v

Table of Contents

1. Introduction.................................................................................................................................1

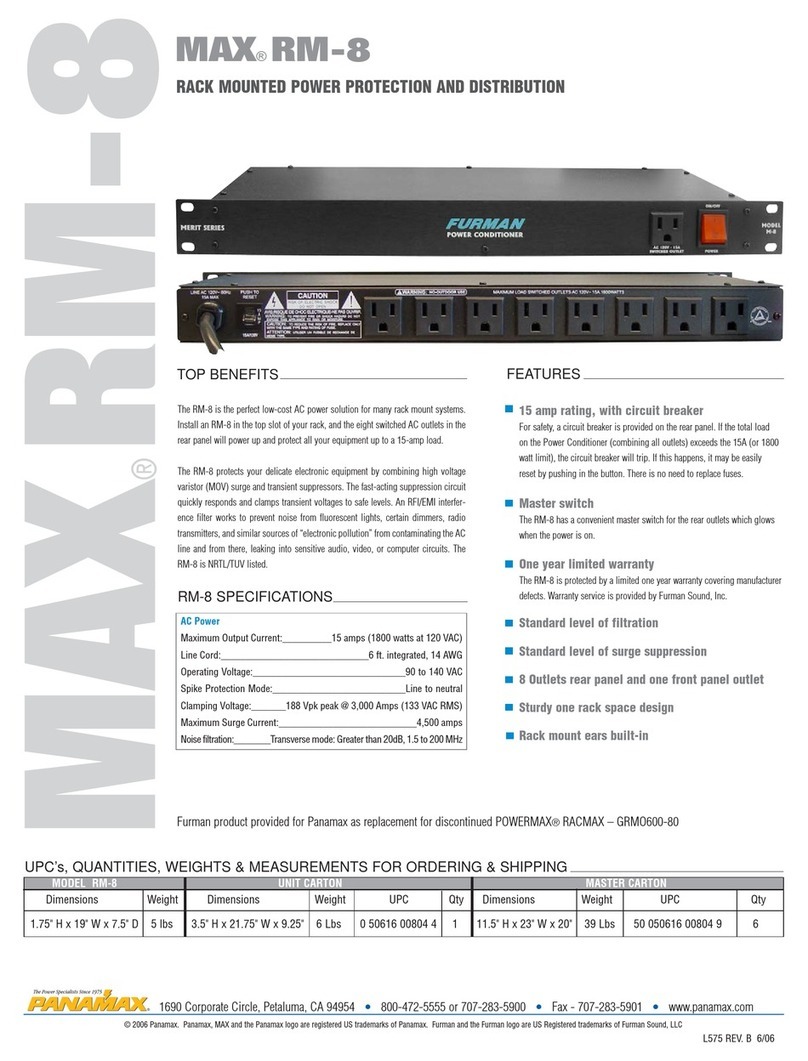

1.1. General Description...................................................................................................................................1

2. Specifications .............................................................................................................................2

2.1. Electrical....................................................................................................................................................2

2.2. Mechanical ................................................................................................................................................5

2.3. Environmental............................................................................................................................................6

2.4. Regulatory.................................................................................................................................................6

2.5. Front Panel Controls..................................................................................................................................7

2.6. Available Options.......................................................................................................................................7

3. Unpacking and Installation .........................................................................................................8

3.1. Unpacking .................................................................................................................................................8

3.2. Power Requirements.................................................................................................................................8

