SPECIFICATIONS

Tape

Width

Reel

Size

Tape

Speed

Playing

Time

Reproduce

Timing

Accuracy

Flutter

and Wow

Starting

Time

Stopping

Time

Fast

Forward

Time

Rewind

Time

Frequency

Response

Signal-to-Noise

Ratio

Record

Inputs

Reproduce

Output

Operating

Controls

VA inch.

7inch,RETMAreel(maximum).

IV2 ips,

lull

track.

IVj ips,halftrack.

3Mips,

full

track.

.3Mips,halftrack.

Full

Track—32

minutes

witii

7 inchreel,

IV2 ips,1200

feet.

Half

Track—64

minutes

with

7 inchreel,

71/2ips,1200

feet.

±0.2%,oran

accuracy

of±3.6

seconds

in

a30-rninuterecording.

71/2ips—Below0.17%rms.

ips—Below0.3%rms.

The

tape

attains

full

speed

in

less

thanone-

fifth

second

ineithertheplayorrecordmode.

Less

thanone

second.

90

seconds

for

full

1200footreel.

90

seconds

for

full

1200footreel.

71/2

ips—40

to

15,000

cps±2db50to

10,000

cps

down

nomorethan4 dbat

15,000

cps.

3M

ips—±2db50to

7500

cps.

Full

Track—over55dbbelow

peak

rec-

ord

level.

Peak

recordlevelisdefinedasthe

point

of3%totalrmsiiarmonicdistortion,

measuredwhileusinga 400cpstone;and

peak

recordlevelincludes

bias,

erase

andre-

produceamplifiernoise.

Half

Track—50

dbbelow

peak

recordlevel.

MICROPHONE:Accommodatesanyhigh

impedancemicrophone,andcanbequickly

convertedfora lowimpedancemicrophone

with

the

plug-in

accessory

transformer(Cat-

alogNo.

17331-1).

LINE:

0.5

volt

requiredfornormalprogram

level.

1.23voltsrmsinto600ohmsatprogramlevel.

