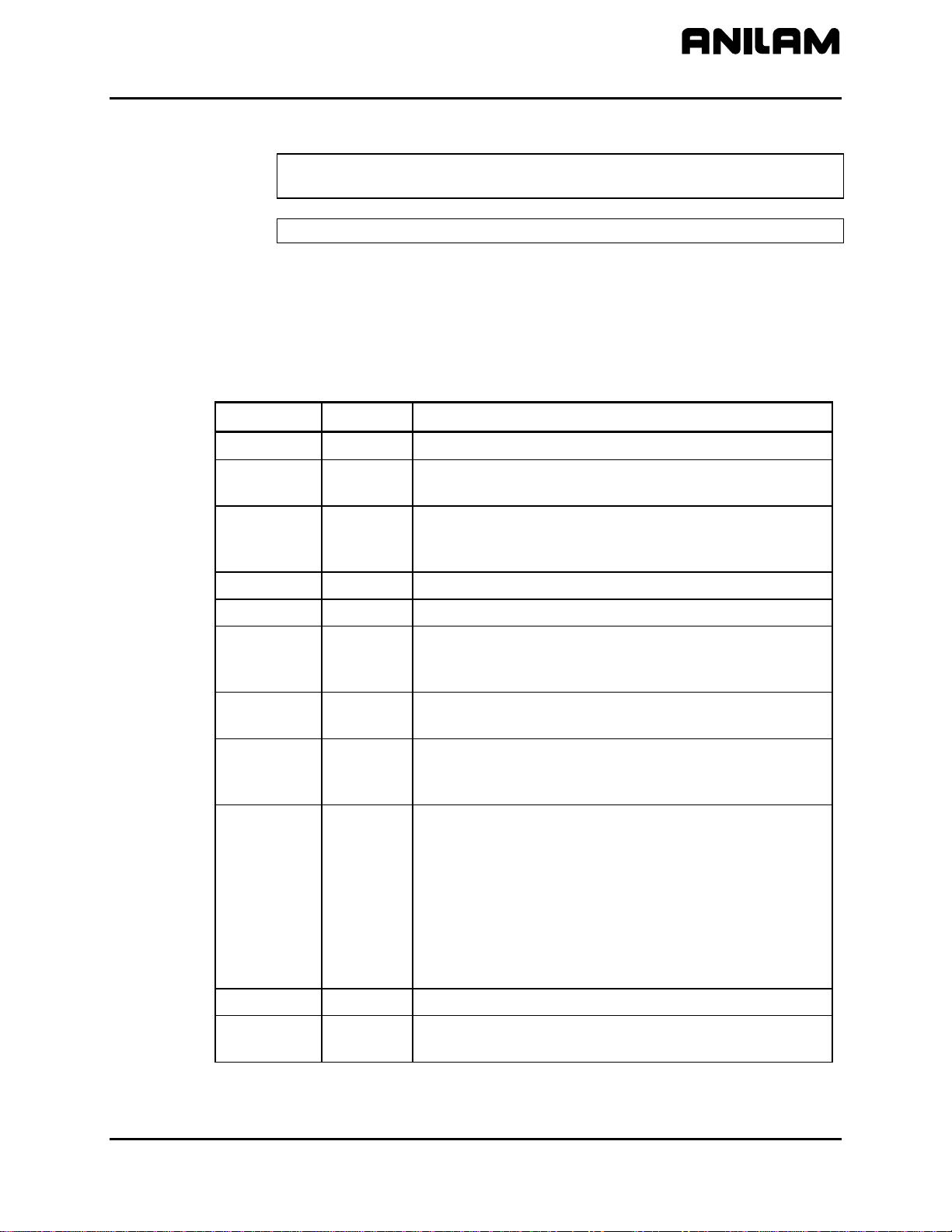

CNC Motion Setup/Testing Utility

P/N 70000634C - Contents

All rights reserved. Subject to change without notice. iii

November 2009

Introduction ...................................................................................................................1

Accessing the MST Utility ............................................................................................1

