1-3

1

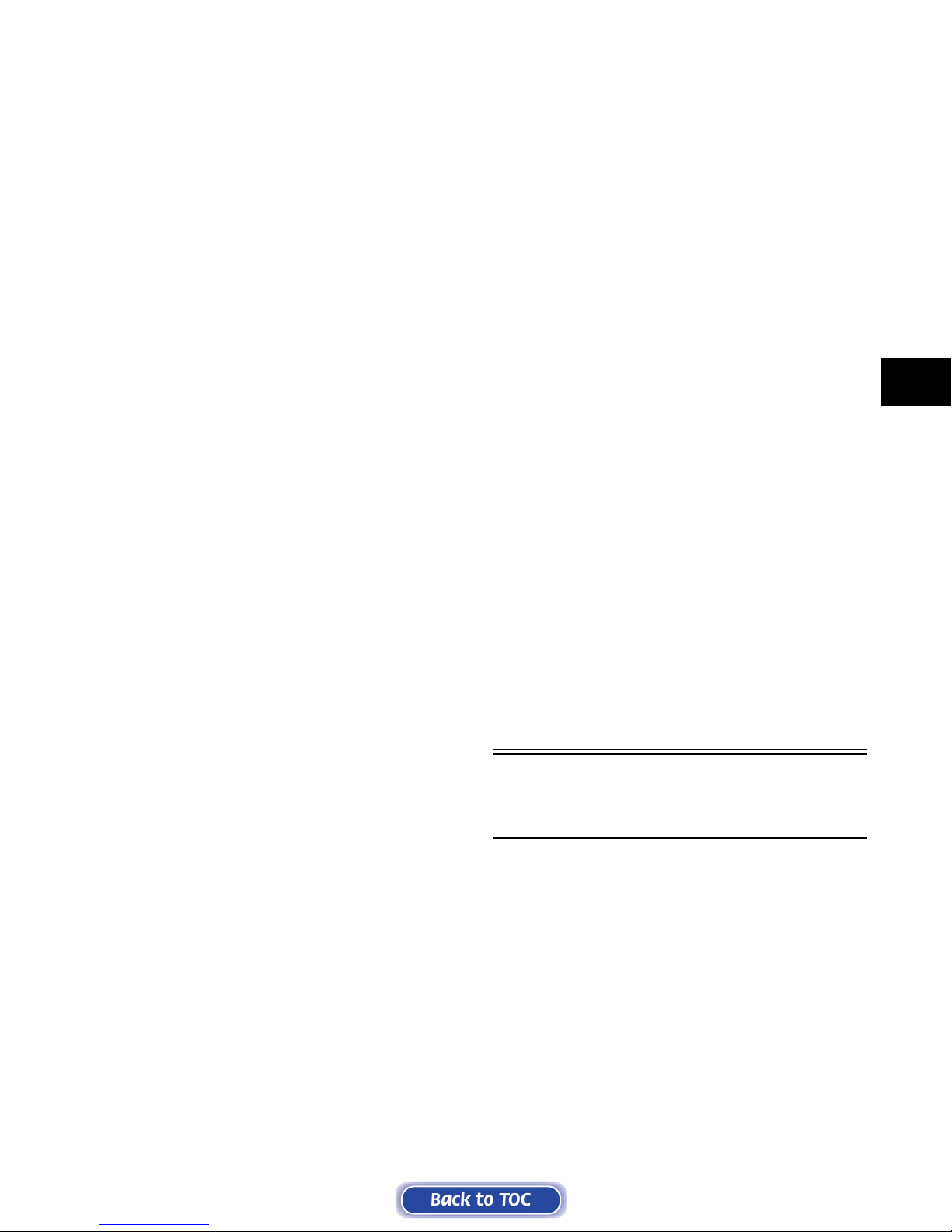

Torque Conversions

(ft-lb/N-m)

Tightening Torque

(General Bolts)

Break-In Procedure

A new ATV and an overhauled ATV engine require a

“break-in” period. The first 10 hours (or 200 miles) are

most critical to the life of this ATV. Proper operation

during this break-in period will help assure maximum

life and performance from the ATV.

During the first 10 hours (or 200 miles) of operation,

always use less than 1/2 throttle. Varying the engine

RPM during the break-in period allows the compo-

nents to “load” (aiding the mating process) and then

“unload” (allowing components to cool). Although it

is essential to place some stress on the engine compo-

nents during break-in, care should be taken not to

overload the engine too often. Do not pull a trailer or

carry heavy loads during the 10-hour break-in period.

When the engine starts, allow it to warm up properly.

Idle the engine several minutes until the engine has

reached normal operating temperature. Do not idle the

engine for excessively long periods of time.

During the break-in period, a maximum of 1/2 throttle

is recommended; however, brief full-throttle accelera-

tions and variations in driving speeds contribute to

good engine break-in.

After the completion of the break-in period, the engine

oil and oil filter should be changed. Other maintenance

after break-in should include checking of all pre-

scribed adjustments and tightening of all fasteners.

Gasoline - Oil -

Lubricant

RECOMMENDED GASOLINE

The recommended gasoline to use is 87 minimum

octane regular unleaded. In many areas, oxygenates

(either ethanol or MTBE) are added to the gasoline.

Oxygenated gasolines containing up to 10% ethanol,

5% methane, or 5% MTBE are acceptable gasolines.

When using ethanol blended gasoline, it is not neces-

sary to add a gasoline antifreeze since ethanol will pre-

vent the accumulation of moisture in the fuel system.

ft-lb N-m ft-lb N-m ft-lb N-m ft-lb N-m

11.4 26 35.4 51 69.4 76 103.4

22.7 27 36.7 52 70.7 77 104.7

34.1 28 38.1 53 72.1 78 106.1

45.4 29 39.4 54 73.4 79 107.4

56.8 30 40.8 55 74.8 80 108.8

68.2 31 42.2 56 76.2 81 110.2

79.5 32 43.5 57 77.5 82 111.5

810.9 33 44.9 58 78.9 83 112.9

912.2 34 46.2 59 80.2 84 114.2

10 13.6 35 47.6 60 81.6 85 115.6

11 15 36 49 61 83 86 117

12 16.3 37 50.3 62 84.3 87 118.3

13 17.7 38 51.7 63 85.7 88 119.7

14 19 39 53 64 87 89 121

15 20.4 40 54.4 65 88.4 90 122.4

16 21.8 41 55.8 66 89.8 91 123.8

17 23.1 42 57.1 67 91.1 92 125.1

18 24.5 43 58.5 68 92.5 93 126.5

19 25.8 44 59.8 69 93.8 94 127.8

20 27.2 45 61.2 70 95.2 95 129.2

21 28.6 46 62.6 71 96.6 96 130.6

22 29.9 47 63.9 72 97.9 97 131.9

23 31.3 48 65.3 73 99.3 98 133.3

24 32.6 49 66.6 74 100.6 99 134.6

25 34 50 68 75 102 100 136

Type of Bolt

Thread

Diameter A

(mm)

Tightening

Torque

(Conventional or 4 Marked Bolt) 5 12-36 in.-lb

6 36-60 in.-lb

8 7-11 ft-lb

10 16-25 ft-lb

(7 Marked Bolt) 5 24-48 in.-lb

6 6-8 ft-lb

8 13-20 ft-lb

10 29-43 ft-lb

CAUTION

Do not use white gas. Only Arctic Cat approved gaso-

line additives should be used.

Back to TOC Back to Section TOC Next

Back

FOR ARCTIC CAT ATV DISCOUNT PARTS CALL 606-678-9623 OR 606-561-4983

www.mymowerparts.com