AQUATECH MINIPACK MP Series User manual

INSTRUCTIONS FOR

0. GENERAL SAFETY INFORMATION, WARNINGS & CAUTIONS

1. INSTALLATION

2.THEUSER

3. SERVICING

4. DISPOSAL

MINIPACK MP SERIES

PRESSURISATION UNITS WITH

MICROPROCESSOR CONTROLS

MODELS: MP31, 32, 71, 72

ISSUE: 6 30/01/2019

Head Office: AGM House, London Rd, Copford, Colchester, Essex CO6 1GT UK

Manchester Office : Unit 10, Wheel Forge Way, Ashburton Road West, Manchester. M17 1EH

PRODUCT IDENTIFICATION

All pressurisation units described in this manual automatically maintain a minimum set pressure, the “Cold Fill”

pressure, in a heating or chilled system by transferring make-up liquid from a breaktank or sealed vessel into the

system.

When the system pressure falls below the required level the Duty pump automatically refills the system until the

pressure is restored. If the Duty Pump fails to maintain the required pressure the Support pump (where fitted) will

operate in addition to the Duty Pump.

Please note that the Serial Number “WNxxxxx” or “SNxxxxx” and model reference will be visible on the unit’s label and

on the back page of the manual supplied with the unit.

Examples of units manufactured by Aquatech Pressmain are shown below: -

Please note: it is also possible for the pump/controls/tanks to have been sold as a separate item, in which case the

O&M manual and CE declaration may only be applicable in part.

Model number examples: -

MiniPack MPxx-B MiniPack MPxx-E

Pressurisation unit with Basic controller Pressurisation unit with Enhanced controller

MP - MiniPack MP

3 max 3.0Bar cold fill pressure

7 max 7.0Bar cold fill pressure

1 1 pump

2 2 pump

B Basic MPC controller

E Enhanced 2020+ controller

e.g. MP31-B = max 3.0Bar cold fill pressure with 1pump and Basic MPC controller.

A “standard/basic” –B pressurisation unit controller has a 2 digit

display: -

An “Enhanced” –E controller with BMS volt free relays has

a 2 line by 20 or 24 character display: -

2.3

PRESSURE SYSTEM IS O.K.

Pressure 2.3 bar

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

3

CONTENTS

0.0 GENERAL SAFETY INFORMATION .................................. 4

0.1

WARNINGS .........................................................................................................................5

0.2

CAUTIONS FOR INSTALLATION...............................................................................5

0.3

CAUTIONS FOR OPERATION/USER .......................................................................7

0.4

CAUTIONS FOR MAINTENANCE .............................................................................7

1. INSTALLATION INSTRUCTIONS......................................................................... 8

1.1

GENERAL...................................................................................................................................................8

1.2

ADDITIONAL WARNINGS & CAUTIONS....................................................................................8

1.3

PROCEDURE ...........................................................................................................................................8

1.3.1

LOCATION .....................................................................................................................................8

1.3.2

FIXING..............................................................................................................................................8

1.3.3

PIPEWORK.....................................................................................................................................9

1.3.4

EXPANSION, CONTROL and HYDRAULIC ACCUMULATOR VESSELS........... 11

1.3.5

IDENTIFYING MiniPack “Standard/Basic” -B or “Enhanced” -E UNITS..............12

1.3.6

ELECTRICAL ...............................................................................................................................12

2. USER INSTRUCTIONS ...........................................................................................14

2.1

CUSTOMER ASSURANCE...............................................................................................................14

2.2

COMMISSIONING.............................................................................................................................. 15

2.3

OPERATING INSTRUCTIONS .......................................................................................................15

2.3.1

ADDITIONAL CAUTIONS..................................................................................................... 15

2.3.2

NORMAL OPERATION..........................................................................................................15

2.3.3

STANDARD/BASIC “-B” CONTROLLER OPERATION..............................................15

2.3.4

ENHANCED “-E” CONTROLLER OPERATION ............................................................ 16

2.3.5

STANDARD/BASIC CONTROLLER SYSTEM WARNINGS & ALARMS.............. 18

2.3.6

ENHANCED CONTROLLER SYSTEM WARNINGS....................................................18

2.3.7

ENHANCED CONTROLLER SYSTEM ALARMS...........................................................19

REMOTE SIGNALS ON ENHANCED MODELS ONLY............................................ 20

RESETTING PARAMETERS................................................................................................20

SERVICING REMINDER......................................................................................................20

2.4

MAINTENANCE INSTRUCTIONS................................................................................................ 20

2.4.1.

ADDITIONAL CAUTIONS..................................................................................................... 20

2.4.2

PROCEDURE.............................................................................................................................. 20

3. SERVICING ................................................................................................................21

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

4

3.1

MAINTENANCE AND CARE OF YOUR EQUIPMENT.........................................................21

3.2

LEGAL REQUIREMENTS.................................................................................................................. 21

3.3

SERVICE CONTACTS ........................................................................................................................21

4. DISPOSAL ..................................................................................................................21

EC DECLARATION OF CONFORMITY ....................................................................22

OPERATING PARAMETERS ........................................................................................22

0.0 GENERAL SAFETY INFORMATION

These instructions are intended for the installer/operator/user/maintenance of this equipment and

must be kept with the equipment, for the life of the equipment and made available to all persons. Please

read GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4 before

doing anything else, and then follow them carefully.

The unit must only be installed/operated/used/maintained by a competent person; A competent person

is someone who is technically competent and familiar with safety practices and the hazards involved.

Hydraulic Accumulators/Expansion Vessels installed as part of/in conjunction with this equipment, with

Pressure x Volume above 250 Bar-litres, require regular formal inspection by a competent person. This is

a Legal Requirement under the “Pressure Systems Safety Regulations” (PSSR) and the Owner/User

should be made aware of their responsibility for this. (see section 3. Servicing).

Failure to install/operate/use/maintain the equipment as recommended below could cause damage to

the equipment any anything subsequently connected to it, and invalidate the warranty provided by

AquaTech-Pressmain to the buyer.

Any damage caused to the equipment by misapplication, mishandling or misuse could lead to risk of

Electrocution, Burns, Fire, Flooding or injury to people or property dependent upon the circumstances

involved.

This equipment contains moving/rotating parts that must remain guarded. Removal of or missing

guards could lead to serious personal injury.

This equipment automatically restarts after a power interruption.

We accept no responsibility or liability for any consequences or damage/losses due to misapplication,

mishandling or misuse of the equipment.

It should be noted that the assembly of pressure equipment on site under the responsibility of the user

(or his representative) is not subject to the Pressure Equipment Directive 97/23/EC. (National

legislation covering assembly on site will apply)

The latest version of this instruction manual with up to date safety information can be downloaded

from our website at www.aquatechpressmain.co.uk

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

5

0.1 WARNINGS

0.1.1 Do not touch any live parts for at least 5 minutes after switching off the electricity supply. Failure to

observe this will constitute a severe Electric shock and/or Burns hazard and may be lethal.

0.1.2 The equipment is only suitable for earth referenced supplies and must be permanently earthed to avoid

Electric shock hazard.

0.1.3 With equipment isolator OFF, mains voltage may still be present from BMS system. This constitutes an

Electric shock hazard.

0.1.4 Emergency stop button does not remove dangerous voltages from control panel/pump motor

assemblies. This constitutes an Electric shock hazard.

0.1.5 Metal parts (e.g. heat sinks) may reach temperatures of 90 degrees centigrade and will constitute a Burns

hazard.

0.1.6 Some equipment is designed to operate with liquid temperatures up to 150 degrees centigrade and will

constitute a Burns/scalding hazard.

