AMANTI Technologica®Instruction Manual

F

FR

RE

EE

Ec

ca

al

ll

l

1

1-

-8

80

00

0-

-C

CO

OF

FF

FE

EE

E

A

AM

MA

AN

NT

TI

Ic

co

of

ff

fe

ee

e.

.c

co

om

m

F

FR

RE

EE

Ef

fa

ax

x

1

1-

-8

80

00

0-

-A

AM

MA

AN

NT

TI

I

T:\Photos Digital\Coffee Equipment - New Ours\Technologica\Technologica Instruction Manual 080304.doc

I

In

ns

st

ta

al

ll

la

at

ti

io

on

n

C

Co

on

ns

si

id

de

er

ra

at

ti

io

on

ns

s

SafetyWarnings

1. Start upandinstallation of thisespressocoffee machinemust bedone by aqualified technician.

2. Make sure that installation of water and electricity are compliant withofficial requirements.

3. Checkoutthatelectricalvoltage andcurrent requirement of the installationmatcheswiththeequipment specifications

plate.

4. All electrical appliancesmust begrounded withanEarthwire.

5. Keepthismanual forfuture reference.

6. Inappropriateuseof the coffee machine or usage not inaccordancewith theindicationsof this manualwill

automatically cancel anywarrantiesandresponsibilities of themanufacturer and equipment seller. Thismachinemust

beoperatedandusedproperly by anadult and responsibleperson.

7. AnEspressocoffee machine ismanufacturedonly to produce espresso coffee, hot water forinfusions and steam.

8. User must informtheinstaller about any factors that could compromise the safety of the installation.

9. Installer must testthat conditions are adequate withregardto safety and hygieneforoperators and the public.

10. Themanufacturer can not beconsidered responsible for damages caused by improper, incorrect or unreasonableuse.

11. Nevertouch themachine with wet hands.

12. Donot expose machine to sun, rain, etc...

13. Before cleaning or checkingthe machine rememberthat groups, steam wandsorother components may be hot.

14. Donot obstruct upper sideof themachine (cuptray grille). Donot pour liquids or introducematerialsthroughthe topof

the machine(cuptray grille)

15. Machine partsandpacking materials (metal, plastic,cardboard,staples,etc.) maycutorinjure people or become

dangerousif nothandled properly orusedimproperly.Neverletchildren or unauthorized personsnear materials that

mayinjurethem.

16. Maintenanceoperationsmust be donebyspecialized and AMANTI accredited technicians.

17. Themanufacturer can not be held responsiblefortheincorrect application of this advice.

Before Commissioning the Equipment

1. Theespresso coffeemachineshouldbelocated on asurfacethatcan safely support its weight (allow for at least

100kgs). The manufacturercannotbe held responsible for damage causedby instability of the supporting structure.

2. Wheninstallingisnecessarytomakeaholefor water connections,dischargepipesandelectricwires below the

machine. Werecommend a holewith adiameter of approximately 50 mm.

3. Water pipesand electrical wires should not bekinked.

4. Theespresso coffeemachine is suppliedwithout an electricplug.

5. The machineshould beprotectedby an approved and appropriate electrical fuseand earthleakage detector.In the

event that the main power cordis not longenough, the cordshould be replaced by an AMANTI authorized technician.

6. Thewaterconnectionto themachineshould be through atap so that the water supply tothemachine canbeturned

off.

7. To guarantee thereliability ofthepump, it isnecessary to install a 50 micron filter after thepressurelimitingvalve and

beforeconnectionto the machine. An AMANTI triple action water filter will protect themachineagainst impuritiessuch

assand particles, minerals and rust that woulddamage thedelicate graphite vanes of thepump.

8. Is always advisabletoflushwater pipesbeforeconnectingtothe machine.

9. Plumbedindrainage is recommend .

10. Thecoffee grinder can be positionedon either side of the Technologica® coffeemachine.

The Technologica® is supplied with

•An Instruction manual

•Braided water hose, 1 meter, 3/8" female thread

•Braided water hose, 1.5meters, 3/8"female thread

•One waste drainage tube

•One single basket, single spout, handle

•Double basket, doublespout, one handleforeach groupon themachine

•One blind cleaningbasket.

