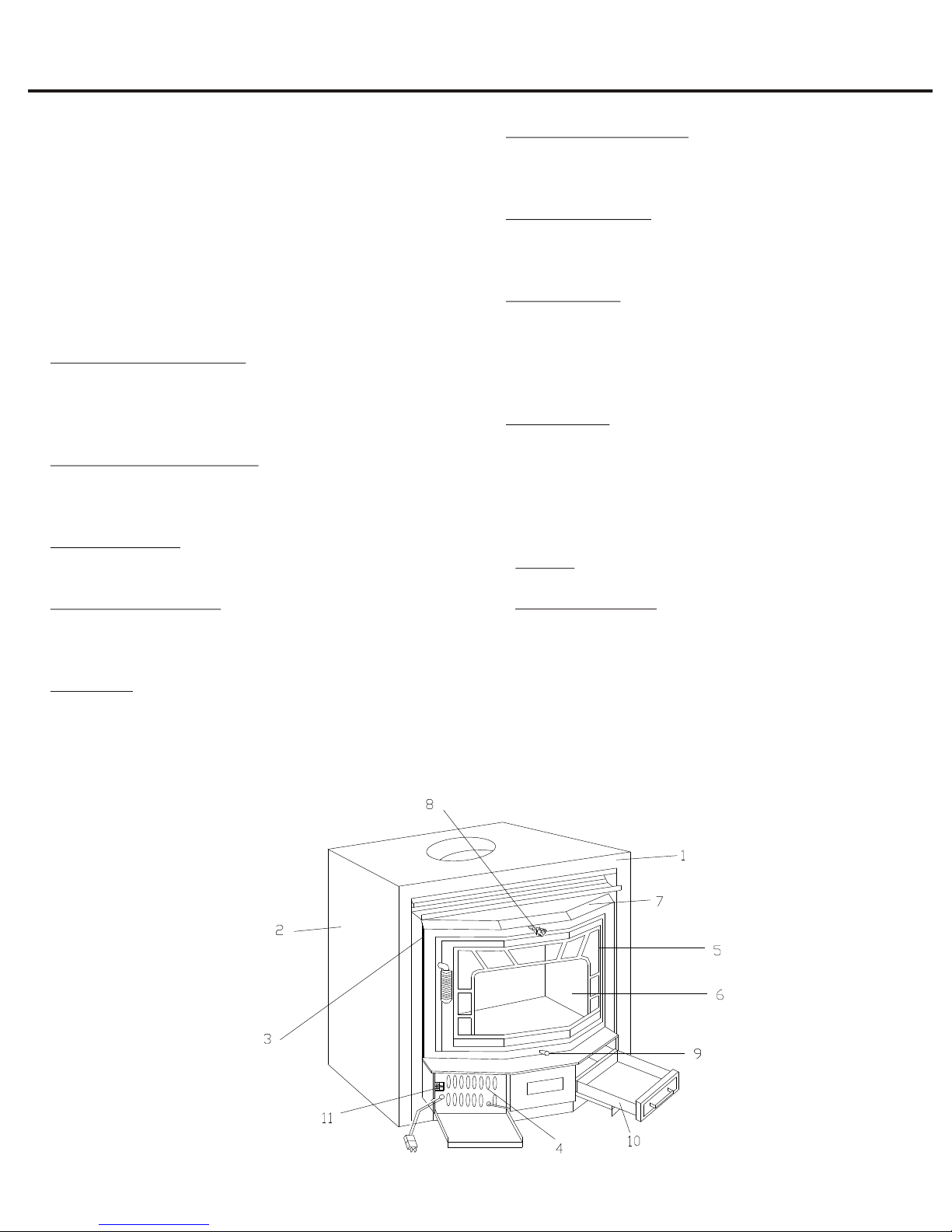

I. Stove Features and Operating Controls....................3

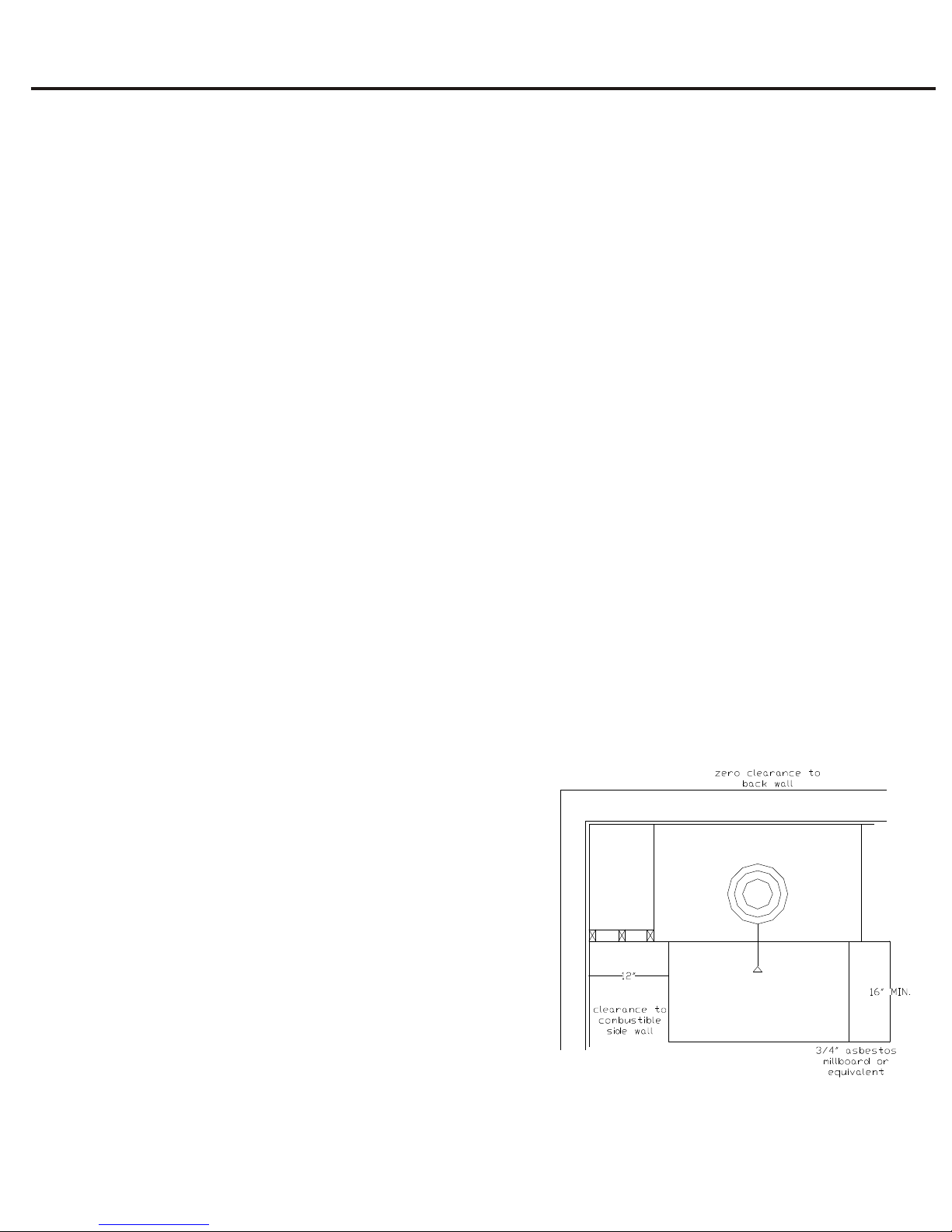

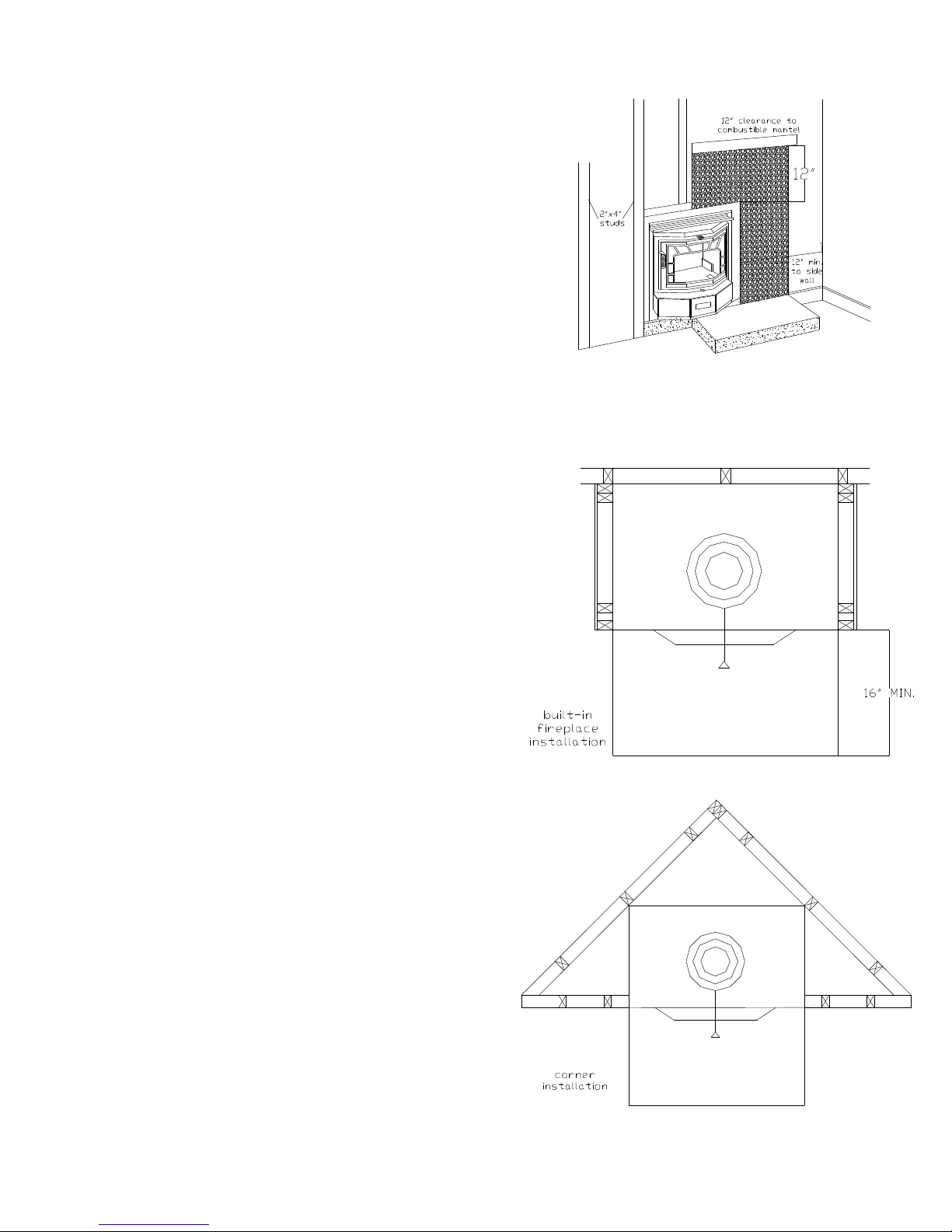

II. Clearances for Installation.......................................4

1. Clearances for Fireplace Installation.....................4

2. Clearances for Freestanding Installation...............4

III. Installation as a Fireplace Unit...............................5

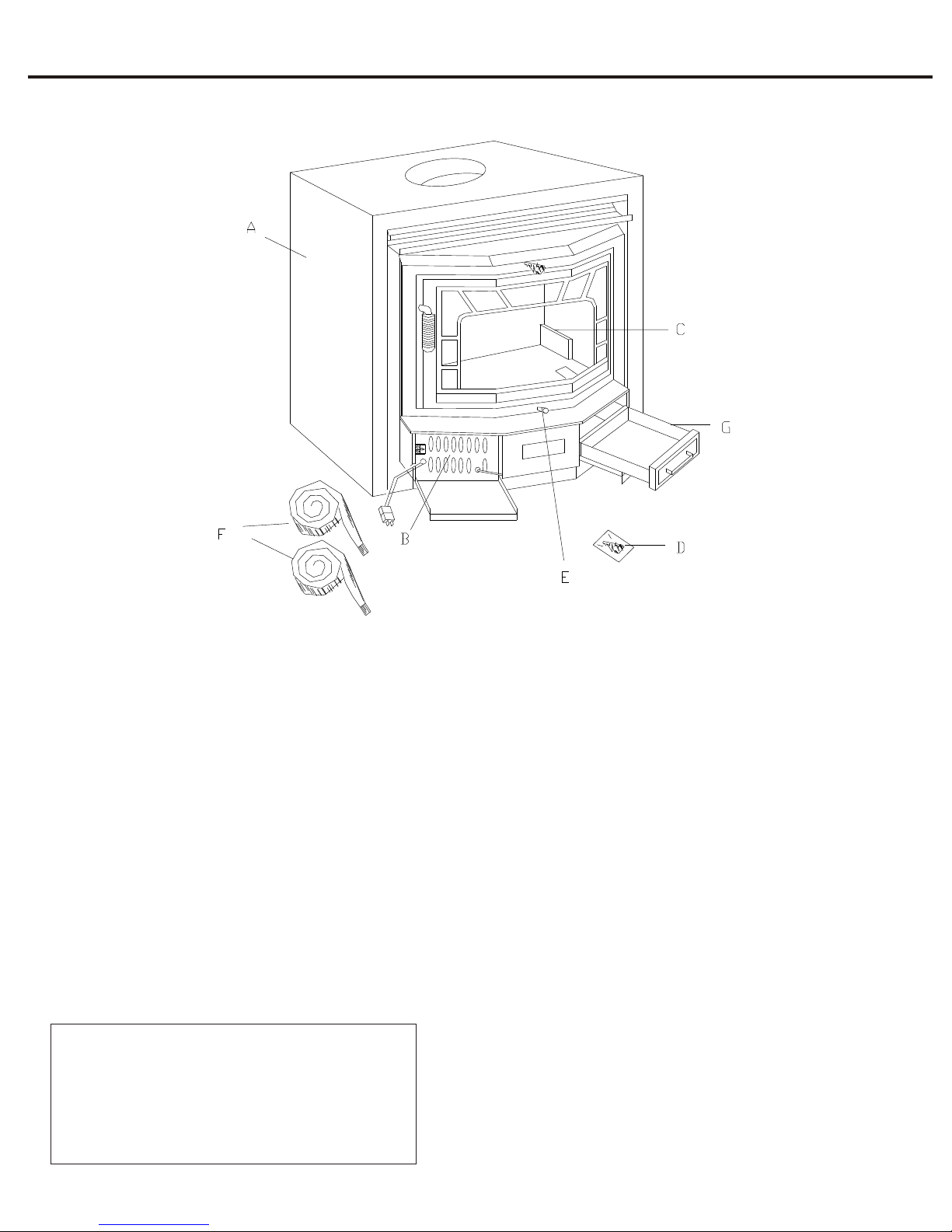

1. Stove Components...............................................5

2. Mounting the Optional Trim Panels......................5

3. Installing the Gemini XLB Unit............................6

4. Importance of Proper Draft..................................6

IV. Freestanding Installation.........................................7

