10

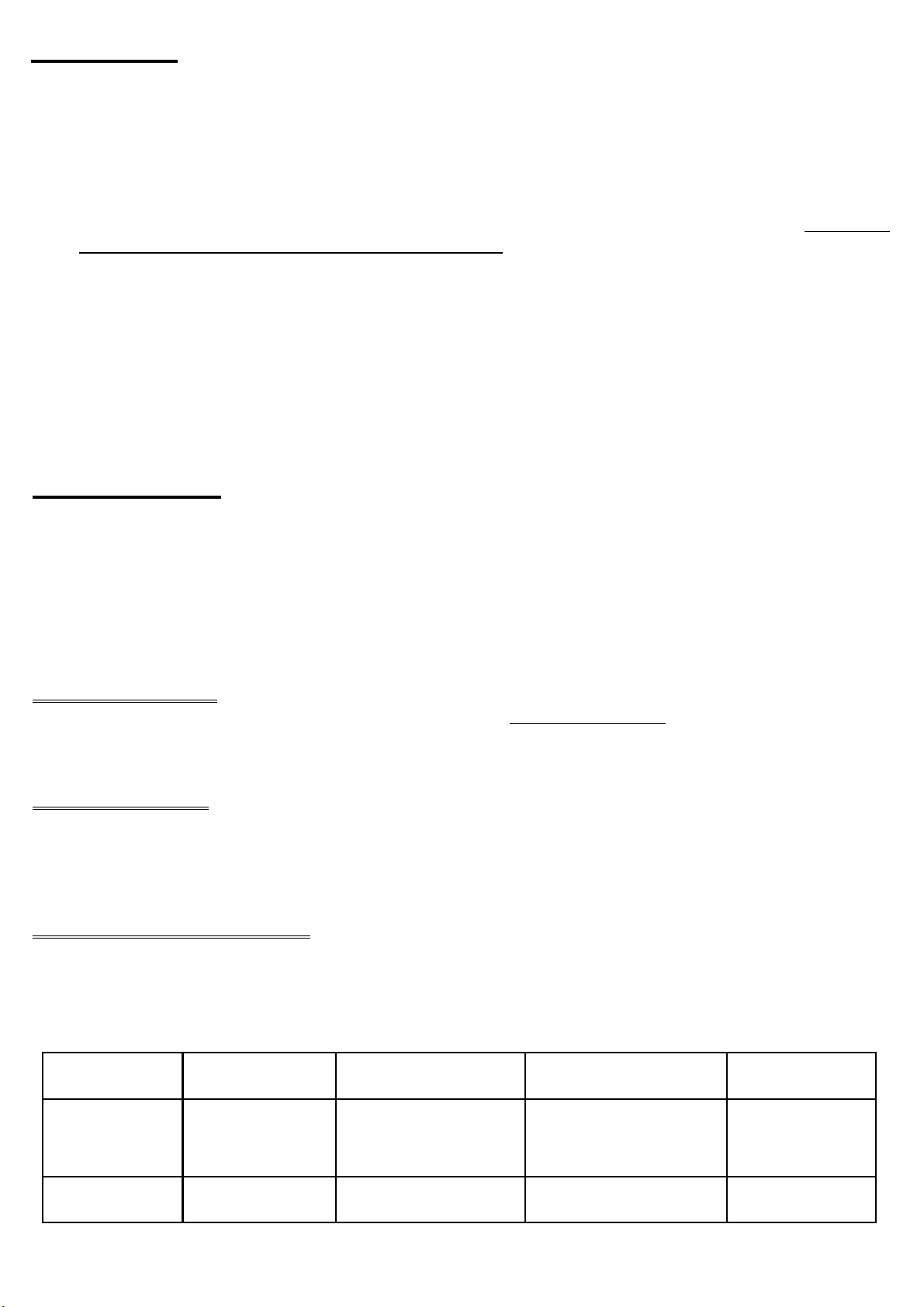

Troubleshooting

Trouble Cause Remedy

Does not start.

Starts, but imme-

diately stops.

(1) Power failure (1)~(3) Contact electric power company and

devise counter-measures

(2) Large discrepancy between power source and voltage

(3) Significant drop in voltage

(4) Motor phase malfunction (4) Inspect electric circuit

(5) Electric circuit connection faulty (5) Correct wiring

(6) Faulty connection of control circuit (6) Inspect connections and magnetic coil

(7) Fuse is blown (7) Check circuit then replace fuse

(8) Faulty magnetic switch (8) Replace with correct one

(9) Water is not at level indicated by Float (9) Raise water level

(10) Float is not in appropriate level (10) Adjust the position of float

(11) Float is not effective (11) Repair or replace

(12) Short circuit breaker is functioning (12) Repair location of short circuit

(13) Foreign matter clogging pump (13) Remove foreign matter

(14) Motor burned out (14) Repair or replace

(15) Motor bearing broken (15) Repair or replace

Operates, but

stops after a

while.

(1) Prolonged dry operation has activated motor protector

and caused pump to stop (1) Raise water level to C.W.L

(2) High liquid temperature has activated motor protector

and caused pump to stop (2) Lower liquid temperature

(3) Reverse rotation ! WARNING : (3) Correct rotation

Does not pump.

Inadequate vol-

ume.

(1) Reverse rotation (1) Correct rotation (see Operation)

(2) Significant drop in voltage (2) Contact electric power company

(3) Operating a 60Hz pump with 50Hz (3) Check nameplate

(4) Discharge head is high (4) Recalculate and adjust

(5) Large piping loss (5) Recalculate and adjust

(6) Low operating water level causes air suction (6) Raise water level or lower pump

(7) Leaking from discharge piping (7) Inspect, repair

(8) Clogging of discharge piping (8) Remove foreign matter

(9) Foreign matter in suction inlet (9) Remove foreign matter

(10) Foreign matter clogging pump (10) Remove foreign matter

(11) Worn impeller (11) Replace impeller

Over current (1) Unbalanced current and voltage (1) Contact electric power company

(2) Significant voltage drop (2) Contact electric power company and

devise counter-measure

(3) Motor phase malfunction (3) Inspect connections and magnetic

switch

(4) Operating 50Hz pump on 60Hz (4) Check nameplate

(5) Reverse rotation ! WARNING : (5) Correct rotation (see Operation2)

(6) Low head. Excessive volume of water (6) Replace pump with high head pump

(7) Foreign matter clogging pump (7) Remove foreign matter

(8) Motor bearing is worn out or damaged (8) Replace bearing

Pump vibrates;

excessive oper-

ating noise.

(1) Reverse rotation (1) Correct rotation

(2) Pump clogged with foreign matter (2) Disassemble and remove foreign matter

(3) Piping resonates (3) Improve piping

(4) Strainer is closed too far (4) Open strainer