.---------

WARRANTY

Warranty

service policy

is

printed

below

and

on the

warranty

registration card included

with

the

unit. The registration card must be

filled

in

and

mailed

to

the

manufacturer.

The card

is

postage

paid

.

Warranty

service

will

be

handled

by

all

authorized

AMF

Ski.Daddler dealers.

SERVICE

---------,

• •

SNOWMOBILES

• •

Your

Manual

No.

_________

is

a registered number.

Additional

parts

and

service

information

will

automatically

be sent

to

you.

~~~~~~~~~~~~~~~~~~~~~~~~

~~

WARRANTY

CERTIFICATE

~t.

~~

AMF

SKI-DADDLER

SNOWMOBILE

~~

;

~

AMF

WESTERN

TOOL

DIVISION

warrants this vehicle

to

the first retailpurchaser

to

be

free from defects in

mao

~

~

terial

and

workmanship for a period

of

ninety days from its first operation (thirty day limit on commercial use

and

f~

thirty day limit on rental service). This shall

be

limited to replacing free

of

charge, F.O.B., Des Moines, Iowa,.any

~

~)

defective

part

provided that:

~,

~

1.

Vehicle has

not

been subject to accident or misuse.

;

~

2. No repairs or alterations have been made outside

of

our factory or factory approved service station in any

~

~

respect which in our judgment affects its condition or operation.

f~

3. Defective parts

must

be

returned by authorized dealer within

30

days after failure.

~

~)

4.

That

our examination

of

the

part

has disclosed to our satisfgction the defect.

r.;

.~

5.

Warranty does

not

apply,

if

the vehicle in question has been used by

an

authorized dealer or any otherperson

'\

.

~

prior

to

the original retail sale.

~

~

This warranty does

not

cover normal wear or apply

if

the sled has been subject

to

misuse, competition raci

,!g,

negli·

f~

gence, accident, or submersion under water, or operated on any surface other

than

snow or ice.

~

~)

AMF

WESTERN

TOOL

DIVISION

shall not

be

responsible for damage in transit or handling by any common

~,

~.

contract carrier.

\Jj Under no circumstances, within or without the warrantyperiod, will the Company

be

liable for damages, for loss

of

~f"

~~

use, or damages resulting from delay or any consequential damages.

f""

\~'

This warranty is in lieu

of

all other warranties expressed or implied,

and

all other obligations or liabilities on the

'

~~"i

~

part

of

AMF

WESTERN

TOOL

DIVISION.

The Company reserves the right

to

incorporate changes in design into

f'"

this product without obligation

to

make

these changes on units previously sold.

~

~

IMPORTANT

f~

~~

While

the

warranty

covers defects in material and

workman-

~~

~)

ship, certain

maintenance

items

as

listed

below

are considered

~,.

f4

normal

operating

expense items and are

not

covered

under

the

fl

~)

warranty.

?~

~

1. Engine

tune-up

cleaning

or

replacement

of

spark plugs.

clutch

or

traction

belt

damage

due

to

running

engine

at

~

~~

2. Ski

Alignment.

high

RPM

on

kickstand,

or

with

variable speed belt

~.

removed.

3 Brake, variable speed,

or

traction

belt

adjustment,

or

~

~)

. variable speed

belt

replacement. 7. Broken windshields.

f~

f4

4.

Brake

lining

or

ski

wear

rod replacement.

8.

Any

modifications

other

than

factory

recommendations.

~

~)

5. Paint,

body

dents,

damaged

fiberglass, and

chrome

Of

g. Use

of

sled

for

competition

racing

will

void

warranty

f~

~

trim

damage

due

to

use

10

. Traction belt failure

due

to

misalignment

or

abuse.

~

~)

6 Engine

damage

due

to

lack

of

suffiCient

od

In fuel

mlx-

r.;

l

'"".

000"'"''

",I.

'"" 1o,"

wbo,","'

,d,o"mo",.

"'

~

..

~