1. Stove Components...............................................7

2. Preparation...........................................................7

3. Attaching the Freestanding Kit..............................8

4. Importance of Proper Draft..................................8

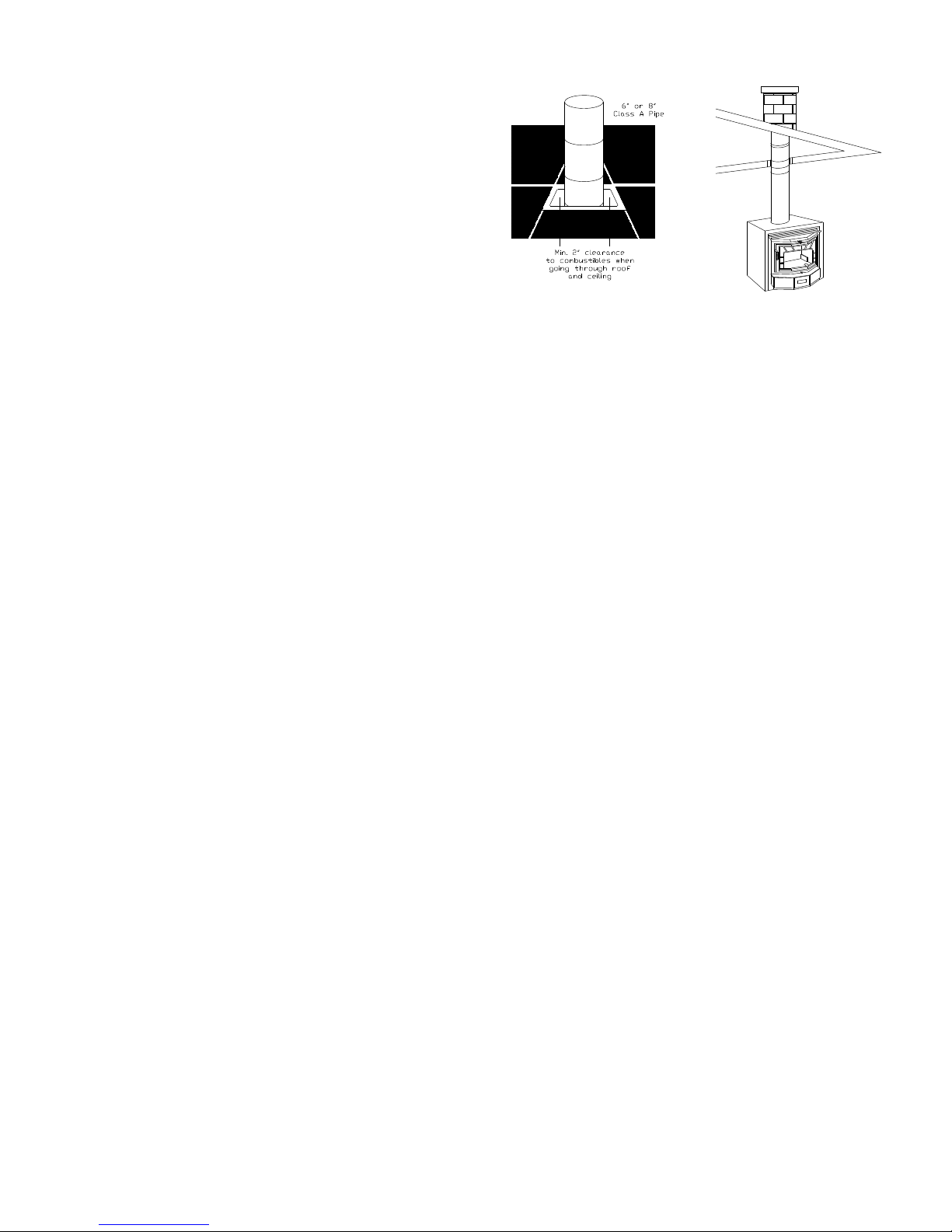

5. Mounting the Stove Pipe......................................8

6. Chimney Installation............................................9

V. Installing the Brass Trim........................................10

1. Standard Brass....................................................10

2. Optional Brass....................................................10

VI. Catalytic Combusters...........................................11

1. General Information...........................................11

(A) Tamper Warning...........................................11

