3

• Do not install the furnace where the combustion air

is exposed to the following substances: permanent

wavesolutions,chlorinatedwaxesorcleaners,chlo-

rine based swimming pool chemicals, water soften-

ing chemicals, deicing salts or chemicals, carbon

tetrachloride, halogen type refrigerants, cleaning

solutions(suchasperchloroethylene),printinginks,

paint removers, varnishes, hydrochloric acid, ce-

ments and glues, antistatic fabric softeners for

clothes dryers, and masonry acid washing materi-

als. Ifthefurnaceisinstallednearanareawhichwill

be frequently contaminated by these substances,

the furnace should be sealed from this area so that

little contaminated air can reach the furnace. The

furnace must still have an adequate supply of com-

bustion air, either from a nearby uncontaminated

room or from outdoors. For details, see “AIR RE-

QUIREMENTS” Section III.

• Provisions must be made for venting combustion

productsoutdoorsthroughaproperventingsystem.

The length of flue pipe could be a limiting factor in

locating the furnace.

• When installed horizontally, the furnace must be

installed with the access doors vertical so that the

burners fire horizontally into the heat exchanger.

The unit cannot be installed with the access doors

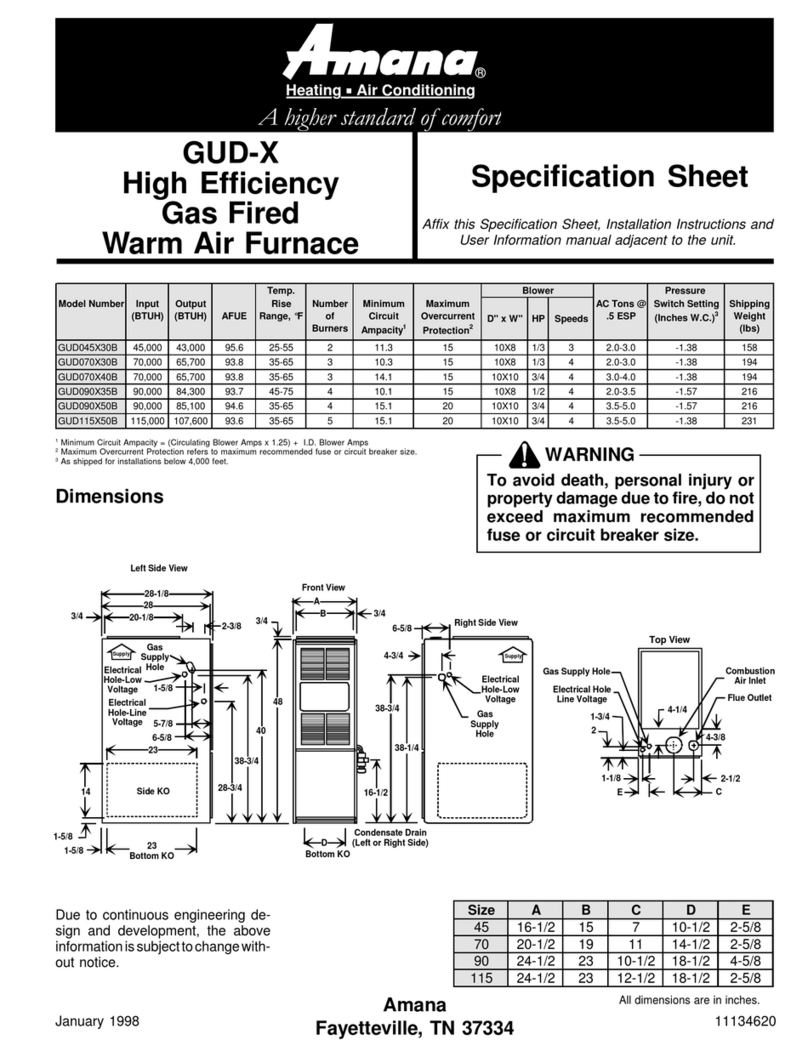

on top or bottom. (See Specification Sheet)

• Allow clearances from the enclosure as shown on

SpecificationSheetforfireprotection,properopera-

tion,andserviceaccess.Theseclearancesmustbe

permanently maintained. The combustion and ven-

tilatingairopeningsinthefrontandtoppanelsofthe

furnace must never be obstructed.

• This furnace shall not be connected to a chimney

flue serving a separate appliance designed to burn

solid fuel.

• When the furnace is used in connection with a

cooling unit, the furnace must be upstream of, or in

parallelwith,thecoolingunit.FordetailsseeSection

VIlI.

• On Counterflow Installations, the air conditioning

coil must be downstream from the heat exchanger

of the furnace.

•

CounterflowInstallationoveranoncombustiblefloor.

Beforesettingthefurnaceovertheplenumopening,

insure the surface around the opening is smooth

and level. A tight seal should be made between the

furnace base and floor by using a silicone rubber

caulking compound or cement grout.

•

Counterflow Installation over a combustible floor.

If

installation over a combustible floor becomes nec-

essary,useanaccessorysub-baseasshownonthe

SpecificationSheet.Followtheinstructionswiththe

sub-base for proper installation. Do not install the

furnace directly on carpeting, tile, or other combus-

tible material other than wood flooring. (Note: The

sub-base will not be required if an air conditioning

coil is installed between the supply air opening on

the furnace and the floor.)

I. Safety and Unit Location

WARNING

To prevent personal injury or death due

to improper installation, adjustment, al-

teration, service, or, maintenance refer

to this manual or for additional assis-

tance or information consult a qualified

installer, service agency or the gas sup-

plier.

WARNING

This product contains or produces a

chemicalorchemicalswhichmaycause

serious illness or death and which are

knowntotheStateof California tocause

cancer, birth defects or other reproduc-

tive harm.

WARNING

To prevent possible death, personal in-

jury or equipment damage due to fire,

the following points must be observed

when installing the unit.

WARNING

To prevent possible death, personal in-

juryorpropertydamageduetoelectrical

shock, the furnace must be located to

protect the electrical components from

water.

NOTE: This unit must not be used as a “construction

heater” during the finishing phases of construction on a

new structure. This type of use may result in premature

failure of the unit due to extremely low return air tem-

peratures and exposure to corrosive or very dirty atmo-

spheres.

WARNING

To prevent possible death, personal in-

jury or property damage, do not install

this unit in a mobile home, trailer or

recreational vehicle.

Additional Safety Considerations

• This furnace is approved for Category I Venting

only.

• Whenthefurnace is heating,thetemperature ofthe

return air entering the furnace must be between

55°F and 100°F.