3

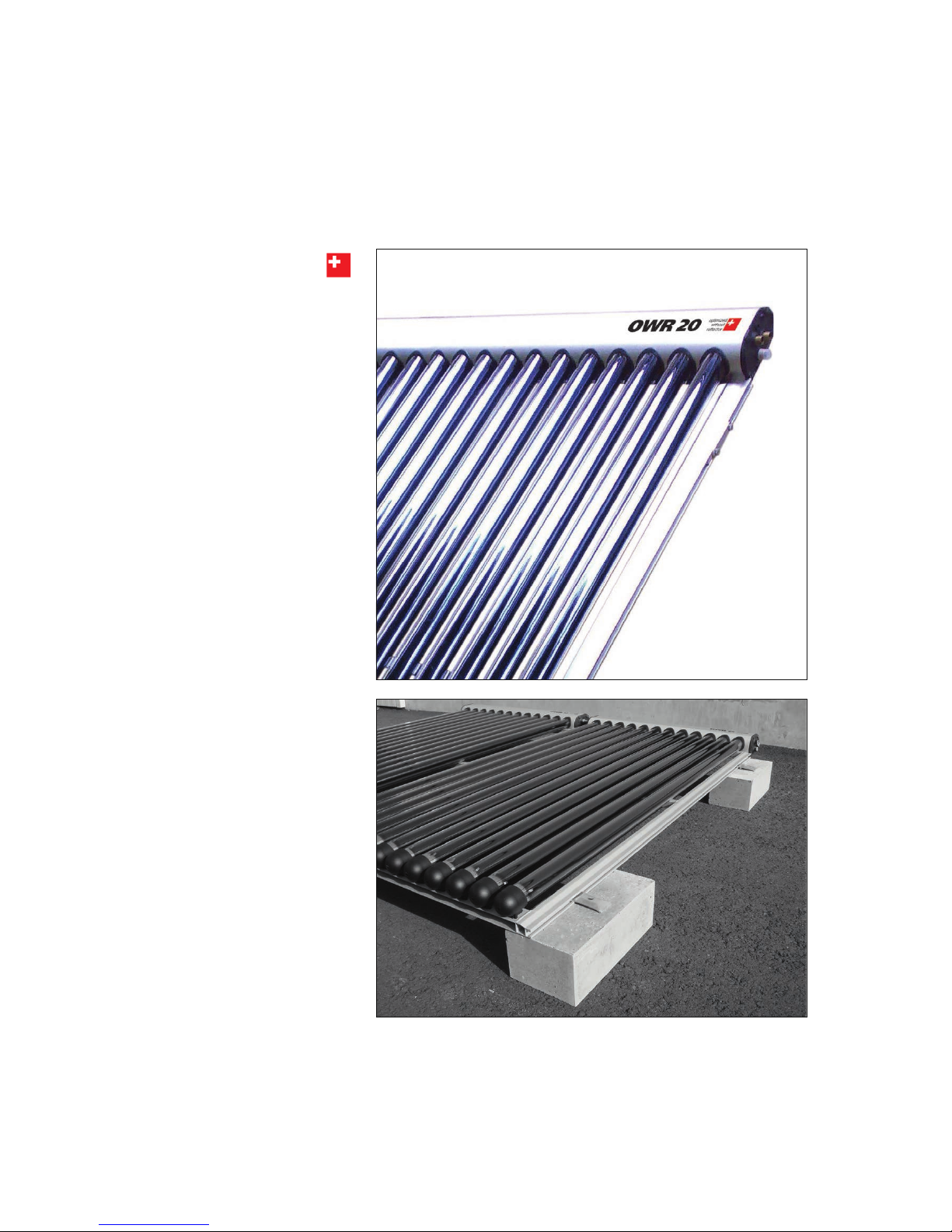

OWR 20 data

Notes

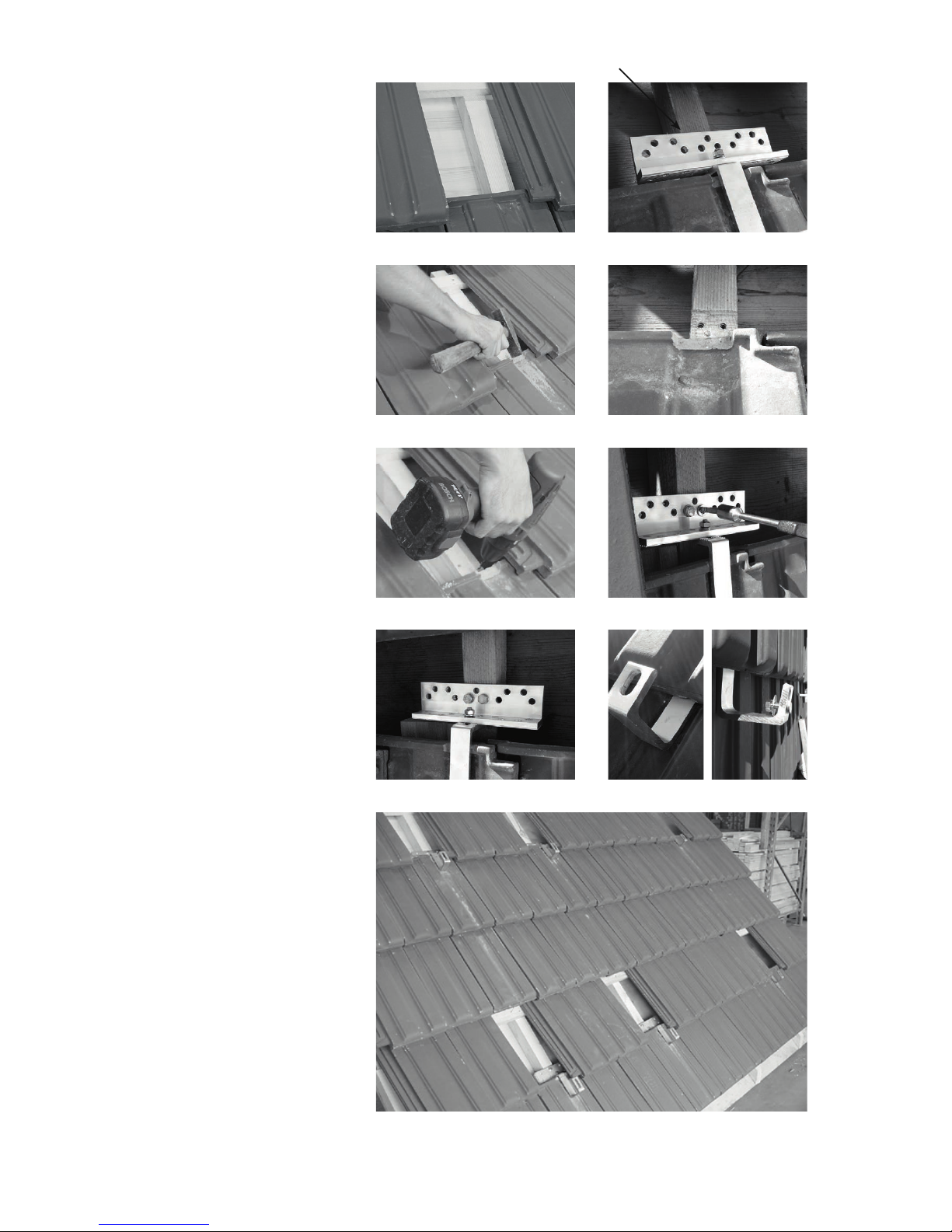

Collector angle/installation

The collector can be installed at

any angle between 0° (horizon-

tal) and 90° (vertical).

Installation is possible on roofs,

on walls, or free-standing. An-

gles between 15° and 75° are

optimal.

Position of the collector pipe

The collector can be installed

with the collector pipe either

vertical or horizontal. However,

the application is optimised

for horizontal installation. It is

not possible to install with the

collector pipe at the bottom.

Filling the system

Do not fill the system in direct

sunlight. Danger of steam ham-

mering!

Flow setting

The standard collector flow setting

can be found in the data table.

Manual bleed valves

Only use manual bleed valves

which are stable at high tem-

peratures, and which have no

plastic parts.

Setting the pressures correctly

For trouble-free operation, it

is essential that the pre charge

pressure in the expansion ves-

sel, and the operating pressure

in the solar system, are set cor-

rectly. Correct dimensioning

and correct connection of the

expansion vessel are just as im-

portant (pp. 17-21).

Automatic bleed valves

We do not recommend auto-

matic bleed valves! If, however,

there is no alternative, automat-

ic bleed valves must always be

installed vertically. A mechani-

cal shut-off in the form of a

suitable stop valve is imperative

(see instructions).

Frost risk

Outdoor pipes with no flow-

through are bound to be at risk

from frost. During installation

care must be taken to keep all

outdoor pipes as short as pos-

sible.

Sensor installation

For trouble-free functioning of

the entire system, the sensor

must be inserted 19 cm into the

provided sensor well in the col-

lector on the input/output side.

Devices/Fittings

For trouble-free functioning of

the entire system, it is impera-

tive to install the devices and

fittings described in the product

documentation.

Vacuum test

Reflective tube ends

= vacuum is okay.

Milky tube ends

= vacuum (insulation) damaged.