0.1.7 The equipment must not be pressurised beyond the maximum working pressure as stated on

pumps/pipework/vessels/control panel otherwise serious mechanical damage/destruction could occur

causing injury to people or property.

0.1.8 The equipment must not be heated/chilled beyond the maximum/minimum working temperature as

stated on pumps/pipework/vessels/control panel otherwise serious mechanical damage/destruction

could occur causing injury to people or property.

0.1.9 Any damage to equipment, pumpset, vessels, pipework or system components caused by misapplication,

mishandling or misuse could lead to Electric shock hazard, Burns hazard, Fire hazard, Flooding hazard or

cause injury to people or property.

0.1.10 This equipment may contain moving/rotating parts that must remain guarded. Removal of or missing

guards could lead to serious personal injury.

0.1.11 Pressure vessels must never be disassembled whilst in use, they contain high pressure air/gas charge

which could cause injury to people or property.

0.1.12 Pump motors with lifting eyes; the lifting eyes are only suitable for lifting motors NOT the entire pump

assembly. This could cause injury to people or property.

0.1.13 Ensure the base/foundation/plinth/wall to which the equipment is to be attached is sufficiently strong

enough to carry the entire mass of the equipment including the water that it will contain under worst-

case fault conditions. E.g. fully saturated pressure vessel with no air charge, break tank full to

overflowing, etc. Failure to observe this could cause serious mechanical damage/destruction resulting in

injury to people or property.

0.1.14 This equipment contains a fluid which may under certain circumstances leak/drip/spray fluid (e.g.

servicing, repair or malfunction). Ensure any fluid discharge will not cause damage to the surroundings by

taking appropriate action. E.g. install in a place that will not be damaged by leakage or install in a bunded

area with adequate drainage.

0.2 CAUTIONS FOR INSTALLATION

0.2.1 READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

0.2.2 The unit should only be installed/operated by a competent person; A competent person is someone who is

technically competent and familiar with safety practices and the hazards involved.

0.2.3 Do not lift the pumpset by pipework. Lift the pumpset by the container pallet using a pallet/forklift or crane

by passing strops underneath the skid using a spreader bar. Failure to utilise these facilities will result in

damage to the pumpset.

0.2.4 Store in a dry place to avoid damp conditions deteriorating the equipment.

0.2.5 Protect against dirt, damage and frost. It is absolutely essential that no foreign matter such as pipe thread

swarf, welding slag, grit or stones are allowed to enter the set. Debris of this type can cause severe damage

to the mechanical seals, diaphragms and impeller. Frost/freezing will damage pumps/pipework and control

panel components.

0.2.6 The equipment is only suitable for installation in a clean, dust free indoor environment, with adequate

protection from heat and frost, and sufficient ventilation to ensure cooling of the motors. Ambient air

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK 6

temperature should be between 5 and 40 degrees centigrade, non-condensating. Operation outside of

these conditions could seriously damage the equipment.

0.2.7 If the equipment were to be stored or taken out of service for a period of time (e.g. 1 week or more), then

we would recommend draining the equipment of all water/liquid (with due regard to any local regulations)

to prevent frost damage to components. When restarting is required we would recommend commissioning

by our authorised service agent.

0.2.8 Ensure the base/foundation/plinth/wall to which the equipment is to be attached has sufficient mass

compared to the equipment, in order to avoid noise/vibration transmission. E.g. the mass of the base should

be at least five times the mass of the equipment.

0.2.9 Ensure the electrical supply is the correct voltage, current, frequency and type for the equipment supplied

and that suitable circuit protection equipment is installed in the supply. Incorrect electrical installation

could be an electric shock/burns/fire hazard.

0.2.10 When accessing the control panel to make electrical connections adopt anti-static procedures e.g. wear

anti-static earthed wristband, to avoid risk of damaging the controller.

0.2.11 All products that are packaged to include Pressure vessel(s)/Hydraulic Accumulator(s)/Expansion Vessel(s)

are classed as “Assemblies” under the Pressure Equipment Directive (PED). Where units are despatched

with “Loose” vessel(s) for assembly on site it is absolutely essential that they be installed as detailed in the

instructions using the fittings provided where appropriate. Failure to observe this will nullify compliance

with the PED and may present a safety hazard. Your warranty may also be affected.

0.2.12 Where Hydraulic Accumulator(s)/Expansion Vessel(s) are supplied as a loose item, they must be

installed/connected correctly before operating the equipment, otherwise serious damage from over-

pressure/pump overheating could occur.

0.2.13 Do not operate this equipment/pumpset prior to commissioning (section 2.2) This could cause irreparable

damage to equipment/pumpset/pipework/system components.

0.2.14 Isolate the equipment/pumpset before pressure testing system. Excess pressure could irreparably damage

the pressure transducer, pressure switches (where fitted) and the diaphragms of pressure vessel/hydraulic

accumulators.

0.2.15 It is the installers’ responsibility to ensure subsequent pipework etc can accept the pressures generated by

the equipment/pumpset and to install an overpressure safety device into the system with due respect to

the suction pressure present on the pumpset, the pump closed valve pressure stated on the pump, the

maximum working pressure stated on any of the attached pressure vessels and any other device connected

to the system e.g. boilers, calorifiers etc.

0.2.16 When chlorination of the system is carried out, ensure that any residual chlorine is removed by thorough

flushing as detailed in the HSE approved code of practice L8, to avoid damaging the equipment/pumpset.

The normal level of chlorination is up to 2 parts per million (ppm), but shock dosing for sterilization

purposes, at 25-50 ppm for 24-48 hours is acceptable as long as all chlorine is removed once the process is

complete. Chlorination beyond these limits could seriously damage pumpset components and WILL NOT

be covered by the warranty.

0.2.17 The installer/user is responsible for the installation of the correct earthing and protection according to

valid national and local standards. All operations must be carried out by a suitably qualified person.

0.2.18 The equipment is only suitable for earth referenced supplies and must be permanently earthed to avoid

electric shock hazard.

0.2.19 The equipment must be permanently earthed with appropriate sized Earthing.

0.2.20 Equipment containing variable speed drives/motors has high earth leakage current >3.5mA and will require

additional earth bonding whereby a single conductor of increased size or duplicate earth conductors must

be provided.

0.2.21 Never perform high voltage resistance tests on control panels, variable speed drives/motors without first

disconnecting the panel/drive/motor from the circuit being tested as this will damage the built in electronic

components.

0.2.22 Metal parts (e.g. heat sinks) may reach temperatures of 90 degrees centigrade.

0.2.23 EMC - With respect to BS EN61000-3-2 this equipment is defined as ‘professional equipment’ and

therefore the installer/user may need to seek permission from the supply utility to connect this equipment

to the public low voltage mains supply.

0.2.24 It is very strongly advised that the system is pre-filled prior to commissioning. Use of the “Pressurisation

unit” for filling the system pipework, may take considerable time, and in some cases may invalidate the

equipment warranty.

0.2.25 Where “Expansion vessels” are used on LTHW heating system pressurisation units, the temperature of the

fluid returning to the vessels should not exceed 70 degrees Centigrade as this could damage the vessel

diaphragm. Where the temperature exceeds 70C an intermediate cooling vessel should be fitted.

0.2.26 For MTHW and HTHW pressurisation units use a Nitrogen vessel suitable for the system conditions.

Please contact AquaTech-Pressmain for further information.

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

7

0.2.27 Do not use the “Pressurisation unit” for dosing the system with chemicals. Only allow clean cold water into

the break tank. Anything other than clean cold water could damage the pumps/pipework components.