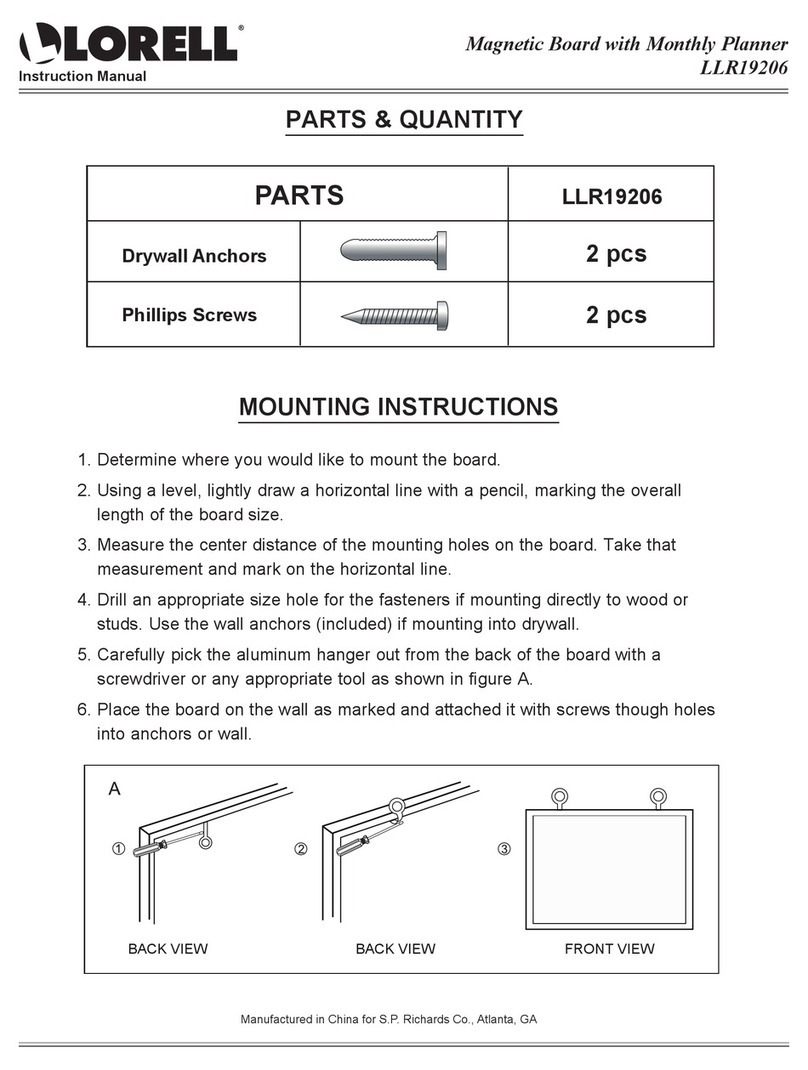

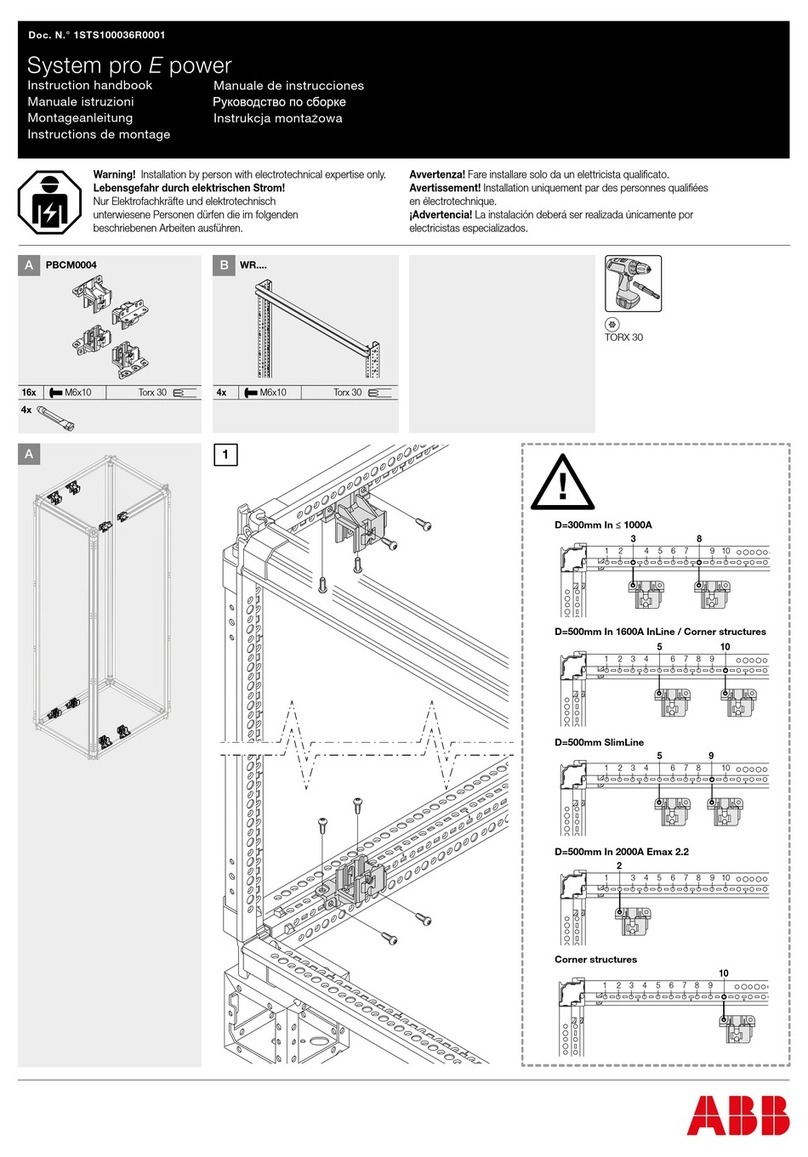

3.3. Mechanical Installation..............................................................................................................................8

3.4. Input Wiring...............................................................................................................................................9

3.5. Output Connections...................................................................................................................................9

3.6. Output Voltage Ranges...........................................................................................................................10

3.7. Functional Test........................................................................................................................................10

4. Front Panel Operation ..............................................................................................................12

4.1. Front Panel Guided Tour.........................................................................................................................12

4.2. How to... ..................................................................................................................................................16

5. Principle of Operation...............................................................................................................19

5.1. General....................................................................................................................................................19

5.2. Overall Description..................................................................................................................................19

5.3. Power Factor Correction Module (PFC) ..................................................................................................19

5.4. DC - DC Converter Module......................................................................................................................20

5.5. 20

5.6. Oscillator Control Board ..........................................................................................................................21

5.7. DC to AC Power Module..........................................................................................................................22

5.8. IEEE 488/ RS232 ....................................................................................................................................22

6. Calibration.................................................................................................................................24

