MANUAL OLYMPUS HP E-START AMT NETHERLANDS

Page :1

1. Introduction Revision: 2.07

1.1 Profile of Advanced Micro Turbines

Advanced Micro Turbines develops small gas turbines for the propulsion of radio-

controlled flying airplanes, remote heat/power generators, and auxiliary power units.

The company originates from Jet Team Holland, which has been giving flight

demonstrations with jet propelled models since 1987, both in the Netherlands and

abroad.

Our first turbojet, the Pegasus MK-1, which was developed in 1991 and 1992 had a

thrust of 90 Newton at 90,000 rpm. In 1995 the Olympus was developed with a thrust of

170 Newton and further refined specifications. AMT’s latest version of this engine the

Olympus HP now provides a thrust of 230 Newton at 108,000 RPM.

The production version of the Olympus HP turbojet has been developed from

knowledge gained during design and operation of the Mercury HP, Pegasus HP and

Olympus motors, and it has specifications and performance which have never been

achieved before in a motor of this size.

In 2004 the Electric Start version of the Olympus HP was developed together with a

new type of ECU capable of fully automatic start with our own newly developed electric

starter.

All materials used in all AMT's turbojets are carefully selected according to extensive

calculations and operational tests, and our stringent quality controls.

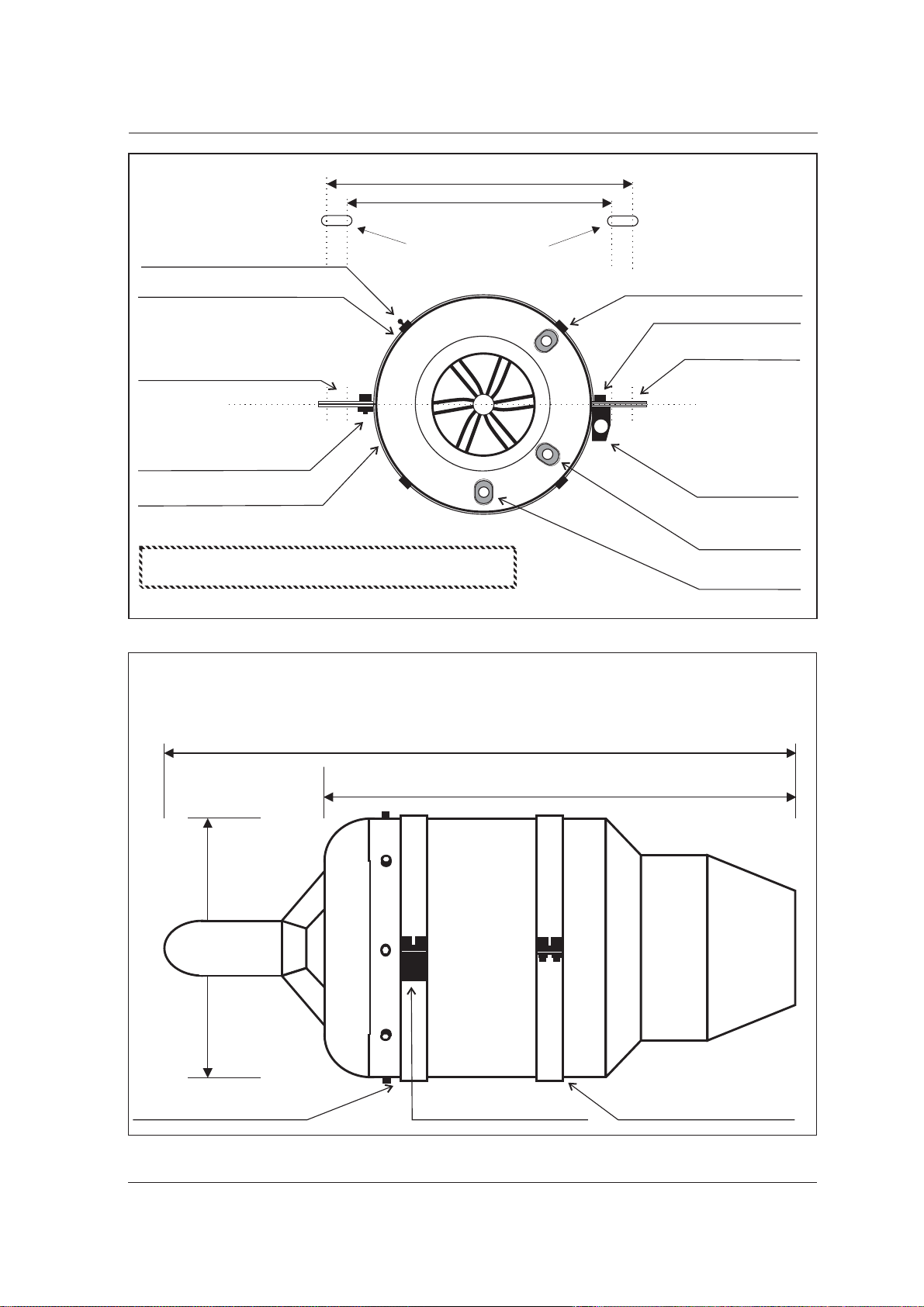

1.2 Description of Olympus HP and HP ES

The Olympus HP has been constructed from a single radial compressor and an axial

flow turbine. The Olympus HP owes much of its excellent performance and superb

power/weight ratio to this turbine wheel which was designed by AMT staff especially for

our motors. The time required for the turbojet to spool up and down is also positively

influenced by the low mass of the axial turbine wheel, taking less than 4 seconds and

from min. to max. rpm and only 3 seconds from max. rpm to min. rpm.

The combustion chamber is of the annular type, which is fitted with a unique "low

pressure" fuel system, also developed by AMT Netherlands. Both the front and the rear

hybrid bearings are also lubricated and cooled by the fuel system, and therefore the

motor requires no separate lubrication system or oil tank.

The turbine is protected from misuse and accidental damage by means of a

microprocessor based controller (ECU) which regulates the maximum performance

within preprogrammed software limits. The ECU is fully automatic and needs no

adjustment by the operator.