8

Bulletin

Type Parts Manual Update

Policy Letter

√Service Information

Attention Service Managers

√Service and Parts Managers

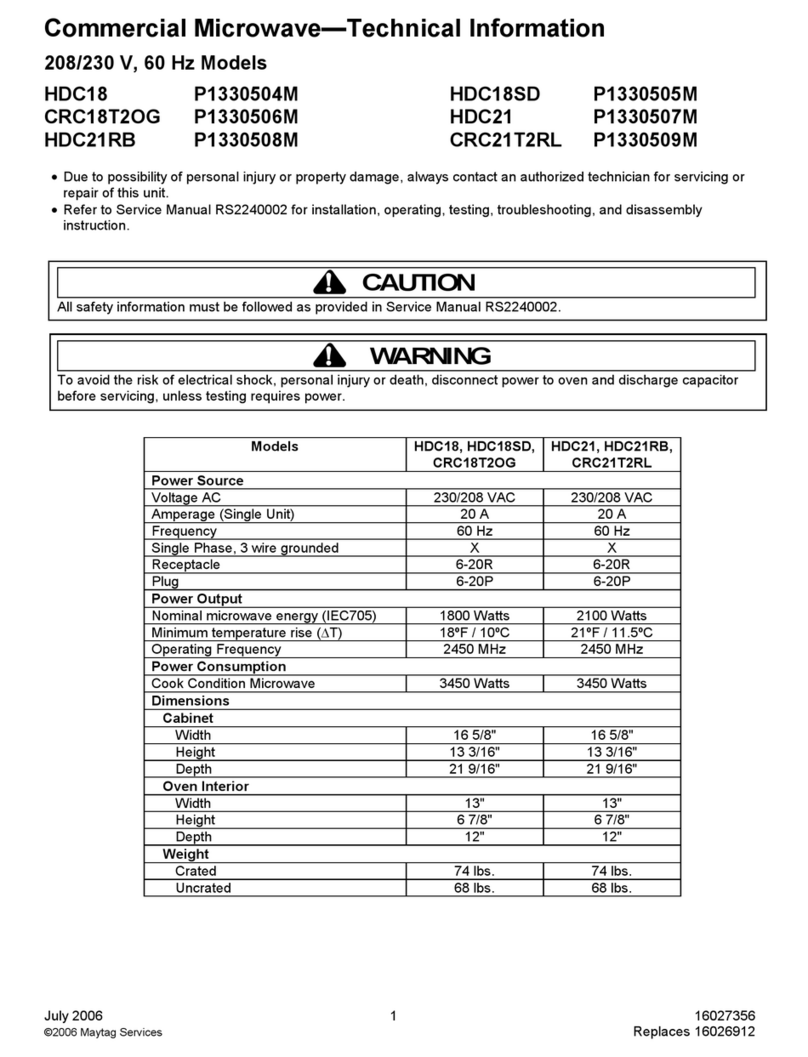

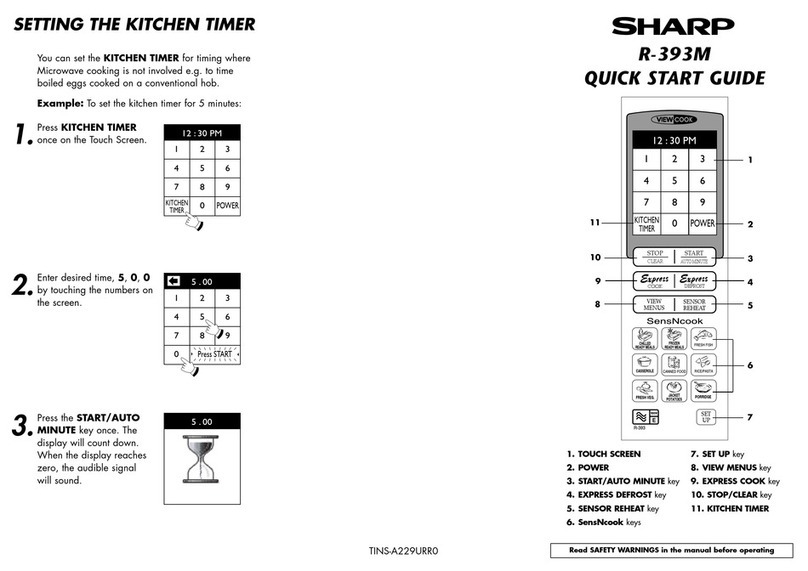

Models CRC and HDC Compact Commercial Ovens

Issue Broken tray as a result of arcing at front lip of cavity.