0.2.28 Drain cocks/valves and air bleed screws must not be left open as this could cause flooding.

0.3 CAUTIONS FOR OPERATION/USER

0.3.1 READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

0.3.2 The unit should only be operated/used by a competent person; A competent person is someone who is

technically competent and familiar with safety practices and the hazards involved.

0.3.3 The Owner/User of this equipment has a Legal Responsibility to ensure that it is subject to regular formal

inspections. See Section 3. Servicing, for details.

0.3.4 Where Hydraulic Accumulator(s)/Expansion Vessel(s) are supplied as a loose item, they must be

installed/connected correctly before operating the equipment, otherwise serious damage from over-

pressure could occur.

0.3.5 The set must not be run until commissioned by an authorised AquaTech-Pressmain agent, this could

irreparably damage the pump set and/or system components/pipework connected to it.

0.3.6 The pumpset should be left switched ON with the pumps switched to AUTO for normal operation.

0.3.7 The pumpset should not be left in “Hand” operation for more than 1 minute. This could lead to severe

damage of pumpset components and/or pipework system from over-pressure and/or overheating.

0.3.8 Ensure pumpset has an adequate water supply at all times to prevent dry running causing pump seal

damage and water leakage.

0.3.9 Do no attempt to start pumps without liquid in volutes (pumps must be fully primed); mechanical seals must

have a film of liquid between faces for proper operation and to prevent damage.

0.3.10 Portable telephones or other electro-magnetic equipment must not be used near the set to avoid

corruption of program and unpredictable operation of unit.

0.3.11 For Pressurisation units utilising Nitrogen Vessels (generally HTHW units) ensure there is an adequate

supply of Nitrogen at all times to avoid mis-operation of the equipment.

0.4 CAUTIONS FOR MAINTENANCE

0.4.1 READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

0.4.2 The unit should only be operated/maintained by a competent person; A competent person is someone who is

technically competent and familiar with safety practices and the hazards involved.

0.4.3 Where the set is fitted with Building Management Services (BMS) interconnections, notify the appropriate

persons before switching OFF for maintenance or adjustments, to avoid unnecessary alarm conditions

occurring. WARNING: With pumpset isolator OFF, mains voltage may still be present from BMS system.

This constitutes an Electric shock hazard.

0.4.4 To prevent seizing, pumpsets must not be left unused for long periods (e.g. 1 week).

0.4.5 Do not vent air from air valves on vessels. These are for adjustment of pre-set cushion pressures. If wrongly

adjusted this will lead to incorrect operation of the pumpset and possible damage to pumps, pipework and

system components from overheating and over-pressure.

0.4.6 Switch OFF pumpset before accessing pumps and/or control panel.

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK 8

1. INSTALLATION INSTRUCTIONS

1.1 GENERAL

These instructions are intended for the installer of this pressurisation unit. Please follow them carefully.

The unit should only be installed by a competent person; A competent person is someone who is technically competent and

familiar with safety practices and the hazards involved.

It should be noted that the assembly of pressure equipment on site under the responsibility of the user (or his

representative) is not subject to the Pressure Equipment Directive 97/23/EC. (National legislation covering assembly

on site will apply).

Failure to install the equipment as recommended below could invalidate the warranty provided by AquaTech-

Pressmain to the purchaser.

1.2 ADDITIONAL WARNINGS & CAUTIONS

1.2.1 READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

1.3 PROCEDURE

1.3.1 LOCATION

The pressurisation unit should be connected to the underside of the return header on the suction side of the

circulating pump, but not within any influences from the circulating pump, and for a heating system, at the

point of lowest temperature i.e. before the boiler.

If the equipment is to be installed in an unheated room, ensure that there is adequate frost protection. On a

heating system do not lag any expansion vessel or its connection to the system. This can result in damage

occurring.

The location of the equipment should have adequate drainage, bunding or other appropriate measures to

protect assets and the building fabric in the event of leakage or water spillage. Failure to provide such

measures may result in water damage to property and assets.

Ensure that location for the equipment provides adequate clear space to accommodate unit with reasonable

access to all parts; AquaTech-Pressmain recommend a minimum distance of 500mm. There must be

sufficient room to:-

fully open control panel door & withdraw diaphragms from vessels,

Should any of these location conditions not be satisfied AquaTech-Pressmain reserve the right to charge

labour on any warranty work required on the pumpset.

1.3.2 FIXING

Lugs are provided for wall fixing on the back of the panel (see fig. 1.1)

Fig 1.1

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

9

1.3.3 PIPEWORK

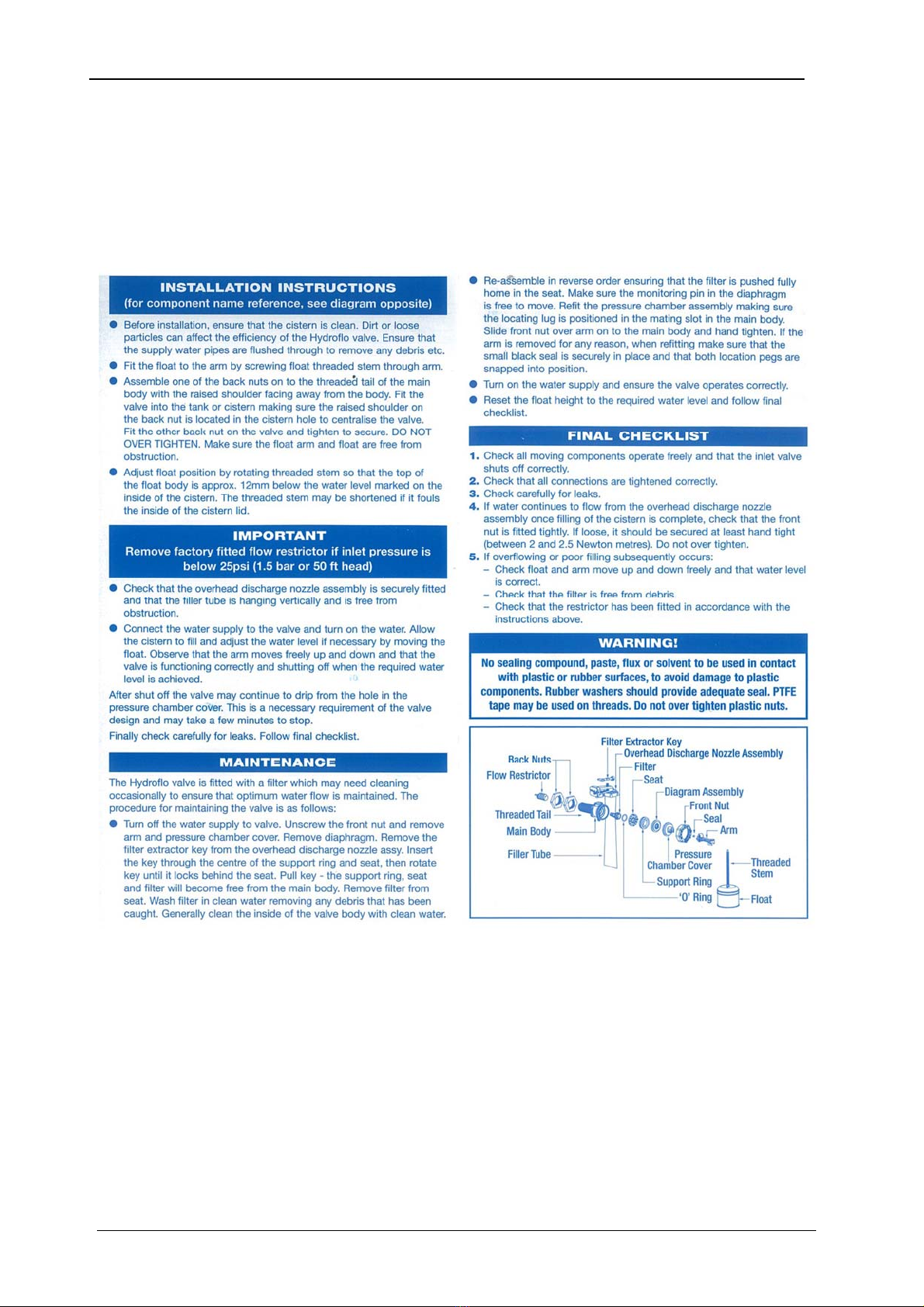

1.3.3.1 Mains Water Supply

i. Fit an isolating valve in the supply to enable the unit to be isolated from the supply for maintenance. Make

sure the float valve restrictor is fitted if the mains water inlet pressure exceeds 1.5 Bar. If the mains

water inlet pressure is less than 1.5 Bar, the restrictor should not be fitted.

ii. Float Valve Instructions as follows: -

iii. For category 4 & 5 installations remove the filler tube to comply with local water regulations.

