10

its own knock-out. However if all inputs are to be used it is possible to route line

level signals with the loop cable for a short distance.

Once knock-outs are removed fit suitable cable glands with strain

relief or conduit fittings to protect the cable and maintain safety. If

the AC power is fed to the unit using a cable which is accessible

to the user use the P-clip provided for additional strain relief as

well as a suitable cable gland. see Connections drawing.

Any knock-outs left open must be blanked off with a suitable plug. Cable

glands and conduit fittings are available at most electrical suppliers.

The CLS1 is classed as permanently connected apparatus and as

such shall be installed in accordance with relevant building and

wiring regulations.

Connection and Set-up

It is advised that the loop system is initially set up using a local audio source

such as a CD player, which is not connected into any other system. This

avoids the complication of ground loops and feedback etc, whilst the unit is

set up.

The following procedure assumes cables have already been

installed to the site where the unit will be mounted and that

the AC power feed is isolated.

1. Mount the unit in its intended position.

2. Route cables / conduits to appropriate knock-outs or through the back

panel. The black heatsink bar can reach 90°C in normal operation

and may affect cables which are touching it. Cables must be

routed away from this area.

3. Turn all controls fully anti-clockwise.

4. Connect the loop feed cable into the loop terminals. The feed cable

should be tightly twisted. The ‘Designing Induction Loops’ handbook

contains more details on loop and feed cables. The correct design and

positioning of the actual loop is vital for satisfactory system performance.

If in doubt consult Ampetronic for advice.

5. Connect the signal inputs appropriately:

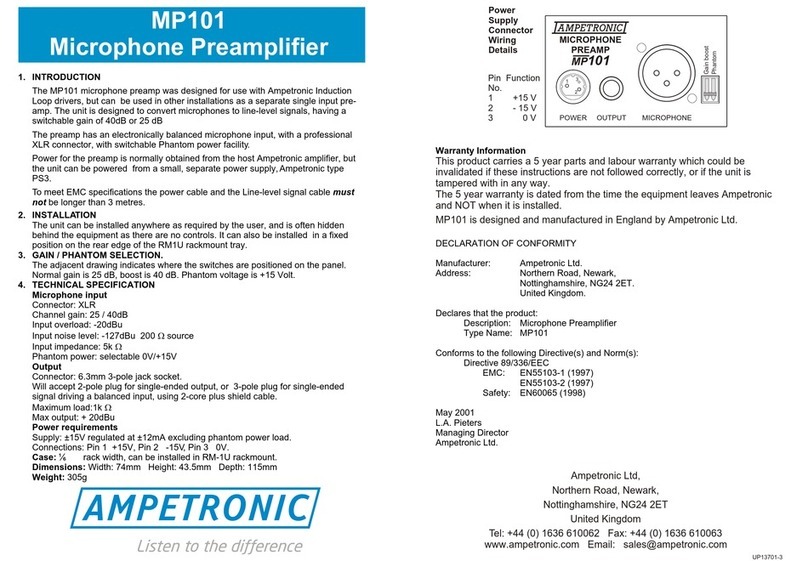

Microphones (balanced only):Suitable dynamic or condenser

microphones. Select phantom power as required. Connect to

appropriate terminals of INPUT 1 (with Mic/line selector switch in the

Mic. position) see Connections drawing.

Line level signals (balanced or unbalanced): From other audio

equipment such as PA system, mixing desk or CD player. If no

microphone is used connect to appropriate terminals of INPUT 1 (with

selector switch in the Line position) see Connections drawing.