INSTALLATION

OPERATION

MAINTENANCE

Self Regulating Fresh Air Inlet

For Indoor Air Quality Ventilation

* Some jurisdictions/utilities may have different requirements. Consult your code official/utility representative.

TheAirlet200isafreshairinletdesignedtosupply

make up air ventilation for bedrooms and living

areas, and is not intended to supply combustion

air for fireplaces or large exhaust fans, such as

range hoods.

The Airlet 200 is compatible with zonal electric,

radiant and hydronic heating systems. It must not

be used with forced air heating systems, unless

return registers are provided in each room in

which an Airlet 200 is installed. This is to prevent

exfiltration through the inlet when the forced air

systemisoperating anddoorsareclosedbetween

rooms.

For make up air products specifically engineered

for use with forced air heating systems, request

an ALDES FAK from your supplier.

General Notes and Suggestions

Best results will be obtained in homes with tight air-

vapor retarders, and continuous central exhaust from

bathrooms, kitchen and laundry.

The goal is to achieve a home with slight negative

pressure, to avoid exfiltration into the walls and attic.

Install one fresh air inlet in each bedroom, and living/

dining room area(s). Inlets should not be installed

in kitchens, bathrooms or laundry areas. These

areas should be exhaust points to a central exhaust

system.

When placed high on exterior walls, drafts from the

inlet should not be noticeable. The interior fixture has

louvers to direct the airflow upwards where it quickly

mixes with warmer air near the ceiling.

INSTALLATION INSTRUCTIONS

TOOLS REQUIRED

• 5-1/4" diameter hole saw,

Keyhole saw, saber saw

or router

•Drywall knife

• Philips No.1 screwdriver

• Silicone or exterior butyl

caulk

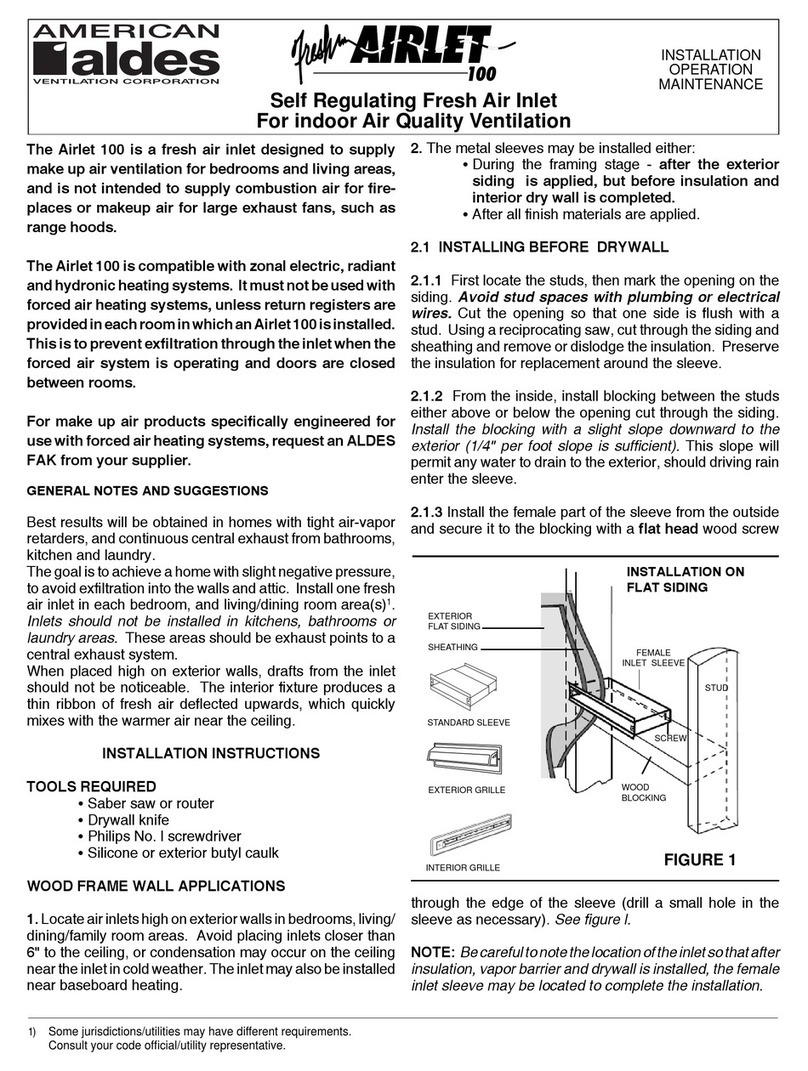

1. ON FLAT SIDING, OR

SIDING WITH MINIMUM

SIX INCH EXPOSURE

1.1 Locate the position of the inlet on the

exterior with reference to the interior. The inlet on the

interior should be within 12 inches of the ceiling, but

not closer than 6 inches to the ceiling.

1.2 Using the appropriate hole cutting tool, cut

a 5-1/8" diameter hole through the siding, sheathing,

insulation and interior wall surface. Be careful to properly

align the holes on the interior surface with the exterior.

CAUTION: Avoid cutting through any vertical framing

members, pipes or electrical wiring.

1.3 Apply a 1/4

inch bead of caulk

(siliconeorbutylcaulk

is recommended) on

the interior side of the

square flange within

1/4 inch of it edges,

and its connection

with the cylindrical

sleeve. These

precautions are

necessary in order

to avoid infiltration of

rain leakage or water

behind the flange.

1.4 Insert the

outer sleeve with the square flange through the siding

toward the interior.

1.5 Attach the exterior grille with mesh to the

square flange and secure to the siding with the screws

provided.

NOTE 1: The aluminum exterior grille may be painted

with latex acrylic paint, after cleaning with a mild acid

wash,suchasvinegar. Thewhite grillemaybepainted

with an oil base paint if desired, though several coats

may be necessary to obtain good results.

NOTE 2: If the siding is painted after installation of

the exterior grille, take precautions to avoid paint

clogging the mesh screen of the grille.

1.6 To install the interior half of the sleeve, first fit

the plastic collar to the male sleeve with the two concave

beads. Note that one bead is deeper than the other. The

deeper bead must be oriented close to the plastic collar.

Install the filter between the two beads. This should be a

snug friction fit. (In the event of wind-driven rain entering

the inlet, the filter can block further penetration, and the

accumulating water can drain over the shallow bead to the

exterior.)

Apply a generous bead of caulk to the concave beads.

In addition, apply a small caulk bead to the flange of the

plastic collar, to make an airtight

Install filter in male

sleeve, between 2

beads. NOT in the

grille collar.