1.3.3.2 System Connection

i. The unit must be connected with any expansion vessels and cooling vessels, to the underside of the return

header on the suction side of the circulating pumps and boiler/chiller (see Location 1.3.1)

ii. The system connection on the pressurisation unit is 15mm compression/1/2” BSP at the side of the cabinet.

An isolating valve must be fitted to isolate the unit from the system.

iv. All hydraulic accumulators and expansion vessels fitted to the system must have isolating and drain off

valves to enable them to be serviced.

v. All hydraulic accumulators and expansion vessels fitted to the system must have connecting pipework that

is removable to give access for replacing vessel diaphragm, and must be large enough to avoid friction

losses.

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK 10

1.3.3.3 Overflow

i. An overflow warning pipe is fitted to the side of the panel. This can be extended as required using 22mm

OD pipe which will fit inside the supplied overflow.

Pressure

Transducer

Level Sensor Mains Water Break Tank

15mm Float Valve

15mm Incoming

Mains Supply

Microprocessor Controller System connection

on suction side of

Circulating Pumps

Sytem filling device

e.g. quick fill loop,

(check local water

regulations)

Drain Cock

Isolating Valve

Pressurisation

pumps

IMPORTANT

Make connection to the

UNDERSIDE of system

pipework

"AquaTank"

diaphragm

expansion

vessel

CONTROLLER

MiniPack Pressurisation Unit Pipework supplied and fitted by installer

Isolating Valve

Isolating

Valve

System

connection

Fig 1.2: Typical Pipework Layout.

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

11

1.3.4 EXPANSION, CONTROL and HYDRAULIC ACCUMULATOR VESSELS

D

H

DN

60 - 500 Litre

Fig 1.3 typical expansion vessel dimensions

Type (stockcode MTH-) 300060 300100 300200 300300 300500 700100 700200 700300 700500

Nominal Content –litres 60 100 200 300 500 100 200 300 500

D mm 409 480 634 634 740 450 485 485 600

H mm 740 840 980 1280 1485 850 1400 1965 2065

Water Connection DN BSP 1” 1” 1 ¼” 1 ¼” 1 ¼” 1” 1 ½” 1 ½” 1 ½”

Weight Kg 25 32 50 55 85 18 49 60 90

Max. working Pressure-bar 10 10 10 10 10 10 10 10 10

Max. Continuous

temperature deg. C

70 70 70 70 70 100 100 100 100

All vessels must be securely mounted to prevent any movement from imposing strain on the attached pipework.

Vessels of 60 litres capacity or greater MUST be mounted vertically on the integral legs with water connection

lowermost.

Set up the vessel so the air charge filling valve (top) and the diaphragm (bottom on 70°C vessels, top on 100°C vessels)

are accessible for future maintenance. All vessels must have isolating and drain off valves fitted to enable them to be

serviced. The connecting pipework should be removable to give access for replacing the diaphragm and should be the

same size as the vessel connection to minimise friction losses. Note: if using a flexible hose it must be suitable for the

temperature of the system.

Fig. 1.4a & b Isolation valve on system pipework & Flexible hose with drain cock on vessel

Set the air cushion pre-charge pressure (see 2.4.2 Maintenance Procedure for details) to the correct level, dependent

on the application required for the vessel. Refer to the Operating parameters at the back of this manual or Aquatech-

Pressmain for advice.

Caution: If the air cushion pre-charge pressure required exceeds 4.0 Bar then you must follow the procedure shown in

section 2.4 to avoid damaging/rupture of the internal diaphragm and consequences of. E.g. High and/or low pressure

problems, unstable pump operation.

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

12

1.3.5 IDENTIFYING MiniPack “Standard/Basic” -B or “Enhanced” -E UNITS

1.3.5.1 The control panel fascia will state the “Model” and the “Serial Number” e.g. WN12345 or SN0654321. In

addition to this: -

1.3.5.2 A “standard/basic” –B pressurisation unit controller has a 2 digit

display:-

1.3.5.3 An “Enhanced” –E controller with BMS volt free relays has

a 2 line by 20 or 24 character display: -

1.3.6 ELECTRICAL

READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

1.3.6.1 All wiring must comply with the latest addition of local wiring Regulations.

1.3.6.2 Wear anti-static wrist strap at all times to avoid static discharge causing problems with the built in

electronic program.

1.3.6.3 Connect incoming electrical mains supply to isolating switch & Earth stud in panel (see fig.1.6). Ensure

voltages and frequency indicated on the motor nameplates and wiring diagrams correspond with supply

mains data and that the supply fuse ratings are correct for the total current rating of the equipment.

Refer to wiring diagram supplied with the unit or AquaTech-Pressmain.

