tefen MixRite 2.5 User manual

™

Propotional Pump

Nahsholim 30815 Israel, Tel 972-4-6395554, Fax 972-4-639-0813

User Manual

Tefen is pleased to welcome you as a new client.

We highly appreciate your choice of our quality MixRite series product. Our MixRite

proportional dosing pumps were designed to provide precision, efficiency and easy

operation. We wish you an excellent user experience with our product.

Please read this manual carefully before using the product and follow the safety

guidelines.

For support, please contact our service department.

YOUR MixRite

Please record your MixRite serial number.

This information will come in handy when you call

your distributor for

information, parts, and service.

Model S/N Purchase Date

3/4” BSPT

male thread

water outlet

Additive suction

tube

Water engine

Air release

valve

3/4” BSPT

male thread

water inlet

Suction unit

with adjustable

proportional dosing

Tefen’s MixRite line of water-driven proportional dosing pumps are used to ensure

precise additive injection directly into the water or fluid line, with various flow rates,

feed ratios and pressure ranges. These pumps are extremely durable,

manufactured from engineered composite materials to withstand the rigors of the

elements, as well as chemicals and acids for injection.

The Tefen MixRite water powered dosing pump is a simple, user friendly and

ingenious system that has demonstrated its value over 90 countries.

Tefen is ISO 9001 2015 certified.

CONTENTS

1. Safety and Responsibility ..................................................................................5

2. Technical data....................................................................................................5

2.1. MixRite Operational Conditions.................................................................5

3. Configuration......................................................................................................7

4. Installation..........................................................................................................8

4.1. Mounting the MixRite.................................................................................8

4.1.1. Mounting on Wall...............................................................................8

4.1.2. Mounting on Stand*...........................................................................9

4.2. MixRite Installation...................................................................................10

4.2.1. Installing the MixRite on a Direct Line (in line) ................................11

4.2.2. Installing the MixRite on a Bypass Line (offline)..............................12

5. Operation .........................................................................................................13

5.1. Adjusting the MixRite...............................................................................13

5.2. Air-Release Valve....................................................................................14

5.3. On/Off System .........................................................................................14

6. Maintenance ....................................................................................................15

6.1. Rinsing and Cleaning the Unit.................................................................16

6.2. Cleaning and Refitting the Suction Check Valve......................................16

7. Troubleshooting...............................................................................................17

8. Specifications...................................................................................................19

9. Limited Warranty..............................................................................................20

1. SAFETY AND RESPONSIBILITY

- Follow the instructions in this manual when installing, operating, and maintaining

the MixRite pump and take additional safety measures appropriate to the liquid

being pumped and the temperature of the water.

- During any action, the operator must stay in front of the MixRite and wear

protective eyewear, clothing and gloves and use proper tools. DO NOT USE

METALLIC TOOLS.

- It is the responsibility of the owner/operator to make sure water flow and

pressure do not exceed the MixRite specifications.

- An air inlet, impurity or chemical damage to a seal can interrupt the dosing

function. It is recommended to periodically check that the solution is being

correctly drawn up into the MixRite.

- Be extremely careful in the presence of hazardous substances (e.g. corrosives,

toxins, solvents, acids, caustic, flammables, etc.).

- Before applying any aggressive chemicals, please consult your distributor to

confirm compatibility with the dosing pump.

- The user must respect the recommendations given by the manufacturer of the

chemical product.

- Change the suction tube as soon as it seems damaged by the chemical.

- It is advised to relieve the pressure after use.

2. TECHNICAL DATA

2.1. MixRite Operational Conditions

Minimum Flow Rate

10 L/H (2.64 Gal/H)*

Maximum Flow Rate

2,500 L/H (660 Gal/H)

Minimum Temperature

4°C (39°F)

Maximum Temperature

40°C (104°F)

Operation Pressure Range

0.2 Bar to 8 Bar (2.9 to 120 PSI)

*7 L/H (1.85 Gal/H) in P0 model only.

L (Height)

Air Release

On/Off

Max.

496 (19.5”)

528 (20.7”)

Min.

457 (17.9”)

497 (19.5”)

160 (6.3”)

L

A

A

A

A

L

160 (6.3”)

219 (8.62”)

260 (102”)

3. CONFIGURATION

01=0.1%-0.9%

04=0.4%-4%

05=0.5%-5%

22=0.2% Fix

28=0.8% Fix

4. INSTALLATION

4.1. Mounting the MixRite

Important!