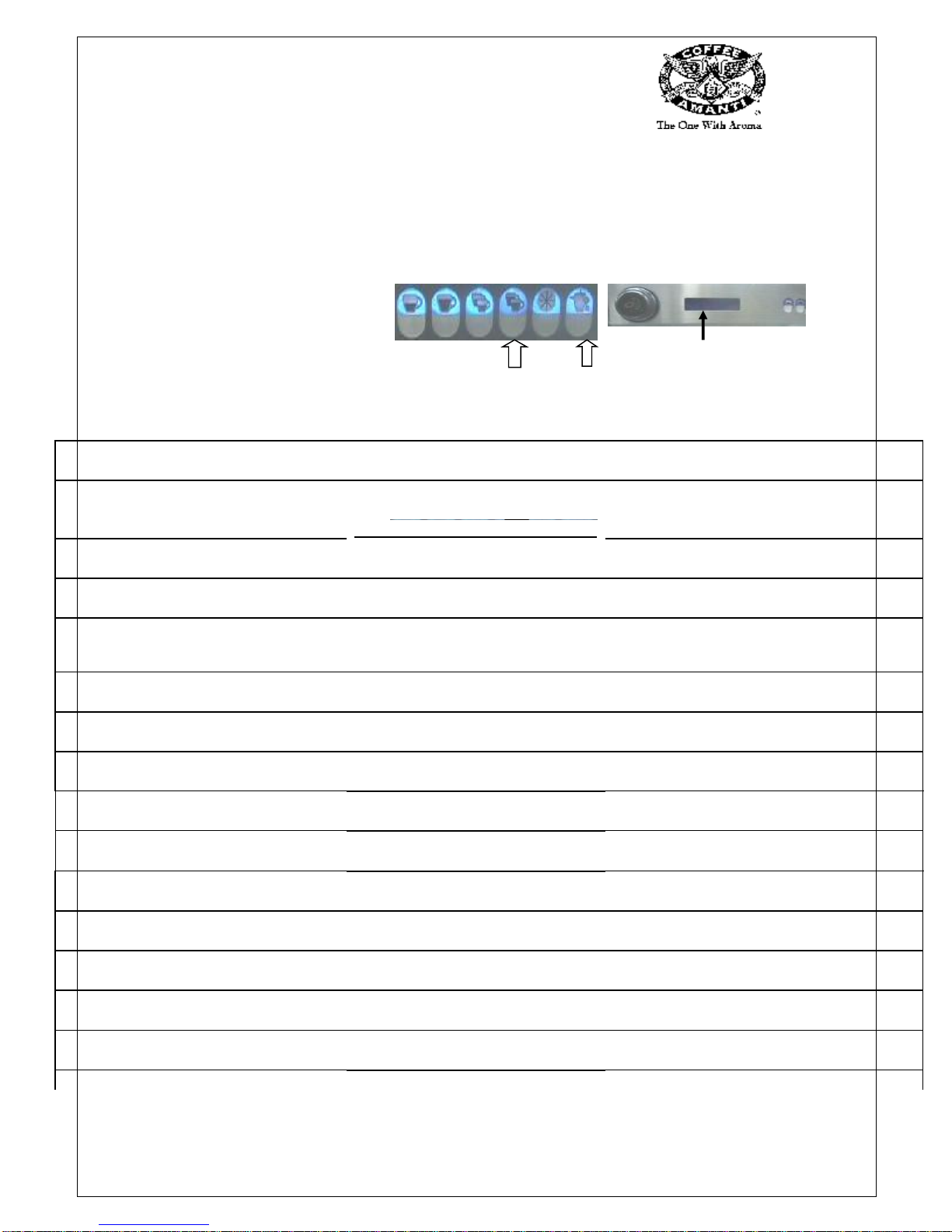

Indicator Lights and Controls

Steam tap: locatedat the uppercorneron thefront panel.

Use: to obtainsteam. Clean after each use.

Green arrow boiler fillingindicator light: located at the right side of thewaterfill tap.

Green ON indicatorlight: located next to the main on/ off switch

Heating element on indicator light: located next to themainon / off switch.

0

2