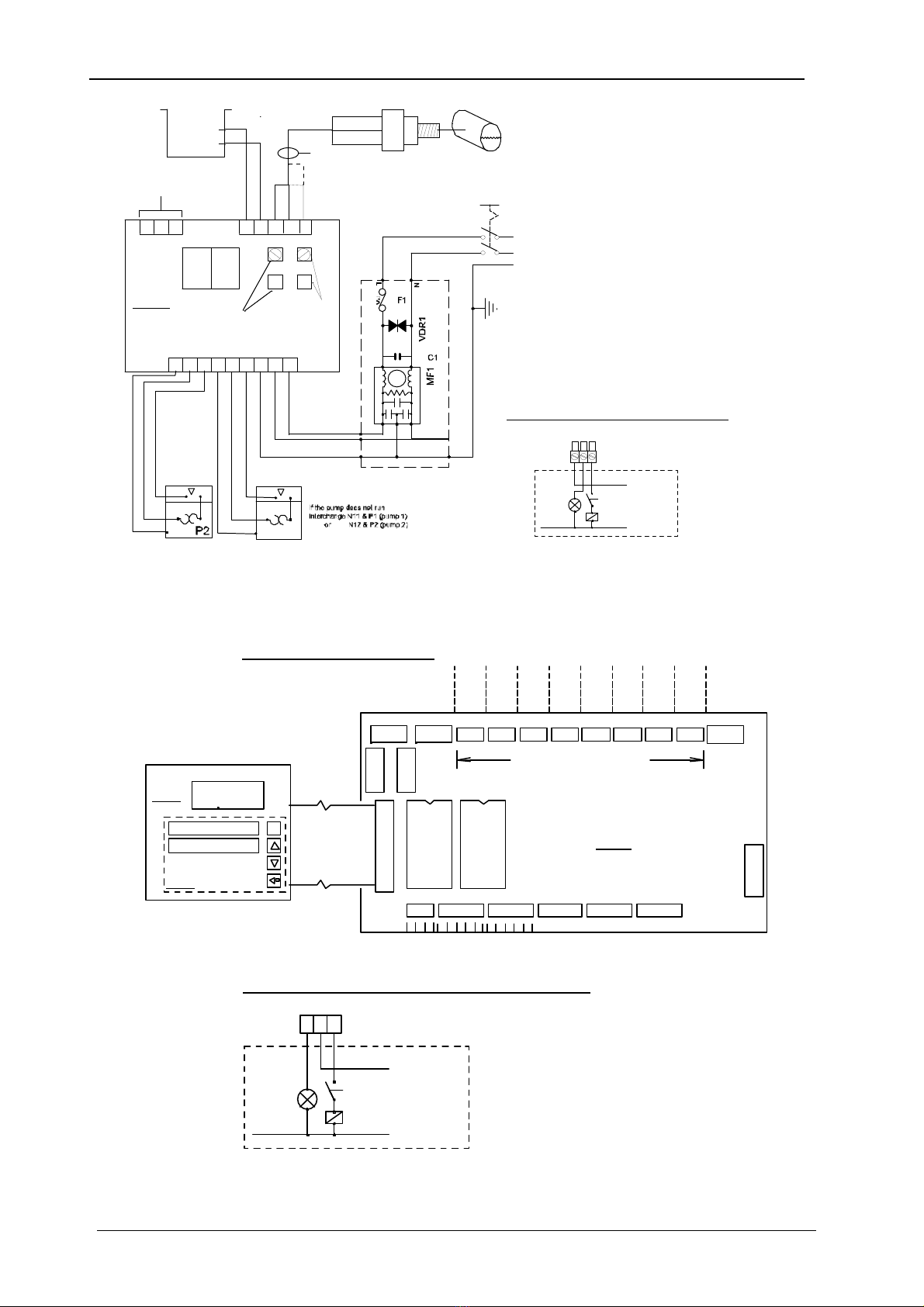

1.3.6.4 For standard controller units: Connect boiler/chiller to plug/socket terminal on pcb card in series with the

boiler/chiller control circuits so that in the event of a fault condition occurring the boiler/chillers shut

down and remain inoperative until the fault condition is rectified. (See fig 1.6b). Boiler relay is energised

for normal condition and releases to a high or low-pressure alarm fault condition.

1.3.6.5 For Enhanced controller units: Make any BMS connections required to terminals A-Z on Interface pcb

card inside control panel. Connect boiler/chiller terminals nos. X,Y,Z on interface card in series with the

boiler/chiller control circuits so that in the event of a fault condition occurring the boiler/chillers shut

down and remain inoperative until the fault condition is rectified. (See fig 1.7). Boiler relay is energised for

normal condition and releases to a high or low-pressure alarm fault condition.

1.3.6.5 Complete any required earth bonding.

Note: To aid access to the controls, switch off the power, remove outer cover, undo the two control shelf retaining

screws (Fig 1.5a), the control shelf will now hinge forward (Fig 1.5b). When complete reverse the above sequence

ensuring the two control shelf retaining screws are refitted correctly to ensure the keypad & display line up with the

holes in the outer cover. DO NOT trap any wires!

Fig 1.5a Control shelf retaining screws. Fig 1.5b Control shelf hinged down.

2.3

PRESSURE SYSTEM IS O.K.

Pressure 2.3 bar

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK 13

P1P2 N NEEENL

+10

I/P E

E

NC

NO C

(2)

(1)

(3)

Set Point adjust

Boiler/Chiller

volt free relay

240VAC 1A max.

High pressure

adjust

Delivery Pipework

PT1

OL1

3

2

OL2

P1

PCB1

MPC-Pu Controller

G/Y

L1

N

E

3

G/Y

2

1

3 core

screened cable

292 Pressure

Transducer

Supply

240VAC

2A 50Hz

(black)

(black) N

(black) L

Break

Tank

LWP1

Low Water

Probes

(G/Y)

(black)

(G/Y)

(G/Y)

P2

N12

(G/Y)

(black) P1

(black) N11

(G/Y)

N1

L11

(G/Y)

P1

N11

P2

N12

P11

P21

1

(G/Y)

0

0

1

(Black)

(Black)

(G/Y)

PCB2

E

N

L

E

IS1

8.8.

Typical Boiler Interrupt Circuit (wiring by others)

Control relay

Control thermostat

N

SUPPLY

Boiler/burner controls

no

Pressure fault

ncc

21 2220

Fig 1.6a Typical standard –B controller Wiring Diagram Fig 1.6b Typical Boiler wiring (by

others)

PCB1

PCB2

PCB3

O

Keypad

2020Plus controller

Pump 2 Auto/Off/Hand

Pump 1 Auto/Off/Hand

Display

Pressure fault

nocnc

Boiler/burner controls

ZYX

SUPPLY

N

Control thermostat

Control relay

Typical Boiler Interrupt Circuit (wiring by others)

IP2

4-Channel

Level

Sensing

Module

IP1

4 Channel

Analogue

Input

Module

Boiler

Cut-out

Common

Warning

Transducer

Failed

Pump

Failed

Pump Starts

Excessive

High/Low

Water

Low

Pressure

High

Pressure

F2F1

Pump2Pump1

T1A T1A

BMS volt free outputs

max 240VAC 50Hz 1.5A

no

c

nc

no

c

nc

no

c

nc

no

c

nc

no

c

nc

no

c

nc

no

c

nc

no

c

nc

13

12

11

10

9

3

2

1

8

7

6

5

4

to Controller

on door

24VAC

12VAC

0V

C

BA

Z

YXWV

U

TS

R

P

ONM

LKJ

HGF

E

D

B1

B2

B3

A1

A2

A3

2ETM40E Mothercard

Typical wiring connections

Fig 1.7 Typical Enhanced -E controller Wiring Diagram

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK 14

2. USER INSTRUCTIONS

2.1 CUSTOMER ASSURANCE

AQUATECH PRESSMAIN ASSURE YOU THAT IF ANY PART OF THIS EQUIPMENT BECOMES

DEFECTIVE DUE TO FAULTY MANUFACTURE OR MATERIALS WITHIN 24 MONTHS

FROM THE DATE OF INVOICE THE PART WILL BE REPAIRED OR REPLACED.

The only conditions are: -

The equipment must have been installed, commissioned, operated and maintained as recommended by

AquaTech-Pressmain.

The equipment must not have been neglected, misused, modified, or used for any other purpose than its original

application.

The commissioning should be carried out within 6 months of the date of invoice by an authorised AquaTech-

Pressmain agent

This Assurance does not apply to those items not supplied by us or to defects arising from parts not made or

approved by AquaTech-Pressmain. The individual manufacturers own policies for dealing with defects will apply.

Any part repaired or replaced under these Assurances will be covered for the balance of the appropriate

Assurance period.

If we have any disagreement about these Assurances which we are unable to resolve we will both abide by the

decision of an agreed Arbitrator or, if we are unable to agree, one appointed by the Building and Engineering

Services Association (B & ES) Arbitration Scheme Rules.

These Assurances are in addition to, and do not detract from, the contractual rights you have under Statute or at

common law.

Failure to comply with the installation, commissioning and maintenance procedures will invalidate the warranty.

For full details please see the AquaTech-Pressmain "CONDITIONS OF SALE"

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

15

2.2 COMMISSIONING

Whilst this set has been tested in the factory to the required settings (detailed in operating parameters at the back of

instruction manual), it is impossible to simulate the actual on-site conditions, especially if they are unusual. Also, the

settings may have been disturbed since leaving the factory.

