H-1.601.00024-A3.0

IV

Contents

1. The Basics ..................................................................................................................................1

2. Description..................................................................................................................................3

2.1 Uses.....................................................................................................................................3

2.2 Ventilation function ............................................................................................................3

2.3 Demand flow function.........................................................................................................4

2.4 Patient valve........................................................................................................................4

2.5 Audio response....................................................................................................................5

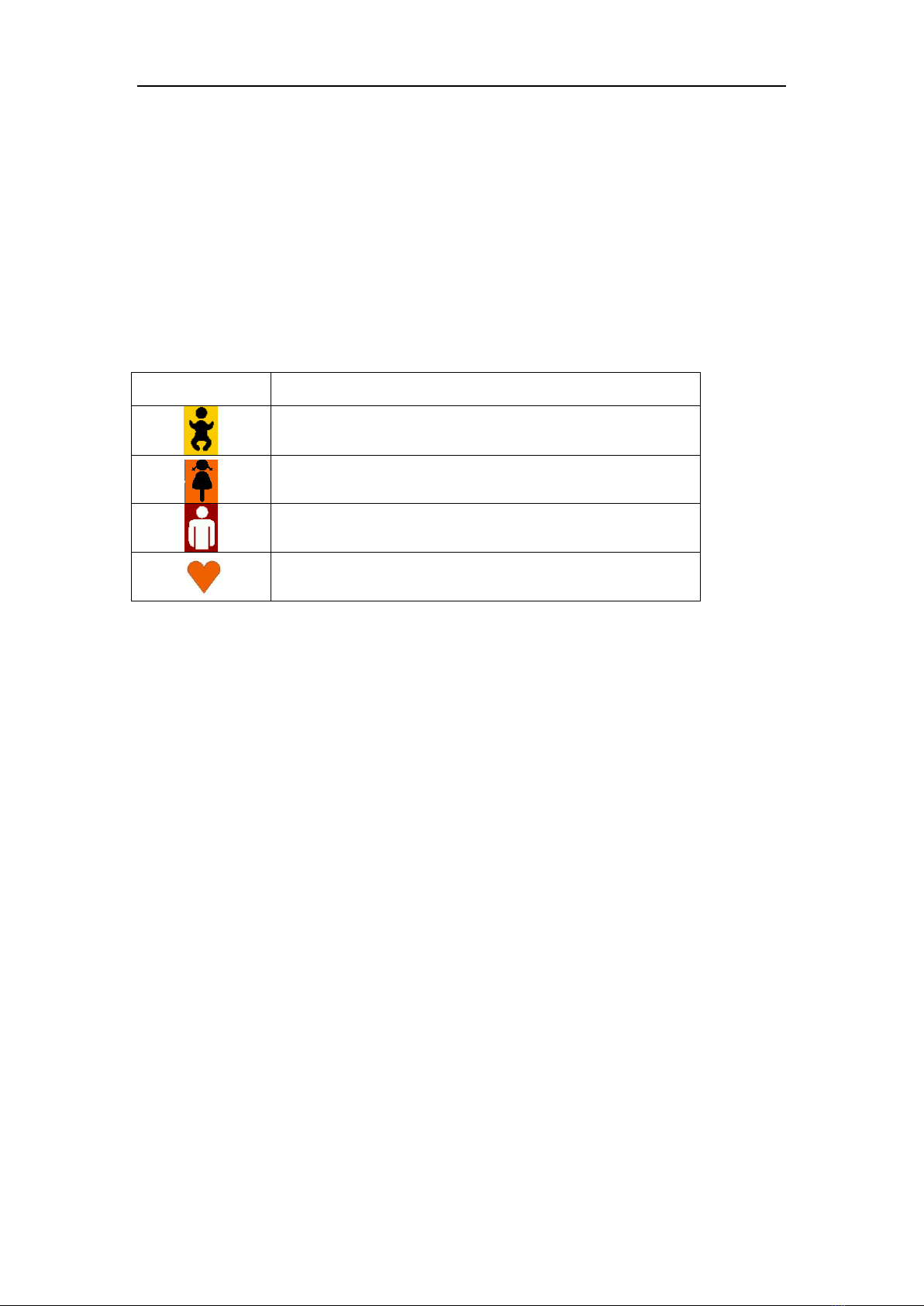

3. Safety instructions......................................................................................................................6

3.1 Safety regulations................................................................................................................6

4. Installation.................................................................................................................................10

4.1 Connecting the oxygen cylinder........................................................................................10

4.2 Ventilation hose ................................................................................................................11

4.3 Wall mounting set.............................................................................................................12

4.4 Please check as below advised carefully before using............................................13

5. Using the ventilator..................................................................................................................14

5.1 Switching on / self test......................................................................................................14

5.2 Selecting the ventilation settings.......................................................................................14

5.3 Performing ventilation ......................................................................................................15

5.4 Monitoring ventilation ......................................................................................................16

5.5 Demand Flow....................................................................................................................16

5.6 Terminating ventilation or Demand Flow.........................................................................17

5.7 Alarm signals ....................................................................................................................17

5.8 Audio response for user guidance.....................................................................................20

5.9 Calculation of oxygen content/remaining operating time.................................................22

5.10 Alternative ventilation procedures..................................................................................23

6. Hygienic preparation................................................................................................................24

6.1 AII6000A..........................................................................................................................24

6.2 Patient valve......................................................................................................................24

6.3 Ventilation hose ................................................................................................................24

6.4 Masks................................................................................................................................25

6.5 Fittings ..............................................................................................................................25

6.6 Cleaning and disinfection procedure.................................................................................25

7. Functional checks....................................................................................................................27

7.1 Intervals.............................................................................................................................27

7.2 Checking for leaks in the system.......................................................................................28

7.3 Checking the patient valve................................................................................................28

7.4 Checking the alarm systems..............................................................................................29

8. Troubleshooting........................................................................................................................31

9. Servicing....................................................................................................................................33

9.1 Intervals.............................................................................................................................33

9.2 Performing technical safety check and servicing..............................................................33

9.3 Battery...............................................................................................................................34

9.4 Change valve membrane in patient valve..........................................................................35

9.5 Storage ..............................................................................................................................35

9.6 Disposal.............................................................................................................................35

10. Product and accessories......................................................................................................36

10.1 Standard product.............................................................................................................36

10.2 Optional Accessories.......................................................................................................36

10.3 Consumables...................................................................................................................36

11. Technical data.........................................................................................................................37

11.1 Specifications..................................................................................................................37

11.2Product structure diagram................................................................................................38

11.3 Relationship between ventilation parameters..................................................................39

12. Warranty..................................................................................................................................40

13. Storage and transportation...................................................................................................41