6.1. Calibration Equipment.............................................................................................................................24

6.2. Routine Calibration..................................................................................................................................24

6.3. Non-Routine Calibration ..........................................................................................................................27

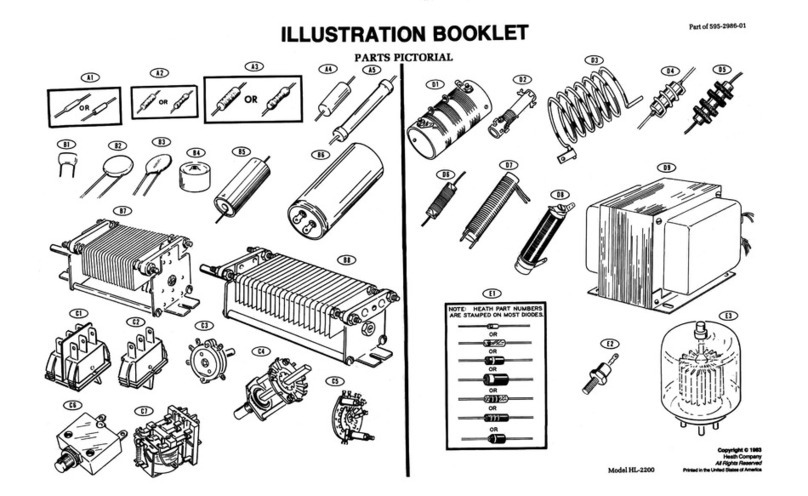

7. Service......................................................................................................................................29

7.1. General....................................................................................................................................................29

7.2. Basic Operation.......................................................................................................................................29

7.3. Advanced Troubleshooting......................................................................................................................31

8. Introduction to PGUI32.............................................................................................................34

8.1. About This Program.................................................................................................................................34

8.2. About This Section of the Manual............................................................................................................34

8.3. Program Requirements ...........................................................................................................................34

8.4. RS232C Cable Wiring .............................................................................................................................35

9. PGUI32 Setup and Installation .................................................................................................36

9.1. Connecting the AC Source to the PC When Using RS232 .....................................................................36

9.2. Connecting the AC Source to the PC Using IEEE-488 ...........................................................................36

9.3. Installing the PGUI32 Software ...............................................................................................................36

9.4. Trouble Shooting - RS232C ....................................................................................................................37

9.5. Registration .............................................................................................................................................39