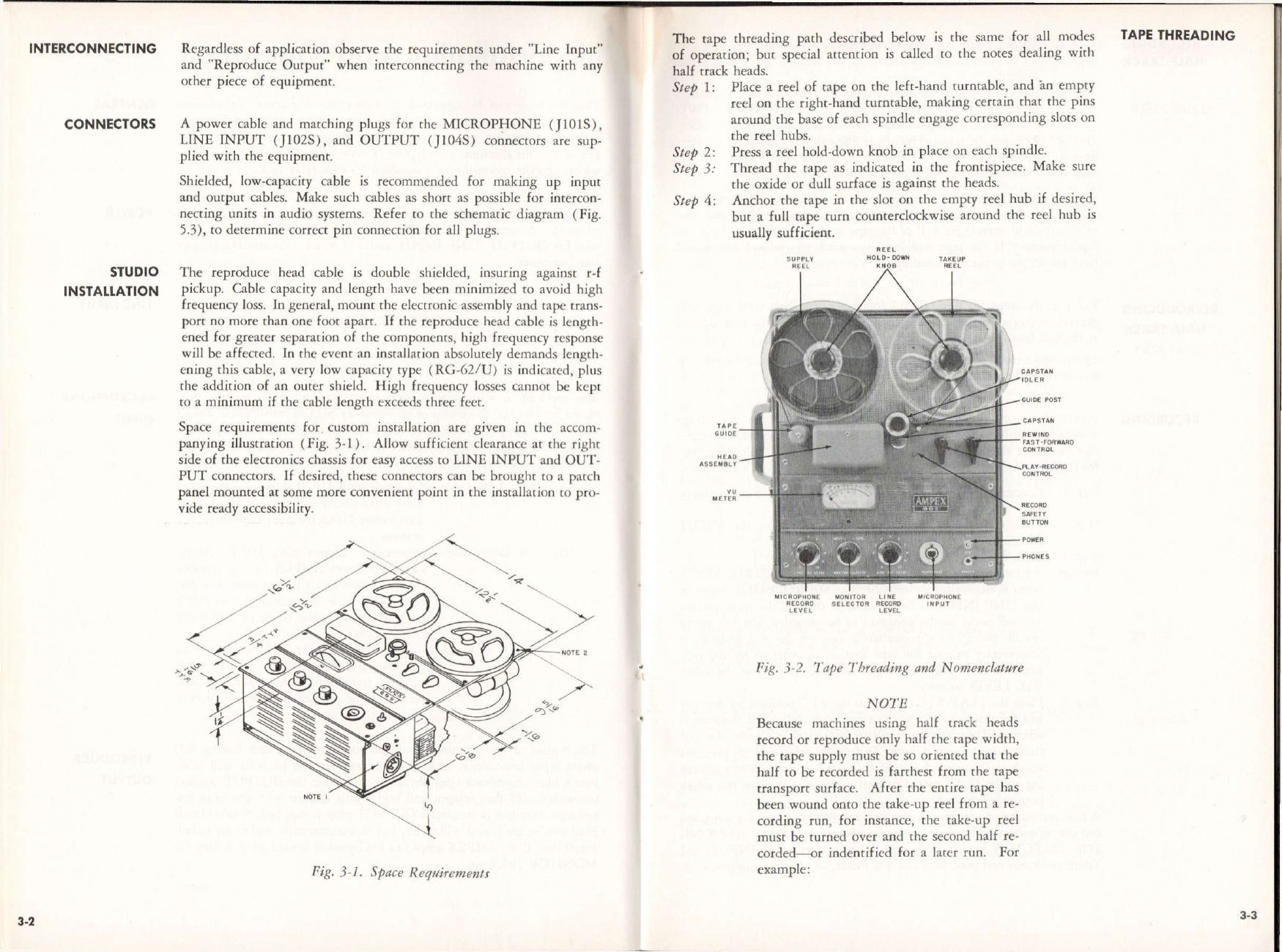

PLAY—REC:Theplaymodeis

selected

by

placing

theswitchinPLAYposition.

Therecordmodecanbe

selected

onlybyde-

pressingthe

safety

buttonatthe

same

time

the

selector

switchisplacedinRECposition.

The

safety

button,a flattoppedneonlamp,

remainslightedwhilethemachineisinthe

recordmode.

REWIND—FASTFWD:This

selector

switch

ismechanicallyinterlocked

with

the

PLAY—RECswitch.

1-2

Reproduce

Output

Operating

Controls

Miscellaneous

Monitoring

Head

Assembly

Power

Requirements

Accessories

MIC

RECLEVEL,andLINERECLEVEL

are

separate

mixingcontrols.

TheMONITOR

SELECTOR

switchisused

for

monitoringasdescribedinthe

following

paragraphs;butitfunctions

also

asanoper-

ating

control.InthePLAYmode,the

MON-

ITOR

selector

switchmustbeintheTAPE

position

inordertobringthereproducehead

signaltotheOUTPUT.

A

toggleON—OFFswitch,locatedonthe

control

panel,turnspoweronoroff.When

placedintheONposition,thistoggleswitch

will

cause

the

capstan

torotate;butthe

tape

will

notmove

until

oneofthetwooperating

switchesisturned

from

itsneutralposition.

TheMICROPHONE

input,

a threecircuit

connector,isconvenientlylocatedonthecon-

trol

panel.

ThePHONESoutputisa twocircuit

jack,

locatedonthefrontpanel.

TheLINEINPUT

connector

isa twocircuit

jack

recessed

intothe

right

sideoftheequip-

ment.

TheOUTPUT

connector

isa threecircuit

jack

also

recessed

intothe

right

sideofthe

equipment.

Mating

connectors

aresupplied(see

Table

1-1).

TheMONITOR

SELECTOR

switchallows

monitoring

ofprogram

input,

orreproduce

output.

A phone

jack

andilluminatedv-u

meterareonthefrontpanel.

WhentheTAPEpositionis

selected,

there-

produceoutputcanbemonitored.

WhentheINPUTpositionis

selected,

the

headphones

andmeterreportprogramsignal

level.

Separate

erase,

record,andreproduce

heads

arecontainedina singlehousing.

117volts,50or60cps;0.52ampere,61

watts.

MaintenanceKit:

6392-1

Speed

ConversionKitsto:

3M

ips,60cps

7556-0

71/2ips,60cps

7556-1

3%ips,50cps

7556-2

71/2ips,50cps

7556-3

SPECIFICATIONS

1-3