de Wijs 2007 User manual

User manual of the 10 slide rotary viewer model 2007

motor advance mechanism

The contents are subject to changes without giving notice. Last update May 2007

Ing. J. de Wijs.

Populierstraat 44,

4131 AR Vianen,

the Netherlands

Design and production of stereoscopic instruments.

Tel/Fax. +31 (0)347-372242

e-mail: info@dewijs-3d.com

Website: www.dewijs-3d.com

Bank: Postbank account: 6084601,

Swiftcode: INGBNL2A

Bank code: NL24PSTB0006084601

Tax number: NL 1899.16.084 B01

K.v.K. Reg. Nº

23071201

Utre

cht

Contents

INTRODUCTION

......................................................................................3

1. FIRST INDICATIONS FOR OPERATIONAL USE ...........................3

1.1

O

PENING THE VIEWER FOR EXCHANGING THE SLIDES

............................................... 3

1.2

W

ERE DO

I

PLACE THE VIEWER

?............................................................................... 4

1.3

H

OW DO

I

MOUNT THE VIEWER AGAINST A WALL

?................................................... 4

2. MANUAL OPERATION (WITHOUT PC CONTROL).......................5

2.1

F

OUR OPERATIONAL MODES

:.................................................................................... 5

4. EXTERNAL CONTROL (WITH PC) ....................................................6

4.1

S

ETTING UP THE EQUIPMENT AND CABLE CONNECTIONS

.......................................... 6

6 DATA ..........................................................................................................7

6.1

T

ECHNICAL SPECIFICATIONS OF THE ROTARY VIEWER

............................................. 7

6.2

E

XTERNAL CONNECTION DIAGRAM

.......................................................................... 8

6.3

C

ONNECTIONS OF THE

D25

AND

J3

CONNECTOR

...................................................... 9

6.4

E

LECTRONIC COMPONENT LIST MODEL

06-02-A-M............................................... 10

6.5

I

NTERNAL ELECTRICAL CONNECTION DIAGRAM

. .................................................... 11

6.6

E

LECTRONIC SCHEMATICS

..................................................................................... 12

6.7

PCB

LAYOUT

......................................................................................................... 13

Introduction

This viewer is the result 30 years of experience in building high quality 3D slide viewers for

public use. Each change in the previous models extended the durability, stability and the

quality. Especially this 10-slide rotary viewer 2007 has been adapted for the demand to

show short 3D slide series to large amounts of public to be informed. To give any idea about

the changes with respect to the previous model:

-The CCFL is more protected against damaging when inserting the slide drum.

-The assembly of the slide drum to the main axle is more solid.

1. First indications for operational use

1.1 Opening the viewer for exchanging the slides.

-For exchanging the slides you have to remove the right cover of the round housing;

see the image. That is the side where the text window and the pushbutton are

located.

-Remove the 6 bolts.

-Remove the DC adapter plug from the rear side of the

drum.

-Now pull gently the right cover away of the main drum

and place the whole thing right up on a table.

-Now you can insert or exchange your slides and text

cards. Keep the order and position of the slides in

mind that they won’t be presented up side down!

Picture 1

Picture 2

1.2 Were do I place the viewer?

Obviously you already have chosen a spot for the viewer in your museum, exhibition or

other public environment. Here are some considerations that might help you to check the

spot;

−Keep in mind the height of the viewer. Children and grown-ups both want to look in the

viewer!

−Depending on the interest of the viewer, people might form a queue. This could cause

congestion for the rest of the public.

−Watch out for sunlight coming through the lenses! The lenses will act like burn glasses

on the slides. A few minutes in the sun will cause enough damage to the slide that it

should be replaced. Within 1 day, in worst case, you have to replace all slides. You can

see this on the slide like tiny little white spots showing the track of the sun during the

day.

−Avoid spotlights to be shinning on the lenses. The slides are not going to be burned but

it does shorten the lifecycle of the slide.

−When the viewer is to be mounted inside some kind of panel, be sure you can get easy

access to the viewer for replacing the slides.

1.3 How do I mount the viewer against a wall?

The 10 slide rotary viewer holds a bracket at the back that has several holes to attach the

viewer with screws or bolts against a wall. First you have to remove the 3 bolts on the top of

the bracket (see the image) and the bolts underneath the viewer to position the bracket only

against the wall. Think about how you want to let the cables run through the bracket; are

they going through the wall or do they go through the hole at the bottom of the bracket?

