2.1 Identifying the Best Mounting Position

Using the following points as guideline, identify a position on the vehicle or inside the

cabin where the compressor can be safely and conveniently mounted.

NOTE : The ideal position of the compressor should give consideration to all of the

following points:

1. The location should allow for quick and easy access to the compressor for attaching an

optional pump-up kit air hose for tire re-filling if desired.

2. Keep away from sources of heat (e.g., too close to exhaust system components or

directly behind the radiator, etc.).

3. The position should be safe from damage or abrasion caused by sand or gravel from

the road surface.

4. Avoid any extended exposure to direct sunlight.

5. Keep away from excessive moisture (e.g., directly exposed to road spray or rain runoff).

6. Mounting location should be above the highest possible waterline to avoid submerging

during water crossings.

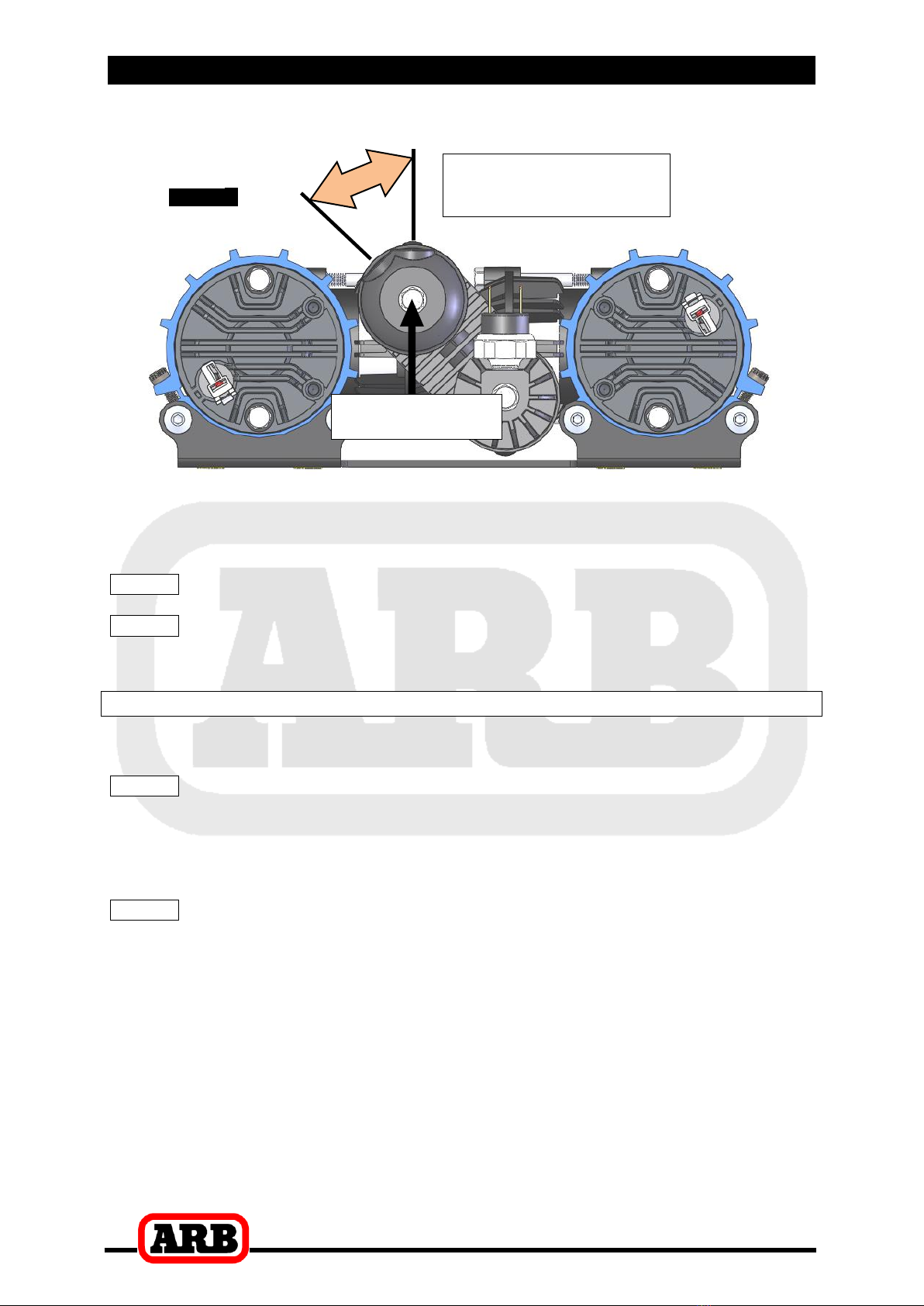

7. The position must allow free flow of dry, cool air to the air filter assembly (unless an

intake extension tube is to be used, in which case it is the filter assembly and the

extension tube which must be located accordingly).

8. The position should allow access to the air filter assembly for filter disassembly and

cleaning (unless an intake extension tube is to be used).

9. If an intake extension tube is to be used then consideration should be given to the

intake position so that the distance (length of tube) between the compressor mounting

location and the actual air intake point can be kept to a minimum.

10. The position must allow the compressor motor mounting bracket to firmly secure the

compressor using all 4 bolts provided.

11. The position must allow access to the opposite side of the mounting location so that the

bolts and washers may be installed.

12. Parts of the compressor may get hot while running for long periods of time, and

therefore the compressor should be located away from where it could be touched by

children or pets.

13. The position should permit a short (close to the battery), protected and accessible route

for the wiring loom to follow.

LONGER POWER WIRES = MORE INLINE RESISTANCE = LESS AIR FLOW RATE

14. The compressor should not be mounted in a position where the running sound might be

considered startling or irritating for vehicle occupants.

15. The compressor should not be mounted in close proximity to devices that are sensitive

to the electromagnetic fields of DC motors (e.g., compasses, radio/GPS antennas,

engine management sensors, etc.).

16. Where possible, the compressor should be mounted close to the location of the Air

Locker equipped axle in a single Air Locker system, or halfway between both axles in a

dual Air Locker system.

17. Never mount the compressor in a position where it would be considered unsprung

mass (e.g., mounted directly to the axle or the engine block).