Warranty Ceramic trays may be claimed under warranty only if damage was caused by

antenna failure (arcing).

Trays are not covered under warranty if there is evidence that damage was caused by impact,

thermal shock (frozen or refrigerated product placed on warm tray), oven operated with metal pans,

oven operated without a food load or lack of proper cleaning and maintenance.

NOTE: Typical symptoms of metal pan usage or empty cavity operation include arc spots on the

front lip of cavity, 1 to 2 inches from either side.

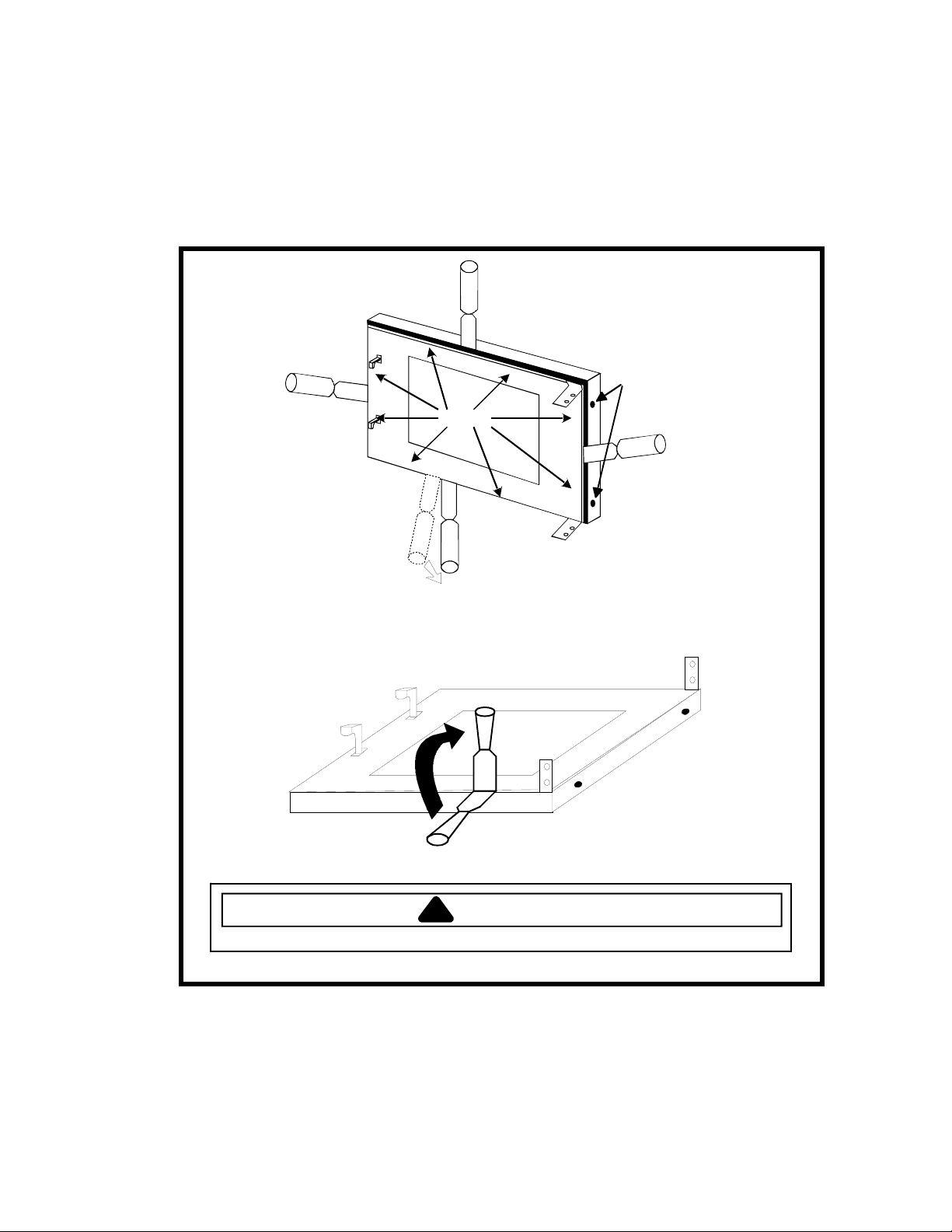

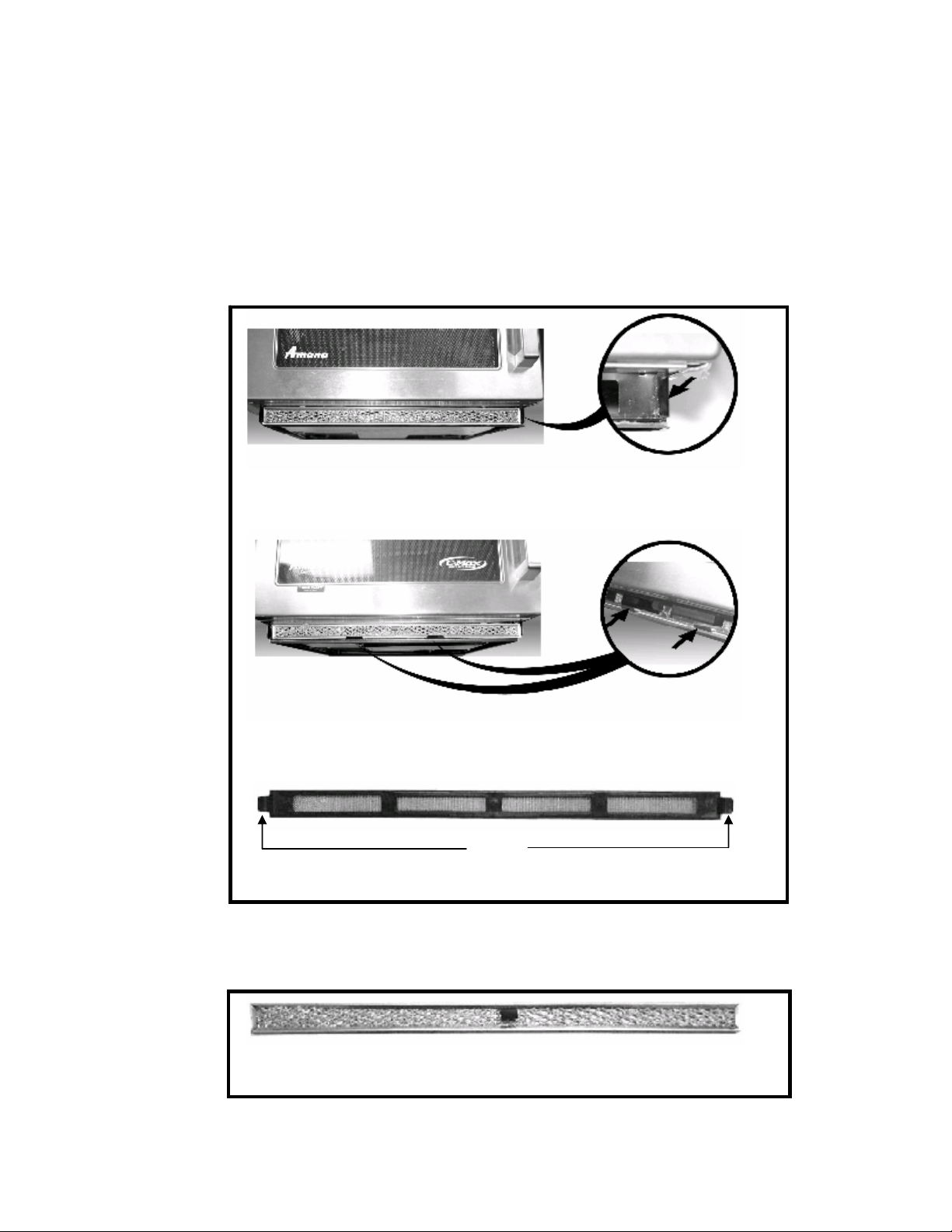

Action If encountering arcing at front lip of cavity, proceed as follows:

1. Check antenna operation – if either antenna is stalled, hot spots will occur.

2. Remove oven tray.

3. Thoroughly remove any carbon build-up from front lip using fine grade sandpaper.

4. Thoroughly clean cavity and front lip removing all old RTV.

5. Before installing new tray, apply a generous bead of RTV on the front lip of cavity, (see below).

6. Install new tray and reseal using instructions supplied with the tray.

7. If arcing has damaged the oven door, replace inner oven door and inspect door ring weldment

for arcing.*

8. Replace door ring weldment if it is damaged.*

*To ensure proper operation, use the instructions in the Service Manual when reinstalling the

oven door.