Picture 3

5

2. Manual operation (without PC control)

In this situation, the rotary viewer is used in stand-alone mode, without any external devices.

2.1 Four operational modes:

The rotary viewer is able to work in 4 different modes. These modes are configurable using

the small switches inside the viewer. To get access to these switches follow the next

directions:

-Removing the 6 bolts of the right cover of the viewer (the side where button is located,

picture 4).

-Now you see the round slide drum. Through the bars of the slide drum, you see the

red dipswitches (picture 6)

To change the turn off time of the lamp, you have to remove the

slide drum by taking the 3 bolts on top of the drum away. Be

careful with removing and replacing the drum. You can damage

some electronic parts. Now the time is set to ± 40 seconds.

Turning with a screwdriver the pot-meter counter clockwise, will

increase the time, turning anticlockwise will decrease it.

IT IS BETTER TO LEAVE THE LAMP ON, ALL THE TIME. THIS SAVES THE DURABILITY

OF THE ELECTRONICS.

BY DEFAULT, THE LAMP IS ALWAYS ON

KEEP DIP SWITCH Nº 1 DOWN

Picture 6

Picture 7

Picture 4 Picture 5

6

At the right you see an illustration of the dipswitch.

The black square marks the position of the switch.

Mode 1:

After the pre-set shut-off time, the lamp turns off and the viewer stays at

this slide.

Mode 2:

After the pre-set shut-off time, the lamp turns off and the drum revolves

to slide number 1.

Mode 3:

The lamp is always on, after the shut-off time the viewer stays at the

current slide.

Mode 4:

The lamp is always on, after the shut-off time the drum revolves to slide

number 1.

- You can adjust the shut-off time of the lamp by turning with a screwdriver the knob beside

the small switches inside the viewer. Turning counter clockwise will increase the time,

turning anticlockwise will decrease it.

4. External control (with PC)

In this situation, the rotary viewer is able to operate according to a

configured program with audible explanation of the slide. An IBM

compatible PC is required to work with the accompanied software of the

rotary viewer to control the rotary viewer.

4.1 Setting up the equipment and cable connections

List of materials:

−10 slide Rotary viewer of ‘de Wijs’ model 2003

−One 12 Volts dc adapter for the rotary viewer.

−Language panel (if you need it).

−1 Euro connector power cables for the computer

−1 parallel extension cable with a male D25 and female D25 plug.

−An IBM compatible x86 computer with at least 1 free parallel printer port connector and

CD-ROM player, complete it with the usual keyboard, monitor, etc. (mouse not necessary)

−3.5” Boot disk for the rotary viewer.

−An audio cable with 2,5 mm stereo jack to double cinch or headphones.

Connect all cables according to the connection diagram (chapter 6.2).

Set the small switches at the back of the rotary viewer according to the

picture on the right.

For more information about the how to configure the computer and to make audio tracks,

take a look at the software manual that can be downloaded at www.dewijs-3d.com at the

technical support download page.

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

7

6 Data

6.1 Technical specifications of the rotary viewer

Slides:

•Slide frame format; 41x101 mm.

•Maximum picture size; 23x33 mm.

•Compatible with RBT frames, mounted between glass maximum 3 mm. Thickness.

•The drum can hold 10 slides and accompanying text cards (cut to size 42x74 mm.)

Optics:

•One lens barrel holds 2 achromatic lenses of ∅37 mm. f= 120 mm. each.

•Total focal distance is 60 mm.; magnification: 4.2 x

•Lenses are coated on all sides

•Lens separation is fixed to 62 mm.

Illumination:

•The slide is illuminated by a single CCFL (Cold Cathode Fluorescent Lamp) passing

its light through a light guide.

•The colour temperature is 5500 Kelvin.

•The lamp runs on 12 Volts dc at ± 300mA using an inverter.

Mechanics;

•The Housing of the viewer is made of plain anodised aluminium. The wall bracket and

lens barrels are made of stainless steel.

•The slide drum revolves on ball bearings and don’t need any lubrication.

•A 12 Volts motor using a cock wheel mechanism revolves the drum.

•When removing the steel plate at the left side of the viewer (4 bolts), you get access to

four M4 bolts. These bolts make it possible to adjust the focus of the slide drum with

regards to the fixed lenses. Do NOT un-fasten these bolts, the focus has been

adjusted in the factory very carefully!