Therefore we strongly recommend the set is commissioned by our authorised agent who will prepare the set, make

any necessary adjustments and leave the set in operational order.

Commissioning is a requirement to validate the Warranty (see Customer Assurance)

Prior to requesting an engineer to attend the site for commissioning, the client must ensure that;

the equipment has been correctly installed;

a written scheme of examination has been obtained where required under the Pressure Systems Safety

Regulations;

an adequate water supply and permanent electricity supply are available;

the equipment and pipework in the building being served by the pressurisation unit is capable of accepting

the generated pressures.

2.3 OPERATING INSTRUCTIONS

This unit is used for maintaining the pressure in pressurised heating or chilled systems with a volume up to 10,000

litres at 82ºC or boiler power up to 1000kW.

READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

2.3.1 ADDITIONAL CAUTIONS

2.3.1.1 Isolate the pressurisation unit from the system before draining or modifying the system. If the unit is

drained it must be recommissioned.

2.3.2 NORMAL OPERATION

The pressurisation unit automatically maintains a minimum set pressure, the “Cold Fill” pressure, in a heating or chilled

system by transferring make-up liquid from a breaktank or sealed vessel into the system. When the system pressure

falls below the required level the Duty pump automatically refills the system until the pressure is restored. If the Duty

Pump fails to maintain the required pressure the Support pump (where fitted) will operate in addition to the Duty

Pump.

2.3.3 STANDARD/BASIC “-B” CONTROLLER OPERATION

The control is by AquaTech-Pressmain “MPC-Pu” Microprocessor, with a 2 character display on the control panel,

showing the current system pressure in Bar.

To spread the wear evenly between the pumps the Duty Pump alternates each time both pumps stop (where two

pumps are fitted).

If there is an interruption in the electrical supply the unit will restart on restoration of the supply.

The unit must be left switched ON with the system connection valve OPEN.

When switched on the display shows the controller type

Then self checks stating the firmware ref. eg.

Followed by the system pressure in bar

(Screens shown are examples only)

1

2

2.3

P

u

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

16

2.3.4 ENHANCED “-E” CONTROLLER OPERATION

The control is by AquaTech-Pressmain “2020Plus” Microprocessor, with a 2-line by 20 or 24 character display on the

control panel, showing the current system pressure and status.

When switched on the display shows,

then self-checks, flashing all LED lights on keypad,

and identifies configuration for pump operation

(e.g. “MP” pressurisation unit)

followed by the system status and pressure

For “normal” operation, all Hand/Off/Auto switches should be left in “Auto”, all isolating valves should be left open, all

hydraulic accumulator/expansion vessel isolating valves should be left open, and drain cock/valves should be left

closed. Should it be necessary to have a situation that is not “normal” operation, then we would strongly recommend

attendance to site by our trained/authorised service personnel. Please contact AquaTech-Pressmain for more details.

Pump Operation

Sealed system pressurisation unit; All Models:

The pressurisation unit automatically maintains a minimum set pressure, the “Cold Fill” pressure, in a heating or chilled

system by transferring make-up liquid from a breaktank, into the system. When the system pressure falls below the

required level the Duty pump automatically refills the system until the pressure is restored. If the Duty Pump fails to

maintain the required pressure the Support pump (where fitted) will operate in addition to the Duty Pump.

Duty Pump Rotation.

To spread the wear evenly across both pumps (where fitted), their sequence is

automatically rotated either by starting the pump that has been idle the longest and/or by timed operation (dependent

upon unit type).

Indicator lights (where fitted) on the fascia show which pump is running.

Automatic Restart (when “manual restart” is set to “not enabled” on 2020 Plus controller)

If there is an interruption to the electrical supply the unit will automatically restart on restoration of the supply.

Pumps will restart at timed intervals.

Manual Restart (when set to “enabled” on 2020 Plus controller)

If there is an interruption to the electrical supply, or there is a low water level condition, the unit will need to be

manually reset on restoration of the supply, or low water level condition, by pressing the “Reset Alarm” key. Pumps

will then restart at timed intervals.

Pressure setting.

The pumpset is set at the default 'duty/cold fill' pressure at the factory. If necessary, the

pressure will be adjusted at commissioning to suit local conditions.

To view the parameters (Enhanced controller only)

Press <SET/VIEW> on the keypad. Then, press the same key 4more times.

Press the <UP> (7) key, to view the next parameter.

Page through the parameters by using the <UP> (7) and <DOWN> (8) keys to view:

Various parameters will be displayed dependent upon unit type. The main parameters that customers are interested in

are shown on the following page.

Date and Time (24 hour clock) not password protected to allow

on site adjustment.

Fault Log (last 30 faults) press <view> to see log followed

by <up> (7) or <down> (8) to view

log.

press <enter> to return

Manual Restart upon power failure not password protected to

AQUATECH 2020Plus V5.01

PRESSMAIN

MP

Time

14/01/15…….22:40:15

Fault Log

PRESSURE SYSTEM IS O.K.

Pressure ………… bar

Manual Restart

Not enabled

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

17

or low water level condition allow user to enable/disable

Pumps 1 & 2 hours run time

Time elapsed since last service service reminder after 6 months

Total run time (power up time) not resetable

Enable service call enable/disable service reminder

Low pressure alarm low pressure alarm. Note: low

pressure approach warning is 0.2

bar more than this value

Low pressure delay time before alarm is initiated.

High pressure high pressure alarm. Note: high

pressure approach warning is 0.2

bar below this value

High pressure delay time before alarm is initiated.

Duty delay to delay duty pump starting to

circulator pump pressure dips

Support delay to delay support pump starting in

normal operation preventing

electrical/pressure dips/surges

Starts in 12 minutes sets frequency of pump starts

warning (system leak detection)

Duty pressure (cold fill) duty pump cut-out/cold fill

pressure. All other pumps are

derived from this value.

Minimum run time for each pump

Pump x run time

000123.4 Hours

Since last service

000987.6 Hours

Total run time

005000.0 Hours

Enable service call

Enabled

Low pressure

0.8 Bar

Low p delay

10 sec

High pressure

3.0 Bar

High p delay

10 sec

Duty delay

0 sec

Support delay

10 sec

Starts/12 mns

8

Duty pressure

1.6 bar

Min run time

3 sec

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK 18

2.3.5 STANDARD/BASIC CONTROLLER SYSTEM WARNINGS & ALARMS

Flashing 2 digit display giving type of fault and a boiler/chiller volt free output signal for high or low pressure

condition. Relay energised for normal condition and releases for a high or low pressure alarm fault condition.