- The MixRite inlet and outlet must reach the inlet and outlet pipes.

- The MixRite must be positioned above the liquid additive container.

- Do not install the MixRite above an acid container, (fumes may damage the

MixRite) and protect it from possible contact with corrosive products.

- The MixRite must be protected from frost and excessive heat.

4.1.1. Mounting on Wall

Phillips

screw (x2) MixRite

Bracket

MixRite 2.5

Lug (x2)

MixRite

Bracket

4.1.2. Mounting on Stand*

* Stand delivered upon request.

4.2. MixRite Installation

Important!

- When connecting a MixRite either to the public water supply or to its own water

source, you must respect the regulations in force concerning protection of the

source i.e. backflow prevention, etc.

- Use 120 mesh –130 micron filter.

- For water with high particle content, use 250 mesh –60 micron filter depending

on your water quality.

- Use plastic record.

- Ensure water flow is according to the arrows on the unit.

- If the water line is higher than the MixRite itself, there is a possible risk of water

and additive flowing back through the MixRite. In such a case, installing a non-

return valve downstream is necessary.

- It is recommended to place an anti-siphon valve on the downstream side of the

dosing pump in installations in which there is a risk of siphoning.

- The strainer must be suspended at least 10 cm (4") above the bottom of the

additive tank to avoid sucking up the insoluble particles that may damage the

pump assembly. Do not put the strainer on the ground.

- Water hammer/excessive flow :

•For installations subject to water hammer, a protection device such as a

check valve or union ball check must be fitted (pressure/flow control system).

•For automatic installations, slow opening and closing solenoid valves are

preferable.

•In an installation where the MixRite serves several sectors, the closing of one

sector and the opening of another sector must be done at the same time

(simultaneous operation of the solenoid valves).

* Where water is supplied at a higher flow rate than the working flow rate of the

pump, or where the pump is not needed for continuous operation, the MixRite

must be installed on bypass line (see page 12).

4.2.1. Installing the MixRite on a Direct Line (in line)

4.2.2. Installing the MixRite on a Bypass Line (offline)

5. OPERATION

5.1. Adjusting the MixRite

Important!

- It is the responsibility of the owner/operator of the MixRite, to determine the

correct amount of solution and injection ratio to obtain the desired result

- Adjustment must be made when there is no pressure in the MixRite. Turn off

the water supply and allow the pressure to drop to zero.

- Do not remove the lower U-Latch (For maintenance purpose only)!

Every stroke of the MixRite moves a predetermined volume of water with a

predetermined volume of liquid additive. Adjust the volume of liquid additive as

follows:

5.2. Air-Release Valve

After initial operation of the MixRite, press the cap

(air release valve) for several seconds to open

valve that allows trapped air to escape. This air

release is accompanied by a slight loss of water.

Release the cap to close the valve.

5.3. On/Off System

Important!

On pumps with On/Off knob there is no air-release

valve.

It is highly recommended to use the On/Off knob

when the additive container is empty, or if there is a

need for the water flow to continue without the

additive.

ON position- The knob should be in its high position;

the pump is working and pumping.

To turn on, push and turn CCW.

OFF position- The knob should be in its low

position; the water flow continues without the

pumping action.

To turn off, push and turn CW.

Air release valve

6. MAINTENANCE

Important!

- To maintain the dosing pump in good condition, it is advisable to operate the

pump with suction of clean water after each use.

- Regular yearly maintenance will help extend the lifespan of your MixRite dosing

pump. In addition, kit seals need to be replaced every year.

- Regularly clean the water filter at the pump inlet and the fertilizer suction filter.

- If the pump is planned to be out of use for a long period of time, operate the

pump for a few minutes with the suction tube immersed in a tank with clean

water to remove fertilizer residues from the pump, preventing them solidifying in

the pump.

- If there is a fear of frost, and the temperature falling below 4°C (39ºF), empty

the water from the pump. To do this, close the entry and exit valves securely.

Open and dismantle record nut that connects the suction pipe. Press the

backflow prevention valve using a finger or a thin rod, allowing all the water that

has collected in the pump to drain out while pressing the air-release valve at the

top of the pump.

- It is advisable to carry out the maintenance of the pump body whenever soluble

products are used. To carry out the maintenance, remove the pump body and

wash it thoroughly with plenty of clean water. When finished and before

reassembly onto the motor body, lubricate the seal with silicone.