(B) Manufacturer and Warranty Info..................11

2. Catalyst Monitoring...........................................11

3. Catalyst Troubleshooting General Info...............12

4. Catalyst Replacement.........................................13

VII. Stove Operation.................................................14

1. Fuel Selection.....................................................14

2. Building and Maintaining a Fire.........................14

3. Refueling the Stove.............................................14

4. Achieving Catalyst Light-Off

From a Cold Start..........................................14

5. Catalyst Light-Off When Refueling....................14

VIII. Maintenance.....................................................15

1. Ash Removal......................................................15

2. Care of the Glass................................................15

3. Chimney Care....................................................15

4. Stove Finish........................................................15

5. Blower Care.......................................................15

6. Door Gasket Replacement..................................15

7. Motor Maintenance...........................................15

TABLE OF CONTENTS

IX. Safety......................................................................16

X. Limited Warranty....................................................16

XI. Warranty Registration.............................................17

NOTE: Tested and listed by Arnold Greene Testing

Laboratories to test standards ANSI-UL 1482, 737, 127

HUD specifications and Uniform Building Code.

Thank you for purchasing the Gemini XLB stove.

Appalachian Stove welcomes you to the growing ranks of

energy conscious Americans.

Heating with wood and bituminous coal is one way to

conserve resources and to stimulate a healthy economy.

The forest industry has worked for many years to assure a

continual supply of our most abundant renewable

resource - wood.

To fully benefit from your stove and to ensure safe

operation, follow the instructions in this manual carefully.

We hope you enjoy many years of safe, economical heat

from your Gemini XLB stove.

This manual describes the installation and operation of

the Appalachian Stove’s Gemini XLB catalytic equipped

wood heater. This heater meets the United States

Environmental Protection Agency’s emission limit for

wood heaters sold after July 1, 1988. Under specific

conditions, this heater has been shown to deliver heat at

rates ranging from 10,100 to 26,900 BTU/hour.

2