

Section II. Components and Figures...................................................................................................... 4

Workstation Rear Connector Panel (Figure 1B)...................................................................................... 4

Workstation Components........................................................................................................................ 5

Workstation Front View (Figure 2)......................................................................................................... 6

Workstation Front Panel - Panel Controlled (Figure 3A)........................................................................ 7

Workstation Front Panel - Pendant Controlled (Figure 3B).................................................................... 7

Workstation Control Panel (Figure 4)..................................................................................................... 8

Workstation Electrical Bay (Figure 5)................................................................................................... 10

Safety Circuit Utilizing Laser Emergency Stop and Door Safety Interlock (Figure 6) ........................ 11

Workstation Side View (Figure 7)......................................................................................................... 12

Workstation Top View (Figure 8)......................................................................................................... 12

Workstation Rear View (Figure 9)........................................................................................................ 13

Appendix A...................................................................................................Error! Bookmark not defined.

Labels and Warnings..............................................................................Error! Bookmark not defined.

Appendix B................................................................................................................................................ 1

Base Options............................................................................................................................................ 1

Appendix C................................................................................................................................................ 1

Additional Height Options....................................................................................................................... 1