Electronics;

•The whole viewer runs on 12 Volts dc. The viewer comes with a 220 Volts AC adapter

giving 12 Volts dc. at 500mA. Or 12 Volts ac at 500mA (models produced after

February 2009). Check your viewer!

•The internal circuitry is fused with an 1 Amp. fuse.

8

6.2 External connection diagram

Lamp turn-off delay

Viewer control interfaceexternal switch box

SW1: up- lamp turn-off delay active

down- lamp always on

SW2: up- front button passes signal to external device.

down- front button directly controls viewer

SW3: up- after lamp turns off, nothing happens

down- after lamp turns off, drum goes to slide Nº 1

SW4: up- amplifier turned off

down- amplifier turned on

Internal CD-ROM in PC

Dutch Enlish German French

Language selection box

adapter:

12 Volts d.c.

1,5A

stabelized

9

6.3 Connections of the D25 and J3 connector.

D25 connector:

Connector

pin

Description computer side

and addressing

Description rotary viewer

side

Direction looking from

computer side.

1 Strobe Base+2 bit 0 Not used Output

2 D0 Base+0 bit 0 Change slide, 1= moving Output

3 D1 Base+0 bit 1 Lamp, 1=lamp on. Output

4 D2 Base+0 bit 2 Not used Output

5 D3 Base+0 bit 3 Not used Output

6 D4 Base+0 bit 4 Loop through to D15 con. Output

7 D5 Base+0 bit 5 Loop through to D15 con. Output

8 D6 Base+0 bit 6 Loop through to D15 con. Output

9 D7 Base+0 bit 7 Loop through to D15 con. Output

10 Acknowle

dge

Base+1 bit 6 Button front panel,

1=pressed

Input

11 Busy Base+1 bit 7 Loop through to D15 con. Output

12 Paper end

Base+1 bit 5 Light gate ‘zero’ detection. Input

13 Select out

Base+1 bit 4 Light gate ‘stop’ detection. Input

14 Auto feed Base+2 bit 1 Not used Output

15 Error Base+1 bit 3 Loop through to D15 con. Input

16 Init Base+2 bit 2 Not used Output

17 Select in Base+2 bit 3 Not used Output

18 Gnd

19 Gnd

20 Gnd

21 Gnd

22 Gnd

23 Gnd

24 Gnd

25 Chassis

ground

J3 vertical 8-pin header: (for language selection box)

Connector

pin

Description computer side

and addressing

Description rotary viewer

side

Direction looking from

computer side.

1 Busy Base+1 bit 7 Loop through to D25 con. Input

2 Ground

3 +12 Volt.

4 +5 Volt.

5 D5 Base+0 bit 5 Loop through to D25 con. Output

6 D6 Base+0 bit 6 Loop through to D25 con. Output

7 D7 Base+0 bit 7 Loop through to D25 con. Output

8 Error Base+1 bit 3 Loop through to D25 con. Input

9 D4 Base+0 bit 4 Loop through to D25 con. Output

10

11

12

13

14

15

10

6.4 Electronic component list model

06-02-A-M

R1 10K 1/4 Watt IR detect

R2 10K 1/4 Watt IR detect

R3 100K 1/4 Watt

R4 10K 1/4 Watt

R5 100K 1/4 Watt

R6 10K 1/4 Watt

R7 10K 1/4 Watt

R8 100K 1/4 Watt

R9 180 1/4 Watt

R10 100 1/4 Watt

R11 100K 1/4 Watt

R12 100K 1/4 Watt

R13 10K 1/4 Watt

R14 10K 1/4 Watt

R15 1M 0.15 Watt 10 mm. standing Pot.

R16 10K 1/4 Watt

R17 100K 1/4 Watt

R18 180 1/4 Watt

R19 100K 1/4 Watt

R20 10K 1/4 Watt

R21 22 1 Watt

C1 47uF 10 Volt axial

C2 100n 50 Volt polyester

C3 4,7uF 50 Volt Elco rad.

C4 100n 50 Volt polyester

C5 100n 50 Volt polyester

C6 1000uF 16 Volt Elco rad.

C7 100n 50 Volt polyester

C8 47uF 10 Volt axial

C9 100uF 16 Volt Elco ax.

