4. Seal head and shaft sleeve (Ref. No.

17) (where applicable) can now be

pulled from shaft.

5. Pry seal seat from adapter.

6. Push seal head from shaft sleeve

(where applicable).

INSTALLATION OF NEW SEAL

The precision

lapped faces on

shaft seal are easily damaged. Handle

your replacement seal carefully.

1. Thoroughly clean all surfaces of seal

seat cavity.

2. Using a clean cloth, wipe shaft and

shaft sleeve (where applicable) and

make certain that they are perfectly

clean.

3. Wet rubber portion of new seal seat

with a light coating of soapy water.

While wearing clean gloves or using a

clean light rag, press seal seat

squarely into adapter recess. Avoid

scratching white ceramic surface. If

seat will not position properly, place

a cardboard washer over polished

surface and use a piece of pipe to

press in, firmly but gently.

4. Dispose of cardboard washer. Check

again to see that polished surface is

free of dirt and all other foreign

particles and that it is has not been

scratched or damaged.

5. Wet inside rubber portion of new

seal head with a light coating of

soapy water. Slide head onto

shaft/shaft sleeve. Slide shaft sleeve

with seal head onto motor shaft

(where applicable). Seal head and

seal seat will meet. Reinstall any

shims which have been removed. (See

“Shim Adjustment” section.)

6. Replace impeller key (where

applicable), and impeller. Replace

impeller seal (where applicable)

before screwing impeller fastener in

place.

7. Reassemble pump.

8. A short “run-in” period may be

necessary to provide completely leak

free seal operation.