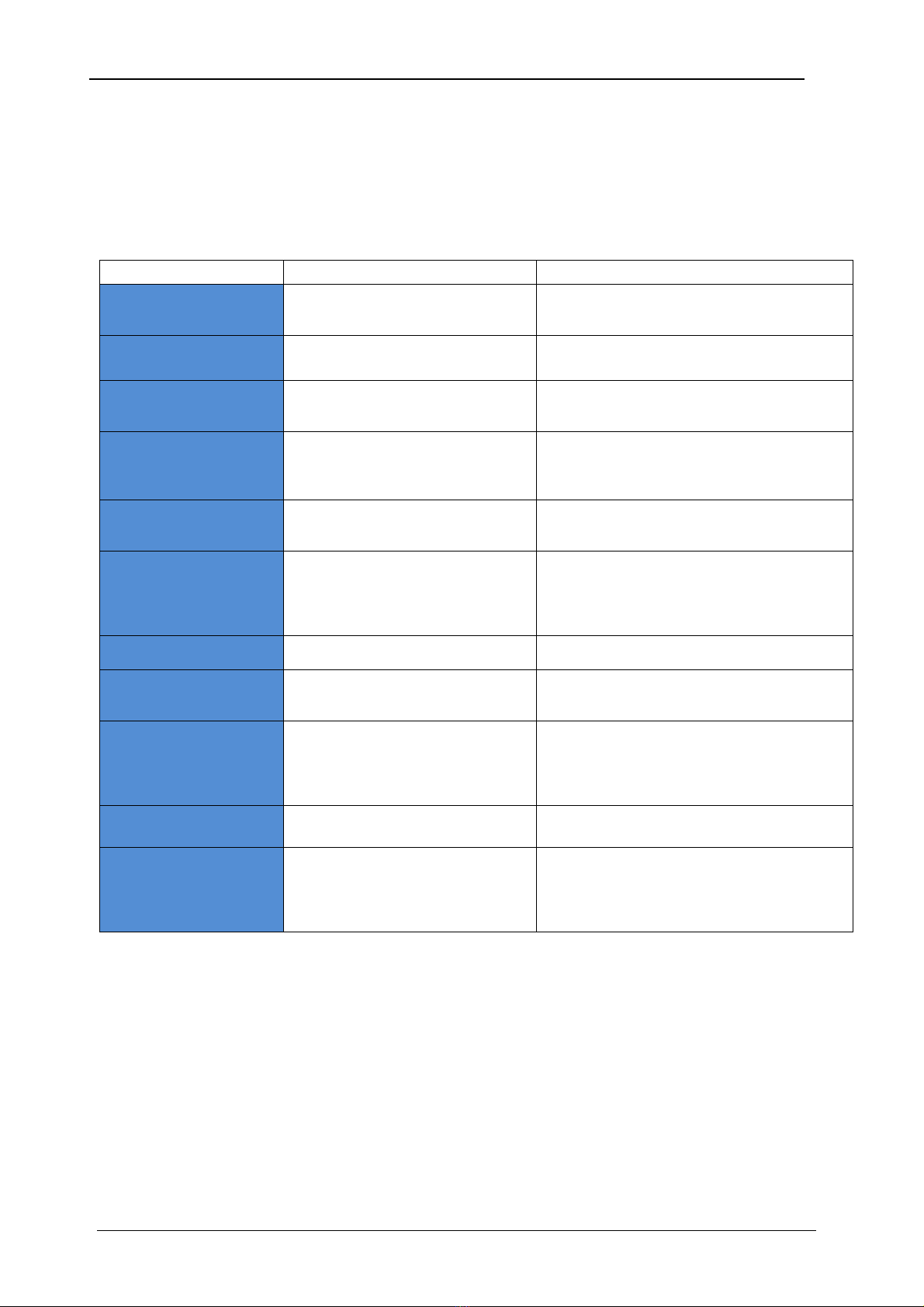

Displayed Message Cause Check

L P (Low pressure) system pressure at/below low

pressure setting & delay timer expired

Pressure vessel air charge wrong? Or

water usage exceeds design capacity?

Or pump(s) are tripped or air locked.

LL(Low water Level)

water level below supply tank low

water alarm probe or pipework sensor

dry. (240 second delay on automatic

restart, after restoration of water

level).

Break tank float valve stuck closed?

Or output of pumpset exceeds mains

water supply into break tank? Mains

water interruption to break tank?

H P (High pressure) system pressure at/above high

pressure setting & delay timer expired

Pressure vessel air charge wrong? Or

system water content exceeds design

capacity? Or pump(s) are continuously

running?.

O r (system pressure Over Range)

Pressure sensor output above 9.9 Bar

or pressure sensor not connected

correctly.

Pressure higher than 9.9 Bar? Or

pressure sensor failed? Or pressure

sensor wiring loose?

S P (setpoint point out of range) The setpoint pressure has been set

either below 1.2 Bar or above 9.9 Bar.

Adjust setpoint pressure within

normal range.

No Display 1 Amp control fuse may have blown.

If unit has been switched off for a long

period, a turbine pump (where fitted)

may have seized. Switch off unit, insert

flat blade screwdriver into slot on end

of motor shaft and rotate pump until

free. Replace fuse with T1Ax20mm,

try again.

2.3.6 ENHANCED CONTROLLER SYSTEM WARNINGS

Flashing display giving type of fault and a various volt free output signals on BMS enhanced models. (see wiring

diagram provided with unit to see which volt free signal relays are present. Typical example shown in fig. 1.7).

***** Warning ***** Cause Check

High pressure approach system pressure at high pressure

setting minus 0.2 Bar

Pressure vessel air charge wrong? Or

insufficient expansion capacity?

Low pressure approach system pressure at low pressure

setting plus 0.2 Bar

Pressure vessel air charge wrong? Or

water usage exceeds design capacity?

Pump starts exceeded/is system

leaking?

duty pump starts exceeded “starts in

12 mins” parameter

System pipework is leaking

excessively? Starts parameter set too

low?

Excessive run time/ is system leaking? duty pump continuously running for

12 minutes

System pipework is leaking

excessively?

Commissioning needed Unit has not been commissioned by

authorised service engineer

Have unit commissioned by

authorised service engineer.

Power Up Power interruption started “Power

Up” sequence

Incoming electrical supply

interruption? Or missing phase? Or

loose connections?

Low level delay

A low water level condition has reset,

and a 4 minute delay is now initiated

before normal operation will resume

Check pumps are vented and wait for

the delay time to expire

Manual restart

(when set to enabled)

A power interruption or low water

level has occurred,

Carry out all necessary checks, then

press the “Reset alarm” key on the

micro

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK 19

2.3.7 ENHANCED CONTROLLER SYSTEM ALARMS

Flashing display giving type of fault, audible alarm, volt-free output signals on BMS Enhanced models, and action as

described. (see below). (see wiring diagram provided with unit to see which volt free signal relays are present. Typical

example shown in fig. 1.7).

RESET: Alarms are manually muted and reset using the UP (7) or DOWN (8) buttons on the keypad. (Automatic

reset facility can be provided)

***** Alarm ***** Cause Check

Pressure system Fault Check pumps 1 & 2 for a pump-tripped

condition.

Check electrical supply is within tolerance, or

missing phase? Pump seized? motor failed?

Motor thermistor overheated?

High pressure system pressure at/above high

pressure setting & delay timer expired

Pressure vessel air charge wrong? Or insufficient

expansion capacity? Pump(s) left in Hand?

Low pressure system pressure at/below low

pressure setting & delay timer expired

Pressure vessel air charge wrong? Or water

usage exceeds design capacity? Pump(s) switched

Off or Tripped?

Transducer failed

Pressure sensor output above normal

range of pressure sensor or pressure

sensor not connected correctly.

Pressure higher than sensor range? Or pressure

sensor failed? Or pressure sensor wiring loose?

Pump overload fault Pump/Inverter tripped signal present

Check electrical supply is within tolerance, or

missing phase? Pump seized? motor failed?

Motor thermistor overheated?

No water in feed tank

water level below supply tank low

water alarm probe or pipework sensor

dry. (240 second delay on automatic

restart, after restoration of water

level).

Break tank float valve stuck closed? Or output of

pumpset exceeds mains water supply into break

tank? Mains water interruption to break tank?

Pump overheated Pump motor temperature too high. Pump seized? motor failed? Motor thermistor

overheated?

High water level Tank 1 water level above supply tank high

water alarm probe

Break tank float valve wrongly adjusted, stuck

open or letting by? HP restrictor fitted to

F/valve?

