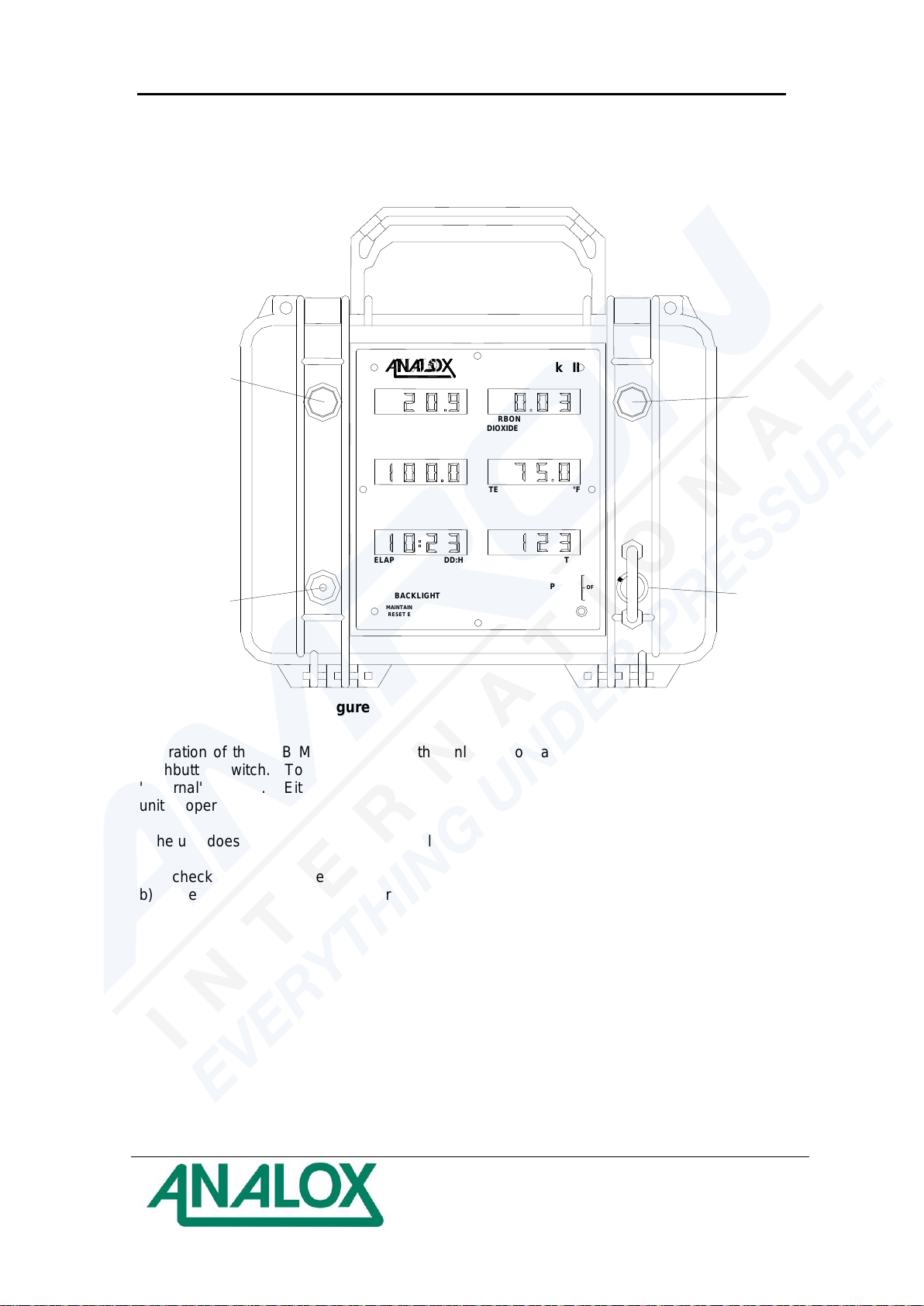

Sub MkIIP Oxygen & Carbon Dioxide Monitor

User Manual - US Navy Version

Document Ref: AS2-802-14 - January 2016

Page 7

4 Installing batteries

4.1 Main batteries

The instrument is fitted with four 'D' size 1.5v alkaline cells. Although the instrument will

operate from other types of D size battery, their use is not recommended. The operating life

using batteries such as zinc chloride or nickel cadmium will be significantly less than with

alkaline. Batteries with cell voltages in excess of 1.5v must not be fitted.

The instrument is designed such that if a new set of alkaline batteries is installed at annual

maintenance, and if the equipment is then powered for 1 hour every month for testing

purposes, then in the event of a DISSUB incident, the batteries will power the instrument for

in excess of ten days. A DISSUB incident is believed to be no longer than seven days,

therefore under these conditions there will be no need to access the batteries during the

incident. It is assumed that the backlight would only be used on an occasional basis during

this period, since it has the biggest effect on battery life.

To replace the batteries:

a) In dry conditions (to prevent damage) open the lid of the instrument using the two

catches beside the handle

b) Undo the two Velcro retaining straps around the batteries

c) Ease each battery from its clips - use one hand to grip the battery and the other hand to

apply a little pressure to release the clips.

d) Insert the new batteries, taking care to observe the polarity markings on each of the

battery holders, and ensuring that the battery is retained by the clips in the holder. Fitting

the batteries incorrectly could cause them to leak.

e) Refasten the Velcro retaining straps to prevent the batteries becoming dislodged from

their holders inadvertently.

f) Close the lid of the instrument, and secure in place with the two catches.

4.2 Backup batteries

The instrument is also fitted with 2 additional LR43 Alkaline Manganese cells to maintain the

Real Time Clock within the instrument. The Real Time Clock is used to calculate the elapsed

time and for instruments with the data logging option.

These cells are mounted on the main printed circuit board on the underside of the lid. The

batteries should be replaced at 5 year intervals. Observe the polarity markings on the cell

holders, positive uppermost.

The instrument will operate without these batteries fitted, although the Elapsed Time function

will not operate when switched off. Data logging functions (where fitted) will also be affected.