2 Safe Air Compressor Operation

12

2.6 Understanding The Built-In Protection Devices

This compressor has been equipped with both THERMAL and OVER

PRESSURE protection devices in the interests of personal safety and to protect

the unit from unnecessary internal damage.

NOTE : Never disable or modify any of the compressor’s built-in

protection devices.

2.6.1 Thermal Cutout Switch

The process of compressing air is a natural generator of heat. This heat

generation is increased accordingly by increasing the compressed air flow rate

or increasing the pressure level of the air flow.

The large DC electric motor inside the compressor is also a source of heat

which increases with the amount of work being done by it.

The compressor has been designed to naturally disperse this heat into the air

around it, however, the ambient temperature outside will have an effect on

how fast this heat can be dispersed. If excessive levels of heat are allowed to

build up inside the compressor the unit may be put at risk of internal damage.

For this reason an internal electric switch has been designed into the back of

each motor which will simply turn the compressor off if the temperature

approaches a dangerous level, and will automatically reset and turn the

compressor back on once the unit has cooled down to a safe temperature.

This off time may last anywhere from just a few minutes up to half an hour

depending on conditions around the compressor.

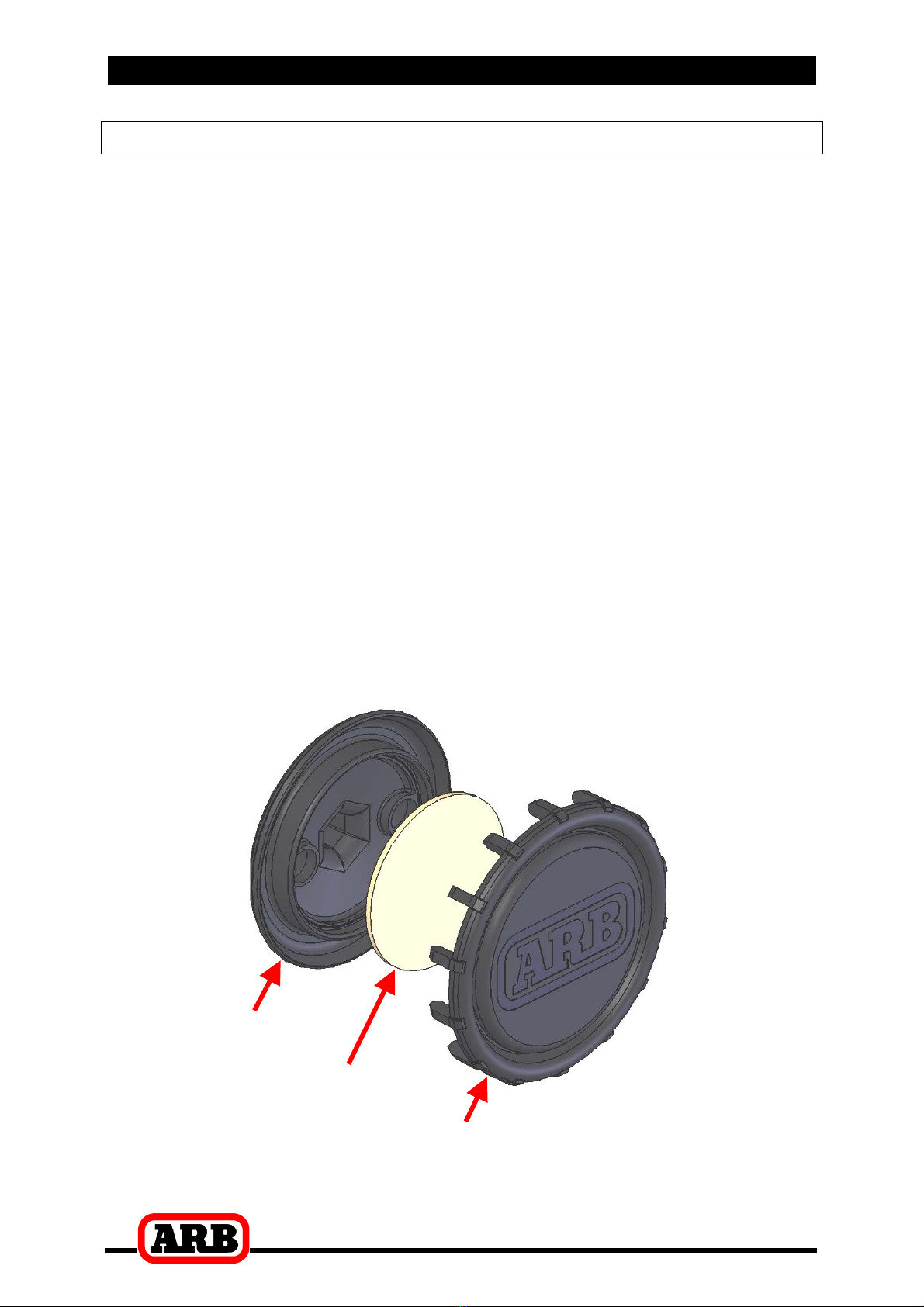

2.6.2 Over Pressure Safety Valve

This compressor is equipped with a pressure operated electric switch which

has been factory set to turn off the compressor at a safe level of pressure, and

then turn it back on again once the pressure has been exhausted down to a

lower level. Should this switch fail for any reason the compressor is capable of

producing pressure well beyond its safe shut off limit.

A compressor which has reached its safe pressure maximum that has been

left in direct sun or inside a hot vehicle may build up additional pressure past

the safe working level.

Connecting your compressor up to any air system which might already contain

a residual pressure that is higher than the compressor’s safe pressure limit

may raise the internal pressure of the compressor past the safe pressure limit.

This compressor is equipped with a mechanical over pressure safety valve

which has been factory set to bleed off to atmosphere any excessive pressure

build up (i.e., from any of the situations above) before it can pose any personal

danger or cause damage to compressor components.