Apply a generous bead

of RTV along this lip

before installing oven tray

Date July 31, 2001

No CR−236−B

EXCMW-125-B

Page 1 of 1

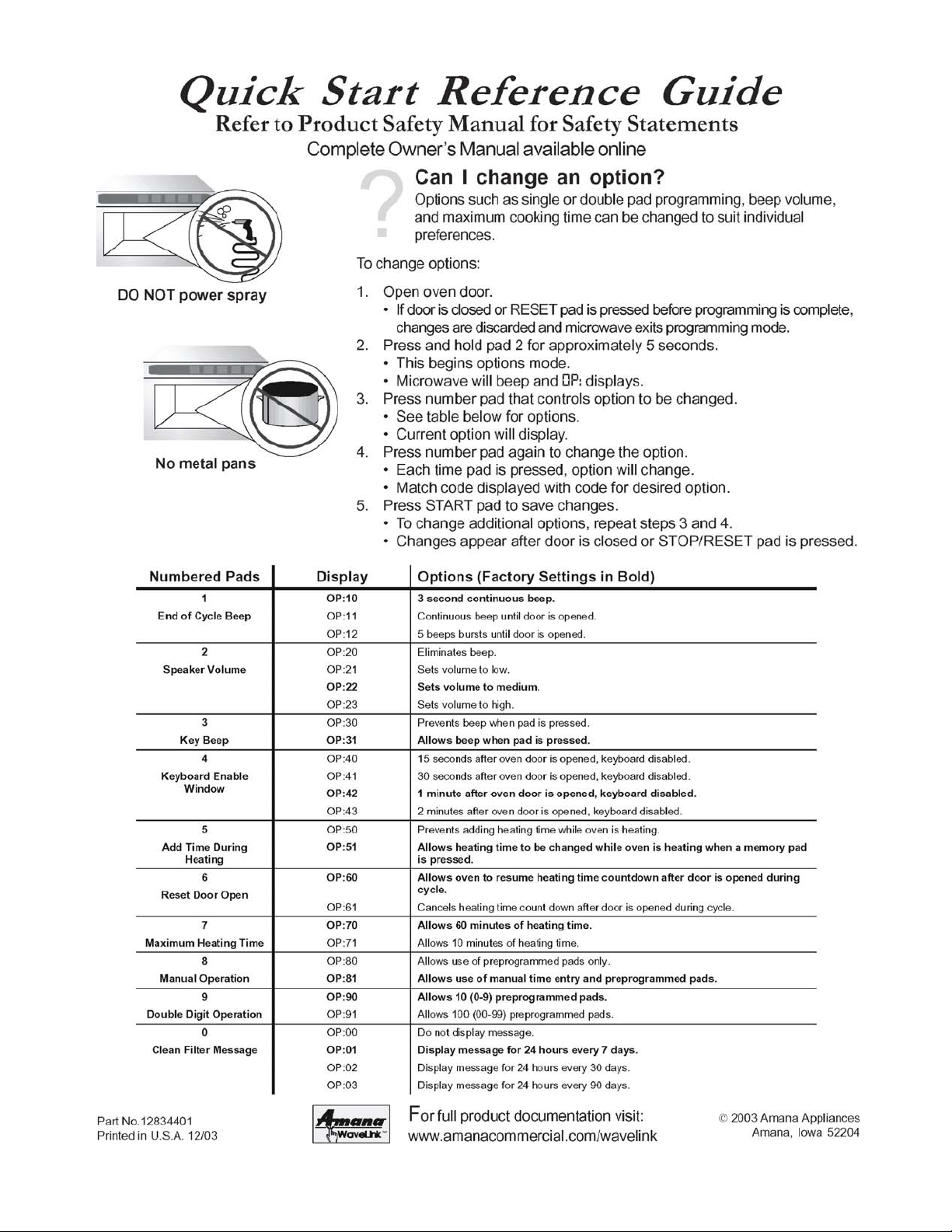

√Comm. Microwave Dehumidifier Dishwasher

Domm. Microwave √Export Comm. Heating Product

Laundry Product PTAC Products Range Product

Refrigerator/Fzr Room Air Cond.