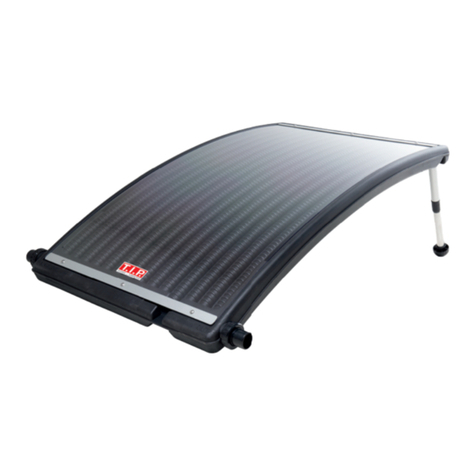

CHAPTER 1: MOUNTING THE SOLAR COLLECTORS

Overview

!When mounting the collectors, always make provisions for inlet connections at the bottom header and outlet

connections at the top. The outlet headers must be pitched a vertical distance of at least 1/8” per foot

above the inlet headers to assure uniform flow and proper drainage to prevent freezing. Plan the

collector location to allow at least one foot on all sides of the row(s) of collectors for mounting brackets and

piping.

!Roof obstructions, if present, should now be taken into consideration to determine the exact collector location.

Collectors can be installed over or around different diameter roof vent pipes or other obstructions. After

snapping the top chalk lines but before marking and pre-drilling for your outlet header brackets, refer to the

following instructions:

• With roof vents up to 2”(50mm) in diameter the collectors can be installed directly over these vents. Locate

the seam in the panel nearest to where the vent pipe is to come through. Separate by pulling up on top plate,

and pushing down on the lower plate. Should the vent pipe protrude near a sonic tack weld, it will have to be

cut apart. Using a sharp utility knife, cut through the weld while pulling the two plates apart. Lay the

collector over the vent pipe, keeping the vent pipe at least 12 inches (30cm) away from a header. It will be

easier to complete an installation by mounting this panel first and then working away from it.

• For a roof vent pipe over 3”(80mm) in diameter, the collectors can be positioned on either side of the vent.

Two 7” (18cm) System Connector Hoses (Part #60691-1 for 1 1/2” or #60691-2 for 2”) can be employed to

couple the collectors together for vent pipes or other obstacles up to 7” (18cm) in diameter. Mark your

51” (128cm) centers wherever the outlet header brackets ‘fall’ on the upper chalk line. With obstructions of

over 7”(18cm), such as attic fans and skylights, lay out the panels on either side of the obstructions using a

Row Spacer Kit (Part #12017-1 for 1 1/2”; #12017-2 for 2”) or Header Blanks.

•Refer to Figure 2 throughout this section.

2