ACTION

FREQUENCY

Cleaning cycle

After each use

General check

Yearly

Replace seals

Yearly

Replace other components

As needed

6.1. Rinsing and Cleaning the Unit

Rinsing of the MixRite is required when changing chemicals and before handling

the MixRite, to avoid any contact with the chemical.

Rinse the MixRite as follows:

1. Rinse the unit by pumping clean water from the additive container.

2. Wash the external surface of the unit with clean water.

6.2. Cleaning and Refitting the Suction Check Valve

Before removing Suction Check Valve, turn off the water supply and allow the

pressure to drop to zero.

Remove Suction Check Valve according to the steps shown.

Rinse parts of Suction Check Valve with clean water, re-assemble them in the order

shown and ensure that the spring is in good working condition.

Re-assemble Suction Check Valve in the reverse order.

7. TROUBLESHOOTING

Subject

Check

Solution

The pump does not

work.

Direction of arrows on the pump is

the same as water flow.

Install the pump so that the

arrows point in direction of

water flow.

Inlet and outlet valves are open.

Open the valve

Inlet filter is not clogged.

Clean the filter.

Line’s water pressure.

Make sure there is water

pressure in the line –check

the system input filter and

make sure it is clean.

Springs are not broken.

Change the motor.

Cylinder is not scratched.

Change cylinder.

Piston seals are not damaged.

Change the seals.

Bypass installation* pump test at

low pressure.

Disconnect the water outlet

hose from the outlet, by

installing a bypass make

sure there is no water

returning to the pump. If

the pump is working check

the ΔP –as described in

the item below.

Bypass installation* make sure

the pressure difference.

The water pressure at the

outlet of the pump is equal

to or greater than the water

pressure at the main line.

The pump has

stopped working.

There is no water flow at the

appropriate pressure. Open the

main valve. Open the nut locking

the motor cover, remove the

motor cover, and remove the

mechanism. Check if the motor

seals are defective.

Replace the motor seals.

Check if the springs are broken.

Replace the motor.

Check if one of the parts of the

mechanism is broken.

Replace the motor.

Subject

Check

Solution

MixRite does not

draw additive.

The suction filter is blocked.

Clean the filter.

Dismantle the pump unit and

check if the suction seal is

defective.

Replace the suction seal.

The non-return valve is defective.

Replace the non-return

valve.

MixRite makes

scratching noises.

Check if there is liquid in the

additive container.

Add liquid to the container.

Check if the suction pipe is

immersed and not folded.

Straighten or change the

pipe.

Check suction filter to see if it is

blocked and if it is immersed in

the additive tank.

Clean and rinse suction

filter. Fill liquid into tank to

cover filter

Water flowing back

into additive

container.

Check valve.

Clean or replace the check

valve.

8. SPECIFICATIONS

7

9. LIMITED WARRANTY

Tefen Flow and Dosing Technologies Ltd. (“Tefen”) will replace all parts shown to

be defective in material or workmanship during a period of twelve months from the

date of purchase by the original purchaser (“Warranty Period”). Warranty shall be

limited to Warranty Period and shall not be extended in any event.

To obtain warranty replacement of a part, the MixRite must be returned with original

proof of purchase receipt to Tefen or authorized distributor and thereafter

recognized as defective after examination by the technical services of the

manufacturer or distributor.

The MixRite must be flushed of any chemical and sent to the manufacturer or

distributor prepaid but will be returned free of charge once repairs are made if found

to be covered by the warranty.

This warranty only covers circumstances where the part has failed due to defects

caused by the manufacturing process. This warranty is invalid if the defects are

found to be due to the product’s misuse, inappropriate use of tools, negligence,

changes and/or alterations made in the Product not by Tefen, combination and/or

use with other products not manufactured by Tefen, lack of maintenance and/or

defective installation or environmental accidents or corrosion by foreign bodies and

liquids found within or in proximity to the MixRite.

The seals and “O” rings are not covered under warranty, nor is damage to the

MixRite caused by water impurities such as sand. A filter (200 Mesh) must be used

in front of the unit for this warranty to be valid.

Tefen declines any responsibility if the MixRite is not used in compliance with the

operating instructions and tolerances as indicated herein.

There are no warranties, express or implied, which will extend beyond those

described above.