C10 100n 50 Volt polyester

C11 100n 50 Volt polyester

C12 100n 50 Volt polyester

D1 1N4001

D2 1N4001

D3 1N4001

T1 BC547b

T2 BC547b

T3 BC547b

T4 BC547b

T5 BC547b

U1 4081 Quad And

U2 Relais 2x 12V OMRON G2R-2

U3 LM555 timer IC

U4 Relais 1x 12V OMRON G5V-1

U5 4071 Quad Or

U6 LM7805 1A

U7 4049 Hex inv. Buff.

U8 LM555 timer IC

U9 LM555 timer IC

J1 D25 PCB socket 90º male

J2 Header 8 pins

Header Socket 8 pins

J3 D15 PCB socket 90º male

J5 Header 2 pins

J6 Header 2 pins

Header Socket 2 pins

Shrink contacts for Headers

SW1 Dip switch 4x 90º

3 DIL8 sockets

2 DIL14 sockets

1 DIL16 sockets

F1 Fuse holder internal metal clamps

1 Opto switches 5mm. Gap with PCB

1 04-01-PCB; circuit board

11

6.5 Internal electrical connection diagram.

Motor

Drum

Optical

switches

top view

blinking

LED

Front

panel

button

ccfl inverter

+

-

12Vdc 500mA

2.1 mm plug

12

6.6 Electronic schematics

13

6.7 PCB layout

Table of contents

Popular Engine manuals by other brands

Kohler

Kohler Command PRO CV732 Service manual

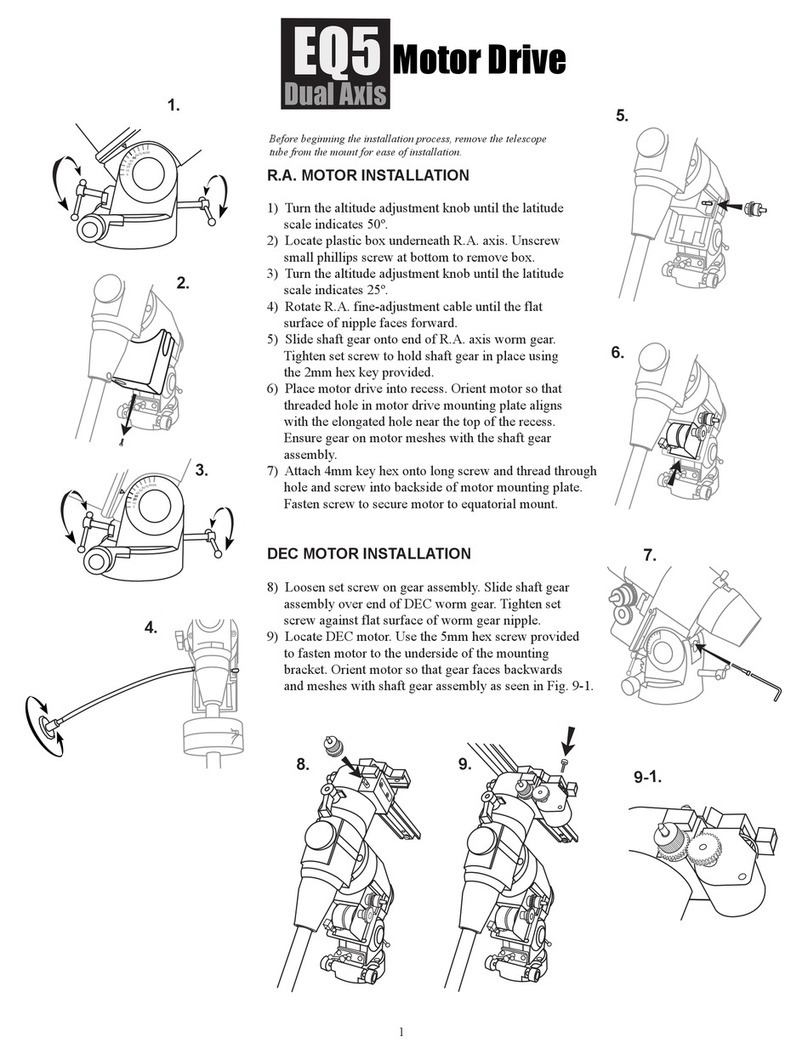

SKY-WATCHER

SKY-WATCHER EQ5 quick start guide

Briggs & Stratton

Briggs & Stratton Vanguard 540000 Series Operator's manual

Ruggerini

Ruggerini RY 125 Use & maintenance

YS

YS 140 LIMITED Operator's manual

LOMBARDINI MARINE

LOMBARDINI MARINE LDW 1603 M Use and maintenance manual