Low water level Tank 1

water level below supply tank low

water alarm probe or pipework sensor

dry. (240 second delay on automatic

restart, after restoration of water

level).

Break tank float valve stuck closed? Or output of

pumpset exceeds mains water supply into break

tank? Mains water interruption to break tank?

Other Fault Hardware shutdown Please call AquaTech-Pressmain for advice

No Display 1 Amp control fuse may have blown.

If unit has been switched off for a long period, a

turbine pump (where fitted) may have seized.

Switch off unit, insert flat blade screwdriver into

slot on end of motor shaft and rotate pump until

free. Replace fuse with T1Ax20mm, try again.

If a problem persists contact AQUATECH-PRESSMAIN quoting the serial number WN:_______

or SN:_________ (on control panel fascia)

MINIPACK

X:/Aquatech-Pressmain Instruction manuals/current/MINIPACK

20

REMOTE SIGNALS on Enhanced models only

- volt free contacts in control panel (see fig 1.7) :

High system pressure, Low system pressure, High/Low Water level in break-tank, Excessive pump starts, Pump

tripped/failed, Transducer failed, Common warning, , Boiler/chiller cut-out

RESETTING PARAMETERS

The parameters can be protected from inadvertent alteration by a password security code. The factory default is for

no password protection to be enabled. This can be changed to password protected if required.

Parameters may be reset on site by a user or an Aquatech-Pressmain Service engineer.

SERVICING REMINDER

When routine service is due display gives telephone no. to call

This can be deactivated if required.

If a problem persists contact AQUATECH-PRESSMAIN service department quoting the serial

number WN:_______ (on control panel fascia)

2.4 MAINTENANCE INSTRUCTIONS

2.4.1. ADDITIONAL CAUTIONS

2.4.1.1. READ GENERAL SAFETY INFORMATION 0.0, WARNINGS 0.1 and CAUTIONS 0.2, 0.3 & 0.4

2.4.2 PROCEDURE

Every 6 months the unit should be maintained by authorised AquaTech-Pressmain service agents - see Servicing

(Section 3).

Expansion, Control and Hydro Accumulator vessels

1. Air Charge Pressure.The correct charge pressure provides reliable operation of the system and a prolonged

lifetime of the diaphragm. This should be checked regularly. Caution: If the air cushion pre-charge pressure

required exceeds 4.0 Bar then you must follow the procedure shown below to avoid damaging/rupture of the

internal diaphragm and consequences of. E.g. High and/or low pressure problems, unstable pump operation.

2. To adjust air charge pressure < 4.0Bar: isolate the vessel from the system and release pressure on water side

by opening the drain cock disposing of the water-mix in the appropriate manner. The water inside the bladder

will be pushed back by the air charge pressure. Remove cap on the filling valve, set air charge pressure refilling

using dry air or nitrogen. Screw cap firmly on filling valve. Close the drain cock and slowly open water

connection to the system.

3. To adjust air charge pressure > 4.0Bar: If vessel is already in use then isolate hydraulically, reduce the air

charge to 4.0Bar then evacuate the water side of the vessel followed by evacuation of the air side. With the

vessel empty of water and air, set the air charge pressure (using dry air or nitrogen) to 4.0Bar, bring the water

side pressure up to 5.0Bar and close isolating valve, then add more air until the air side pressure is equal to the

required pre-charge pressure multiplied by 1.2 e.g. for a pre-charge pressure of 6.0Bar after filling vessel with

air to 4.0Bar followed by water to 5.0Bar, fill the air side to 6.0 x 1.2 = 7.2Bar. Screw cap firmly on filling valve

and slowly open isolating valve & water connection to the system.

4. Float Valve Maintenance. See installation instructions section for extract regarding cleaning float valve filter

etc.

LEAVE SET WITH ALL PUMPS SWITCHES IN THE AUTO POSITION,

THE MAINS SUPPLY SWITCHED ON, AND THE SYSTEM CONNECTION OPEN

System O.K./routine service due/

for maintenance call/ AquaTech

Pressmain. 01206 215121

Pressure ……….. bar

This manual suits for next models

4

Table of contents

Other AQUATECH Water Pump manuals

Popular Water Pump manuals by other brands

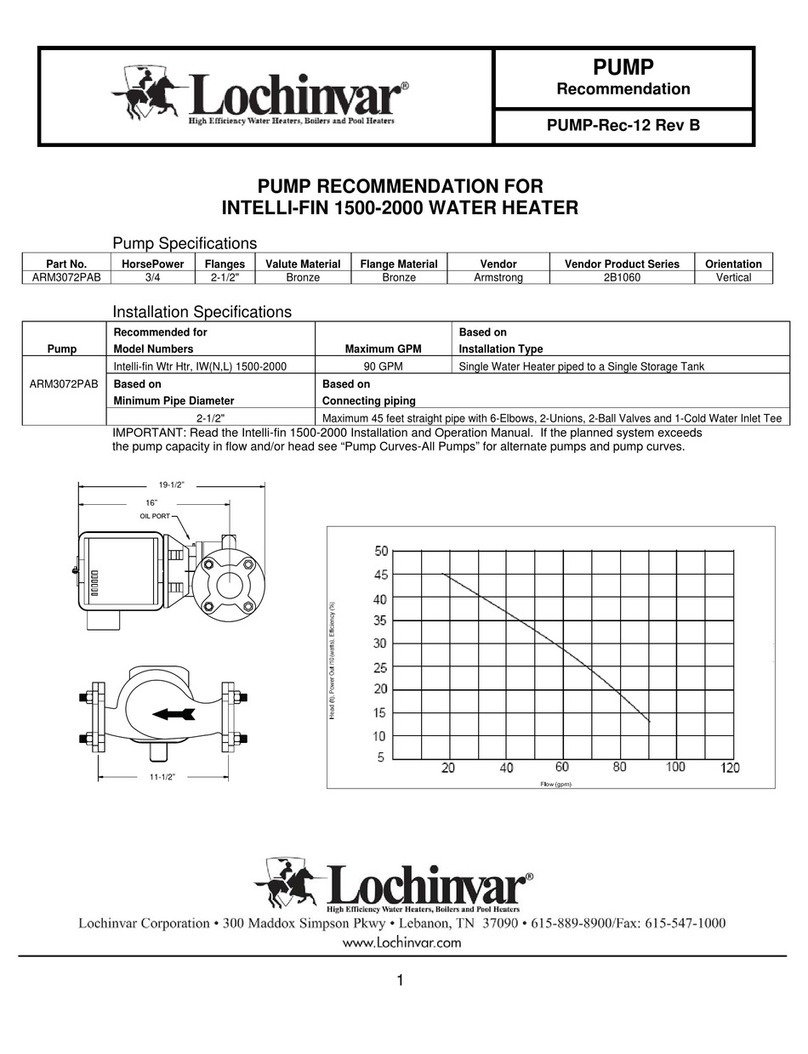

Lochinvar

Lochinvar ARM3072PAB Specification sheet

Solinst

Solinst 410 operating instructions

Mega

Mega SPV Series Installation & operating instructions

Pentair

Pentair HYPRO 93HPS Series Installation and operation manual

Milwaukee

Milwaukee M18 TP Operator's manual

STA-RITE

STA-RITE DURA-JET 5DJAFB-0001 owner's manual

Kessel

Kessel Aqualift XL Basic Installation and operating manual

Crane

Crane Barnes 8SHDA Installation and operation manual

SPX

SPX Accumulator instruction manual

Pentair Hydromatic

Pentair Hydromatic FG-3100RF Installation and operation manual

Eckerle

Eckerle EE 1200 instruction manual

North Ridge Pumps

North Ridge Pumps RBT Series operating instructions