TEFEN OR AUTHORIZED DISTRIBUTOR SHALL NOT BE LIABLE FOR ANY

LOSS OF USE, SALES OR PROFIT OR FOR ANY INDIRECT, CONSEQUENTIAL

OR INCIDENTAL DAMAGES CAUSED BY OR SUFFERED AS A RESULT OF

THE SALE OR USE OF THE PRODUCT AND SHALL BE LIMITED TO THE

CONSIDERATION ACTUALLY PAID BY YOU FOR THE PRODUCT.

This warranty is personal, and you may not assign, transfer, sell, indorse, pledge

its rights under this warranty to any third party without Tefen’s prior written consent.

Any dispute arising in connection with this warranty shall be referred to the

competent court in Tel Aviv Israel, which shall have exclusive jurisdiction in relation

to all matters which may arise out of or in connection with this warranty. The

provisions of the substantive law prevailing in Israel shall govern this warranty.

Table of contents

Other tefen Water Pump manuals

Popular Water Pump manuals by other brands

Travaini Pumps USA

Travaini Pumps USA PVL 10-15 Installation and operation manual

Linear Technology

Linear Technology 909 quick start guide

SHG

SHG Mini-CHIEMSEE Series operating manual

Tuthill

Tuthill AC Installation and service instructions

STA-RITE

STA-RITE SG11200 Series owner's manual

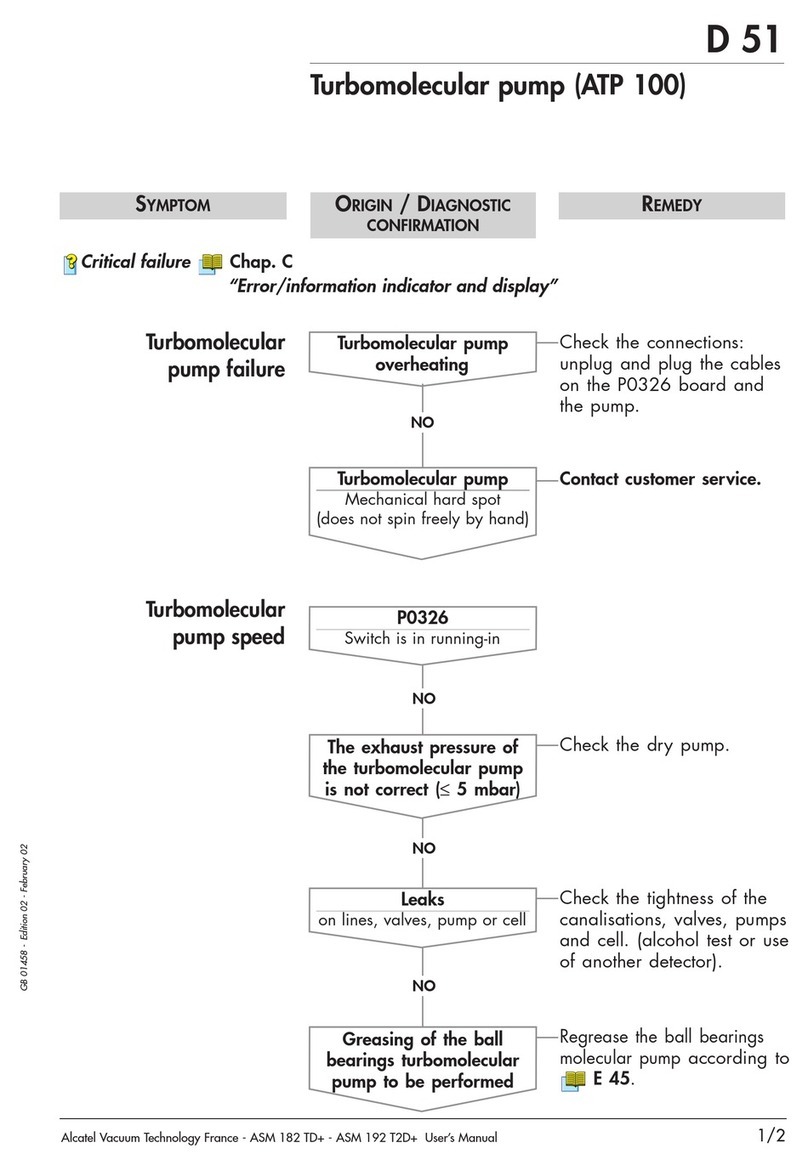

Alcatel Vacuum Technology

Alcatel Vacuum Technology ATP 100 Service manual & troubleshooting guide