c

c

TABLE

OF

CONTENTS

Section

INTRODUCTION

CHASSIS

Hood

Assembly,

Removal

and

Replacement

......

..

...........................

.

Hood

Assembly,

Repair

...................................................

.

Steering

..

.

...........•...•...

...

.............•..........................

POWER

TRAIN

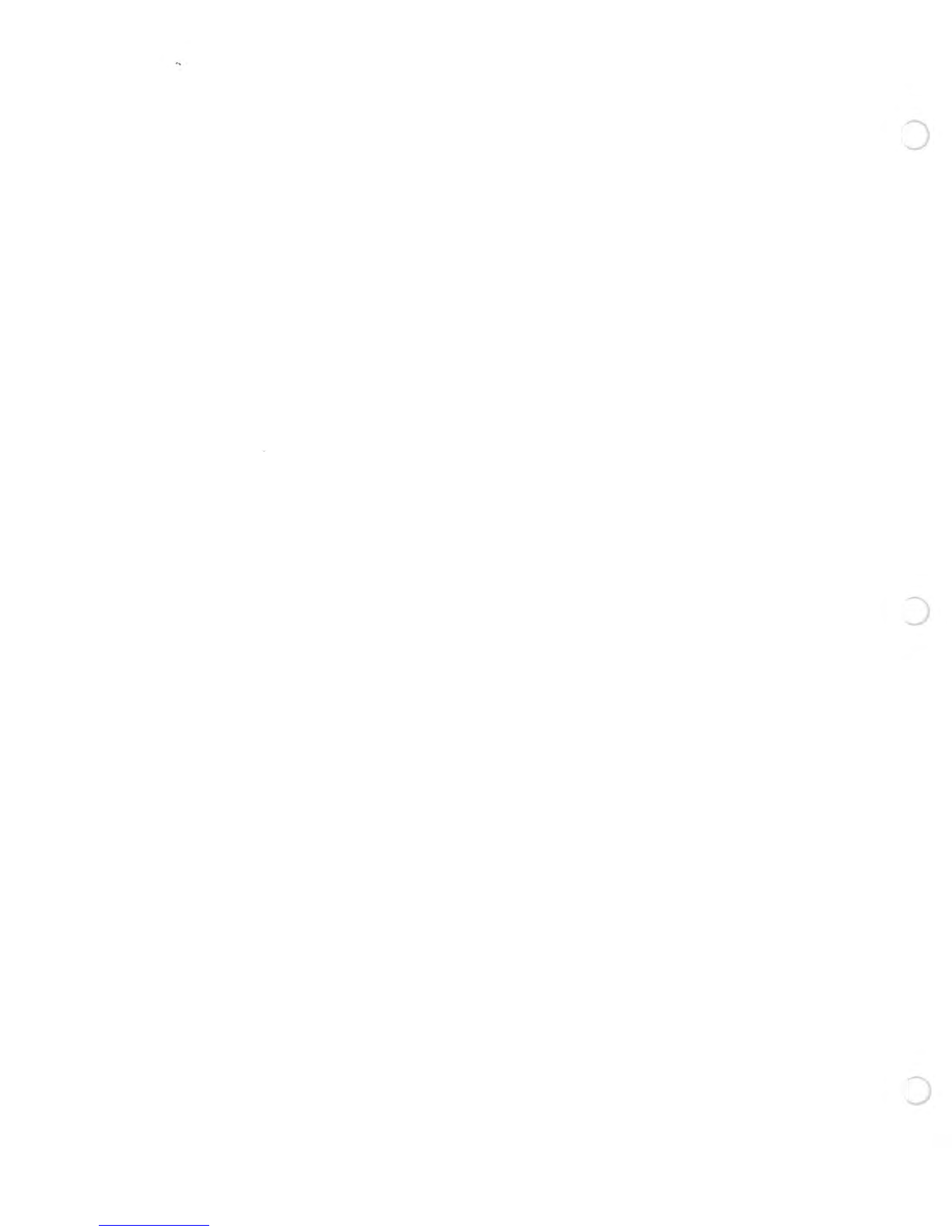

Drive

-

Belt

Tension

.......•..•

.

..•....•...••.......•••.......•..

...

•........

Drive

Belt,

Removal

and

Replacement

................•.......•...............

