SERVICE

AND

REPAIR

I~

sufficiently to

take

up the

play

in

the

throttle

control

lever.

• Adjust

carburetor

as

described

in

carburetor

adjustment

procedures.

Carburetor Adjustment

When adjusting the

carburetor,

best

results

will

be

obtained

if

the

adjustments

are

made on a

warm

engine. During

carburetor

adjustments,

DO

NOT

FORCE ADJUSTMENT SCREWS INTO SEATS.

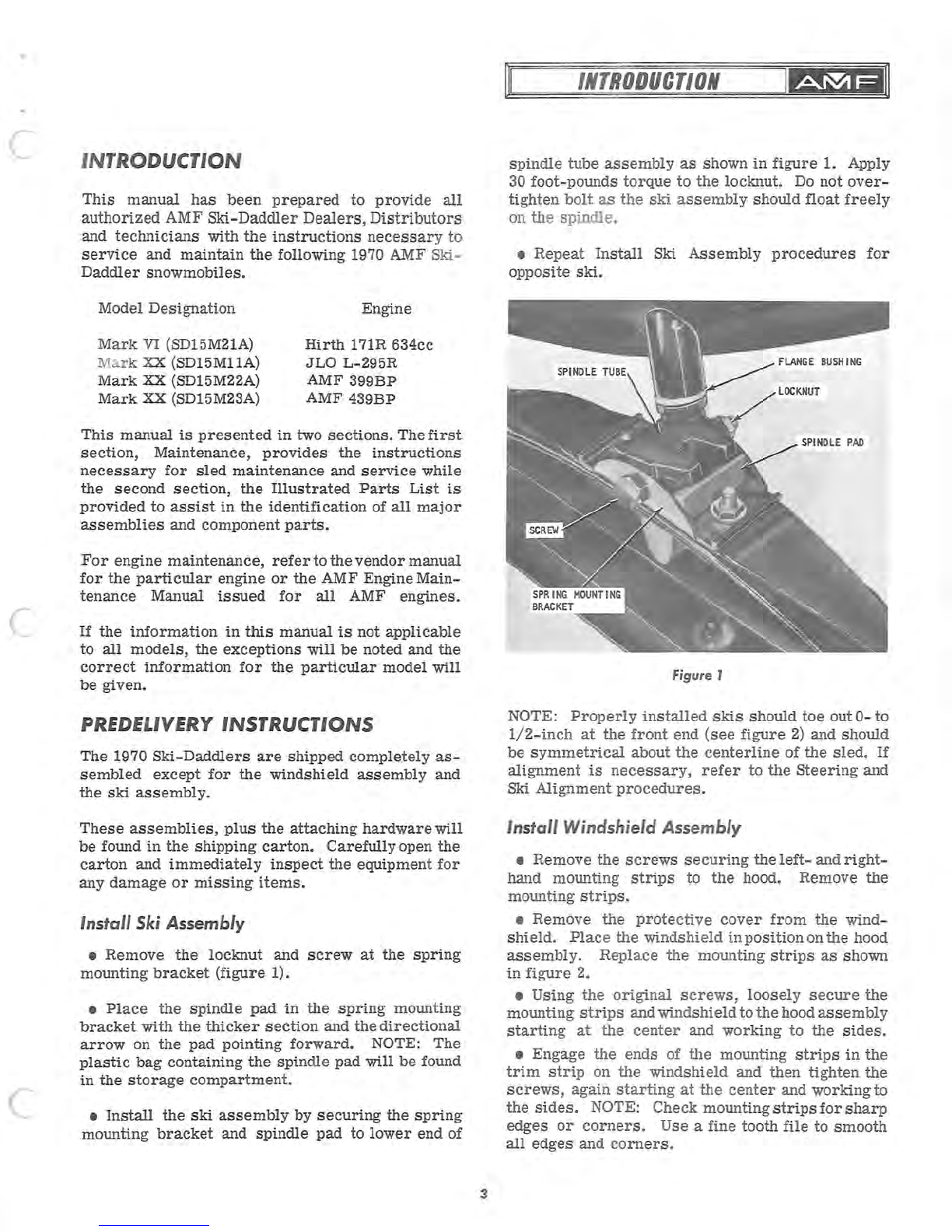

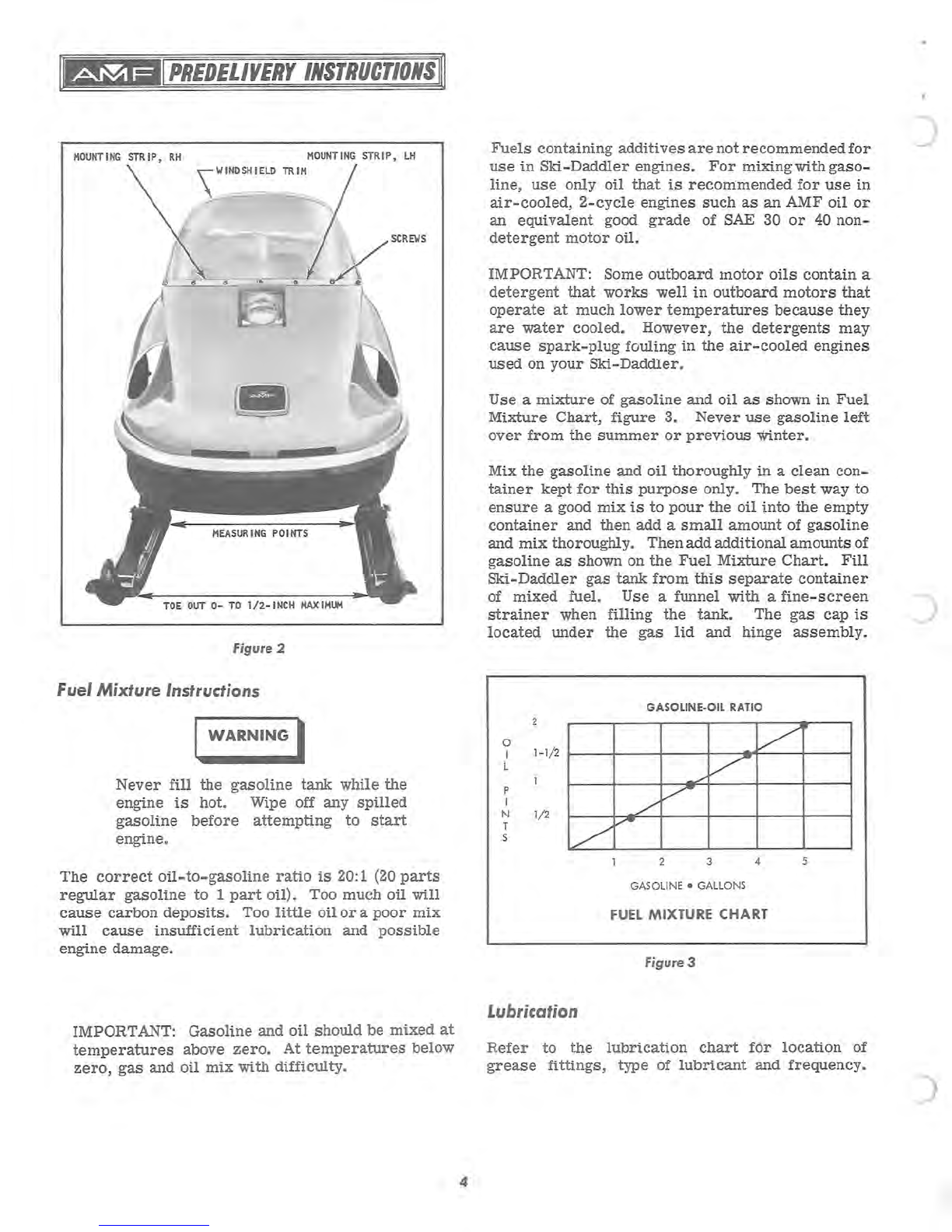

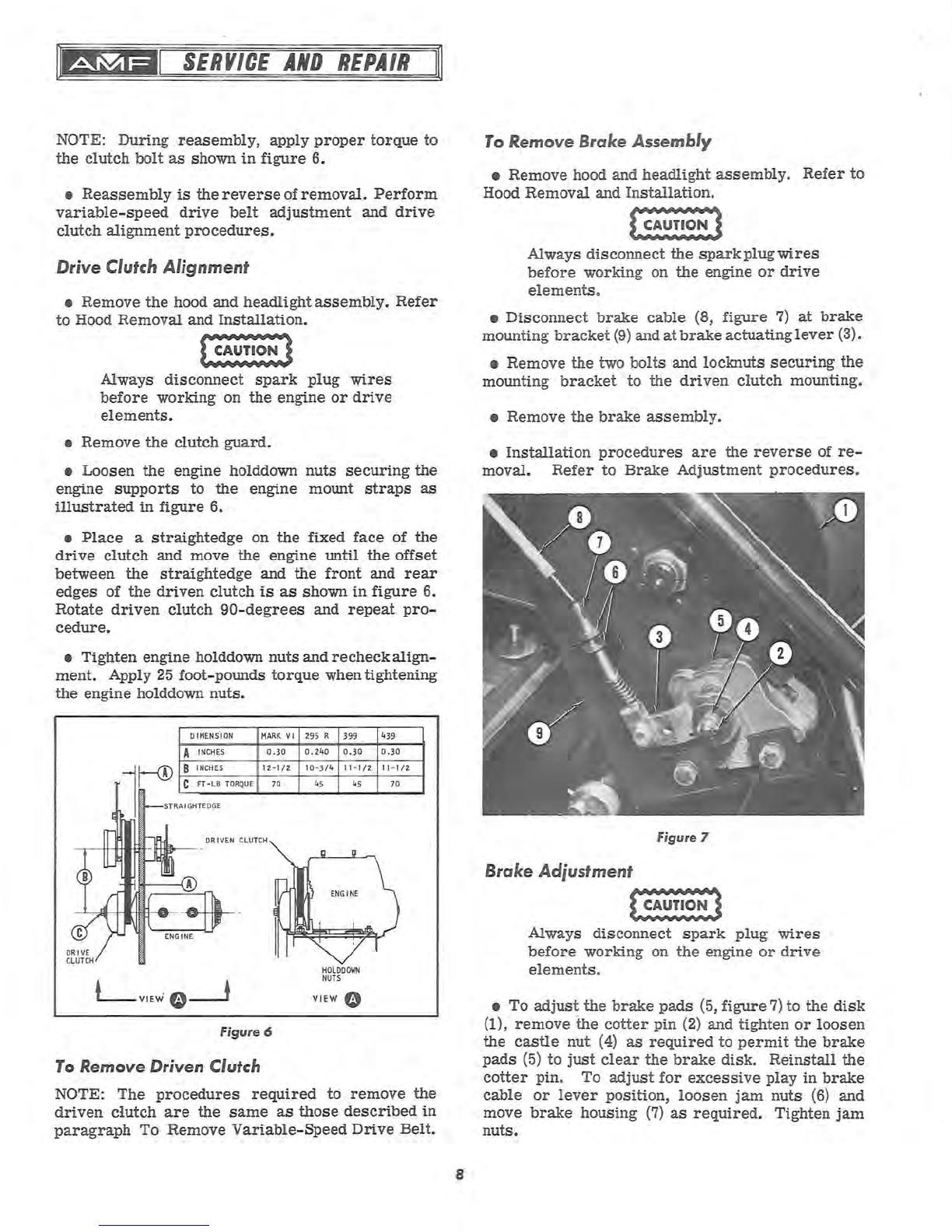

• TO ADJUST CARBURETOR -Close the high-

speed

jet

as

shown

in

figure

10

(DO

NOT

FORCE).

Then open

as

indicated

in

the

carburetor

adjustment

chart,

figure

11

for

the

particular

model

Ski-

Daddler.

•

Turn

the

low

speed

jet

(idle-mixture

screw)

as

shown

in

figure

10

all

theway

in

(DO

NOT FORCE),

then open

as

indicated

in

figure

11

for

the

particular

model

sled.

This

adjustment

controls

the

mixture

at

idling

speeds.

A

lean

idle

mixture

will

result

in

poor

acceleration.

Keep the

idle

speed

slower

than the clutchengaging

speed

'by adjustingthe

idle-speed

screw.

NOTE:

Do

not

use

the

low-speed

jet

to

adjust

for

idle

speed.