Notes

Length:

Width:

Height (including frame):

Number of tubes:

Gross surface area:

Aperture area:

Active absorbing area 360°:

Weight:

Total content:

Max. permissible operating pressure:

Recommended volume flow

200 mm

1670 mm

120 mm

20

3.457 m2

1.98 m2

5.46 m2

72.5 kg

3.52 litres

10 bar

1.7 l/min (per module)

Data OWR 20

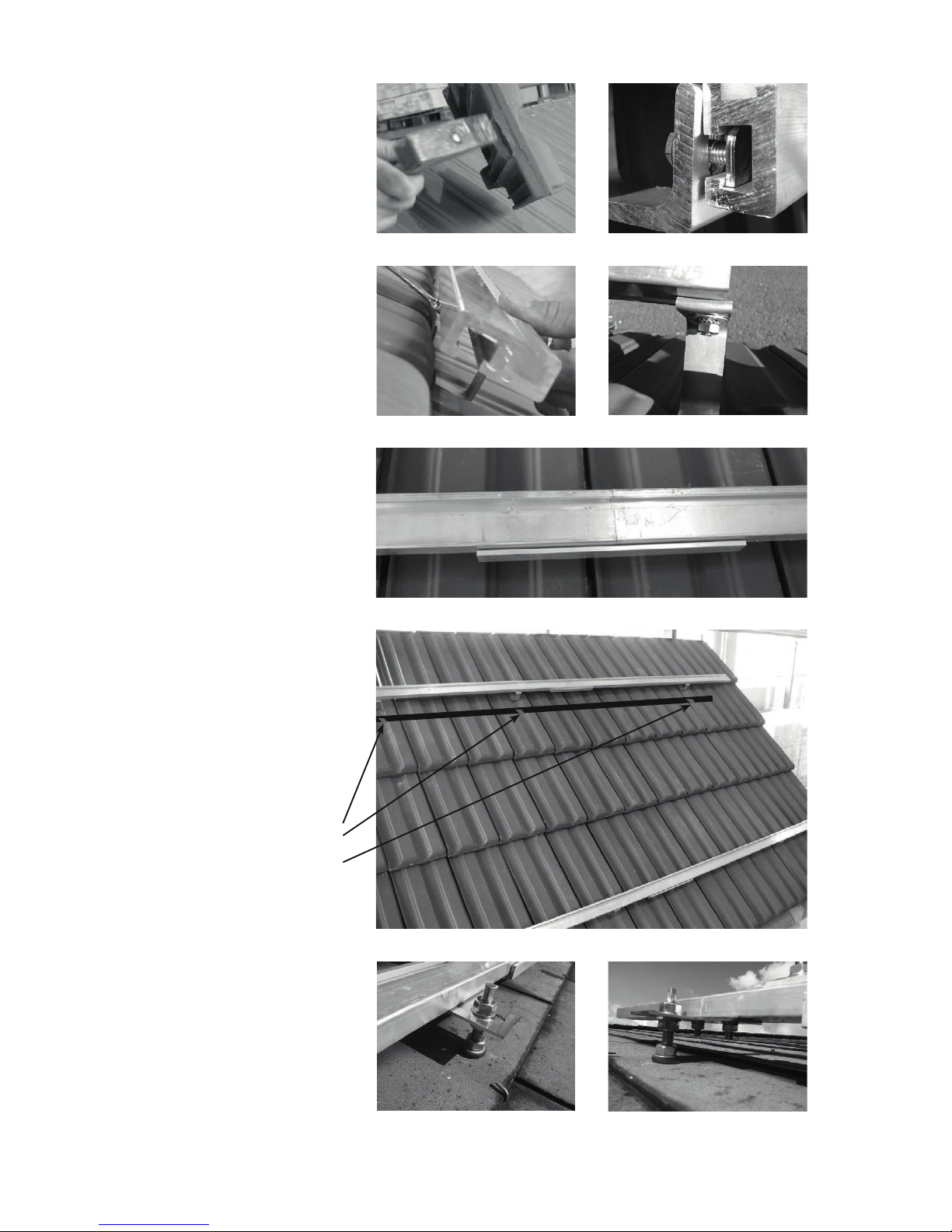

In addition to the collector frame,

the packaging unit also contains

the associated glass tubes.

These packaging units should be

transported carefully and may not

be dropped or thrown. AMK-Col-

lectra AG cannot extend warranty

cover for improper transport and

will replace defective parts only

against charge.

The packaging units may not be

stored outside.They must be

stored in a dry room and protect-

ed from damage.The temperature

should not be under 15°C and not

above 50°C.The relative air hu-

midity should not exceed 75%.

No hamp seals must be used (e.g.

use high temperature resistant

teflon).

The solar circuit is to be bled thor-

oughly; every circuit must be

flushed separately.

Warning!

Local regulations must be ob-

served during installation!

Packaging, transport

and storage of the

system