~~~~~~~~~~~~~~~~~~~~~~~

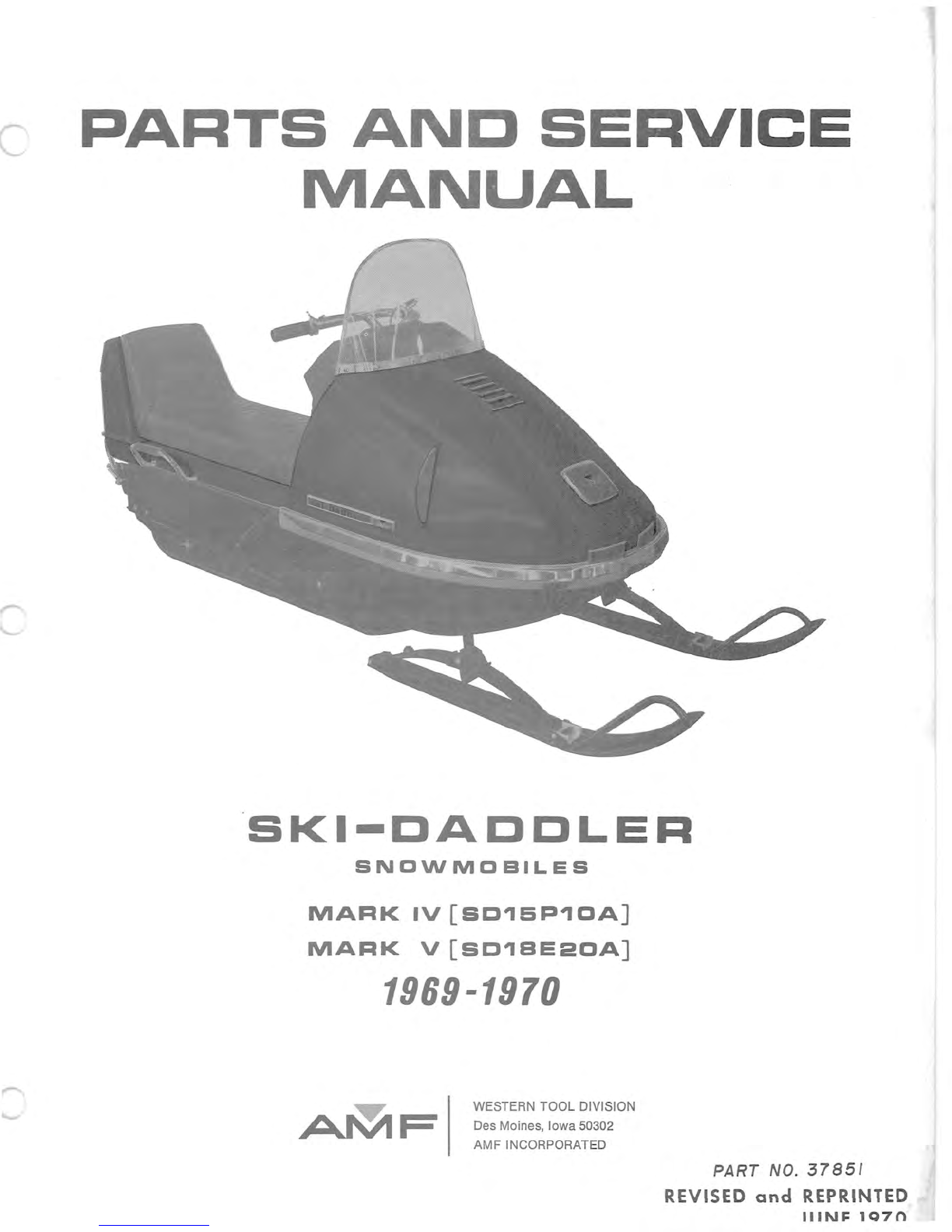

Include

the

complete

(8

digit)

model

number

as

shown

on

Model

Plate

when

ordering

parts

or

asking

for

information.

Due

to

slight

engineering

changes,

this

is

for

identification

purposes

only

.