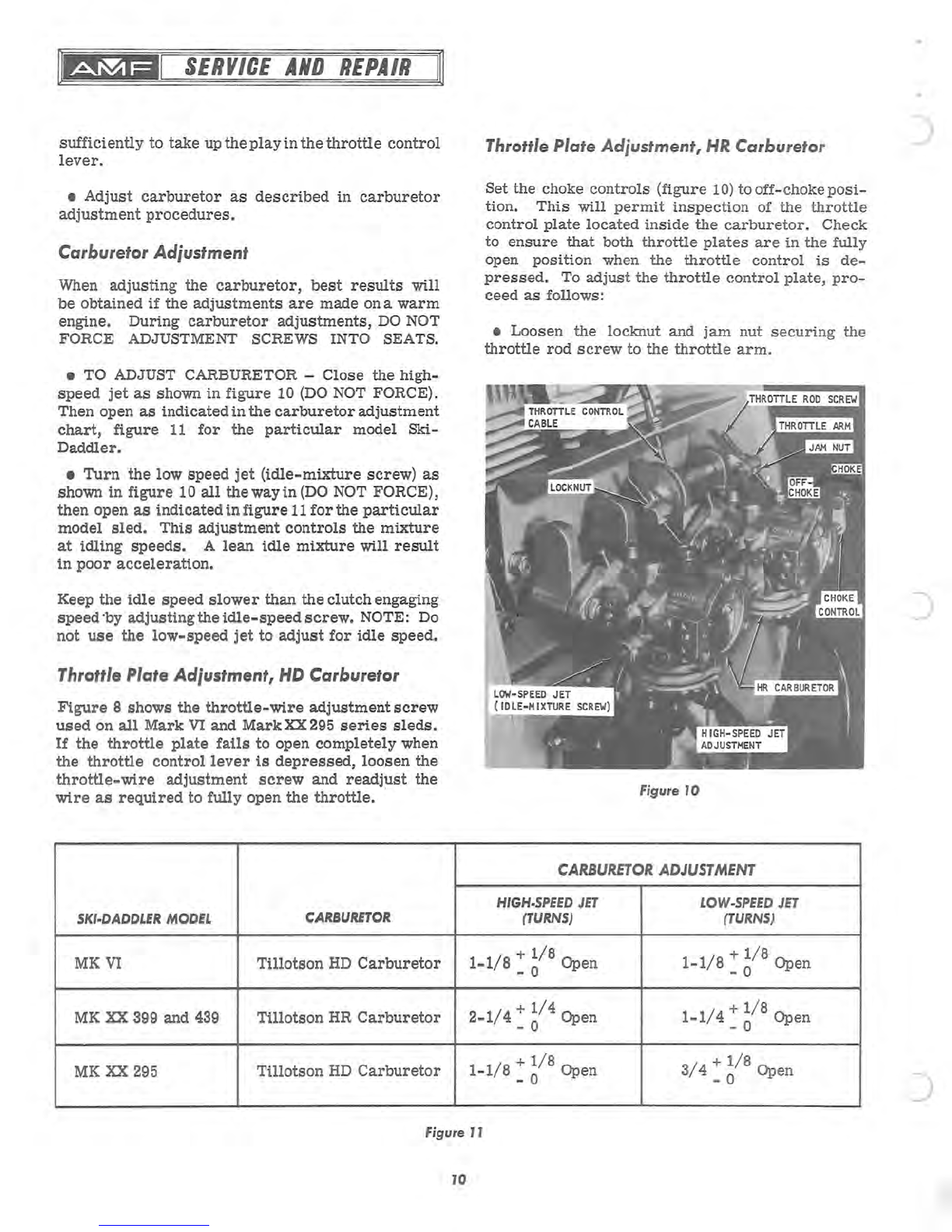

Throttle Plate Adjustment,

HD

Carburetor

Figure

8 shows the

throttle-wire

adjustment

screw

used

on

all

Mark

VI

and

Mark

XX

295

series

sleds.

If

the

throttle

plate

fails

to open completely when

the

throttle

control

lever

is

depressed,

loosen

the

throttle-wire

adjustment

screw

and

readjust

the

wire

as

required

to fully open the

throttle.

