Page 7

LOCATIONS AND RECOMMENDATIONS

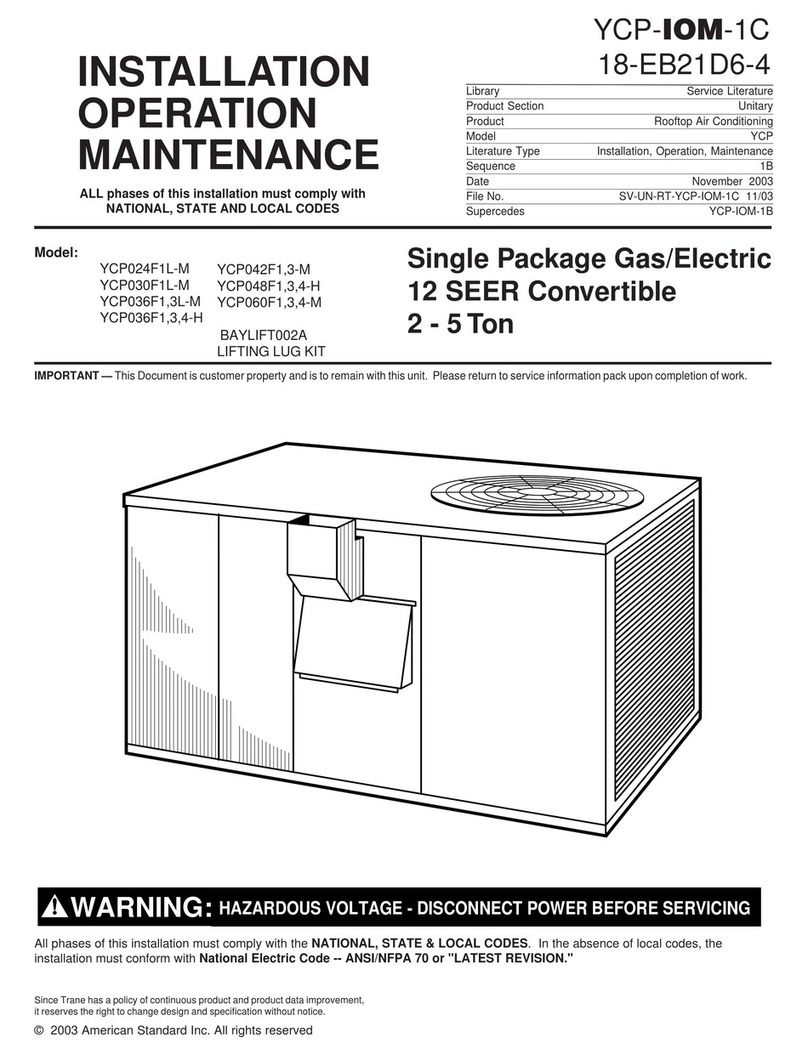

HORIZONTAL AIRFLOW APPLICATION

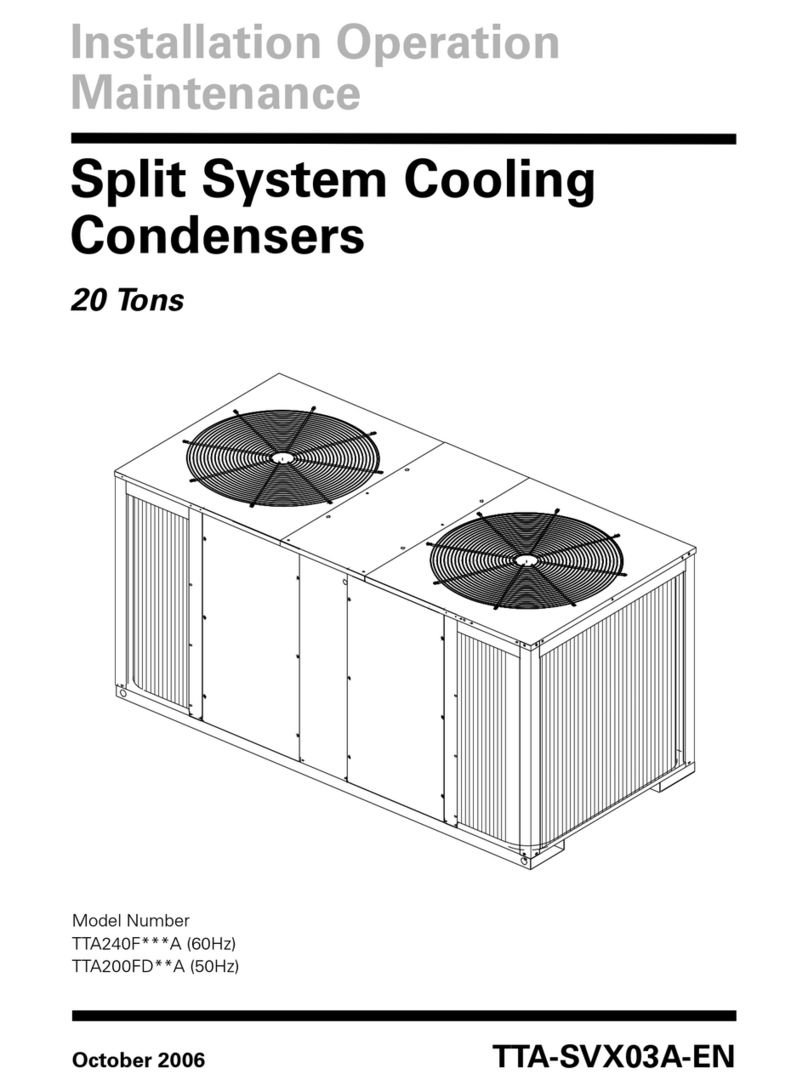

1. Theseunitsaredesigncertifiedforoutdoorinstallations. These

units may be installed directly on wood flooring or on Class A,

Class B, or Class C roof covering material. The discharge air

from the condenser fans must be unrestricted for a minimum of

3 feet above the unit.

NOTE: The unit is shipped for horizontal installation.

TheAirInlet Hood in the combustionblower access panelmust

have adequate clearance around the air opening into the

combustion area. See Outline Drawing, Figure 3.

Examine all flue product-carrying areas of the furnace, its vent

system, and the main burner for safe operation. A periodic

inspectionof the furnaceshould bemadeby a qualified service

agency at the start of each heating season.

ReplacementpartslistforthisGas/ElectricAirConditioner,maybe

obtained by contacting your local manufacturer representative.

NOTE: If any internal accessories are to be added to the unit,

install them at the shop if at all practical.

2. Location of the unit must allow service clearance around it.

Clearance of the unit must be given careful consideration. See

Figures 2, 3, and 4.

IMPORTANT: Air outlet duct must have 1" clearance to

combustible material downstream from the unit.

3. Check the handling facilities to ensure the safety of personnel

and the unit(s).

4. CAUTION MUST BE TAKEN AT ALL TIMES TO AVOID

PERSONAL INJURIES AND/OR DAMAGE TO EQUIPMENT

5. The unit must be mounted level for proper drainage of water

through the holes in the base pan.

6. The unit must not be exposed to direct roof water runoff.