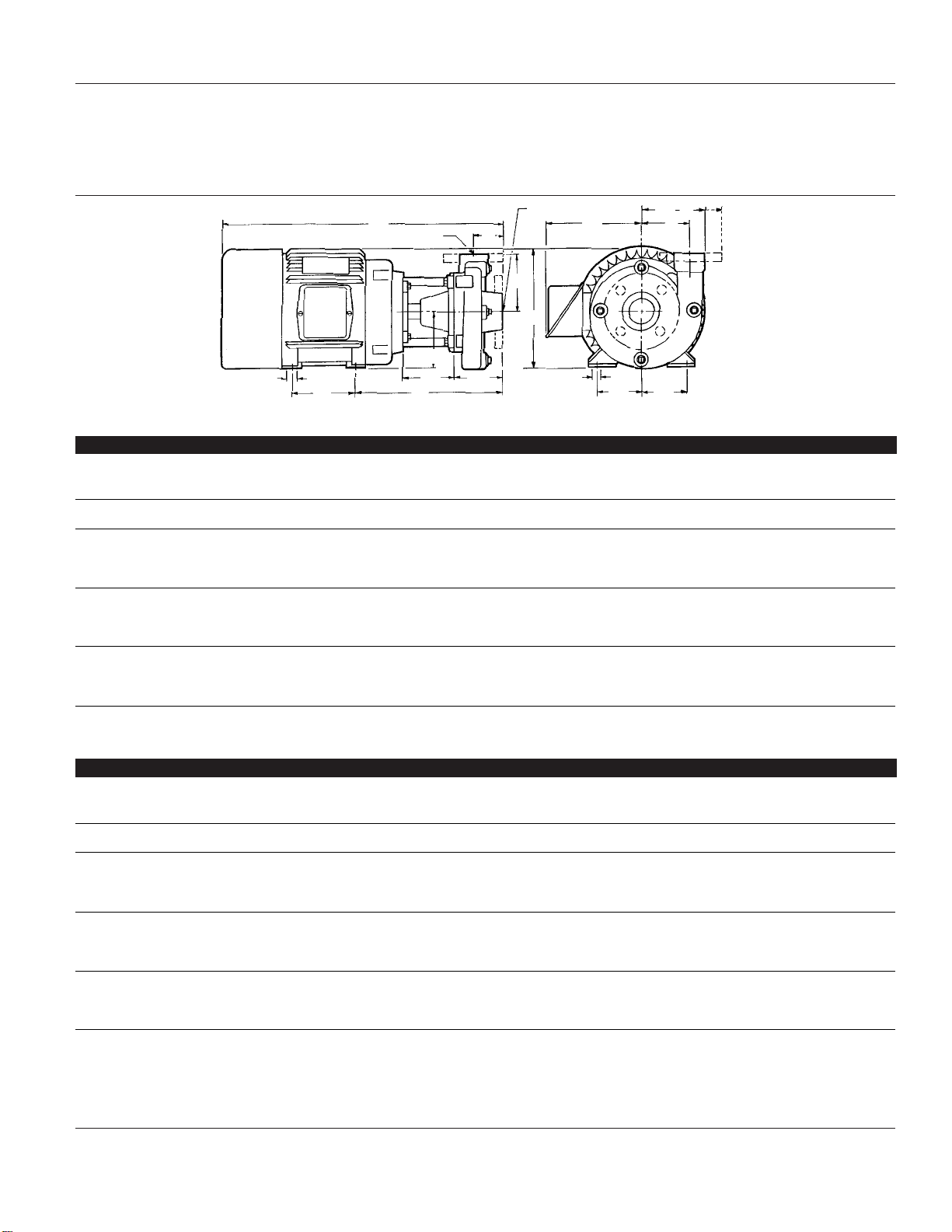

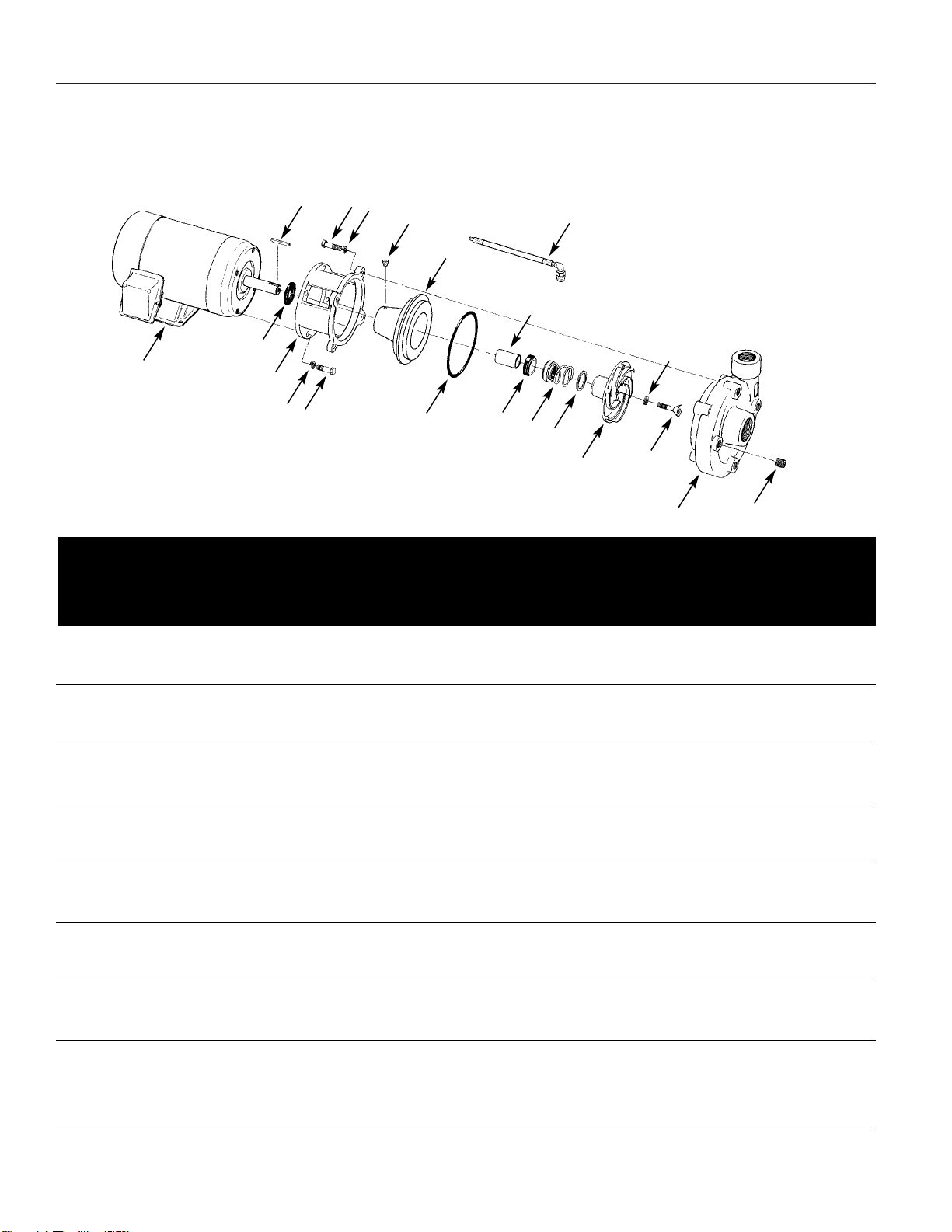

SHIM ADJUSTMENT

When installing a replacement impeller

(Ref. No. 12) or motor (Ref. No. 1), it

may be necessary to adjust the number

of shims (Ref. No. 11) to insure proper

running clearance between impeller

and casing (Ref. No. 14). Proceed as

follows:

NOTE: A proper running clearance is

less than 0.010”.

1. For impeller replacement, add one

0.010” shim in addition to those

removed originally.

2. For motor replacement, add two

0.010” shims in addition to shims

removed during disassembly.

3. Reassemble pump as described in

Steps 6 and 7. (See “Installation of

New Seal” section.)

IMPORTANT: Insure that casing is

snugly in place and check shaft to

make sure it is turning freely (rotate

impeller by impeller fastener, Ref. No.

13, with a wrench). If it turns freely,

check to insure that adapter (Ref. No.

3) and casing are fitted “metal to

metal“ where they meet on outside.

If they are not “metal to metal“,

tighten fasteners (Ref. No. 6) and

recheck shaft for free turning.

Tighten carefully, turning shaft while

tightening so that motor bearings are

not damaged in the event that too

many shims were installed. If shaft

seizes before fasteners are completely

tight, disassemble pump and remove

one shim and repeat reassembly.

Specifications Information and

Repair Parts Manual

Centrifugal Pumps

Cast Iron & Bronze Models

3150 thru 315E and

4240 thru 4261

6

Maintenance (Continued)