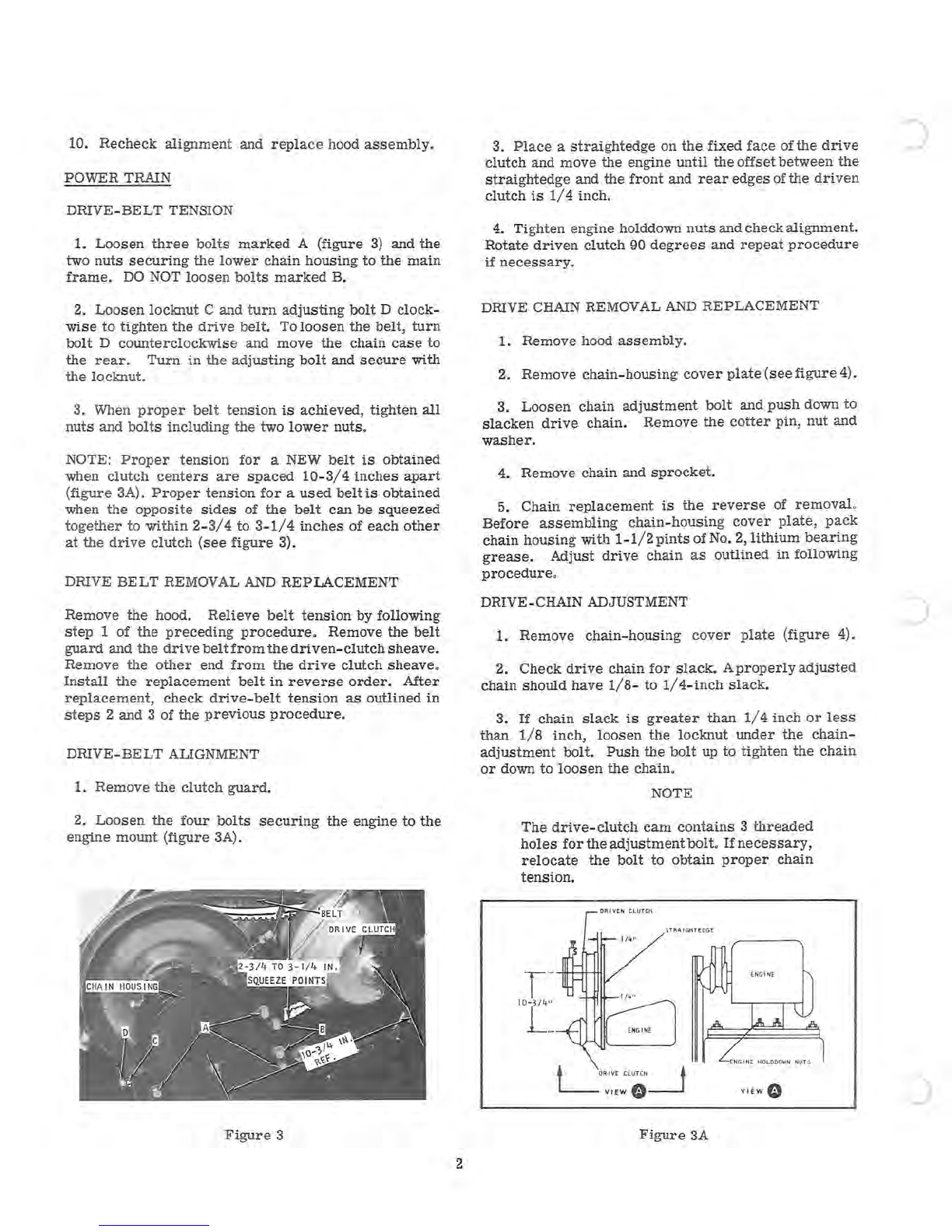

Drive-Belt

Alignment

.....•..............................................

Drive

Chain,

Removal

and

Replacement

....

,

...........

....

...............

.

Drive

-

Chain

Adjustment

...................................................

.

Brake

Adjustment

..............••..

.

.....•.......

.

.........................

Driven

Clutch,

Removal

and

Replacement

•....••.........•......•......•.•...

TRACK

GROUP

Traction-Belt

Tension

Adjustment

...........................................

.

Traction

-

Belt

Alignment

....•..........................................•....

Bogie

Wheel

Assembly,

Removal

and

Replacement

......•....•................

Mark

23

and

Mark

26

...••....••.....•.....••.............•..............

Mark

III

.......................

...........

.....................

.

...

.

Bogie

Wheels

and

Spring

Assembly,

Removal

and

Replacement

.•..............

Rear

Sprocket

Assembly,

Removal

and

Replacement

.....

......................

.

Drive

-

Sprocket

Assembly,

Removal

and

Replacement

...•......

0

•••••••••••••

Traction

Belt,

Removal

and

Replacement

....•...............................

CARBURETOR

ADJUSTMENTS

Hig

h-

and

Low-Speed

Adjustments

...........................................

.

Mark

23

(Tillotson

HR24A

Carburetor)

. ,

.............................

...

"

Mark

26

(Tillotson

HR42A

Carburetor)

......................

"

...........

.

Mark

III

(Tillotson

HD15A

Carburetor)

......

......

............

...

........

.

Idle

-

Speed

Adjustment

.....................................•..............

ELECTRICAL

SYSTEM

Mark

23

..............••............................................

Mark

26

....•.........•..............................•......

0

•••••••

Mark

III (Model 5815-1100A)

.......................•.........•.......•......

Mark

III (Model 5815

-2

000A)

•............................................

.

..

Headlamp

Assemblies

......••................•............•

0 • 0

•••••••••••

Mark

23

and

Mark

III (Model

5815-1!00A)

.........

0

••••••

o

•••••••••••••••

Mark

26

and

Mark

III (Model 5815-2000A)

.......•.•......

0

•••••••••••••••

Taillamp

Assemblies

........

0

••••••••

0

••••••••••••

0

•••••••••••••••••••••••••

FUEL

MIXTURE

Oils

and

Additives

LUBRICATION

ILLUSTRATED

PARTS

LIST

Page

No.

1

1

1

1

1

2

2

3

3

3

3

3

3

3

3

4

4

4

4

4

5

5

6

6

6

6

7

7

7

7

7

7

7

7

7

7

7

10

10

10

10

10