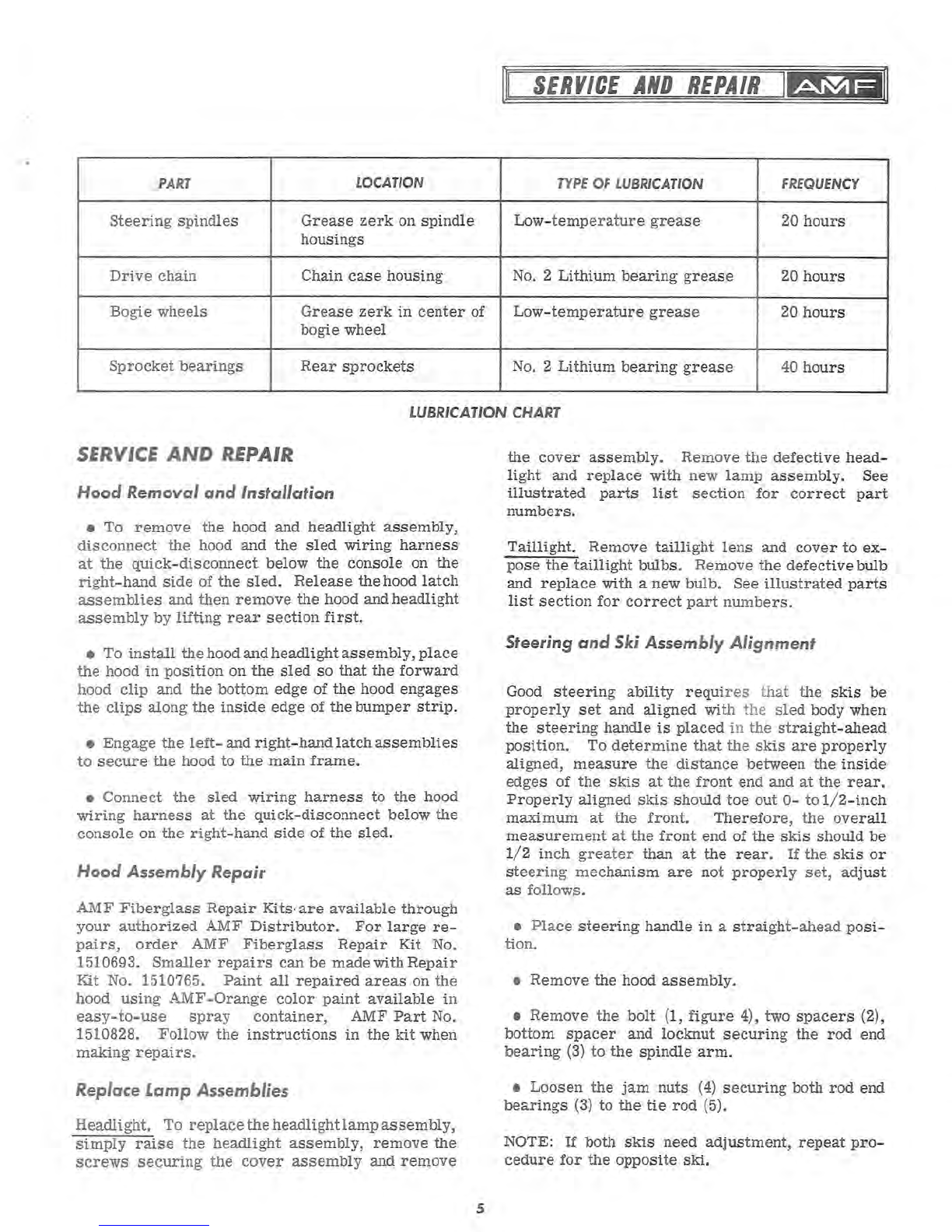

SKI-DADDLER

MODEL

CARBURETOR

MKVI

Tillotson

HD

Carburetor

MK

XX

399 and

439

Tillotson

HR

Carburetor

MK

XX

295

Tillotson

HD

Carburetor

Throttle Plate Adjustment,

HR

Carburetor

Set the choke

controls

(figure

10)

tooff-choke

posi-

tion.

This

will

permit

inspection

of the

throttle

control

plate

located

inside

the

carburetor.

Check

to

ensure

that

both

throttle

plates

are

in

the

fully

open position when the

throttle

control

is

de-

pressed.

To

adjust

the

throttle

control

plate,

pro-

ceed

as

follows:

• Loosen the locknut and

jam

nut

securing

the

throttle

rod

screw

to the

throttle

arm.

Figure

JO

CARBURETOR

ADJUSTMENT

HIGH-SPEED

JET

LOW-SPEED

JET

(TURNS)

(TURNS)

1-1/8

:

~/8

Open

1-1/8

+

1/8

Open

- 0

2-1/4

+

1/4

Open

- 0

1-1/4

+

1/8

Open

- 0

1-1/8

+

1/8

Open

- 0

3/4

:

~/8

Open

Figure JJ

JO

)