7. Flexible duct connectors must be of a flame retardant material.

All duct work outside of the structure must be insulated and

weatherproofed in accordance with local codes.

8. Holesthroughexteriorwallsmustbe sealed in accordance with

local codes.

9. All fabricated outdoor ducts should be as short as possible.

CLEARANCES

1. The recommended clearances for single-unit installations are

illustrated in Figure 4. These minimum requirements are not

only an important consideration when determining unit place-

ment, but they are also essential to ensure adequate service-

ability, maximum capacity, and peak operating efficiency.

2. Any reduction of the unit clearances indicated in these illustra-

tionsmayresultin condenser coil starvation or the recirculation

of warm condenser air. Actual clearances which appear to be

inadequate should be reviewed with a local engineer.

3. See the unit’s nameplate for the absolute minimum clearance

between the unit and any combustible surface(s).

IMPORTANT:

1. Removethe FlueandAirInlet Hoodwithgasket fromthereturn

air section of the unit.

Thescrewsthatattachtheflueandairinlethoodwillbeinstalled

in their proper location at the factory. Therefore, they must be

removedand then used toattach theflue andthe airinlet hood.

2. Remove the packaging material from the components and

secure the Flue and Air Inlet Hood with the gasket to the unit

with sheet metal screws as illustrated in Figure 5. See “Firing

Rate Selection” section for additional information.

NOTE: Outdoor air or other requirements during heating

operation that result in supply air temperatures below 80

degrees F or return air temperatures below 50 degrees F may

cause flue gas condensate to form and is to be avoided.