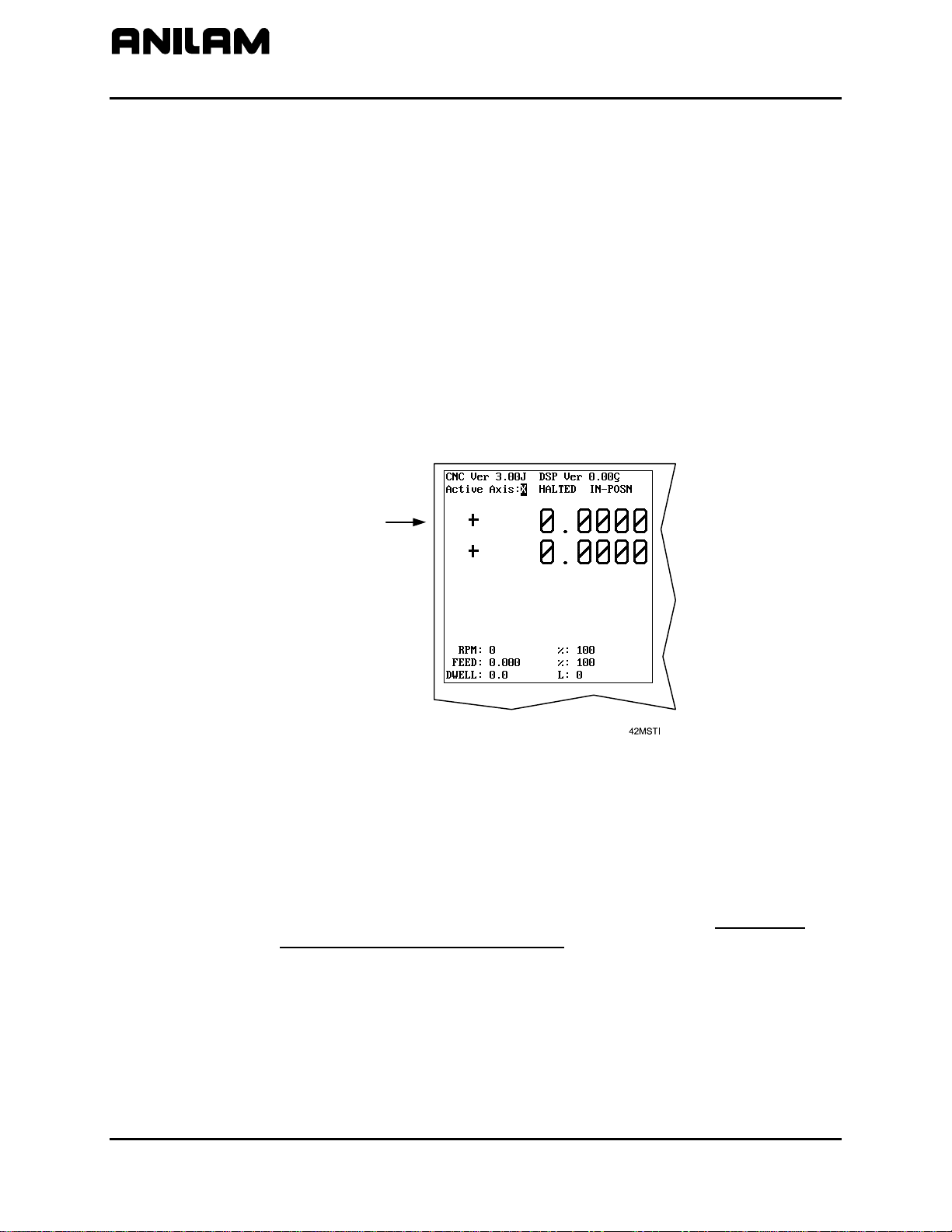

Activating the MST Screen...........................................................................................2

MST Soft Keys...............................................................................................................3

Clearing a Prompt Field or Message (F1) ...........................................................................................4

Selecting an Axis.................................................................................................................................4

Entering a Password...........................................................................................................................4

Checking Axis Resolution (F2)............................................................................................................5

Detecting the Index Pulse (F3)............................................................................................................6

Canceling the Active MDI or Test Command ......................................................................................6

Activating Manual Data Input Mode (MDI)...........................................................................................6

Balancing Motion Control Axes...........................................................................................................7

Differential (AC Systems) and Single-Ended (DC Systems) DSP2 Board ...........................................8

DC Systems........................................................................................................................................9

Servo Drive Test Board...................................................................................................................9

Balancing the DSP2 Board (F6) .....................................................................................................10

Balancing Servo Amplifier Outputs (F6) ........................................................................................12

Amplifier Faults..............................................................................................................................13

Setting the Signal Gain (F7) ..........................................................................................................17

AC Systems ......................................................................................................................................19

Servo Amplifier Test Board............................................................................................................19

Balancing the DSP2 Board (F6) .....................................................................................................21

ANILAM Amplifier Parameter Files................................................................................................22

Balancing Servo Amplifier Outputs (F6) ........................................................................................23

Amplifier Faults..............................................................................................................................27

Miscellaneous Tests (F9) ..............................................................................................................27

AC and DC Systems.........................................................................................................................32

Tuning (F8)....................................................................................................................................32

Saving Final Values.......................................................................................................................35

Exiting the MST Screen (F10) .......................................................................................................35

Setting Up and Tuning the C-Axis .............................................................................36

Index......................................................................................................................................Index-1