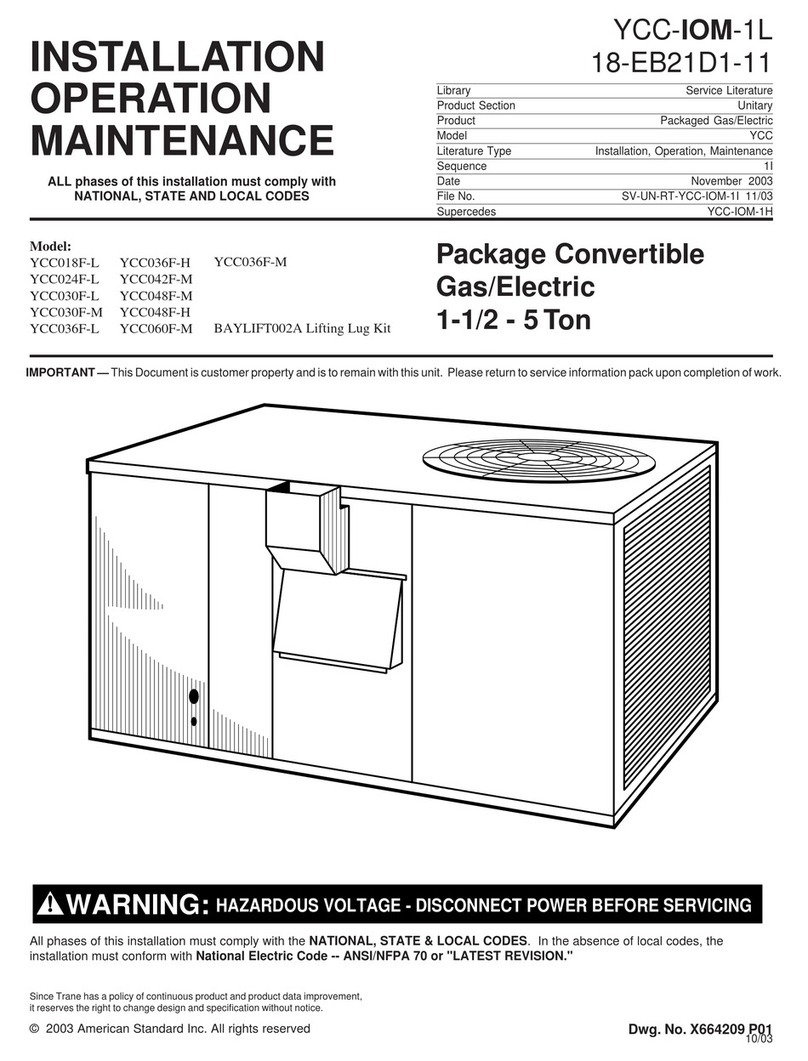

DOWNFLOW APPLICATION -- CURB MOUNTING

1. The Roof Mounting Curb, (field assembled

BAYCURB030,038,033,034A), or a field fabricated curb must

be in place before the unit is hoisted to the roof top.

2. TheRoofMounting Curb(frame)mustbeinstalled onaflat,

level section of the roof (maximum of 1/4" per foot pitch)

and provide a level mounting surface for the unit. In

addition,besuretoprovidesufficientheightabovetheroof

to prevent water from entering the unit.

NOTE: This unit was shipped for horizontal installation. Con-

vert to downflow per instructions:

Remove covers from the downflow supply and return air open-

ings and place them over the horizontal supply return air

openings(paintedsideout)andsecurewithsheetmetalscrews.

See Figure 6.

3. Be sure the mounting curb spans structural members (trusses)

oftheroof, thereby providing sufficient supportfor the weightof

the unit, the curb, the duct(s), and any factory or field installed

accessories. See Figures 1, 7, 8, 9, 10, and 11.

4. Be sure the hole in the structure for the ducts is large enough

to accommodate the fabricated ducts and the insulation sur-

rounding them. See Figure 4.

Note: If any internal accessories are to be added to the unit,

install them at the shop if at all practical.

5. These units are design certified for outdoor installation. These

units may be installed directly on wood flooring or on Class A,

Class B, or Class C roof covering material. The discharge air

from the condenser fans must be unrestricted for a minimum of

3 feet above the unit.

The air inlet hood in the combustion blower access panel must

haveadequateclearancearoundairopeningsintothecombus-

tion area. See Outline Drawing, Figure 3. continued on next page